CGC 400 Installation Instructions 4189340785 UK - 2014.08.22

Diunggah oleh

Gustavo PereiraJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CGC 400 Installation Instructions 4189340785 UK - 2014.08.22

Diunggah oleh

Gustavo PereiraHak Cipta:

Format Tersedia

INSTALLATION INSTRUCTIONS

Compact Genset Controller, CGC 400

Mounting

Terminal overview

Wiring

Communication wiring

Unit dimensions and cutouts

DEIF A/S Frisenborgvej 33 DK-7800 Skive Tel.: +45 9614 9614 Fax: +45 9614 9615 info@deif.com www.deif.com

isenborgvej 33 DK-7800 Skive Tel.: +45 9614 9614 Fax: +45 9614 9615 info@deif.com www.deif.com

14 9614 Fax: +45 9614 9615 info@deif.com www.deif.com

Document no.: 4189340785B

SW version: 1.00

CGC 400 installation instructions

4189340785 UK

1. General information

1.1. Warnings, legal information and safety..................................................................................................3

1.1.1. Warnings and notes ......................................................................................................................3

1.1.2. Legal information and disclaimer ..................................................................................................3

1.1.3. Safety issues ................................................................................................................................3

1.1.4. Electrostatic discharge awareness ...............................................................................................3

1.1.5. Factory settings ............................................................................................................................4

1.2. About the installation instructions...........................................................................................................4

1.2.1. General purpose ...........................................................................................................................4

1.2.2. Intended users ..............................................................................................................................4

1.2.3. Contents and overall structure ......................................................................................................4

2. Mounting

2.1. CGC 400 mounting.................................................................................................................................5

2.1.1. Mounting of the unit.......................................................................................................................5

2.1.2. Unit dimensions and panel cutout..................................................................................................5

2.1.3. Tightening torques.........................................................................................................................6

3. Terminals

3.1. Terminal overview and description.........................................................................................................7

3.1.1. Terminal overview..........................................................................................................................7

3.1.2. Terminal description .....................................................................................................................7

4. Wiring

4.1. Wiring diagram.....................................................................................................................................11

4.2. DC connections....................................................................................................................................12

4.2.1. Communication, multi-input and tacho wiring instructions ..........................................................12

4.2.2. Binary inputs................................................................................................................................12

4.3. Breaker selection..................................................................................................................................13

4.3.1. Breaker selection.........................................................................................................................13

4.4. Connection of the 3-phase voltage and current...................................................................................15

4.4.1. Connection of the 3-phase voltage and current...........................................................................15

4.4.2. 3-phase AMF wiring ....................................................................................................................16

4.5. Connection of the 1-phase voltage and current...................................................................................17

4.5.1. 1-phase wiring ............................................................................................................................17

4.5.2. 1-phase AMF wiring ....................................................................................................................18

4.6. Connection of the split-phase voltage and current...............................................................................19

4.6.1. Split-phase wiring .......................................................................................................................19

4.6.2. Split-phase AMF wiring ...............................................................................................................20

5. Communication

5.1. Wiring instructions................................................................................................................................21

5.2. Modbus RTU........................................................................................................................................22

5.2.1. Connection with 2-wire shielded cable (recommended) .............................................................22

5.2.2. Connection with 3-wire shielded cable........................................................................................23

5.3. CAN bus engine communication..........................................................................................................24

5.3.1. Connection with 2-wire cable (recommended) ...........................................................................24

5.3.2. Connection with 3-wire shielded cable .......................................................................................25

DEIF A/S

Page 2 of 25

CGC 400 installation instructions

4189340785 UK

General information

1. General information

1.1 Warnings, legal information and safety

1.1.1 Warnings and notes

Throughout this document, a number of warnings and notes with helpful user information will be presented.

To ensure that these are noticed, they will be highlighted as follows in order to separate them from the general text.

Warnings

Warnings indicate a potentially dangerous situation, which could result in death, personal injury or damaged equipment, if certain guidelines are not followed.

Notes

Notes provide general information, which will be helpful for the reader to bear in mind.

1.1.2 Legal information and disclaimer

DEIF takes no responsibility for installation or operation of the generator set. If there is any doubt about how

to install or operate the engine/generator controlled by the unit, the company responsible for the installation or

the operation of the set must be contacted.

The unit is not to be opened by unauthorised personnel. If opened anyway, the warranty will be

lost.

Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

1.1.3 Safety issues

Installing and operating the unit may imply work with dangerous currents and voltages. Therefore, the installation should only be carried out by authorised personnel who understand the risks involved in working with

live electrical equipment.

Be aware of the hazardous live currents and voltages. Do not touch any AC measurement inputs as this could lead to injury or death.

DEIF do not recommend to use the USB as the primary power supply for the unit.

1.1.4 Electrostatic discharge awareness

Sufficient care must be taken to protect the terminal against static discharges during the installation. Once the

unit is installed and connected, these precautions are no longer necessary.

DEIF A/S

Page 3 of 25

CGC 400 installation instructions

4189340785 UK

General information

1.1.5 Factory settings

The unit is delivered from factory with certain factory settings. These are based on average values and are

not necessarily the correct settings for matching the engine/generator set in question. Precautions must be

taken to check the settings before running the engine/generator set.

1.2 About the installation instructions

1.2.1 General purpose

These Installation Instructions mainly include general product and hardware information, mounting instructions, terminal strip descriptions, I/O lists and wiring descriptions.

The general purpose of this document is to give the user important information to be used in the installation of

the unit.

Please make sure to read this document before starting to work with the unit and the genset to

be controlled. Failure to do this could result in human injury or damage to the equipment.

1.2.2 Intended users

These Installation Instructions are mainly intended for the person responsible for the design and installation.

In most cases, this would be a panel builder designer. Naturally, other users might also find useful information

in the document.

1.2.3 Contents and overall structure

This document is divided into chapters, and in order to make the structure simple and easy to use, each

chapter will begin from the top of a new page.

DEIF A/S

Page 4 of 25

CGC 400 installation instructions

4189340785 UK

Mounting

2. Mounting

2.1 CGC 400 mounting

2.1.1 Mounting of the unit

The unit is designed for mounting by means of six fixing clamps, which are included at delivery.

2.1.2 Unit dimensions and panel cutout

The unit is designed for mounting in the panel front.

In order to ensure optimum mounting, the panel door must be cut out according to the following measurements:

H W = 151.00 211.00 + 1.00 mm

H W = 5.94" 8.31" + 0.04"

234.1 (9.22)

158.5 (6.24)

174.1 (6.85)

0.3 Nm

38.1 (1.50)

45.6 (1.80)

218.5 (8.60)

DEIF A/S

Page 5 of 25

CGC 400 installation instructions

4189340785 UK

Mounting

2.1.3 Tightening torques

Unit panel door mounting:

Plug connections (terminals):

DEIF A/S

0.3 Nm (see diagram in "Unit dimensions and panel cutout")

0.5 Nm

Page 6 of 25

CGC 400 installation instructions

4189340785 UK

Terminals

3. Terminals

3.1 Terminal overview and description

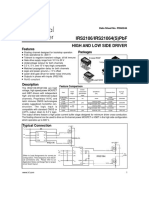

3.1.1 Terminal overview

CGC 400 unit rear view

28

L1

29

N

30

L2

31

NA

32

L3

33

L1

Mains voltage

49

B(-)

34

N

35

NA

36

L2

37

NA

38

L3

39 40 41 42 43 44

s1

s2

s1

L1

Generator voltage

s2

L2

s1

45 46 47 48

s2

L3

GB

MB

Generator current

RS485

Modbus

50 GND

USB

51 A(+)

53 CAN H

54 GND

CAN J1939

55 CAN L

Emer.

stop

58 59

W/L

Relays

Com

RPM inputs

MPU

+

1

Status

Binary inputs

Com

Power

supply

Multi-functional

inputs

10 11 12 13 14 15 56 57 16 17 18

20 21 22 23 24 25

26 27

Terminals 28-32, 56-57 and 58-59 are not available in CGC 412.

3.1.2 Terminal description

Description of terms

DEIF A/S

For the relay outputs, the following terms will be used:

NO means Normally Open.

NC means Normally Closed.

Com. means common terminal for the individual relay.

