Concrete Tests

Diunggah oleh

'Sayed AsadullahHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Concrete Tests

Diunggah oleh

'Sayed AsadullahHak Cipta:

Format Tersedia

Concrete Technology Laboratory

Table of Contents

Chapter 1............................................................................................................... 4

Premix Design........................................................................................................ 4

Preface................................................................................................................ 4

Standard Mix...................................................................................................... 4

Chapter 2, Soft Concrete Tests............................................................................... 6

Chapter: Chapter 1

Slump Test............................................................................................................. 6

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Introduction........................................................................................................ 6

Objective............................................................................................................ 6

Theory................................................................................................................ 6

Equipment.......................................................................................................... 7

Procedure........................................................................................................... 7

Result................................................................................................................. 8

Chapter: Chapter 1

Discussion and conclusion.................................................................................. 8

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Appendix............................................................................................................ 8

Compacting Factor Test.......................................................................................... 9

Introduction........................................................................................................ 9

Objectives........................................................................................................... 9

Theory................................................................................................................ 9

Apparatus........................................................................................................... 9

Chapter: Chapter 1

Procedure......................................................................................................... 10

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Result and Calculation...................................................................................... 11

Discussion........................................................................................................ 11

Advantages:.................................................................................................. 12

Disadvantages:.............................................................................................. 12

Conclusion........................................................................................................ 13

Appendix.......................................................................................................... 13

Chapter: Chapter 1

Vebe Time Test..................................................................................................... 14

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Introduction...................................................................................................... 14

Objectives......................................................................................................... 14

Theory.............................................................................................................. 14

Apparatus......................................................................................................... 15

Procedure......................................................................................................... 16

Discussions....................................................................................................... 16

Chapter: Chapter 1

Advantages:.................................................................................................. 16

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Disadvantages:.............................................................................................. 17

Conclusion........................................................................................................ 17

Appendix.......................................................................................................... 17

Chapter 3............................................................................................................. 18

Destructive Concrete Test.................................................................................... 18

Compressive Strength Test.................................................................................. 19

Chapter: Chapter 1

Introduction...................................................................................................... 19

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Objectives......................................................................................................... 19

Theory.............................................................................................................. 19

Apparatus......................................................................................................... 19

Procedure......................................................................................................... 20

Rate of Loading................................................................................................. 20

Result............................................................................................................... 21

Chapter: Chapter 1

Precautions....................................................................................................... 21

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Discussion........................................................................................................ 21

Conclusion........................................................................................................ 22

Appendix.......................................................................................................... 22

Flexural Test......................................................................................................... 23

Introduction...................................................................................................... 23

Objective.......................................................................................................... 23

Chapter: Chapter 1

Theory.............................................................................................................. 23

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Apparatus:........................................................................................................ 24

Procedures........................................................................................................ 24

Result............................................................................................................... 25

Discussion........................................................................................................ 25

Conclusion........................................................................................................ 25

Appendix.......................................................................................................... 25

Chapter: Chapter 1

Chapter 4............................................................................................................. 26

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Non-Destructive test............................................................................................ 26

Rebound Hammer Test......................................................................................... 27

Introduction...................................................................................................... 27

Objectives......................................................................................................... 27

Theory.............................................................................................................. 27

Apparatus......................................................................................................... 27

Chapter: Chapter 1

Procedure......................................................................................................... 28

10

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Result and calculation....................................................................................... 29

General Discussion........................................................................................... 30

Conclusion........................................................................................................ 30

Appendix.......................................................................................................... 31

Micro Cover Meter................................................................................................ 32

Introduction...................................................................................................... 32

Chapter: Chapter 1

Objective.......................................................................................................... 32

11

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Apparatus......................................................................................................... 32

Procedure......................................................................................................... 33

Result and calculation....................................................................................... 33

Discussion........................................................................................................ 33

Conciliation....................................................................................................... 34

Appendix.......................................................................................................... 34

Chapter: Chapter 1

PUNDIT Plus Test.................................................................................................. 35

12

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Introduction...................................................................................................... 35

Objective.......................................................................................................... 35

Theory.............................................................................................................. 35

Apparatus:........................................................................................................ 35

Procedure......................................................................................................... 36

Result and calculation....................................................................................... 36

Chapter: Chapter 1

Discussion........................................................................................................ 37

13

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Conclusion........................................................................................................ 37

Appendix......................................................................................................... 38

Conclusion........................................................................................................... 39

Chapter: Chapter 1

References........................................................................................................... 39

14

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter 1

Premix Design

Preface

Chapter: Chapter 1

For the concrete laboratory under the Laboratory 3, we have Slump test, Vebe

Time Test, Compacting Factor Test for soften concrete and destructive and non-

15

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

distractive tests of harden concrete. We started our testing session with the mix

design of the concrete proportions. As bellow calculations.

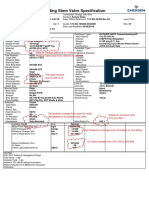

Standard Mix

G 25 ST5

Chapter: Chapter 1

1. C= 340kg

TA= 1830kg

16

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

30

1830=549 Kg

100

2.

Fine Aggregate=

3.

