WPQR SMAW EN-2 - 30mm (Under Modification)

Diunggah oleh

Mohamed Reda HusseinJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

WPQR SMAW EN-2 - 30mm (Under Modification)

Diunggah oleh

Mohamed Reda HusseinHak Cipta:

Format Tersedia

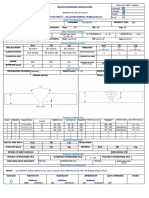

Welding Procedure Qualification Record

Date

EN ISO 15614-1(2004 edition)

EN ISO 15609-1(2004 edition)

Sheet No.

Client's Technical specifications

WPQR No.:

ENWELDING PROCESS

EN ISO 4063

pWPS No.:

EN-

Date of welding:

( )TYPE:

JOINT

Manual

Semi-auto

EN ISO 9692 & EN ISO 22553

Automatic

FILLER METAL

Mechanized

EN Designation

Filler Matal Make(manufacturer/trade name)

Filler Metal Size

None

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

Max.Fillet Thickness

Flux wire class

Solid/metal/flux cored

Supplemental

Groove angle

(A)

Root face

(F)

Root opening

(R)

Backing :

Yes

Type

:

Base metal

Retainers:

Yes

Sup. Powder

Alloy elements

Alloy Flux

NO

Weld metal

NO

Flux Designation

Recrushed slag

Flux Type

Flux (brand name)

BASE METAL

ISO TR 15608

Material spec.

Designaton

Group

Subgroup

Material Thickness

Outside Pipe Diameter

NA

WELD METAL

Deposited Weld Metal Thickness

Throat Thickness

Contact tube/work piece Dis.

Consumable Insert

POSITION

JOINT TYPE

BUTT

TECHNIQUE

NA

single

NA

Single/multi-process

Mode of Metal Transfer

String / Weave

NA

Preparation and Cleaning

INTIAL HEAT TREATMENT CONDITION FOR PRECIPITATION HARDENING MATERIALS: NA

Backgouging

NA

PREHEAT &INTERPASS TEMPERATURE

Peening

EN ISO 13917

Preheat Temp. Min.( C )

C

Preheat Method

Flame

Max. Interpass Temp.

C

Measuring method

digital thermometer

POST HEATING / POST WELD HEAT TREATMENT

NA

Frequency and dwell time of oscillation

Type

Electrode wire feed speed

POST HEATING (NA)

WELD TYPE

BUTT(groove)

HEAT TREATMENT(NA)

Max. Width of the Run

Multi

Single

NA

NA

NA

Single / multi-Run

Single / multi electrode

Orifice /gas cup size

Tungsten Electrode size/type

GAS

Method of heating

Grinding

Grinding

NA

NA

EN 439

Holding Time

NA

Type & composition Designaton

Flow rate L/min

Shielding

Backing

Trailing

Heating Rate

Cooling Rate

Free cooling Temp.

ELECTRICAL CHARACTERSTICS EN15614 & EN1011-1

Weld

Sequence

Process

Mode of metal

transfer

Position

FILLER METAL

CLASS.

AMP.

VOLTAGE

RANGE(v)

TRAVEL SPEED(S)

(cm/min)

HEAT INPUT*=

eAV/1000S(kj/mm)

###

###

###

###

ROOT Run

FILLING

CAP

BACK WELD

REMARKS

*e: effeciency(EN 1011-1)

CURRENT (A)

DIAMETER POLARITY

A,amp V,volt S,mm/sec

:

:

:

:

###

###

###

###

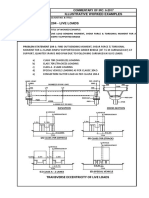

Welding Procedure Qualification Record

EN ISO 15614-2004 edition

EN ISO 15609-2004 edition

Client's Technical specifications

pWPS No.:

EN-

WPQR No.:

ENWELDING PROCESS

EN ISO 4063

Date

Sheet No.

Date of welding:

()TYPE:

Manual

Non-Destructive Examination

Semi-auto

Automatic

Mechanized

Method

Applicable Standard

Result

Report No.

