Appendix 5 Section 5 Example Food Safety Program

Diunggah oleh

Akbar MotaniHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Appendix 5 Section 5 Example Food Safety Program

Diunggah oleh

Akbar MotaniHak Cipta:

Format Tersedia

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh

process

Section 5

Example Food Safety Program of

a Cook-Fresh process

This Food Safety Program is a model only. It is a typical example of a program of a cook

fresh process for a hospital or aged care facility. It would not be appropriate for all

facilities and products. In addition to this cook fresh process, you may likely have other

processes such as cook chill etc.

This example aims to show one way that the components of a Food Safety Program for

Cook Fresh Food Production System can be developed. It covers the following:

Scope and Purpose

Product Description and Intended Use

Process Flow Chart

Hazard Analysis Table

Hazard Control Table

Support Programs

This example Food Safety Program for Cook Fresh Foods has been developed for a

facility that has effective Support Programs.

For example:

Staff Training in Food Safety, Food Handling and Hygiene

Sanitation and Cleaning Programs

Supplier Approval Programs

Building and Equipment Preventative Maintenance Programs

Pest Control Programs

If these programs were not in place and functioning correctly then the Food Safety

Program (eg. the Hazard Analysis) would be invalid.

This example program is to assist NSW hospital and aged care facilities that process

Cook Fresh food to develop their own Food Safety Programs. Facilities must develop their

own Food Safety Programs as products, processes and premises are unique. However,

the example program can be used as a guide. The NSW Food Authority does not take any

responsibility for any food produced or Food Safety Programs developed using this

example program.

The tables used in this example food safety program is not comprehensive and

you will need to refer to other references. The relevant tables list the hazards

that are significant which are controlled by either CCPs or SPs these are ones

which you should consider, but you may have others that are significant for

your facility.

NSW/FA/CP005/0805

Version 2

Page 1 of

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh

process

5.1

Introduction

This facility is committed to maintaining this food safety program so that:

the end product is safe as is reasonably possible

there is compliance with the requirements of the Food Act 2003 and the Food

Standards Code.

5.2

Food Safety Team

This team is responsible for maintaining the Food Safety manual, reviewing and

improving procedures and implementing effective controls to manage food safety risks.

The Food Safety team includes:

Name

Position

TEAM LEADER

Mary Boss

Food Services Manager

TEAM MEMBER

Paul Citizen

Chef

TEAM MEMBER

Peter Worker

Infection Control Officer

TEAM MEMBER

Jane Friend

Cook

5.3

Scope

This Food Safety Program covers:

Receival, storage, thawing, preparation, cooking, post cook processing, hot holding,

service, delivery of cook fresh food and clean up.

5.4

Purpose

The Food Safety Program is being implemented to minimise the risk of hazards during the

handling of the food whilst in the facilitys control; thereby ensuring that the food is as

safe as possible and meets the regulatory requirements of NSW Food Authority.

NSW/FA/CP005/0805

Version 2

Page 2 of

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh

process

5.5 Example Product Description and Intended Use

Product description

Fully cooked meals served hot, no chilling step, to be

consumed on the same day as preparation.

Examples (s)

Spaghetti Bolognaise, Tuna Bake, Vegetarian Casserole

etc.

Product composition

Varies according to recipe. Includes beef, tuna,

vegetables, tomato paste, pasta, water etc.

Method of Preservation

Cooking. Food may be baked, boiled, roasted, steamed,

stir fried and/or grilled

Other food safety

characteristics

None, food is high in moisture, low in salt and has

neutral pH

Food may be cut or portioned prior to serving

Special preparation

characteristics

Food is served hot, it may be held hot prior to serving

Food is served within 60 minutes after cooking

Food is not chilled and stored for later use

Packaging

Plates covered with plastic or lids

Storage and distribution

conditions

Held at 60oC or greater

Shelf life

N/A Food is hot, ready to eat and should be consumed

within 2 hours of cooking

Distribution method

Meal carts

Consumer

Vulnerable populations hospital patients, pregnant

women and elderly people.

Intended Use

Ready-to-eat

NOTE: This is an example outlining in tabular form the information required. However,

this can be presented in any fashion which suits the facility

NSW/FA/CP005/0805

Version 2

Page 3 of

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh

process

5.6 Example Flow Chart of Fresh Cook Food

Onsite confirmation of flow diagram

Is the flow diagram

accurate?

Yes, flow diagram has been

confirmed against actual

processing operations

NSW/FA/CP005/0805

Authorised By

Sign Off / Date

Food Services Manager

Mary Boss

Version 2

Page 4 of

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh

process

12th May 2005

day shift, night shift and

on weekends.

NSW/FA/CP005/0805

Version 2

Page 5 of

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.7 Example Hazard Analysis for Cook Fresh Food

Step

Input(s)

Hazards

Significan

t Hazard?

Ingredien

t or

process

step

Identify potential hazards

introduced, controlled or

enhanced at this step.

C= Chemical (eg

allergens)

Is the

potential

food

safety

hazard

significant

?

P= Physical

B = Biological

(virus, bacteria,

toxins)

Justification

CCP?

Control

Measure

Is this

step a

Critical

Control

Point

(CCP?)

What

control

measure

can be

applied to

prevent

the

significan

t

hazards?

#

No

SPs

No

SPs

No

SPs

(High

severity/hi

gh

likelihood))

1-11 All

steps

Staff (jewellery, bandaids, hair,

gum)

P = Foreign object

contamination

No

Equipment (bolts, grease, glass

objects)

Unlikely to occur due to good food

handling hygiene practices (staff

training) and maintenance programs

avoid foreign objects

Building (flaking paint, glass

objects

Processing (utensils, plastic

packaging)

1. Menu

Design /

Bacteria and viruses that cause

food borne illness introduced

by poor staff hygiene and work

practices

B = contamination by

staff

Harmful or incorrect level of

compound or ingredient as a

result of incorrect blend or

contamination during transit

C = chemical

contamination

NSW/FA/CP005/0805

of 29

No

No

Version 2

Unlikely to occur due to Good Food

Handling practices, Staff Training and

Illness Policy

Unlikely to occur due to Supplier

Approval programs, good compliance

history, and/or Certificate of Analysis

received with each shipment for

Page 6

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

Ordering

&

Purchasin

g

Introduction of foreign objects

(metal, glass, wood)

P= Contamination by

foreign objects

No

Introduction of food borne

bacteria and viruses that cause

illness.