Coars Aggregate=1830549=1281 Kg

4.

Water cement ratio=

5.

Water=0.55 3400=187 Kg

Chapter: Chapter 1

W

=( 0.450.65 )=0.55

C

17

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Our samples:

Chapter: Chapter 1

X3

H=300

mm

d=150mm

H=100

mm

b=100mm

t=100mm

H=100

mm

b=100mm

L=500mm

18

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Total volume=V Cylinder + 3 V Cube +V Beam

Chapter: Chapter 1

Total Volume=( 752 300 ) + ( 3 3 100 )+ ( 100 100 500 )=0.013 m3

19

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Cement=0.013 340=4.42 Kg

Fine Aggregate=0.013 549=7.14 Kg

Coarse Aggregate=0.013 1281=16.65 Kg

Chapter: Chapter 1

Water=0.013 187=2.43 Kg

20

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Since we need to consider the wastage of 1.2% so we multiply all the above

values to 1.2, thus we have:

Cement=0.013 340=4.42 1.2=5.3 KG

Chapter: Chapter 1

Fine Aggregate=0.013 549=7.14 1.2=8.6 Kg

21

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Coarse Aggregate=0.013 1281=16.65 1.2=20 Kg

Water=0.013 187=2.43 1.2=2.9 Kg

We weight the proportions and mixed them well.

Once it ready we did the following tests:

Chapter: Chapter 1

1. Slump Test

22

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

2. Compacting Factor Test

3. Vebe Time Test

23

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter 2, Soft Concrete Tests

Slump Test

Introduction

Chapter: Chapter 1

The slump test is a method used to determine the consistency of concrete and to

check its uniformity from batch to batch. The consistency, or stiffness, of the

concrete shows the fluidity of the concrete indicating how much water has been

24

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

used in the mix, and is often measured by concrete slump. The stiffness of the

concrete mix is often matched to the requirements for the finished product. All

concrete mixes are a combination of aggregate (gravel and/or sand), cement and

water in varying proportions. The concrete mixture and the ratios of ingredients

affect the workability of the end product and the concretes final strength

(water/cement ratio). In terms of workability only, the higher the slump value, the

higher the amount of water and as a result the mixture is more fluid for working

the concrete and finishing. The construction industry perceives that higher slump

25

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

values require less muscular effort to manipulate. The usefulness of the slump

test as a predictor of concrete strength is controversial and the shrinkage has

traditionally been perceived by the industry as affecting the integrity and quality

of the concrete.

Objective

Chapter: Chapter 1

To determine the workability of a sample from fresh concrete of given grate and

proportions using the slump test.

26

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Theory

Chapter: Chapter 1

The apparatus consists of a mold in the shape of a frustum of a cone with a Base

and top 8 and 4 diameter respectively and a height of 12. The mold is filled

with concrete in three layers of equal volume. Each layer is compacted with 25

strokes of a tamping rod. The slump cone mold is lifted vertically upward and the

change in height of the concrete is measured. There are four type of slump can be

occurred [Figure 1]. And the only type of the slump permissible under ASTM C143

Standard is referring to the true slump. Where the concrete remains intact and

27

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

retains a symmetric shape. A zero slump and a collapsed slump are both outside

of the rang of workability. Specifically ASTM C143 advises caution in interpreting

test results less that and greater than 9. If part of the concert shears from

the mass the test must be repeated with a different sample of concrete. A

concrete exhibits a shear slump in a second test is not sufficiently cohesive and

should be rejected.

28

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Figure 1 ; Type of Slump

Equipment

A wheelbarrow and shovel

A metric ruler

Chapter: Chapter 1

29

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

A scoop

A steel tamping rod, 16mm diameter and 600mm long that has at least one

end rounded.

A standard slump mold. The footplates should be positioned 5mm above the

base of the cone.

A mixer

30

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Procedure

Chapter: Chapter 1

The mixing pan placed on the floor and moistest it with some water. Make

sure it is damp but no free water is left.

The slump cone was hold firmly in place using the 2 foot holds.

One-third of the cone filled with the concert mixture. Then the layer tamps

25 times using the steel rod in a circular motion, making sure not to stir.

More concert add mixture to the tow-third mark. Tamping for 25 times

repeated again.

31

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

The whole cone was fill up to the top with some excess concrete coming out

of top, then tamping repeated 25 times.

Excess concrete from the opening of the slump cone was remove by using

tamping rod in a rolling motion until flat.

Slowly and carefully remove the cone by lifting it vertically, making sure

that the concrete sample dose not move.

Wait for the concrete mixture as it slowly slumps.

32

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

After the concrete stabilizes, the slump-height was measures by tuning the

slump cone upside down next to the sample, placing the tamping rod on the

slump cone and measuring the distance from the rod to original displaced

center.

Chapter: Chapter 1

[Figure 2] shows the complete process using pictures.

Figure 2 ; Slump Procedure

33

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

34

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Result

Finally we have shear slump, and slump value equal to (9 cm).

Discussion and conclusion

Chapter: Chapter 1

After we made the test, we get shear slump of value equal to: (9 cm).