Page 7 of 25

CGC 400 installation instructions

4189340785 UK

Term

Terminals

Technical data

Power supply +

Power supply -

3-4*

Status output 2 A @ 35 Vdc

Description

Auxiliary supply

General status output/configurable

Digital input

10

Digital input

Remote start/configurable

11

Digital input

Remote stop/configurable

12

Digital input

Remote alarm ack./configurable

13

Digital input

Shutdown override/configurable

14

Digital input

Configurable

15

Digital input

Configurable

56**

Digital input

Configurable

57**

Digital input

Configurable

20

Emergency stop and common for

21 to 23

Common for relay start prepare, starter (crank) and run coil,

and input for emergency stop

21

Relay output 21

Start prepare/configurable, function NO

22

Relay output 22

Starter (crank)/configurable, function NO

23

Relay output 23

Run coil/configurable, function NO

24-25

Relay output 24

Horn/configurable function NO

26-27

Relay output 26

Configurable, function NO

Output

Multi-functional inputs

5

Common

Common for term. 6 to 8 and 58 to 59

RMI6 4 to 20 mA/binary input

Fuel level/configurable

RMI7 4 to 20 mA/binary input

Oil pressure/configurable

RMI8 4 to 20 mA/binary input

Water temp./configurable

58**

RMI58 4 to 20 mA/resistive/binary

input

Resistive input or

4 to 20 mA from active transducer or

Binary with wire break

Pt100

Pt1000

59**

RMI59 4 to 20 mA/resistive/binary

input

Resistive input or

4 to 20 mA from active transducer or

Binary with wire break

Pt100

Pt1000

Tacho RPM input

16

RPM input (MPU)

Magnetic pickup/tacho generator

17

RPM-GND

Common for RPM input. Internally connected to terminal 2

18

RPM input (W/L)

Magnetic pickup. PNP, NPN or charge alternator W term.

DEIF A/S

Page 8 of 25

CGC 400 installation instructions

4189340785 UK

Term

Terminals

Technical data

Description

3-phase generator voltage input

33

Gen. voltage L1

34

Gen. neutral

35

Not used, must not be connected

36

Gen. voltage L2

37

Not used, must not be connected

38

Gen. voltage L3

GENERATOR VOLTAGE

3-phase generator current input

39

Gen. current L1, s1

40

Gen. current L1, s2

41

Gen. current L2, s1

42

Gen. current L2, s2

43

Gen. current L3, s1

44

Gen. current L3, s2

GENERATOR CURRENT

3-phase mains voltage inputs

28**

Mains voltage L1

29**

Mains voltage neutral

30**

Mains voltage L2

31**

Not used, must not be connected

32**

Mains voltage L3

MAINS VOLTAGE

Breaker relays

45

Relay R45

46

Relay R45

Generator circuit breaker/configurable, function NO (normally

open)

Optional relay for closing mains breaker

47

Relay R47

48

Relay R47

Mains circuit breaker/configurable, function NC (normally

closed)

Modbus RS 485

49

B(-)

50

GND

51

A (+)

Modbus RS-485 RTU. Speed is fixed to 9600 bit/s.

CAN bus port: engine interface

53

CAN-H

54

CAN-GND

55

CAN-L

The CAN bus interface to J1939. The 120 ohm termination resistor is wired internally. It is not needed to add an external resistor.

* The status relay is the uP watchdog output. This relay is normally energised, and the switch

is closed after power-up. If the uP fails or the power is lost, the relay will de-energise and the

switch will open. If the unit fails to start up at power-up, then the relay switch will remain open.

DEIF A/S

Page 9 of 25

CGC 400 installation instructions

4189340785 UK

Terminals

**Terminals are not available in CGC 412.

The relay output functions are configurable via the PC utility software and can be configured to cover the following functions:

Alarm/limit

Engine run indication

Horn

Idle speed output

Not used

Prepare

Run coil

Starter

Stop coil

Engine heater

Fuel pump

It is possible to choose run coil on one relay and stop coil on another, thus supporting engines with double

systems.

The multi-functional inputs can be configured to cover the following functions:

RMI sensor input

Pt100 and Pt1000

4 to 20 mA input

Binary input with wire break (switch function)

Tacho RPM input (MPU) can be configured to cover the following functions:

Magnetic pickup (2-wire)

NPN or PNP pickup (these RPM inputs require external equipment)

Tacho RPM input with capacitor (W/L) can be configured to cover the following functions:

Magnetic pickup (2-wire)

W terminal on charger alternator

NPN or PNP (these RPM inputs require external components)

The generator voltage and current input can be configured to the following:

Voltage 100 to 25000 V primary

Current 5 to 9000 A primary

DEIF A/S

Page 10 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

4. Wiring

4.1 Wiring diagram

The wiring diagram below shows the default factory settings, but the use of inputs and outputs can be chosen

freely.