Visual Testing

EN 970

Accepted

PQR-VT-EN-

MT

EN1290

Accepted

PQR-MT-EN-

Ultrasonic Testing

EN 1714

Accepted

PQR-UT-EN-

TENSILE TEST (EN 15614 & EN 895)

SPECIMEN

WIDTH (mm)

ULTIMATE LOAD

(KN)

AREA (mm2)

THICKNESS (mm)

ULTIMATE STRESS

(N/mm2)

FAILURE LOCATION

1

2

BEND TEST (EN 15614 & EN 910)

SPECIMEN

TYPE

RESULT

SPECIMEN

TYPE

RESULT

ACC.

ACC.

ACC.

ACC.

REMARKS

Bending angle 180O

TOUGHNESS/IMPACT TEST (EN 15614 & EN 875)

Specimen No.

(VHT) HAZ,Joule

Test Temperature

Required Impact

(C)

EN-

(VWT)WM,Joule

3

27 Joule

Average, Joule

#DIV/0!

#DIV/0!

MACRO TEST (EN 15614 & EN 1321)

Macro - Results

Free from Any Defect

HARDNESS TEST (EN 15614 & EN 1043-1)

HV 10

BM

HAZ

WM

HAZ

BM

Max. Permitted Value

1 Row

st

320

2nd Row

3 Row

rd

TESTING DATA

Destructive Testing conducted

by

Mechanical & Welding Testing Lab. (Cairo University)

Laboratory test No.

WELDING DATA

Welder/ Welding Operator

Name

Welder Stamp

STATEMENT

We certify that the statement in this record are correct and that the test welds were prepared, welded, and tested in

accordance with the requirements of The above mentioned standards and were acceptable

Examiner Or Examination Body

Name

Prepared by

Reviewed by

Eng.Mohamed Roshdi

Eng.Mohamed Fathi

10/22/2012

10/22/2012

Signature

Date

Third Party

Anda mungkin juga menyukai

- WPQ Template (Asme Ix) No LogoDokumen4 halamanWPQ Template (Asme Ix) No LogorcpretoriusBelum ada peringkat

- WPQR Welding Procedure QualificationDokumen3 halamanWPQR Welding Procedure QualificationThanasis KyrgiazoglouBelum ada peringkat

- Welding Procedure Qualification Record: Shipyard LogoDokumen4 halamanWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Welder Visual Inspection ReportsDokumen24 halamanWelder Visual Inspection ReportsKyBelum ada peringkat

- Report on Welding Procedure Specifications for Single V-Groove JointsDokumen15 halamanReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokumen2 halaman(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Dokumen2 halamanASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- PQRDokumen2 halamanPQRafqzfieBelum ada peringkat

- P-WPS 135 - MAG (GR 316)Dokumen9 halamanP-WPS 135 - MAG (GR 316)Tarun PatelBelum ada peringkat

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDokumen1 halamanASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechBelum ada peringkat

- Sabari Engineering PQRDokumen3 halamanSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDokumen6 halamanWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Dokumen2 halamanWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialBelum ada peringkat

- 1035 03Dokumen2 halaman1035 03Anuj ShahiBelum ada peringkat

- JIMT Visual Inspection ReportDokumen1.913 halamanJIMT Visual Inspection Reportgomathyselvi100% (1)

- Wps Mma PipeDokumen2 halamanWps Mma PipeDimitris NikouBelum ada peringkat

- QW-484A (WPQ) GTAW 4MM FilletDokumen2 halamanQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- PWPS Fillet WeldDokumen2 halamanPWPS Fillet WeldUgonnaBelum ada peringkat

- GTAW Welding Process ParametersDokumen12 halamanGTAW Welding Process Parametersmiteshpatel191Belum ada peringkat

- WPS ISO 15614-1 WeldNote MetricDokumen1 halamanWPS ISO 15614-1 WeldNote MetricVirgil SorcaruBelum ada peringkat

- WPS Welding Procedure SpecificationDokumen1 halamanWPS Welding Procedure SpecificationburakBelum ada peringkat

- Welding Procedure SpecificationDokumen3 halamanWelding Procedure SpecificationAhmed saber100% (1)

- Proposed WPSDokumen2 halamanProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Dokumen3 halamanWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaBelum ada peringkat