B= microbiological

contamination

No

certain ingredients/products *.

Notes:

# SP = Support Program. You should document exactly which Support Program is used as a control measure. You need to have a written

procedure if a hazards is controlled by a SP. Hence you need to note the procedure name/number.

* Certificate of Analysis is an effective tool which can be used to ensure that high risk products are microbiologically sound. It may not be

appropriate for all situations. Certificate of Compliance may be more suitable for short life ready to eat products which demonstrate the

suppliers commitment to providing product that meet an agreed specification eg their technical specification.

NSW/FA/CP005/0805

of 29

Version 2

Page 7

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.7 Example Hazard Analysis for Cook Fresh Food (continued)

Step

Input(s)

Hazards

2.

Receival

Contamination by visible metal,

plastic, cardboard, wood, glass

and chemicals during transit.

C,P = introduction

of foreign objects

Temperature of food during

transit.

B = Growth of

bacteria that cause

food borne illness

Contamination during handling

at receival step (eg from

thermometer, pests)

B = introduction of

microorganisms

Contamination during storage

by cleaning products

(lubricants, soaps and

detergents) and dangerous

chemicals (rodent bait).

C= chemical

contamination

Contamination by vermin and

dirt during storage.

P,B =

contamination by

foreign objects or

bacteria or viruses

that cause illness

3.

Storage

Temperature of chilled and

frozen ingredients and food

during storage.

NSW/FA/CP005/0805

of 29

B = growth of

bacteria

Signific

ant

Hazard

?

No

Yes

Justification

Unlikely to occur as product integrity checked

upon arrival as part of inspection program.

Increased temperatures can result in bacteria

growth to high levels unable to be controlled by

the cooking process. There is also potential for

growth of organisms that produce heat resistant

toxins (Staphylococcus aureus) at increased

temperatures

CCP

?

Control

Measure

No

SPs

Yes

Check that the

temp of

perishable

ready to eat

foods on arrival

is 5oCmax and

frozen food is

hard frozen

No

Unlikely to occur as Good Hygiene Practices

should outline standard procedures for use of

alcohol wipes prior to taking temps, and

product stored correctly and quickly off receival

dock

No

SPs

No

Unlikely to occur as Sanitation and Pest Control

programs control these hazards. Chemicals are

stored and labelled correctly. Bait stations at

appropriate locations. Tamper proof bait

stations in use.

No

SPs

No

SPs

No

SPs

No

Unlikely to occur, products and ingredients are

packaged, good sanitation practices and Pest

Control Programs are in place.

Premises are in good repair, doorways are kept

closed to prevent pest entry.

No

Version 2

Unlikely to occur. Product storage temperature

(refrigerator is 5oC or below and freezer is -10 oC

or below) is maintained and checked regularly.

Page 8

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

NSW/FA/CP005/0805

of 29

Version 2

Page 9

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.7 Example Hazard Analysis for Cook Fresh Food (continued)

Step

Input(s)

Hazards

4. Thawing

Ingredient or product

temperatures during defrost at

refrigerated temperatures.

B = Growth of

bacteria that cause

food borne illness

Significa

nt

Hazard?

No

Ingredient temperatures during

water thawing and defrosting in

the microwave.

Yes

5.

Preparatio

n

6. Cooking

Contamination by chemicals,

oils and cleaners

C = chemical

contamination

Dust and insects, utensils

P= contamination by

foreign objects

Times. Growth of bacteria when

times out of refrigeration are

not maintained during

preparation.

B = Growth of

bacteria that cause

food borne illness

Cooking process (baking,

boiling, frying, grilling etc.),

times and temperatures.

B = Survival of

bacteria and

contaminating

microbes when foods

are not cooked

properly

NSW/FA/CP005/0805

10 of 29

Justification

CCP?

Unlikely to occur if frozen product is

always completely thawed at

refrigerated temperatures.

No

Increased temperatures can result in

bacteria growth to high levels unable

to be controlled by the cooking

process. There is also potential for

growth of organisms that produce heat

resistant toxins (Staphylococcus

aureus) at increased temperatures.

Yes

Control

Measure

SPs

Make sure

time and

temperatur

es do not

allow

growth.

Use

standard

procedure

No

Unlikely to occur. Residual cleaning

and sanitizing chemicals, lubricants

are addressed by the Sanitation

Program

No

SPs

No

Unlikely to occur. Good Food Handling

Practices and Sanitation Program in

place.

No

SPs

Yes

Strict time monitoring during

preparation. Time of ingredients out of

the refrigerator is minimised.

Ingredients are pre-cooled before use.

Yes

Limit the

amount of

preparation

time

Yes

Bacteria and contaminating microorganisms are likely to occur in raw

ingredients (especially meat). The

cooking process must reduce these to

safe levels.

Yes

Cook to

standard

times and

temperatur

es.

Take core or

cold spot

temperatur

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

es

NSW/FA/CP005/0805

11 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.7 Example Hazard Analysis for Cook Fresh Food (continued)

Step

Input(s)

Hazards

7. Post

Cook

Processing

Contamination by bacteria

during puree process

B = Growth of

bacteria that cause

food borne illness

(portioning

, slicing or

Texture

Modificatio

n

Times and product

temperatures allow growth of

surviving heat resistant and

any contaminating microorganisms while portioning

occurs.

Significa

nt

Hazard?

No

B = Growth of

bacteria that cause

food borne illness

Justification

CCP?

Control

Measure

Severity is high but unlikely to occur if

pure/texture modification support

program is in place. See Section 6.2 for

more information on Texture modified

foods and puree. Also ensure adequate

cleaning and sanitation is undertaken.

No

SPs

If product is not portioned or pured

quickly after cooking and before

cooling or eating, growth of heat

resistant or contaminating bacteria is

possible.

Yes

Yes

Limit the

amount of

time

between

the end of

the cooking

process and

refrigeration

or

consumptio

n.

Monitor the

time out of

cook, chill

or serving

times.

8. Hot

Holding

Times and product

temperature allows growth of

surviving heat resistant and

any contaminating microorganisms

NSW/FA/CP005/0805

12 of 29

B = Growth of

bacteria that cause

food borne illness

Yes

Version 2

Food must be held at sufficient hot

holding temperatures.

Yes

Heat food to

correct

minimum

temperatur

e in the

correct

amount of

time.