35

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

From the experiment we conducted, we can determine the workability of a sample

from fresh concrete of given grade and promotion using the slump test. The slump

apparatus is not suitable for concrete in which the maximum aggregates size does

not exceed 40mm. it should be noted that the value of slump changes with time

after mixing owing to normal hydration processes and evaporation of some of the

free water and it is desirable therefore that test are preformed within a fixed

period of time. It is also advisable to delay testing for around 10miniutes after the

addition of water to allow for the absorption of water by aggregates

36

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

This test varies easy to use in projects and in laboratory, but it is not a true

determination of workability.

This test learnt us about mixing the concrete, and the amount used especially in

big projects.

Chapter: Chapter 1

This test not use in lean mix because it is not the true determination for

workability but is good in site.

37

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Appendix

38

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

39

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Compacting Factor Test

Introduction

Chapter: Chapter 1

These tests were developed in the UK by Glanville (1947 ) and it is measure the degree of

compaction For the standard amount of work and thus offer a direct and reasonably

reliable assessment of the workability of concrete . the test require measurement of the

weight of the partially and fully compacted concrete and the ratio the partially compacted

weight to the fully compacted weight, which is always less than one, is known as

40

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

compacted factor . For the normal range of concrete the compacting factor lies between

(0.8 - 0.92) .

Objectives

Chapter: Chapter 1

To measure the workability of concrete.

The objective of compaction factor is the measure the degree of compaction resulting

from the application of standard amount of work.

41

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Theory

Chapter: Chapter 1

The apparatus which is commercially available, consist of a rigid frame that supports two

conical hoppers vertically aligned above each other and mounted above cylinder, as

shown in the figure, the top hopper is slightly larger the bottom hopper, while the cylinder

is smaller in volume than both hoppers, to perform the test , the top hopper is filled with

concrete but not compacted. The door on the bottom of the top hopper is opened and the

concrete is allowed to drop into the lower hopper. Once all of the concrete has fallen from

the top hopper, the door on the lower hopper is open to allow the concrete to fall to the

42

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

bottom cylinder, a tamping rod can be sued to force especially cohesive concretes

through the hoppers, the excess concrete is carefully struck off the top of the cylinder

and the mass of the concrete in the cylinder is recorded, this mass is compared to the

mass of fully compacted concrete in the same cylinder achieved with hand rodding or

vibration. The compaction factor is defined as the ratio of the mass of the concrete

compacted in the compaction factor apparatus to the mass of the fully compacted

concrete. The standard test apparatus, described above is appropriate for maximum

aggregate sizes of up to 20mm; a larger apparatus is available for concrete with

maximum aggregate sizes of up to 40mm.

43

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Compacting Factor=

Weight of partially compacted concrete

Weight of full compacted concreted

Apparatus

Chapter: Chapter 1

1. A sample of freshly mixed concrete.

2. A scoop

3. A wheelbarrow and shovel.

44

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

4. a steel tamping rod which is 16mm diameter and 600 mm long that has at least one

end rounded

5. Compacting factor.

6. Upper Hoper:

o Top internal diameter 25.4cm

o Bottom internal diamere

12.7cm

o Internal height

27.9cm

7. Lower Hopper:

o Top internal diameter 22.9cm

o Bottom internal diameter

12.7cm

45

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

8. Cylinder:

Internal height

15.2cm

30.5cm

Chapter: Chapter 1

o Internal diameter

o Internal height

As shown in [Figure 3]

22.9cm

Figure 3 ; Compacting Factor Test

Apparatus

46

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

47

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

48

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Procedure

Keep the apparatus on the ground and apply grease on the inner surface of

the cylinders.

Chapter: Chapter 1

49

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Measure the mass as w1 kg by weighing the cylinder accurately and fix the

cylinder on the base in such a way that the central points of hoppers and

cylinder lie on one vertical line and cover the cylinder with a plate.

For each 5 kg of aggregate mixes are to be prepared with water-cement ratio

by weight with 2.5 kg sand and 1.25 kg of cement and then add required

amount of water thoroughly until and unless concrete appears to be

homogeneous.

50

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

With the help of hand scoop without compacting fill the freshly mixed concrete

in upper hopper part gently and carefully and within two minutes release the

trap door so that the concrete may fall into the lower hopper such that it bring

the concrete into standard compaction.

Fall the concrete to into the cylinder by bringing the concrete into

standard Compaction immediately after the concrete has come to rest and

open the trap door of lower hopper and then remove the excess concrete

above the top of the cylinder by a pair of trowels, one in each hand will blades

51

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

horizontal slide them from the opposite edges of the mold inward to

the center with a sawing motion.

Clean the cylinder from all sides properly. Find the mass of partially compacted

concrete thus filled in the cylinder and say it W2 kg. After this refill the cylinder

with the same sample of concrete in approximately 50 mm layers, by vibrating

each layer heavily so as to expel all the air and obtain full compaction of

the Concrete.

52

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Struck off level the concrete and weigh and cylinder filled with fully compacted

concrete. Let the mass be W3 kg.

The top surface of fully compacted concrete is then carefully truck off level

with the top of the cylinder and weighed to the nearest 10grams. This weight is

known as Weight of fully compacted concrete.