CGC 400

Programming

tool

USB

Alarm

27

R26

26

Alarm horn

RUN coil

Starter

Start prep.

Emer. STOP

57

25

R24

24

56

15

23

R23

22

R22

21

R21

20

14

13

12

11

10

Shutd. override

Alarm ack.

Remote stop

Remote start

4

Status

-

Battery

Fuse

3

1

2

17

-

Common

Common

It is important to protect the unit against damage caused by high voltages. Therefore, the fuse

must not be more than 2 A slow-blow.

DEIF A/S

Page 11 of 25

Wiring

CGC 400 installation instructions

4189340785 UK

4.2 DC connections

4.2.1 Communication, multi-input and tacho wiring instructions

Engine communication

Multi-functional inputs

PT100/1000 sensors

Modbus

CGC

CGC

CGC

CAN H

53

B (-)

49

GND

54

GND

50

CAN L

55

A (+)

51

PT 100

PT 100

PT 100

6

5

Multi-functional inputs

RMI sensors

CGC

RMI

RMI

RMI

Multi-functional inputs

Analogue 4-20 mA

-

CGC

CGC

CGC

8

R

5

Tacho input

Magnetic pickup/

Tacho generator

Multi-functional inputs

Binary input w.wirebreak

Tacho input

NPN/PNP pickup

CGC

+24V DC

16

18

17

out 17

7

6

5

Tacho input

W input from charger

alternator

B+ W

B-

CGC

18

17

Wiring of RMI 58 and 59 is done the same way as RMI 6-8

4.2.2 Binary inputs

Binary inputs 10 to 15 and 56 to 57 have an internal common positive (+), this means that they are triggered

by a connection to negative (-).

DEIF A/S

Page 12 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

Dig. input

CGC 400

Term. 5

Com

The binary inputs use fixed signals. Only the mode shift input and the test input (if the timer is

used) use pulse signal.

4.3 Breaker selection

4.3.1 Breaker selection

The controller can handle pulse, continuous and compact breakers. Selection of the breaker type is done in

the application configuration with the PC utility software. Output for breaker handling is chosen in the I/O configuration of the PC utility software. In the table below is listed which outputs are needed for breaker handling

depending on the breaker type.

Breaker type

GB on/MB on/TB on

GB off/MB off/TB off

Pulse breaker

Continuous breaker

Compact breaker

The pictures below are examples of how to set up breakers.