Monitor

holding

times and

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

temperatur

es.

NSW/FA/CP005/0805

13 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.7 Example Hazard Analysis for Cook Fresh Food (continued)

Step

Input(s)

Hazards

9. Hot

Serve

Times and product

temperatures allows growth of

surviving heat resistant and

any contaminating microorganisms

B= Growth of bacteria

that cause food borne

illness

Allergens and food

consistency cause adverse

reactions and choking in

patients and residents with

allergies or swallowing

difficulties.

B = food ingredients

causing allergic

reaction

Times and product

temperature allows growth of

surviving heat resistant and

any contaminating microorganisms

B= Growth of bacteria

that cause food borne

illness

Contamination by unclean

trolley/delivery vehicles, dust,

insects and utensils

B,P= Cross

contamination by

bacteria or viruses

that cause illness or

foreign objects

10.

Delivery

NSW/FA/CP005/0805

14 of 29

Significa

nt

Hazard?

Justification

CCP?

Food must be held at sufficient hot

holding temperatures.

Yes

Serve only

hot food and

serve quickly.

Monitor

serving

temperatures

and times.

No

SPs

Bacteria and contaminating microbes

will be able to grow or survive if

conditions are favourable. The serving

temperature and delivery times need

to eliminate this hazard.

Yes

Deliver only

hot meals.

Deliver

meals

quickly.

Monitor meal

temperatures

and delivery

times.

Unlikely to occur because food is kept

covered and the Sanitation and

Cleaning Program specifically

addresses the cleaning of trolleys etc.

No

Yes

No

Control

Measure

Unlikely to occur. Patient and residents

needs are documented and dietary

needs/changes are tracked

P= food inconsistency

Yes

Yes

Version 2

SPs

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.7 Example Hazard Analysis for Cook Fresh Food (continued)

Step

Input(s)

Hazards

11. Clean

up

Inadequate dishwasher

temperatures allow survival

and subsequent growth of any

contaminating microorganisms on utensils and

crockery.

B = Cross

contamination by

bacteria or viruses

that cause illness.

Inappropriate cleanup

returned food items/plates

and contaminates food

preparation area.

B = Cross

contamination by

bacteria or viruses

that cause illness.

Significa

nt

Hazard?

Yes

Yes

Justification

It is likely that utensils and crockery

are contaminated upon return from

service. Dishwasher rinse

temperatures are monitored as part of

the Cleaning program

CCP?

Control

Measure

SPs

No

Returned, unfinished meals/foods

disposed in a dedicated area (separate

from food preparation areas).

No

SPs

No

SPs

No

SPs

No

SPs

P = Contamination by

foreign objects.

Inappropriate cleaning

procedures, where incorrect

chemicals or incorrect

concentrations are used.

C = chemicals

contaminate food

contact surfaces,

plates and utensils

Infestation of pests due to

garbage as an available food

source.

P = Pests

contaminate food,

environment.

Trays, plates, cutlery are

stored incorrectly.

P= Physical

contamination

Potentially contaminated

items from patients/residents

(eg bandages, vomitus,

medications, syringes, body

fluids etc)

B = Cross

contamination by

micro-organisms

NSW/FA/CP005/0805

15 of 29

No

No

No

No

Unlikely to occur, only approved

cleaning chemicals are use. This is

addressed in the Sanitation and

cleaning program.

Unlikely to occur. Garbage and waste is

removed in a timely manner.

Pest control program includes regular

pest inspections.

Unlikely to occur. Trays, plates, cutlery

are stored correctly after cleaning. This

is addressed in the Sanitation and

Cleaning Program.

Contaminated items to be removed by

nursing staff before being returned to

kitchen.

No

SPs

P = Contamination by

foreign objects

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

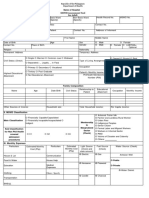

5.8 Example Hazard Control Table for Cook Fresh Foods

Proces

s Step

Potential

Hazard/s

Control

Measures

CC

P

Critical Limit

2.

Receiv

al

Microbiolog

ical

(temperatu

re abuse)

chilled

ready-toeat (RTE)

foods.

Temperatu

re of

chilled

ready to

eat

product on

arrival.

CCP

Maximum

product

temperature

5oC

Microbiolog

ical

(temperatu

re abuse)

frozen RTE

foods

Appearanc

e of frozen

product

SP

No evidence

of

freeze/thawing

(ice crystal

formation).

Monitoring Procedures

What

How

When

Who

Take

representativ

e

temperatures

of chilled RTE

food for

every

delivery or

representativ

e sample.

Sanitised,

calibrated

thermomet

er or IR gun

on packets

(not

cartons) as

per

manufactur

ers

instructions

Every

delivery

Store

perso

n/

chef

Feel of each

product type

per delivery.

Feel or use

IR gun on

frozen

packets(not

cartons) as

per

manufactur

ers

instructions

Every

delivery

Check

packages

and labels

Every

delivery

Must be hard

frozen.

Microbiolog

ical (out of

date)

Contamina

NSW/FA/CP005/0805

16 of 29

Product to

be within

use-by

Appearanc

SP

SP

Must be within

Use by date

No evidence

Visual

inspection of

all products.

Visual

Version 2

Check

Corrective

Action

Records

Contact

Supervisor.

Product

Receivals

Sheet

Reject if

temperature is

above 5oC.

(Form 5)

Notify supplier

and report.

Every

Store

perso

n

Store

perso

n

Store

Contact

Supervisor.

Reject soft,

partially thawed

product and

product with ice

crystal formation

of RTE foods.

Notify supplier

and report.

Product

Receivals

Sheet

(Form 5)

Reject products

that are out of

date or very

close to date if

you cant use it

prior to expiry.

For RTE foods

notify supervisor

Product

Receivals

Sheet

Reject products

Product

(Form 5)

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

Proces

s Step

Potential

Hazard/s

Control

Measures

tion

e of

of problems

Microbiolog

icalChemic

al Physical

a) product

a) dirty,

damaged

product,

b)

packaging

condition

c) delivery

vehicle

NSW/FA/CP005/0805

17 of 29

CC

P

Critical Limit

Monitoring Procedures

What

How

When

Who

inspection

truck,

packaging

and product

delivery

perso

n

b) damaged ,

dirty boxes,

Corrective

Action

Records

that are

damaged or

show signs of

contamination or

tampering.