- Gta+sma PQRDokumen3 halamanGta+sma PQRRahul MoottolikandyBelum ada peringkat

- WPQ Sample PrintoutDokumen1 halamanWPQ Sample PrintoutKannan VelBelum ada peringkat

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokumen3 halamanWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- WPS Updated PDFDokumen2 halamanWPS Updated PDFRaja Muaz Ahmad KhanBelum ada peringkat

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Dokumen3 halamanWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielBelum ada peringkat

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Dokumen14 halamanList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSBelum ada peringkat

- Weldspec ASME PQRDokumen2 halamanWeldspec ASME PQRSunil KumarBelum ada peringkat

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Dokumen2 halamanLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidBelum ada peringkat

- Ilcs-Smaw-D1.3-Deck (G) WPSDokumen3 halamanIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Fcaw 16 THKDokumen5 halamanFcaw 16 THKparesh2387Belum ada peringkat

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokumen3 halamanWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaBelum ada peringkat

- Welding Procedure SpecificationDokumen27 halamanWelding Procedure SpecificationGopakumar K100% (2)

- Wps Sp14 Reva PDFDokumen9 halamanWps Sp14 Reva PDFravi00098Belum ada peringkat

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDokumen3 halamanWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEBelum ada peringkat

- WPQR Welding Procedure Qualification RecordsDokumen3 halamanWPQR Welding Procedure Qualification Recordsramesh rajaBelum ada peringkat

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Dokumen1 halamanWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaBelum ada peringkat

- Joints (Qw-402) DetailsDokumen3 halamanJoints (Qw-402) DetailsNaqqash SajidBelum ada peringkat

- WPS PQR-08Dokumen8 halamanWPS PQR-08Ranjan KumarBelum ada peringkat

- Welding Procecure SpecificationDokumen9 halamanWelding Procecure SpecificationNwoha PeterBelum ada peringkat

- Preliminary Welding Procedure Specification for Dialog TowerDokumen1 halamanPreliminary Welding Procedure Specification for Dialog TowerAzriBelum ada peringkat

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Dokumen2 halamanWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangBelum ada peringkat

- WPQDokumen10 halamanWPQayoki100% (3)

- Welding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokumen11 halamanWelding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh raja100% (1)

- Aws 001Dokumen1 halamanAws 001akshay sarfareBelum ada peringkat

- WPQ-1083 3G PDFDokumen2 halamanWPQ-1083 3G PDFduendex360100% (1)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Dokumen2 halamanWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajBelum ada peringkat

- PT Kuwera Karya Me: PanduDokumen2 halamanPT Kuwera Karya Me: PanduGalang Pratama PutraBelum ada peringkat

- Welding Proposed Pwps For Our Jubail WorkDokumen2 halamanWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDokumen3 halamanWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanBelum ada peringkat

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Dokumen5 halamanWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazBelum ada peringkat

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDokumen5 halamanMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- Weld Joint 1Dokumen81 halamanWeld Joint 1rajibali27100% (1)

- Wps 15614 TemplateDokumen2 halamanWps 15614 Template0502raviBelum ada peringkat

- Welding Procedure SpecificationDokumen5 halamanWelding Procedure SpecificationFranklin londono0% (1)

- PQR Asme Template EDITABLEDokumen6 halamanPQR Asme Template EDITABLErcpretoriusBelum ada peringkat

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Dokumen5 halamanWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- SAP Number DataDokumen5 halamanSAP Number DataMohamed Reda HusseinBelum ada peringkat

- IqamaDokumen1 halamanIqamaMohamed Reda HusseinBelum ada peringkat

- Privacy Notice and ConsentDokumen2 halamanPrivacy Notice and ConsentMohamed Reda HusseinBelum ada peringkat

- Meeting action items Tanmia QA/QC submission inspectionDokumen2 halamanMeeting action items Tanmia QA/QC submission inspectionMohamed Reda HusseinBelum ada peringkat

- Test Procedure NFPA 705Dokumen3 halamanTest Procedure NFPA 705Mohamed Reda HusseinBelum ada peringkat