DEIF A/S

Page 13 of 25

CGC 400 installation instructions

4189340785 UK

Continuous breaker output selection

DEIF A/S

Wiring

Pulse breaker output selection

Page 14 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

4.4 Connection of the 3-phase voltage and current

4.4.1 Connection of the 3-phase voltage and current

Wiring, AC interface

Consumer

N

L1

L2

L3

CGC 400

Supply

45

GB ON

command

46

GB

s2

s1

14

GB OFF feedback

33

UL1

36

34

UL2 GENERATOR

VOLTAGE

N

38

UL3

40

39

s2

s1

42

41

s2

s1

44

43

I1

I2 GENERATOR

CURRENT

I3

GENERATOR

DEIF A/S

Page 15 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

4.4.2 3-phase AMF wiring

MAINS

N

L1

CGC 400

L2

L3

28

UL1

29

30

UL2

32

UL3

15

MB OFF feedback

47

MB ON

command

MAINS

VOLTAGE

Supply

MB

48

Consumers

45

GB ON

command

46

GB

s2

s1

14

GB OFF feedback

33

UL1

36

34

UL2 GENERATOR

VOLTAGE

N

38

UL3

40

39

s2

s1

42

41

s2

s1

44

43

I1

I2 GENERATOR

CURRENT

I3

GENERATOR

DEIF A/S

Page 16 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

4.5 Connection of the 1-phase voltage and current

4.5.1 1-phase wiring

N

L1

CGC 400

Supply

45

GB ON

command

46

GB

s2

s1

14

GB OFF feedback

33

UL1

34

40

39

I1

GENERATOR

VOLTAGE

GENERATOR

CURRENT

GENERATOR

DEIF A/S

Page 17 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

4.5.2 1-phase AMF wiring

MAINS

N

CGC 400

L1

28

UL1

29

MAINS

VOLTAGE

Supply

15

MB OFF feedback

47

MB ON

command

MB

48

Consumers

45

GB ON

command

46

GB

s2

s1

14

GB OFF feedback

33

UL1

34

40

39

GENERATOR

VOLTAGE

I1 GENERATOR

CURRENT

GENERATOR

DEIF A/S

Page 18 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

4.6 Connection of the split-phase voltage and current

4.6.1 Split-phase wiring

Consumer

N

L1

L2

CGC 400

Supply

45

GB ON

command

46

GB

14

GB OFF feedback

33

UL1

36

UL2 GENERATOR

VOLTAGE

N

34

s2

s1

40

39

s2

s1

42

41

I1

I2 GENERATOR

CURRENT

GENERATOR

DEIF A/S

Page 19 of 25

CGC 400 installation instructions

4189340785 UK

Wiring

4.6.2 Split-phase AMF wiring

MAINS

N

L1

CGC 400

L2

28

UL1

31

30

UL2

15

MB OFF feedback

47

MB ON

command

MAINS

VOLTAGE

Supply

MB

48

Consumers

45

GB ON

command

46

GB

14

GB OFF feedback

33

UL1

36

UL2 GENERATOR

VOLTAGE

N

34

s2

s1

40

39

s2

s1

42

41

I1

I2 GENERATOR

CURRENT

GENERATOR

DEIF A/S

Page 20 of 25

CGC 400 installation instructions

4189340785 UK

Communication

5. Communication

5.1 Wiring instructions

Cable

Belden 3106 A or equivalent. 22 AWG (0.324 mm2) shielded twisted pair, min. 95 % shield coverage.

Cable shield

Connect the cable shield to earth at one end only.

GND terminal connection

In case of communication problems, the GND terminals of the CGC 400 unit and the external device can be

linked together using a third wire.

CAN bus termination resistor

The size of the terminating resistors should be 120 1 %, 0.5 W resistor.

Never connect the GND terminal to earth directly or through the shield!

If the GND terminal is connected to a PLC or other device, the GND connection of this device

must be isolated from earth!

Maximum length of the CAN bus line is 400 m.

DEIF A/S

Page 21 of 25

CGC 400 installation instructions

4189340785 UK

Communication

5.2 Modbus RTU

5.2.1 Connection with 2-wire shielded cable (recommended)

CGC

CGC

DATA - (B)

DATA (GND)

DATA + (A)

DATA - (B)

DATA (GND)

DATA + (A)

49

50

51

49

50

51

DATA + (A)

DATA (GND)

DATA - (B)

PLC or other device

DEIF A/S

Page 22 of 25

CGC 400 installation instructions

4189340785 UK

Communication

5.2.2 Connection with 3-wire shielded cable

CGC

CGC

DATA - (B)

DATA (GND)

DATA + (A)

DATA - (B)

DATA (GND)

DATA + (A)

49

50

51

49

50

51

DATA + (A)

DATA (GND)

DATA - (B)

PLC or other device

For wiring details, please refer to Wiring instructions in this section.

In case of very long lines on the network, terminating resistors might be needed (typically 120

1 %, 0.5 W).

The calculation should be based on the following data:

A line internal pull-up bias resistor: 22 k

B line internal pull-down bias resistor: 22 k

Receiver input sensitivity: +/-200 mV

Receiver input impedance: 12 k

DEIF A/S

Page 23 of 25

CGC 400 installation instructions

4189340785 UK

Communication

5.3 CAN bus engine communication

5.3.1 Connection with 2-wire cable (recommended)

CGC

CAN-H

Com

CAN-L

53

54

55

CAN-H

Com

CAN-L

ECM

engine control module

DEIF A/S

Page 24 of 25

CGC 400 installation instructions

4189340785 UK

Communication

5.3.2 Connection with 3-wire shielded cable

CGC

CAN-H

Com

CAN-L

53

54

55

CAN-H

Com

CAN-L

ECM

engine control module

DEIF A/S

Page 25 of 25

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- R 449 PDFDokumen24 halamanR 449 PDFKhaleel KhanBelum ada peringkat

- Uscamaq 21 24VCC 1Dokumen8 halamanUscamaq 21 24VCC 1Gustavo PereiraBelum ada peringkat

- Datasheet Sdmo Nexys2 Control PanelDokumen4 halamanDatasheet Sdmo Nexys2 Control PanelRomulo GomesBelum ada peringkat

- DSE327 Data SheetDokumen2 halamanDSE327 Data SheetEng Mamon StiBelum ada peringkat

- Data Sheet QtaDokumen4 halamanData Sheet QtaGustavo PereiraBelum ada peringkat

- DSE327 Data SheetDokumen2 halamanDSE327 Data SheetEng Mamon StiBelum ada peringkat