Receivals

Sheet

(Form 5)

Reject

excessively

soiled or

damaged fruit

and vegetables

c) poor truck

condition

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.8 Example Hazard Control Table for Cook Fresh Foods (continued)

Process

Step

Potential

Hazard/s

Control

Measures

3.

Storage

(Chilled,

Microbiologic

al

(temperatur

e abuse) of

RTE foods

Temperatur

e of chilled

RTE food

Frozen,

Ambient

)

Storage

temperatur

es of

freezers

Contaminati

on

Monitor

- product

packaging

- store

areas

- stock

rotation

CCP

Critical

Limit

Monitoring Procedures

What

How

When

Who

Maximum

storage

temperatur

e 5oC

Product

temperatur

es

Sanitised,

calibrated,

thermometer

Twice a day

Kitchen

Staff

Maximum

freezer

temperatur

e of -10oC

No

evidence of:

Freezer

temperatur

e

Examine

the product

- damaged

stock or

packaging

(morning

and

afternoon)

Corrective

Action

Records

For food between

5oC and 10oC,

refrigerate and

use within 12

hours.

Refrigerato

r/

Discard any food

over 10oC.

Freezer

thermometer

Store

check

sheet

(Form 2)

Appliance

Temperatur

e Check

Sheet

Visually

inspect

Daily

Store

supervisor

Clean and

remove garbage

more frequently,

correct stock

rotation.

Discard any item

that is damaged

or is unlabelled

(name, date etc.)

or exposed

product (no lids).

- poorly

maintained

store area

(eg. rodent

activity)

Coolroom/

Refrigerato

r/

Coolroom/

Store

check

sheet

(Form 2)

- out of date

stock

- foodstuffs

stored

uncovered

NSW/FA/CP005/0805

18 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

NSW/FA/CP005/0805

19 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.8 Example Hazard Control Table for Cook Fresh Foods (continued)

Process

Step

Hazard/s

4.

Thawing

(general)

Microbiologic

al

4(a)

Water

Thawing

Microbiologic

al

(temperature

abuse,

undercookin

g)

4(b)

Microwav

e

Thawing

4(c)

Refrigera

tor

Thawing

(undercookin

g)

Microbiologic

al

(temperature

abuse)

Microbiologic

al

(temperature

abuse)

NSW/FA/CP005/0805

20 of 29

Control

Measure

s

CCP

Critical

Limit

Monitoring Procedures

Completely

thaw

product

Water

temperatur

e and

product

thawing

times

What

How

When

Who

SP

Time taken

for thaw

process

Check for

evidence

of hard

frozen

product

Visual

inspection

All product

daily

Leading

hand

Continue to thaw

until completely

defrosted

CCP

Water

temperatur

es 21oC or

less

Temperatu

re of

running

thaw

water.

Sanitised,

calibrated

thermome

ter

Every

batch

Chef

If water temperature

is over 21oC throw

product away.

Product

thawed in 4

hours

Amount of

time after

microwave

thaw

before

cooking

begins

CCP

Product

temperatur

e during

thawing

SP

If product remains

frozen after 4 hours,

continue to thaw in

the refrigerator.

Time

taken for

thawing.

Product to

be

immediatel

y cooked

after

microwavin

g (30 mins)

Time

taken

between

thaw and

cook.

Visual

inspection

Product to

be

completely

thawed in

Product

location

Visual

inspection

Version 2

Corrective

Action

All product

daily

All product

daily

Chef

Leading

Hand

Records

Water

Thaw

Check

Sheet

(Form 6)

Discard thawed

micro waved product

if after 30 minutes

has

Food

Process

Time Temp.

Worksheet

Elapsed.

(Form 6)

Continue to thaw in

the refrigerator.

Food

Process

Time Temp.

Worksheet

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

refrigerator

(maximum

5oC)

NSW/FA/CP005/0805

21 of 29

(Form 6)

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.8 Example Hazard Control Table for Cook Fresh Foods (continued)

Process

Step

Hazard

/s

Control

Measures

CCP

5.

Preparatio

n

Growth

of

bacteria

Monitor

product

times

CCP

Critical

Limit

Monitoring Procedures

What

How

When

Who

Maximum

30

minutes

Time in

preparation

room.

Visually

check that

there is no

food left out

of

refrigeration

at

At each

meal

break.

Chef

Or

break times

or once

finished.

Visual

check

Corrective

Action

Records

Check time of any

food found to be

out of refrigeration

when returning

from a break. If

more than 30

minutes cook

immediately or

throw away.

Food

Process

Time Temp.

Worksheet

(Form 6)

Notify supervisor

for disposition.

6. Cooking

Survival

of

bacteria

when

food is

not

cooked

properly

Check

product

temperature

s for oven

cooked,

gently

heated or

grilled

product for

every batch.

CCP

Core is

min 70oC

for 2

minutes

(75oC)

instant *

Take at

least one

final core

temperatur

e of

product (in

oven cold

spot if

applicable).

Sanitised

calibrated

thermometer

.

Every

batch or

every

oven

cycle.

Chef

Keep cooking until

cook temperature

is reached.

Cooking /

Cooling

check

sheet

(Form 6)

NOTES:

* The critical limit will be based on type of meal cooked.

This critical limit can apply for bulk baked or roast meats eg meatloaf and roasts (eg roast chicken, beef, lamb, pork)

For grilled foods need to check that it is cooked through by checking for doneness (eg for steak)

NSW/FA/CP005/0805

22 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

However particular attention needs to be paid to poultry, offal (liver, kidneys), rolled and stuffed meats and formed mince products such as

hamburgers, meat loaf and sausages, in which case a thermometer should be used to ensure desired cook temperature is reached.

NSW/FA/CP005/0805

23 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.8 Example Hazard Control Table for Cook Fresh Foods (continued)

Process

Step

Hazard/s

7. Post

Cook

processing

Growth of

bacteria

(time and

temperatur

e abuse)

(portioning

or texture

modificatio

n)

Microbial

contaminati

on

Control

Measure

s

CCP

Elapsed

time and

temperatur

e at end of

process

CCP

Use of

clean and

sanitised

equipment

and

utensils

according

to Standard

Procedures

SP

Critical

Limit

Monitoring Procedures

What

How

When

Who

Maximum

30 minutes

elapsed

time and

min temp

of 60oC at

of process

Elapsed time

after cooking

and before

hot holding

Record time

out of cook

and holding

start time

Each meal

time

(breakfast,

lunch,

dinner)

Chef

Temp at end

of process

Record temp

at end of

process#

Ensure

equipment

and

utensils are

clean and

sanitised

Check that

all

equipment

and utensils

used are

clean and

sanitised

Visual check

Corrective

Action

Records

Re-heat food to

70oC for 2

minutes (or

equivalent

within 1 hour)

Food

Process

Time

Temp.