Chapter: Chapter 1

Result and Calculation

53

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

3.75kg

13.45kg

concrete

Weight of cylinder with compacted concrete

Partially compact concrete

15.55kg

13.45-

Fully compacted concrete

3.75=9.7kg

11.8kg

Chapter: Chapter 1

Weight of empty cylinder

Weight of cylinder with partially compacted

54

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

compacting factor=

9.7 kg

=0.82 1(it is good workability)

11.8kg

Chapter: Chapter 1

compacting factor=

weigh of partially compacted concrete

weighof full compacted concreted

55

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Discussion

Chapter: Chapter 1

The final value for the conducted experiment is 0.82. The higher value of the calculation

the more workable the concrete. And for the normal range of concrete the compaction

factor lies between (0.8 0.92 ) . This test is particularly useful for dryer mixes for which

the slump test is not satisfactory. The sensitivity of the compaction factor is reduced

outside the normal range of workability and is generally unsatisfactory for compacting

factor Greater than 0.92. The test is sufficiently sensitive to enable difference in work

ability arising from the initial process in the hydration of cement to be measured. Each

56

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

test, there for should be carried out at a constant time interval after the mixing is

completed, if strictly comparable results are to be obtained, and some ranges are in

bellow in table

Degree of

Compaction factor

Slump( m

Small

Larger

m)

apparatus

apparatus

Very low

0-25

0.78

0.8

application

Vibrated concrete in roads of

other large

Chapter: Chapter 1

workabilit

57

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Mass concrete foundation

Low

25-50

0.85

0.87

without vibration simple

reinforced section with

vibration

Normal reinforced work

Medium

50-100

0.92

0.93

without vibration and heavily

reinforced sections with

Chapter: Chapter 1

vibration.

58

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Section with congested

High

100-180

0.95

0.96

reinforcement not normally

Chapter: Chapter 1

suitable for vibration

59

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Advantages:

The test a dynamic test and it is more appropriate then static tests for highly

thixotropic concrete mixtures

The compacting factor test give more information which is compatibility than the

Chapter: Chapter 1

slump test.

60

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Disadvantages:

The test method does not use vibration, the main compaction method used in the

field.

The amount of work applied to the concrete being tested is a function of the

friction between the concrete and the hopper which may not reflect field

Chapter: Chapter 1

conditions.

61

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Although the test is commercially available it is used infrequently.

The bulky nature of the device reduces its usefulness in the field, further the test

Chapter: Chapter 1

method requires a balance to measure the mass of the concrete in the cylinder.

62

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Conclusion

Form test we can obtain that the Compacting factor of fresh concrete is done to

determine the workability of fresh concrete by compacting factor test as per IS: 1199

1959. The apparatus used is Compacting factor apparatus. And it used to determine the

Workability of a concrete signifies the full compaction of concrete using a required or

Chapter: Chapter 1

reasonable amount of work which helps to achieve the desired possible density or void of

63

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

fresh concrete resulting better strength and durable concrete structure and helpful to

Chapter: Chapter 1

maintain durability throughout the job.

64

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Appendix

65

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

66

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

67

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Vebe Time Test

Introduction

Chapter: Chapter 1

It is based on measuring the time (Called VEBE time) needed to transfer the

shape of a concrete mix from a frustum cone to a cylinder (these shapes are

standardized by the apparatus of this test), by vibrating and compacting the mix.

The more VEBE time needed the less workable the mix is. This method is very

useful for stiff mixes. The required Vebe Time Test value may be entered in the

68

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Vebe time field on a Mix Design Form. The Vebe time test is a more scientific test

for workability than the Slump Test, in that it measures the work needed to

compact the concrete. The freshly mixed concrete is packed into a similar cone to

that used for the slump test. The cone stands within a special container on a

platform, which is vibrated at a standard rate, after the cone has been lifted off

the concrete. The time taken for the concrete to be compacted is measured. Vebe

times range from 1 second for runny concrete to more than 12 seconds for stiff

concrete. Unlike the slump test, the Vebe time test gives useful results for stiff

69

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

concretes. The levels of workability defined in the DOE Method give both Slump

values and Vebe times for each level, and these values are used in First mix for

converting between Slump values and Vebe times. See Method of Specifying

Workability for selecting to use the Slump or Vebe tests Range: 0 - 20 seconds.

Objectives

Chapter: Chapter 1

To measure the remolding ability of concrete under vibration.

70

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

To measure indirectly the workability of concrete.

To obtain the workability of concrete suing vebe time test.

Theory

The apparatus shown that the consists of a metal cylindrical container mounted

Chapter: Chapter 1

on a vibrating table, which produces a sinusoidal vibration, in the version of the

71

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

test standardized in Europe as EN 12350-3 a slump cone is placed in the center of

the cylinder and filled in the same manner as in the vebe table is started and the

time for the concrete to remold from the slump cone shape to the shape of the

outer cylindrical container is recorded as a measure of consistency , the sliding

Chapter: Chapter 1

clear plastic disk facilitates the determination of the end of the test.

72

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Apparatus

VEBE consistometer.