- GCP-20 Series Genset Control: Operation ManualDokumen190 halamanGCP-20 Series Genset Control: Operation ManualCristian MardonesBelum ada peringkat

- DSEA109 Data SheetDokumen2 halamanDSEA109 Data SheetGustavo PereiraBelum ada peringkat

- DSE A108 Data SheetDokumen2 halamanDSE A108 Data SheetGustavo PereiraBelum ada peringkat

- DSE327 Data SheetDokumen2 halamanDSE327 Data SheetEng Mamon StiBelum ada peringkat

- Especificações técnicas de motores dieselDokumen7 halamanEspecificações técnicas de motores dieselGustavo PereiraBelum ada peringkat

- H3 Option Serial Communication Profibus DPDokumen44 halamanH3 Option Serial Communication Profibus DPGustavo PereiraBelum ada peringkat

- GCP-20 Series Genset Control: Operation ManualDokumen190 halamanGCP-20 Series Genset Control: Operation ManualCristian MardonesBelum ada peringkat

- DSE327 Data SheetDokumen2 halamanDSE327 Data SheetEng Mamon StiBelum ada peringkat

- Especificações técnicas de motores dieselDokumen7 halamanEspecificações técnicas de motores dieselGustavo PereiraBelum ada peringkat

- Diagrama C15, C18 and 3406E Marine EngineDokumen2 halamanDiagrama C15, C18 and 3406E Marine EngineGustavo PereiraBelum ada peringkat

- Sisweb Sisweb Techdoc Techdoc Print PageDokumen4 halamanSisweb Sisweb Techdoc Techdoc Print PageGustavo PereiraBelum ada peringkat

- Chapter 1. General Information: Installation and OperationDokumen10 halamanChapter 1. General Information: Installation and OperationGustavo PereiraBelum ada peringkat

- Renr2343 02 Vol1 Outside 052110Dokumen4 halamanRenr2343 02 Vol1 Outside 052110Gustavo PereiraBelum ada peringkat

- 60Hz - 50Hz Conversion Procedure C32Dokumen13 halaman60Hz - 50Hz Conversion Procedure C32Gustavo Pereira100% (1)

- Advanced Full Text Search - REHS4636 - Generator Set Control (GSC) and AC Transformer Box (ATB) Replacement (4490)Dokumen15 halamanAdvanced Full Text Search - REHS4636 - Generator Set Control (GSC) and AC Transformer Box (ATB) Replacement (4490)Gustavo PereiraBelum ada peringkat

- Grupo Electrogeno Con Motor 3412-Coripuno PDFDokumen4 halamanGrupo Electrogeno Con Motor 3412-Coripuno PDFDEYNERBelum ada peringkat

- Dse8600 Series Dse Configuration Suite ManualDokumen165 halamanDse8600 Series Dse Configuration Suite ManualGustavo Pereira100% (1)

- Dse8620 Data SheetDokumen2 halamanDse8620 Data SheetGustavo PereiraBelum ada peringkat

- 2012 Manual Tec Nico Power WizardDokumen49 halaman2012 Manual Tec Nico Power WizardЕвгений_Егоров94% (17)

- Control GacDokumen7 halamanControl GacGustavo PereiraBelum ada peringkat

- Pid BasicoDokumen2 halamanPid BasicoGustavo PereiraBelum ada peringkat

- CanbuswiringforDSEcontrollers (Motores Eletrônicos)Dokumen34 halamanCanbuswiringforDSEcontrollers (Motores Eletrônicos)Gustavo PereiraBelum ada peringkat

- Option G4, G5 and G8, 4189340696 UK - 2012.07.13Dokumen88 halamanOption G4, G5 and G8, 4189340696 UK - 2012.07.13Gustavo PereiraBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- A Low-Voltage MOS Cascode Current Mirror For All Current LevelsDokumen23 halamanA Low-Voltage MOS Cascode Current Mirror For All Current LevelsSureshnaidu LekkalaBelum ada peringkat

- Waltenhofen PendulumDokumen3 halamanWaltenhofen PendulumhayiyBelum ada peringkat

- E+H Menu Docs IOMs Analysis Turbidity BA200CEN Liquisys M Cum 223 253 OMDokumen96 halamanE+H Menu Docs IOMs Analysis Turbidity BA200CEN Liquisys M Cum 223 253 OMSuraj PillaiBelum ada peringkat