Workshee

t

(Form 6)

Before use

Leading

hand

RE-clean and

sanitise

equipment and

utensils prior to

use

# If you can validate that the temperature is always above 60oC at the end of the process then you can remove the monitoring of the temp each time.

NSW/FA/CP005/0805

24 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.8 Example Hazard Control Table for Cook Fresh Foods (continued)

Process

Step

Hazard/s

Control

Measure

s

CCP

Critical

Limit

Monitoring Procedures

8. Hot

Holding

Growth of

bacteria due

to

Product

temperatur

es

CCP

Minimum

60oC

temperature

abuse

and times

Take each

product

temperature

and times

before it is

put into Bain

maire

And limit

time to 30

mins

Ensure

equipment is

not

overloaded.

Sanitised,

calibrated

thermometer

Each meal

time

(breakfast,

lunch and

dinner)

Chef

Monitor time

clock.

Visual

inspection

At start of

meal service

Superviso

r

Corrective

Action

Records

Adjust hot

holding

equipment (bain

marie) set point.

Food

Process

Time

Temp.

Workshee

t

Stop serving,

resume serving

when product

temperature is

60oC.

(Form 6)

If food falls

below 60oC for

30 minutes

discard+.

Review process

to ensure all

food is heated

to holding

temperatures or

higher BEFORE

food is

transferred to

hot holding

equipment.

If trays are

overloaded,

remove some of

food, chill

immediately

and reheat

NSW/FA/CP005/0805

25 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

before

reservice.

Retrain staff

member

Note:

+ The max time that the food is out of temperature control is 2 hours (eg from plating to consumption). The time you set here depends on the time

frames surrounding your facility. Target should be around 30 mins.

NSW/FA/CP005/0805

26 of 29

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

5.8 Example Hazard Control Table for Cook Fresh Foods (continued)

Process

Step

9. Hot

Serving

Hazard/s

Growth of

bacteria due

to

temperature

abuse

Adverse

patients/resid

ent reactions

(choking,

allergies)

Control

Measure

s

CCP

Product

temperatur

e

CCP

Patients &

residents

receive

appropriat

e meals

SP

Critical

Limit

Monitoring Procedures

What

How

When

Who

Last meal

served is

60oC

Take product

temperature

(of

meat/chicken/fi

sh etc) of the

last meal

plated.

Sanitised,

calibrated

thermomete

r

Each meal

time

(breakfast,

lunch and

dinner)

Person

serving

meals

Resident

patient food

needs.

Visual

inspection

that correct

meal is

given to

patient

On handing

the meal to

the patient

Person

serving

meal

After any

significant

changes or

on

admission

Superviso

r, care

staff

Do not give

the patient

the meal.

Check other

trays to see if

meal is there,

if not call

supervisor

Visual

inspections

Each meal

(breakfast,

lunch and

dinner)

Person

serving

meals

Cover food

with plate

covers.

Documented

allergies and

special needs

for all

patients /

residents.

Contamination

(foreign

objects,

bacteria

viruses)

NSW/FA/CP005/0805

27 of 29

Protect

food during

transport

SP

All food is to

be covered

after serving.

Covered meals

Version 2

Records

Use

microwave

oven to

reheat meals

if necessary.

Food

Process

Time

Temp.

Workshee

t

Adjust heating

process.

Needs/chang

es are

tracked

10.

Delivery

Corrective

Action

(Form 6)

Patient

menu

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

Growth of

bacteria due

to time abuse

Amount of

time

between

service and

consumpti

on

CCP

Last meal

delivered is

60oC

Elapsed time

between end of

service and

consumption.

Monitor

time periodclock

Each meal

(breakfast,

lunch and

dinner)

Person

serving

meals

Discard any

food that is

not consumed

or

refrigerated

within 30

minutes of

service.+

Food

Process

Time

Temp.

Workshee

t

(Form 6)

Note:

+ The max time that the food is out of temperature control is 2 hours (eg from plating to consumption). The time you set here depends on

the time frames surrounding your facility. Target should be around 30 mins.

5.8 Example Hazard Control Table for Cook Fresh Foods (continued)

Process

Step

Hazard/s

10. Clean

Up

Contaminati

on

(Foreign

objects,

bacteria

viruses).

NSW/FA/CP005/0805

28 of 29

Control

Measures

CCP

Clean with

hot water all

multipurpos

e crockery

and utensils.

SP

Clean up

done in a

dedicated

area.

Critical

Limit

Monitoring Procedures

What

How

When

Who

Dishwash

er must

achieve

wash

cycle

temp

enough to

remove

fat and

soil and

not bake

it on.

Sanitising

rinse

cycle

must

achieve

82oC

minimum.

Water

temperature

Thermomete

r or check

stick

At rinse

cycle

Person

washing up

(Start and

end of

cleanup.)

Corrective

Action

Records

Adjust rinse

temperature

on

dishwasher.

Re-sanitise

dishes etc. in

hot water and

ensure

reaches 82oC

Appliance

Temperatur

e

Worksheet

(Form Z)

Have

equipment

serviced.