Description:

o It consists of: Cylindrical container with diameter = 240 mm, and

Chapter: Chapter 1

height = 200 mm.

o Mould: the same mould used in the slump test.

73

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

o Disc: A transparent horizontal disc attached to a rod which slides

o Vertically. Vibrating Table: 380*260 mm, supported by four rubber

Chapter: Chapter 1

shock absorbers.

Tamping rod.

Stop watch.

Container.

A tamping rod.

Vibration rod.

74

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

As shown in [Figure 4]

Figure 4 ; Vebe Time Test Apparatus

75

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Procedure

Chapter: Chapter 1

Slump test as described earlier is performed placing slump cone inside the

sheet metal cylindrical pot of the consistometer.

The glass disc attached to the swived arm is turned and place on the top of

concrete in the pot.

We placed the mold concentrically in the container.

76

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

It was filled with the concrete mix on four layers with tamping 25 times

each layer.

The mold then is left up, and the slump value was calculated.

The transparent disk was placed on the concrete cone.

The vibrator was started as the timing did.

The timing shall stop when the transparent disc is totally covered with

Concrete and all the cavities in the mix are disappeared.

Chapter: Chapter 1

77

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

The electrical vibrator is then switched on and simultaneously a stop watch

started.

The vibration is continued till such a time as the conical shape of the concrete

disappears and the concrete assumes cylinder shape.

This can be judged by observing the glass dics gram the top from

disappearance of transparency.

Immediately when the concrete fully assumes a cylindrical shape, the stop

watch is switched off.

78

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Discussions

Chapter: Chapter 1

The vebe test is the best method to calculate the workability, because it consist of

slump value and vebe time. this test is different of compaction factor used the

manual compacted. But this test is difficult to use in the project may be we need

electricity . The workability of concrete, define in vebe seconds is the vibration

time in seconds. And the remolding is assumed to be complete when the glass

plate rider is completely covered with concrete and all cavities in the surface of

the concrete have vanish, this judged visually, and the complexity of establishing

79

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

the end point of the test may be a source of error, to avoid it an automatically

operated device for recording the movement of the plate against time may be

fitted, and The main advantage of this test is that it is a dynamic test and can be

used on concretes that are too stiff for a slump test.

80

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Advantages:

Chapter: Chapter 1

Test results are obtained directly.

The test device is standardized in ASTM and identified by ACI committee 211,

in its guide for proportioning low slump concrete.

The vebe consistometer is a dynamic test and can be used on concrete that

are too dry for the slump test.

81

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Disadvantages:

Chapter: Chapter 1

No analytical treatment of the test method has been developed, such

treatment would be complex because the shear rate declines during of the test

the concrete specimen changes shape.

The test device only works low slump concretes.

Due to the need to ensure that all vibration is kept within the test device , the

size of the test device makes the vebe consistometer generally unsuitable for

field use.

82

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Conclusion

According the test results we obtained, concrete mix we used can be judged as follows:

Chapter: Chapter 1

Slump test: The mix has a medium workability.

Compacted factor test: The mix has medium workability.

VEBE test: The mix has low workability.

This variation in the workability between the first 2 tests and the last one (VEBE test) can be a result to

losing the workability with time, the time between making the mix and doing the VEBE time test was

83

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

larger than it to the other two tests. Other reason for that might be an error resulted from the

determination of the end of the test.

Chapter: Chapter 1

Appendix

84

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

85

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

86

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter 3

Destructive Concrete Test

After we done with the above tests we need to start molding the concrete into the chosen

moulds, such as 3 cubes of 100x100, Beam of 100x100x500 and a cylinder of 150x300.

And we keep them on mold for 24 hours to gain the required strength.

Chapter: Chapter 1

After 24 hours, concrete element need to be dismantle and keep in water tank for 7 days

or a week.

87

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

After 7 days when concrete gain there specific strength we have to start our destructive

tests, such as Compression test for cubes and cylinder samples and flexural test for the

beam.

88

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Compressive Strength Test

Introduction

Chapter: Chapter 1

A compression test is a method for determining the behavior of materials under a

compressive load. Compression tests are conducted by loading the test specimen

between two plates and then applying a force to the specimen by moving the

crossheads together. The compression test is used to determine elastic limit,

proportionality limit, yield point, yield strength and compressive Strength.

89

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Compressive Strength, It is the maximum compressive stress that a material is

capable of withstanding without fracture. Brittle materials fracture during testing

and have a definite Compressive strength values. The compressive strength of

ductile materials is determined by Their degree of distortion during testing.

90

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Objectives

To, determine the compression strength of concrete test cube and cylinder

according to BS 1881.

Theory

Chapter: Chapter 1

One of the important properties of concrete is strength in compression; the

strength in compression has a definite relationship with all other properties of

91

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

concrete. The compressive strength is taken as the maximum load it can be carry

on per unit area; BS 1881 and MS \7.1 specify the use of concrete cube to

determining compressive strength. And Structure components such as columns

and struts are subjected to compressive load in applications. These components

are made of high compressive strength materials. Not all the materials are strong

in compression. Several materials, which are good in tension are poor in

compression. Many materials poor in tension are good in compression. Cast iron is

one such example. This strength is determined by conducting a compression test.