- TM-500/600 Setup GuideDokumen33 halamanTM-500/600 Setup GuideKay YusuffBelum ada peringkat

- Lightning Characterization For Flashover Rate Calculation of Overhead Transmission LinesDokumen6 halamanLightning Characterization For Flashover Rate Calculation of Overhead Transmission LinessunitharajababuBelum ada peringkat

- TC4066BP, TC4066BF, TC4066BFN, TC4066BFT: TC4066B Quad Bilateral SwitchDokumen11 halamanTC4066BP, TC4066BF, TC4066BFN, TC4066BFT: TC4066B Quad Bilateral SwitchCandelaria CortesBelum ada peringkat

- MOSFET-Internal Capacitances PDFDokumen11 halamanMOSFET-Internal Capacitances PDFJayanth Sriranga100% (1)

- PL3 PL4 Output Connection - v1.2Dokumen5 halamanPL3 PL4 Output Connection - v1.2Victor GarciaBelum ada peringkat

- Peugeot Codes PDFDokumen3 halamanPeugeot Codes PDFandrewBelum ada peringkat

- E94A - Servo Drives 9400 HighLine - v11-0 - EN PDFDokumen644 halamanE94A - Servo Drives 9400 HighLine - v11-0 - EN PDFUsman KhanBelum ada peringkat

- Acpc 2015 TextDokumen2 halamanAcpc 2015 TextHardik DoshiBelum ada peringkat

- Chapter 7 Additional Problems SolutionsDokumen9 halamanChapter 7 Additional Problems SolutionsypobuleshBelum ada peringkat

- Dna-Stp-Ai-U: General DescriptionDokumen2 halamanDna-Stp-Ai-U: General DescriptionnpcopeBelum ada peringkat

- Cinemate: Universal Remote ControlDokumen19 halamanCinemate: Universal Remote ControlTamara SamanthaBelum ada peringkat

- Multimedia: Content Content FormsDokumen5 halamanMultimedia: Content Content FormsBoobalan RBelum ada peringkat

- Trane TTKDokumen24 halamanTrane TTKAngel Quique Meana100% (2)

- Differential AmplifierDokumen5 halamanDifferential Amplifiermahesh babuBelum ada peringkat

- Lab Report Kirchhoffs Voltage and Current Laws KVL and KCLDokumen2 halamanLab Report Kirchhoffs Voltage and Current Laws KVL and KCLAvishek Chowdhury0% (1)

- PULL OUT TEST STANDARD ADOPTED FROM ASTM E-488-90Dokumen2 halamanPULL OUT TEST STANDARD ADOPTED FROM ASTM E-488-90ศิษย์เก่า ทีเจพี100% (1)

- 205 Unit 1 L04 Superposition TheoremDokumen5 halaman205 Unit 1 L04 Superposition TheoremBINOSHI SAMUVELBelum ada peringkat

- Elektric Schematic - RH 400 400013Dokumen290 halamanElektric Schematic - RH 400 400013Vikranth ReddyBelum ada peringkat

- IRS2106/IRS21064 high and low side driver datasheetDokumen25 halamanIRS2106/IRS21064 high and low side driver datasheetmohamedBelum ada peringkat

- Ca-Dc21e Im 96M11555 GB WW 1021-1Dokumen2 halamanCa-Dc21e Im 96M11555 GB WW 1021-1tomy_ueziBelum ada peringkat

- Insulation TestingDokumen21 halamanInsulation TestingQaisar ShafiBelum ada peringkat

- Making The Perfect Connection: Protectron Electromech Pvt. LTDDokumen33 halamanMaking The Perfect Connection: Protectron Electromech Pvt. LTDlingubhBelum ada peringkat

- HR 550 FS: Product InformationDokumen4 halamanHR 550 FS: Product InformationAgim ZilkicBelum ada peringkat

- OrCAD-Allegro Hardware and Software Requirements 16-6 PDFDokumen1 halamanOrCAD-Allegro Hardware and Software Requirements 16-6 PDFEmanuelePaganiBelum ada peringkat

- Introducing Unisab II Version 2.05.1 and 2.05.2Dokumen4 halamanIntroducing Unisab II Version 2.05.1 and 2.05.2Mahmoud Mohamed100% (1)

- HQDS Hybrid Power System Operator ManualDokumen122 halamanHQDS Hybrid Power System Operator ManualTrung LêBelum ada peringkat