Version 2

Page

Appendix 5: Guide to Developing a Food Safety Program

Section 5: Example Food Safety Program of a Cook-Fresh process

Items

must dry

NSW/FA/CP005/0805

29 of 29

Version 2

Page

Anda mungkin juga menyukai

- CONTENT SIT07 SITXFSA001 Use Hygienic Practices For Food Safety LG V2-0Dokumen56 halamanCONTENT SIT07 SITXFSA001 Use Hygienic Practices For Food Safety LG V2-0Omar Faruque0% (3)

- 2.1 SITXFSA004 Develop and Implement Food Safety Program Student Ass Guide 1 PDFDokumen90 halaman2.1 SITXFSA004 Develop and Implement Food Safety Program Student Ass Guide 1 PDFSehaj SharmaBelum ada peringkat

- SITXFSA001 Use Hygienic Practices For Food Safety-SignedDokumen2 halamanSITXFSA001 Use Hygienic Practices For Food Safety-SignedNasir UddinBelum ada peringkat

- Sith Kop 001Dokumen9 halamanSith Kop 001Abhinav GuliaBelum ada peringkat

- SITXFSA201 Participate in Safe Food Handling PracticesDokumen42 halamanSITXFSA201 Participate in Safe Food Handling PracticesJasmeet Bindra67% (3)

- Course 4... Assessment After Editing Plagarisum Free Work1Dokumen17 halamanCourse 4... Assessment After Editing Plagarisum Free Work1Miraal Ali100% (3)

- SITXINV002 Maintain The Quality of Perishable Items Answers PDFDokumen6 halamanSITXINV002 Maintain The Quality of Perishable Items Answers PDFÇrox Rmg PunkBelum ada peringkat

- Sithkop002 - Plan and Cost Basic Menus: R o S H A N K CDokumen73 halamanSithkop002 - Plan and Cost Basic Menus: R o S H A N K CNidhi GuptaBelum ada peringkat

- Food SafetyDokumen83 halamanFood Safetyapi-350003268Belum ada peringkat

- 3 SITXFSA002 - Student Copy-V 1.0Dokumen53 halaman3 SITXFSA002 - Student Copy-V 1.0chanpreetBelum ada peringkat

- 2.1 - SITXFSA002 Participate in Safe Food Handling Practices Student GuideDokumen74 halaman2.1 - SITXFSA002 Participate in Safe Food Handling Practices Student GuidePiyush Gupta100% (1)

- SITHKOP005 Coordinate Cooking OperationDokumen8 halamanSITHKOP005 Coordinate Cooking OperationBaljeet SinghBelum ada peringkat

- SITXFSA001 - Student AssessmentDokumen31 halamanSITXFSA001 - Student AssessmentNiroj Adhikari100% (3)

- SITXFSA001 Assessment C1 Part A Practical Demo ANS V1-0Dokumen5 halamanSITXFSA001 Assessment C1 Part A Practical Demo ANS V1-0Omar Faruque0% (1)

- 2 - SITXWHS001 - Participate in Safe Work Practices Student GuideDokumen56 halaman2 - SITXWHS001 - Participate in Safe Work Practices Student GuidePiyush GuptaBelum ada peringkat

- Hazards and Risks in The KitchenDokumen30 halamanHazards and Risks in The KitchenCynthia Lopez100% (1)

- Yasmeen Sitxfa002Dokumen35 halamanYasmeen Sitxfa002ranu jain100% (1)

- 2 - SITXFSA001 - USE HYGIENIC PRACTICES FOR FOOD SAFETY Student GuideDokumen56 halaman2 - SITXFSA001 - USE HYGIENIC PRACTICES FOR FOOD SAFETY Student GuidePiyush Gupta50% (2)

- SITXINV002 Assessment 1 - AssignmentDokumen12 halamanSITXINV002 Assessment 1 - Assignmentadeel tarar20% (5)

- QMJGA7MHJQ - Cookery LogbookDokumen108 halamanQMJGA7MHJQ - Cookery LogbooksumandeepBelum ada peringkat

- This Study Resource Was: Sithkop005Dokumen8 halamanThis Study Resource Was: Sithkop005Katrina Isha FernandezBelum ada peringkat

- SITXFSA004 - Develop and Implement Food Safety Program-Written Test V2.1Dokumen13 halamanSITXFSA004 - Develop and Implement Food Safety Program-Written Test V2.1sandeep kesar50% (2)

- SITHCCC006 Prepare Appetisers and SaladsDokumen56 halamanSITHCCC006 Prepare Appetisers and SaladsAlexander LoperaBelum ada peringkat

- SITXFSA101 Assessment 2Dokumen4 halamanSITXFSA101 Assessment 2Dave50% (2)

- SITHKOP005 Coordinate Cooking Operations Instance 1 of 12: Service Plan-2 Festival and Function-Bulk Cooking OperationsDokumen21 halamanSITHKOP005 Coordinate Cooking Operations Instance 1 of 12: Service Plan-2 Festival and Function-Bulk Cooking OperationsDeepika BhandariBelum ada peringkat

- SITXINV002. Maintain The Quality of Perishable ItemsDokumen9 halamanSITXINV002. Maintain The Quality of Perishable ItemsAlBelum ada peringkat

- Enviromental and Ecological Security: Name of Student Name of Instructor DateDokumen14 halamanEnviromental and Ecological Security: Name of Student Name of Instructor DateNiomi GolraiBelum ada peringkat

- Hospitality Works Student User GuideDokumen18 halamanHospitality Works Student User GuideNitinBelum ada peringkat

- SITXFSA004 (Food Safety Plan) 1 (Edited)Dokumen50 halamanSITXFSA004 (Food Safety Plan) 1 (Edited)Mango man GamingBelum ada peringkat

- Assessment 5Dokumen28 halamanAssessment 5manuBelum ada peringkat

- SITHCCC019 Learner Workbook V1.1Dokumen11 halamanSITHCCC019 Learner Workbook V1.1Talha NaseemBelum ada peringkat

- ANJALI RANI - SITHCCC001 Use Food Preparation Equipment-Written Test 1.2Dokumen12 halamanANJALI RANI - SITHCCC001 Use Food Preparation Equipment-Written Test 1.2Anzel AnzelBelum ada peringkat

- SITXFSA101 Assessment 1Dokumen6 halamanSITXFSA101 Assessment 1Jakub25% (8)

- SITHCCC001 Assessment 2 - Practical ObservationDokumen19 halamanSITHCCC001 Assessment 2 - Practical ObservationajayBelum ada peringkat

- Assessment 1 - Case Study Scenario / Project 1. A La Carte 2. Table D'hote/set Menu/function 3. Bulk Cooking 4. FestivalDokumen8 halamanAssessment 1 - Case Study Scenario / Project 1. A La Carte 2. Table D'hote/set Menu/function 3. Bulk Cooking 4. Festivalsunita dhamijaBelum ada peringkat

- Assessment 1 Kiii4021Dokumen34 halamanAssessment 1 Kiii4021Tuvina Sharma100% (1)