92

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

During the test, the specimen is compressed and deformation Vs. the applied is

recorded.

Apparatus

ADR 2000 compression machine.

Three cubes size 150x150x150mm.

One cylinder 150mm x300mm

Chapter: Chapter 1

93

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

[Figure 5] is the complete machine of compressive strength machine.

94

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

Figure 5; Compressive

Strength Test Apparatus

95

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

96

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Procedure

The cubes and cylinder removed from the curing tank after 7 days.

Place the plain (lower) bearing block, with its hardened face up, on the table or

platen of the testing machine directly under the spherically seated (upper)

bearing block.

Chapter: Chapter 1

97

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Wipe clean the bearing faces of the upper and lower bearing blocks and of the

test specimen. Place the test specimen on the lower bearing block.

Carefully align the axis of the specimen with the center of thrust of the

spherically seated block.

As the spherically seated block is brought to bear on the specimen, rotate its

movable portion gently by hand so that uniform seating is obtained.

The cube and cylinder was center carefully.

The type of failure and appearance cracks had been noted.

98

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Rate of Loading

Chapter: Chapter 1

Apply the load continuously and without shock. Apply the load at a constant rate

within the range of 20 to 50 psi per second. During the application of the first half of

the estimated maximum load, a higher rate of loading may be permitted.

Do not make any adjustment in the controls of the testing machine while the

specimen is yielding rapidly immediately before failure.

Increase the load until the specimen yields or fails and record the maximum load

carried by the specimen during the test.

99

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Note the type of failure and the appearance of the concrete if other than the usual

cone type fracture.

Result

Chapter: Chapter 1

Cylinder result after compression test

100

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Diameter

150mm

Sample peak load

151.7kn

Sample stress

8.585

Sample pace rate

5.3kN/s

Chapter: Chapter 1

Cube result after compression test

101

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Sample peak load

Sample stress

Sample pace rate

115.4kn

11.54 MPa

3 kN/s

Chapter: Chapter 1

Precautions

102

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

The test does not apply on concrete whose nominal maximum aggregate size

exceed 40mm first check the maximum aggregate size.

Cubes wouldnt me replaced in the testing machine centrally on platens, before

the load is applied.

Close door of the machine to avoid any crushed pieces of object being to your

eyes.

103

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Discussion

Chapter: Chapter 1

From the compression test we took some data that shows that our specimen is

enough strong, according to the time which was less than 28 days our

specimen was harden and able to carry on enough load, such as the cylinder

sustain 151.7kN which was before the object failed. And as the same for cube

the sustain load was 115.4 kN before the object fail, if we compare the stresses

due to time were also enough strong as a 8.585MPa for cylinder and 11.54MPa

104

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

for cube, this test show if the test carry on at the exact time 28 day the

concrete would be able to sustained big amount of the load.

Chapter: Chapter 1

If the strength of our concrete is not fulfill the requirement, so the following can

be the reasons:

Concrete is not well mixed together.

105

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Water to cement is not in the right proportion, which can make the

hydrations process not complete.

Constituent materials such as cement aggregate and water which were not

according to the right proportions.

Hardening time less than 28 days concrete reach maximum strength at 28

days our specimen was harden In a week.

106

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Conclusion

Chapter: Chapter 1

From result that we took from the testing in the laboratory we conclude that,

that the concrete we tested it in compression machine, and the design and

proportion of it we wouldnt be able to apply it at the work site, because of it

doesnt have the desirable strength, its may can cause the structure collapse.

And as we seen that the restrictive effect of the platens of the testing machine

over the entire high of cylinder but leaves unpretentious a part of test cubes,

since both of the object are mad form the same concrete but their strength are

107

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

different, we consider here human error as well and the moisture condition of

the sampling at the time of testing also establish to be affect the ratio of

strength of two types of specimen.

Chapter: Chapter 1

Appendix

108

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Flexural Test

Introduction

Chapter: Chapter 1

The experiment involves the use of a simply supported beam test to determine

the elastic constants for a material. There are various aluminum and magnesium

beams which may be used in the test. Each beam has an axial and transverse

oriented strain gage on the top (or bottom) surface. And Concrete pavement

carries load as a simple, plain, (non-reinforced) concrete beam. The strength of

109

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

the concrete in flexure is the most important requirement. In previous labs then

primary interest has been the compressive strength of concrete. This strength is

used in the structural design of reinforced concrete, where tension, in which

concrete is very weak, is assumed to be taken entirely by the reinforcing steel.

And cracking problem occur when diagonal tension arising from shearing stresses

develops, but the most frequent case of cracking is due to restrained shrinkage

and temperature gradients. There are three types of test for strength in tension.

110

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Direct tension test, flexure test and splitting tension test. For our laboratory work

we used flexural test.

Objective

to determin the flexure strengh of test beam according to BS1881.

To demonstrate the use of flexure test procedures and the flexure test stress

state theory.

Chapter: Chapter 1

111

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

To demonstrate the use of a strain gauge rosette oriented on the top of an endsupported beam loaded at its middle.