- Copy of PassportDokumen2 halamanCopy of PassportMohamed Reda HusseinBelum ada peringkat

- SATIP document titles and transmittalsDokumen2 halamanSATIP document titles and transmittalsMohamed Reda HusseinBelum ada peringkat

- HCU Train-B Action ItemsDokumen7 halamanHCU Train-B Action ItemsMohamed Reda HusseinBelum ada peringkat

- Internal NCR LogDokumen7 halamanInternal NCR LogMohamed Reda HusseinBelum ada peringkat

- Non-Conformance Details:: Dept./Discipline: Issue Date: Raised by LocationDokumen1 halamanNon-Conformance Details:: Dept./Discipline: Issue Date: Raised by LocationMohamed Reda HusseinBelum ada peringkat

- Receiving, Handling, Storage & Preservation ProcedureDokumen34 halamanReceiving, Handling, Storage & Preservation ProcedureMohamed Reda HusseinBelum ada peringkat

- MaterialsDokumen3 halamanMaterialsMohamed Reda HusseinBelum ada peringkat

- 15-12-2013 - Kubota - ReportDokumen6 halaman15-12-2013 - Kubota - ReportMohamed Reda HusseinBelum ada peringkat

- 09-SAMSS-097 - Ready-Mixed Concrete PDFDokumen9 halaman09-SAMSS-097 - Ready-Mixed Concrete PDFMohamed Reda HusseinBelum ada peringkat

- MaterialsDokumen3 halamanMaterialsMohamed Reda HusseinBelum ada peringkat

- ASME UG 37 Nozzles PDFDokumen6 halamanASME UG 37 Nozzles PDFlatif.deBelum ada peringkat

- 157-RD-12-17 Saudi Perlite CompanyDokumen4 halaman157-RD-12-17 Saudi Perlite CompanyMohamed Reda HusseinBelum ada peringkat

- Agap WPSDokumen181 halamanAgap WPSMohamed Reda Hussein100% (1)

- Client Invoice and Payment RecordsDokumen15 halamanClient Invoice and Payment RecordsMohamed Reda HusseinBelum ada peringkat

- As-built Drawing GuideDokumen1 halamanAs-built Drawing GuideMohamed Reda Hussein100% (1)

- Pressure Testing SafelyDokumen18 halamanPressure Testing SafelyHaleem Ur Rashid Bangash100% (1)

- P1 A C LHDokumen2 halamanP1 A C LHMohamed Reda HusseinBelum ada peringkat

- Installation Manual FPIDokumen60 halamanInstallation Manual FPIMohamed Reda HusseinBelum ada peringkat

- ASME U StampingDokumen1 halamanASME U StampingMohamed Reda HusseinBelum ada peringkat

- Astm D2563-94Dokumen24 halamanAstm D2563-94Santiago AngelBelum ada peringkat

- Hardness 2 PDFDokumen1 halamanHardness 2 PDFMohamed Reda HusseinBelum ada peringkat

- 1104Dokumen45 halaman1104fake nameBelum ada peringkat

- Hardness: Minimum Thickness Requirements For Various Testing MethodsDokumen1 halamanHardness: Minimum Thickness Requirements For Various Testing MethodsMohamed Reda HusseinBelum ada peringkat

- WP056P Rev0Dokumen12 halamanWP056P Rev0Mohamed Reda HusseinBelum ada peringkat

- API ExamDokumen1 halamanAPI ExamMohamed Reda HusseinBelum ada peringkat

- Gmaw Fcaw PrinciplesDokumen136 halamanGmaw Fcaw PrinciplesReza SalimiBelum ada peringkat

- Pauselli 700 Solar Pile Driver BrochureDokumen4 halamanPauselli 700 Solar Pile Driver BrochureJaouad Id BoubkerBelum ada peringkat

- Shop Manual Supplement Komatsu PC400 6, PC400LC 6, PC450 6, PC450LCDokumen38 halamanShop Manual Supplement Komatsu PC400 6, PC400LC 6, PC450 6, PC450LCMilad Rahimi100% (2)

- ONIXline BJ Series Dimensions GuideDokumen5 halamanONIXline BJ Series Dimensions Guidemarcusa85Belum ada peringkat

- ISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsDokumen4 halamanISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsAndy MulyonoBelum ada peringkat

- Bourdon Gauge - BellowDokumen14 halamanBourdon Gauge - BellowBikram RoyBelum ada peringkat

- Models 69NT40-511-300 To 309, 69NT40-511-311 To 399Dokumen117 halamanModels 69NT40-511-300 To 309, 69NT40-511-311 To 399cloviskrelling100% (2)

- Axial Cylindrical Roller Bearings - Cages and WashersDokumen14 halamanAxial Cylindrical Roller Bearings - Cages and WashersKamlesh DalavadiBelum ada peringkat

- Mobilgard HSD Plus 15W40 Engine Oil ExxonMobil MarineDokumen2 halamanMobilgard HSD Plus 15W40 Engine Oil ExxonMobil MarineM. FuentesBelum ada peringkat

- Chevrolet 327 V8 Engine Rebuild ManualDokumen120 halamanChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Product Information: Valvoline™ HD Nitrite Free Coolant RTUDokumen2 halamanProduct Information: Valvoline™ HD Nitrite Free Coolant RTUmcalidonio5656Belum ada peringkat

- Illustrative Worked Examples: Commentary of Irc: 6-2017Dokumen4 halamanIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singla100% (1)

- Mechanical Engineer Muhammad Ibtisam's ResumeDokumen1 halamanMechanical Engineer Muhammad Ibtisam's ResumeshoaibBelum ada peringkat

- Morgana Digifold Service ManualDokumen55 halamanMorgana Digifold Service Manualpfequip100% (1)

- Metrology Chapter 13Dokumen70 halamanMetrology Chapter 13Sweekar KhadkaBelum ada peringkat

- Technical Data For Fan Model VAX-S-710-6/20-E2: Performance - Required ActualDokumen2 halamanTechnical Data For Fan Model VAX-S-710-6/20-E2: Performance - Required Actualkarim tarekBelum ada peringkat

- Training System DS4Dokumen164 halamanTraining System DS4Henrry Roberto Amaya BazánBelum ada peringkat

- Ae2251 - Aerodynamics - IDokumen3 halamanAe2251 - Aerodynamics - IMinu.j.jBelum ada peringkat

- 2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualDokumen382 halaman2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualShelli Godfrey100% (1)

- Adjustable Type EAZ SeriesDokumen8 halamanAdjustable Type EAZ SeriesVimalendra SinghBelum ada peringkat

- 3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsDokumen8 halaman3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsengkjBelum ada peringkat

- Buku PDTO Rabiman FinalDokumen134 halamanBuku PDTO Rabiman Finalilham romadhonaBelum ada peringkat

- View thousands of Crane Specifications on FreeCraneSpecs.comDokumen64 halamanView thousands of Crane Specifications on FreeCraneSpecs.comD Rider Casanova100% (1)

- Driller Controller User ManualDokumen12 halamanDriller Controller User ManualYahya BA100% (1)

- Air Handling Units GuidelineDokumen5 halamanAir Handling Units GuidelineImam MansyurBelum ada peringkat

- Ship Dynamics in Waves - RostokDokumen51 halamanShip Dynamics in Waves - Rostokvivekt510Belum ada peringkat

- DM25-SP Series: Atlas Copco Blasthole DrillsDokumen4 halamanDM25-SP Series: Atlas Copco Blasthole DrillsKOMATSU SHOVELBelum ada peringkat

- Courses Semester II 2019-20: Course Title LPU SEC NODokumen125 halamanCourses Semester II 2019-20: Course Title LPU SEC NOAnjumaBelum ada peringkat

- Explo - Lirika OTC PDFDokumen6 halamanExplo - Lirika OTC PDFMariusz PawlasBelum ada peringkat

- 2019 - Shen Et Al - Two and Three Dimensional Numerical Analyses of Geosynthetic Reinforced Soil GRS Piers PDFDokumen17 halaman2019 - Shen Et Al - Two and Three Dimensional Numerical Analyses of Geosynthetic Reinforced Soil GRS Piers PDFTomaz TurcarelliBelum ada peringkat