- ASSESSMENT 1 SITXFSA001 Use Hygienic Practices For Food SafetyDokumen3 halamanASSESSMENT 1 SITXFSA001 Use Hygienic Practices For Food Safetykawaljeetkaur50% (2)

- Receiving and Storage PDFDokumen12 halamanReceiving and Storage PDFshyamkattiBelum ada peringkat

- Anjali Rani - TestDokumen13 halamanAnjali Rani - TestAnzel AnzelBelum ada peringkat

- HC3 2.1 SITXFSA001 002 GDDokumen65 halamanHC3 2.1 SITXFSA001 002 GDMmc MixBelum ada peringkat

- SITXFSA002 A01 Participate in Safe Food Handling PracticesDokumen19 halamanSITXFSA002 A01 Participate in Safe Food Handling PracticesPardeep Kumar100% (1)

- Use Food Preparation Equipment SITHCCC001 - PowerpointDokumen52 halamanUse Food Preparation Equipment SITHCCC001 - PowerpointJuan Diego Pulgarín HenaoBelum ada peringkat

- Student Name Student ID Qualification Code and Name Trainer NameDokumen56 halamanStudent Name Student ID Qualification Code and Name Trainer Namejoe joyBelum ada peringkat

- SITHFAB005 - Prepare Serve Espresso Coffee - Learner GuideDokumen66 halamanSITHFAB005 - Prepare Serve Espresso Coffee - Learner GuidePema Tamang100% (1)

- SITHKOP001 Student Assessment WorkbookDokumen55 halamanSITHKOP001 Student Assessment WorkbookKomal SharmaBelum ada peringkat

- Unit Code: - SITXFSA002 Unit Name: - Participate in Safe Food Handling PracticeDokumen40 halamanUnit Code: - SITXFSA002 Unit Name: - Participate in Safe Food Handling Practicesandeep kesar0% (1)

- SITXFIN003 Assessment CHDokumen11 halamanSITXFIN003 Assessment CHAH GROUP0% (1)

- SITHCCC006 PowerPoint Slides V1.1 PDFDokumen109 halamanSITHCCC006 PowerPoint Slides V1.1 PDFStacy ParkerBelum ada peringkat

- SITHCCC011 - Written AssessmentDokumen27 halamanSITHCCC011 - Written Assessmentsugunithakoyye35Belum ada peringkat

- SITHCCC005 Learner Guide V1.1 ACOTDokumen72 halamanSITHCCC005 Learner Guide V1.1 ACOTJaspreet GillBelum ada peringkat

- SITHCCC007 - Prepare Stock Sauces and SoupsDokumen57 halamanSITHCCC007 - Prepare Stock Sauces and SoupsAlexander Lopera0% (1)

- Student Name: Subject Code: Due Date: Student ID: Subject NameDokumen10 halamanStudent Name: Subject Code: Due Date: Student ID: Subject NameDavis Sagini ArtBelum ada peringkat

- SITHKOP012 Dietary Requirements Medical 2Dokumen5 halamanSITHKOP012 Dietary Requirements Medical 2Ankit BhattraiBelum ada peringkat

- SITHCCC023 Student GuideDokumen31 halamanSITHCCC023 Student GuideDeep TakharBelum ada peringkat

- Activity 1 Subject 2Dokumen2 halamanActivity 1 Subject 2Chai SuwandiBelum ada peringkat

- Assessment Task 2 Cover Sheet: Student DeclarationDokumen35 halamanAssessment Task 2 Cover Sheet: Student DeclarationNitin0% (1)

- Student Assessment Tasks: Student Name: Student NumberDokumen32 halamanStudent Assessment Tasks: Student Name: Student NumberAmandeep KarwalBelum ada peringkat

- SITHKOP005 Appendix A Food Production ListDokumen60 halamanSITHKOP005 Appendix A Food Production Listsunita dhamijaBelum ada peringkat

- CCC4 2.2 - AssessToolDokumen36 halamanCCC4 2.2 - AssessToolMateen Umair33% (3)

- HACCP in Food and Drinking Water SafetyDokumen31 halamanHACCP in Food and Drinking Water SafetyVivek BidarkarBelum ada peringkat

- Cs Flow DiagramDokumen4 halamanCs Flow DiagramAkbar MotaniBelum ada peringkat

- 07 HotelGrandHyattMumbaiDokumen7 halaman07 HotelGrandHyattMumbaiAkbar MotaniBelum ada peringkat

- Jim Collins - Diagnostic ToolDokumen22 halamanJim Collins - Diagnostic ToolLeon Van Tubbergh100% (3)

- Country Profile On Disability: March 2002 Japan International Cooperation Agency Planning and Evaluation DepartmentDokumen25 halamanCountry Profile On Disability: March 2002 Japan International Cooperation Agency Planning and Evaluation DepartmentAkbar MotaniBelum ada peringkat

- Disabled People in Employment PolicyDokumen9 halamanDisabled People in Employment PolicyAkbar MotaniBelum ada peringkat

- Country Profile On Disability: March 2002 Japan International Cooperation Agency Planning and Evaluation DepartmentDokumen25 halamanCountry Profile On Disability: March 2002 Japan International Cooperation Agency Planning and Evaluation DepartmentAkbar MotaniBelum ada peringkat

- Work CitedDokumen5 halamanWork Citedapi-317144934Belum ada peringkat

- Adult Mswd-ToolDokumen3 halamanAdult Mswd-Toolclaverialc10Belum ada peringkat

- Satir Theory Twenty Years After Her DeathDokumen4 halamanSatir Theory Twenty Years After Her DeathgoshBelum ada peringkat

- Sample Data From Different IndustriesDokumen38 halamanSample Data From Different IndustriesAbrar JazzBelum ada peringkat

- Microbial Contamination in Banks and Its Control PDFDokumen29 halamanMicrobial Contamination in Banks and Its Control PDFPrakashBelum ada peringkat

- VPHin IndiaoieproofDokumen17 halamanVPHin Indiaoieproofhari prasadBelum ada peringkat

- Evening Street Review Number 33Dokumen180 halamanEvening Street Review Number 33Barbara Bergmann0% (1)

- Nestle BoycottDokumen12 halamanNestle BoycottSubhrajit BhattacharyaBelum ada peringkat

- G10 PDFDokumen18 halamanG10 PDFdenisse gabo100% (1)

- COPD Case Study 1Dokumen15 halamanCOPD Case Study 1ifrah tariqBelum ada peringkat