To experimentally determine and compare results of the modulus of elasticity

and Poisson's ratio

Chapter: Chapter 1

112

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Theory

Chapter: Chapter 1

Flexure test is intended to find the flexure strength of concrete in tension. Flexure

strength of concrete gives the tensile strength of concrete in bending. In this test

a simply supported plain concrete beam is loaded at it third point. The resulting

bending moment induce compressive stresses in the top and tensile stresses in

the bottom of the beam

113

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Flexural Test=

p = maximum load applied to the beam

L = distance between the axis of the cuter pair roller

b = width of the beam at the line of fracture

d = depth from the beam at the line of fracture

Chapter: Chapter 1

PL

b d2

114

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

115

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Apparatus:

Chapter: Chapter 1

ADL 2000 Flexure Machine

Beam (150mm x 150mm x 150mm)

[Figure 6] shows the apparatus for flexural test of beam.

116

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

117

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

Figure 6 ; Flexural Test Apparatus

118

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Procedures

Chapter: Chapter 1

Remove the test beam from curing tank after 28 days

Wipe off any grit and remove any fins from the beam

Clean and adjust the lower supporting rollers in position

Place centrally the specimen in the testing machine in such a manner that

the load shall be applied

Lower the loading rollers. Carefully align the axis of the bending device

119

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Apply the load and increase it gradually until the specimen fails.

Record the maximum load applied

Note the appearance of cracks in the concrete and any unusual features in

the type of failure.

[Figure 7], shows before and after the flexural test happens.

Chapter: Chapter 1

Figure 7; Before

After

120

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Result

Chapter: Chapter 1

Beam, reaslut after flexure test

Sample peak load

6.66Kn

Sample stress

1.999 MPa

Sample pace rate

0.200kN/s

121

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

PL

b d2

Chapter: Chapter 1

flexural test =

122

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

100

2

100

6.66 x (500)

flexural test =

123

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Discussion

Flexural test for the beam has done successfully and the maximum peak load that

it sustain was 6.6kN and a stress of 1.999 Mpa.

Chapter: Chapter 1

Conclusion

124

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

In conclusion we can say that we did our compressive and flexural test, to find out

whether our concrete has the required strength to sustain the applied load or not.

In fact we check our mix design for our batch of concrete. If our members didnt

sustain the required load per unit area, so we need to redesign our mix

proportions until it fulfill the requirement. In order to have a safe structure.

Chapter: Chapter 1

Appendix

125

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

126

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

127

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter 4

Non-Destructive test

Chapter: Chapter 1

In this test the concrete is not going to be destroyed.

128

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

129

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

130

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

131

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

132

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Rebound Hammer Test

Introduction

Chapter: Chapter 1

The Schmidt hammer test (rebound hammer) is a surface hardness tester for

which an empirical correlation has been established between strength and

rebound number. The only known instrument to make use of the rebound principle

for concrete testing is the Schmidt hammer, which weighs about 4 lb (1.8 kg) and

is suitable for both laboratory and field work.

133

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Objectives

To find the strength of concrete

Measuring the compressive strength of concrete using the Schmidt hammer

Chapter: Chapter 1

134

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Theory

Chapter: Chapter 1

The Schmidt Hammer Test is based on the principles that the rebound of an elastic

mass depends on the hardness of the surface against which the mass impinges.

However, despite its apparent simplicity, the rebound hammer test involves

complex problems of impact. Loaded mass has a fixed amount of energy imparted

to it by extending the spring to a fixed position; this is achieved by pressing the

plunger against the surface of the concrete under test. Upon release, the mass

rebounds from the plunger, still in contact with the concrete surface and the

135

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

distance traveled by the mass, expressed as a percentage of the initial extension

of the spring, is called the rebound number.

Apparatus

Chapter: Chapter 1

Schmidt Hammer.

Ruler.

Figure 8; Rebound Hammer

136

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

White Chalk.

[Figure 8] shows the Rebound Hammer

Chapter: Chapter 1

137

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Procedure

Determine the structure to be tested. In this case, a column is selected.

A 300 X 300 mm area is set and lines are marked.

The area is then divided into 15 equal boxes as in figure.

Each box is marked with 5 points.

Chapter: Chapter 1

138

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

The test is conducted.

1

Chapter: Chapter 1

139

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

140

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

141

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

142

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Result and calculation

1

Average (kg/c

m2

31

28

26

28

Chapter: Chapter 1

26

27

143

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

A

Average

26

30

28

28.6

32

29

30

28

28

30

26

31

28.2

26

20

26

22

23

27.87

28.13

Chapter: Chapter 1

28

23

30

26.8

27

38

28

28

27

144

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Average

29.4

28

29

27

25

26

27

26

26

25.4

26

28

26

24

14

23.6

22

26

25.67

Chapter: Chapter 1

Average

29.6

26

26

24

28

28

26.4

30

24

145

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

D

Average

25

20

28

25

30

28

30

26

26

24

25

18

23

23

16

28

24

30

24.8

26.87

Chapter: Chapter 1

24

28

26

26.4

31

25

27

30

20

146

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Average

26.6

26

A +B+ C+ D+ E

5

Chapter: Chapter 1

strength of concret =

28

147

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

strength of concret =

27.87+28.13+25.67+24.8+26.87

2

=26.688 kg/cm

5

27.87+ 28.13+25.67+24.8+26.87

=27.19 N /mm 2

5

Chapter: Chapter 1

, strength of concret =

148

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

General Discussion

Chapter: Chapter 1

Testing the compressive strength of concrete using the Schmidt hammer (Also

called: rebound hammer, impact hammer and accelerometer), is considered as a

nondestructive test as no destroyed specimens takes place in it. The main

principle of this test is that it measures the rebound of an elastic mass when it

collides with the concrete surface under the test, this rebound depends on the

149

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

hardness of concrete and on the energy it absorbs from the collision. The tested

concrete has to be smooth and firmly supported. The hammer is pressed against

the concrete, and then the

Chapter: Chapter 1

mass inside the hammer is rebounded from the plunger and gives a reading on

the scale. This reading is called Rebound Number which is the distance traveled

by the mass expressed as a percentage of the initial extension of the spring. Note

that the rebound number is an arbitrary measure that means different device

150

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

might give different rebound numbers in the same test. The rebound number

depends on energy stored in the spring and on the size of the mass, consequently

each device is combined with a graph contains calibrating curves relating the

rebound number with the.

Chapter: Chapter 1

And from the our testing that we done in the laboratory we obtain that the value

of the concrete strength is 27.19 kN/mm2, mean the hummer has to be used as

the smooth surface. And it preferably a concrete, from instance, the presence of a

151

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

large piece of aggregated instantaneously underneath the plunger will result in an

abnormally high rebound number. And the results may be not constant at all

because the Schmidt hammer is not 90 degree through the concrete column.

Moreover that, the reading, from Schmidt hammer after transfer to the graph

reading may be wrong.

Chapter: Chapter 1

Conclusion

152

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

All the reading where considered in calculations as the deviation of all the points

from the average is less than 7 degrees, I think that can be related to the

homogeneity of the mix. The gained compressive strength is satisfactory, but

errors might be occurred in placing the hammer orthogonally on the concrete

surface. The more the rebound number is the more compressive strength of the

concrete. And there are a few errors that had occurred during the experiment that

may change the result a little bit and make that result inaccurate. And that might

153

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

be, such as the test is not a strength test and exaggerated claims of its use as a

replacement for the compression test should not be an accepted.

Chapter: Chapter 1

Appendix

154

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

155

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

156

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Chapter: Chapter 1

Concrete Technology Laboratory

157

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Micro Cover Meter

Introduction

Chapter: Chapter 1

The standard tests of strength of concrete are made on specially prepared

specimens, which perforce are not true sample of the concrete in the actual

structural. The Micro Covermeter is a microprocessor controlled unit weighing only

500 g, and is used for the non-destructive checking of steel reinforcement in

concrete structures and components, such as precast lintels, staircases and

158

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Chapter: Chapter 1

reinforced panels. It accurately determines the position and direction of the

reinforcing bars and the exact measurement of their concrete cover to BS 1881

Part 204. It can also be used for checking mesh reinforcement and concrete pipes.

The instrument is available with either a maxi prob, with a range of up to 360 mm

or a mini probe for cover depths of up to 75-100 mm. Unless measuring deep

cover is a particular requirement, we recommend the mini probe, as it can

differentiate closely spaced bars more readily, and is less prone to interference

from other reinforcing bars or adjacent steelwork.

159

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Objective

Chapter: Chapter 1

Electromagnetic cover devices can be used for determining the position and

direction of steel reinforcement and depth of cover to the steel.

160

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Apparatus

Micro Cover Meter.

Ruler.

White Chalk.

[Figure 9] shows a Micro Cover Meter set.

Chapter: Chapter 1

Figure 9; Micro Cover Meter

161

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Procedure

Chapter: Chapter 1

A column is selected at the in front of the lab.

Micro cover meter is laid at the surface of the column.

Micro meter is laid from the left to right and we get the position of the

main reinforcement.

162

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

The lowest of the result from the scanner will record.

After the entire surface from the right to the left is consider then the

position from bottom to the up of the column will record in the following

table.

Result and calculation

Direction

A= C (mm)

B= D (mm)

28

40

44

Chapter: Chapter 1

26

163

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

34

30

29

36

32

41

28

32

28

44

42

50

44

49

46

42

41

40

44

23

46

44

44

44

29

35

46

Chapter: Chapter 1

Depth of

reinforcement

Bars

24

31

20

26

20

26

20

19

21

164

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Total

Total average

31

349

39

477

49

448

392.25

A + C 255+349

=

=302.0 mm

2

2

Chapter: Chapter 1

Depth=

22

255

165

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

B+ D 477+ 448

=

=462.5 mm

2

2

Depth=

AC+ DB 604 +925

=

=764.5 mm

2

2

Chapter: Chapter 1

Depth=

166

SAYED ASADULLAH

UNISEL, FACULTY OF ENGINEERING,

CIVIL DIVISION

Concrete Technology Laboratory

Discussion

Chapter: Chapter 1

Since it is C37 Micro covermeter Standards, BS 1881:204 C DIN 1045

This hand held instrument with microprocessor provides digital direct readout of