- Detection of Methicillin Resistance in Staphylococcus Species From Clinical SamplesDokumen6 halamanDetection of Methicillin Resistance in Staphylococcus Species From Clinical SamplesOpenaccess Research paperBelum ada peringkat

- United Nations For Class 8Dokumen36 halamanUnited Nations For Class 8zeeschool25% (4)

- Kirloskar Brothers Limited, KirloskarvadiDokumen71 halamanKirloskar Brothers Limited, KirloskarvadiNilesh JadhavBelum ada peringkat

- Purine Rich FoodDokumen3 halamanPurine Rich Foodttstanescu4506Belum ada peringkat

- Student Enrollment FormDokumen3 halamanStudent Enrollment Formapi-239237152Belum ada peringkat

- Uganda Institute of Allied Health and Management Sciences - MulagoDokumen8 halamanUganda Institute of Allied Health and Management Sciences - MulagoMartin SageBelum ada peringkat

- Medical TattooingDokumen66 halamanMedical TattooingTattooTattoo100% (4)

- Non-Hodgkin Lymphoma (NHL)Dokumen11 halamanNon-Hodgkin Lymphoma (NHL)archanaBelum ada peringkat

- Lab Clin Clin Tasks Attempted 1 2 3 4 5 6 7: ST ND RD TH TH TH THDokumen4 halamanLab Clin Clin Tasks Attempted 1 2 3 4 5 6 7: ST ND RD TH TH TH THRichard Patterson100% (1)

- Mindfulness Literature ReviewDokumen7 halamanMindfulness Literature Reviewjquail3Belum ada peringkat

- Cardiac Troponin I Leve in STEMI and Clinical Correlation With LeftVentricular Dysfunction in Indian Population 2329 9517.1000116Dokumen6 halamanCardiac Troponin I Leve in STEMI and Clinical Correlation With LeftVentricular Dysfunction in Indian Population 2329 9517.1000116panjiBelum ada peringkat

- Drug Presentation AtropineDokumen6 halamanDrug Presentation AtropineShivam Malik100% (1)

- English 10 Questionnaire 3rd QuarterDokumen7 halamanEnglish 10 Questionnaire 3rd QuarterklimbaroBelum ada peringkat

- Body ShamingDokumen4 halamanBody ShamingpatriciaBelum ada peringkat

- ICCD Power Point 2015Dokumen16 halamanICCD Power Point 2015OhioOhioBelum ada peringkat

- Free Health and Safety Action Plan TemplateDokumen4 halamanFree Health and Safety Action Plan TemplateAhmed M. RafatBelum ada peringkat

- V. Self-Assessment ACTIVITY 1: Warm You UpDokumen3 halamanV. Self-Assessment ACTIVITY 1: Warm You UpNerissa Lejano RosasBelum ada peringkat

- GBV Indonesia PDFDokumen37 halamanGBV Indonesia PDFVebriana SetiadenyBelum ada peringkat

- Own: ICARUS Training Services Safety Briefing/ Attendance FormDokumen2 halamanOwn: ICARUS Training Services Safety Briefing/ Attendance FormTim Brown0% (1)

- Sanitary PadDokumen5 halamanSanitary PadKenneth GohBelum ada peringkat

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyDari EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyPenilaian: 4 dari 5 bintang4/5 (11)

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideDari EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsidePenilaian: 4 dari 5 bintang4/5 (6)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterDari EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterPenilaian: 3.5 dari 5 bintang3.5/5 (487)

- The Obesity Code: Unlocking the Secrets of Weight LossDari EverandThe Obesity Code: Unlocking the Secrets of Weight LossPenilaian: 4 dari 5 bintang4/5 (6)

- Magnolia Table, Volume 3: A Collection of Recipes for GatheringDari EverandMagnolia Table, Volume 3: A Collection of Recipes for GatheringPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldDari EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldPenilaian: 3.5 dari 5 bintang3.5/5 (5)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookDari EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingDari EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingPenilaian: 4 dari 5 bintang4/5 (9)

- Authentic Mexican: Regional Cooking from the Heart of MexicoDari EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoBelum ada peringkat

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingDari EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingPenilaian: 4 dari 5 bintang4/5 (3)

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingDari EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingBelum ada peringkat

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayDari EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayPenilaian: 4 dari 5 bintang4/5 (4)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomDari EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomPenilaian: 4 dari 5 bintang4/5 (1)

- Mexican Today: New and Rediscovered Recipes for Contemporary KitchensDari EverandMexican Today: New and Rediscovered Recipes for Contemporary KitchensPenilaian: 4 dari 5 bintang4/5 (6)

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyDari EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyPenilaian: 4 dari 5 bintang4/5 (1)

- Chicano Eats: Recipes from My Mexican-American KitchenDari EverandChicano Eats: Recipes from My Mexican-American KitchenBelum ada peringkat

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthDari EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthPenilaian: 2 dari 5 bintang2/5 (1)

- Poilâne: The Secrets of the World-Famous Bread BakeryDari EverandPoilâne: The Secrets of the World-Famous Bread BakeryBelum ada peringkat

- Waiting: The True Confessions of a WaitressDari EverandWaiting: The True Confessions of a WaitressPenilaian: 3 dari 5 bintang3/5 (7)

- Trisha's Kitchen: Easy Comfort Food for Friends & FamilyDari EverandTrisha's Kitchen: Easy Comfort Food for Friends & FamilyPenilaian: 4 dari 5 bintang4/5 (5)

- In-N-Out Burger: A Behind-the-Counter Look at the Fast-Food Chain That Breaks All the RulesDari EverandIn-N-Out Burger: A Behind-the-Counter Look at the Fast-Food Chain That Breaks All the RulesPenilaian: 3.5 dari 5 bintang3.5/5 (28)

- Grape, Olive, Pig: Deep Travels Through Spain's Food CultureDari EverandGrape, Olive, Pig: Deep Travels Through Spain's Food CulturePenilaian: 4.5 dari 5 bintang4.5/5 (15)

- The Fresh Eggs Daily Cookbook: Over 100 Fabulous Recipes to Use Eggs in Unexpected WaysDari EverandThe Fresh Eggs Daily Cookbook: Over 100 Fabulous Recipes to Use Eggs in Unexpected WaysBelum ada peringkat

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoDari EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoBelum ada peringkat