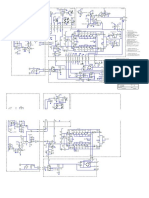

Standel - Artist Reverb - Studio Amplifier Schematic

Diunggah oleh

dodJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Standel - Artist Reverb - Studio Amplifier Schematic

Diunggah oleh

dodHak Cipta:

Format Tersedia

STANDEL SERVICE INFORMATION

PRE-AMPLIFIER SECTION

For simplicity of maintenance, the pre-amplifier is divided into several encapsulated

modules, each containing a separate circuit designated by color code and designed for

rapid replacement.

Signal tracing methods may be used to isolate trouble in any one of the modules, which

may then be replaced without time consuming voltage and component tests.

The following is a module description and color code.

The blue modules are high

impedance input amplifiers.

The green module is an interstage mixer amplifier.

The

yellow is the reverberation amplifier, and the red module is the tremolo oscillator and

modulator.

Defective modules should be returned to the factory for replacement.

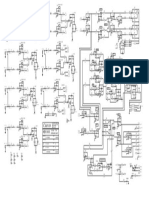

DRIVER AND POWER SECTION

The power amplifier section consists of a driver transistor, driver transformer, and two

power output transistors direct coupled to the speaker.

The driver transistor, driver transformer, and main terminal board are mounted on the

power amplifier heat sink.

If it is necessary to replace the driver transistor,

disconnect the leads and unscrew the top of the heat sink.

Silicon grease should be

applied to the new transistor before it is installed in the heat sink.

It may be

necessary to reset the collector current to 30 M.A. by adjusting the value of R14 and

measuring the drop across the driver transformer primary.

If the adjustment of R14 requires a resistance less than 47000 ohms the beta of the

transistor is too low for satisfactory operation and a new transistor must be selected.

The power amplifier section is operated Class B in a single-ended push-pull

configuration, which is similar to a balanced bridge with the speaker connection at

approximately zero voltage.

The static current is very low until the transistors are

switched into a high current condition by the signal applied to the base.

Each

transistor conducts on alternate signal cycles through the speaker to the ground. Since

the internal resistance of the transistor in a conduction state is negligible, the

speaker resistance becomes the limiting factor, and in this case a speaker impedance of

less than 8 ohms will allow excessive current to flow which will damage the transistors.

For this reason extension speakers should not be used.

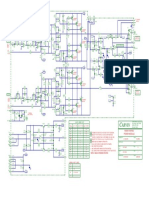

The usable life of the transistor is indefinite as long as the temperature, voltage and

current ratings are not exceeded.

When the amplifier is operated at high power levels

for long periods of time, it is possible to accumulate heat on the heat sinks more

rapidly than it can be dissipated.

Under these conditions the customer should be

instructed to use the power switch as a standby, and turn the amplifier off at regular

intervals.

The amplifier has been operated in factory tests at full undistorted sine

wave power for periods of one and one-half hours without damage.

This should be

considered a maximum condition.

When it is necessary to replace the power transistors, matched sets should be obtained

from the factory and silicon grease should be used between the transistor and heat sink

to provide maximum heat transfer. Care should be taken to position the Teflon insulating

spacers correctly to avoid shorting the transistors to the chassis.

If further information or replacements parts are required, contact the factory service

department at the following address:

Anda mungkin juga menyukai

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDari EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileBelum ada peringkat

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDari EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsPenilaian: 3 dari 5 bintang3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- Carvin Schematic - DCM2000 Rev MDokumen1 halamanCarvin Schematic - DCM2000 Rev MdodBelum ada peringkat

- Differential AmplifiersDokumen38 halamanDifferential AmplifiersVianca CamilLe Incognito-Castillo PanganibanBelum ada peringkat

- Simple DIY Induction Heater CircuitDokumen8 halamanSimple DIY Induction Heater CircuitPramillaBelum ada peringkat

- Dc30 Owners ManualDokumen17 halamanDc30 Owners ManualMike Giordano100% (1)

- Best Receiver Eddystone Ever Built - The EC958Dokumen34 halamanBest Receiver Eddystone Ever Built - The EC958rotexBelum ada peringkat

- Basic Interview-Questions-for-Electrical EngineersDokumen5 halamanBasic Interview-Questions-for-Electrical EngineersAbm Rahat KaisarBelum ada peringkat

- Carvin Schematic - DCM2000 REV. HDokumen2 halamanCarvin Schematic - DCM2000 REV. Hdod100% (2)

- Transformer ProtectionDokumen18 halamanTransformer ProtectionTanmayBelum ada peringkat

- Transformer types and applicationsDokumen20 halamanTransformer types and applicationsnabeel hassan ali100% (1)

- Build A Class-A AmplifierDokumen9 halamanBuild A Class-A AmplifierFe DnyBelum ada peringkat

- AC Current Monitor by LM358Dokumen14 halamanAC Current Monitor by LM358wlen2012Belum ada peringkat

- Unit IV Measurement of Non-Electrical ParametersDokumen17 halamanUnit IV Measurement of Non-Electrical ParametersAleesha100% (6)

- Analog Communications Lab ManualDokumen60 halamanAnalog Communications Lab ManualmailmeasddBelum ada peringkat

- Transformer TroubleshootingDokumen12 halamanTransformer TroubleshootingShahadat Hossain75% (4)

- Power Transfer and Circuit Breaker TypesDokumen15 halamanPower Transfer and Circuit Breaker TypesHimanshu Soni100% (1)

- Power Control SystemDokumen29 halamanPower Control SystemJames XgunBelum ada peringkat

- Transformers FAQ: Altitude, Temperature, Harmonics and MoreDokumen5 halamanTransformers FAQ: Altitude, Temperature, Harmonics and MorenmvikramBelum ada peringkat

- Analog Circuits: GATE EC Topic Wise QuestionsDokumen50 halamanAnalog Circuits: GATE EC Topic Wise Questionsdeepthi1993100% (1)

- SMPS300RDokumen4 halamanSMPS300RNadia SalemBelum ada peringkat

- Seminar On Substation TrainingDokumen24 halamanSeminar On Substation TrainingPankaj SharmaBelum ada peringkat

- Transformer Switching RelayDokumen3 halamanTransformer Switching RelayamishcarBelum ada peringkat

- Transformer 1Dokumen29 halamanTransformer 1utharun3Belum ada peringkat

- 440kv GSSDokumen37 halaman440kv GSSready2cheerBelum ada peringkat

- Power AssignmentDokumen8 halamanPower AssignmentHaseeb AdilBelum ada peringkat

- Various Transistor Throttles CircuitsDokumen16 halamanVarious Transistor Throttles CircuitsRenny PaoloneBelum ada peringkat

- Constructional Details of TransformerDokumen16 halamanConstructional Details of TransformerAravind NBelum ada peringkat

- Transformers Guide: Parts, Tests, Maintenance & TypesDokumen6 halamanTransformers Guide: Parts, Tests, Maintenance & TypesOkegbile OlawaleBelum ada peringkat

- General Technical Information: Fans: CasingDokumen35 halamanGeneral Technical Information: Fans: CasingVivek SakthiBelum ada peringkat

- Power TransformerDokumen8 halamanPower TransformervaibhavvikramBelum ada peringkat

- HNC Operations Engineering Noel Jennings Engineering Design AssignmentDokumen13 halamanHNC Operations Engineering Noel Jennings Engineering Design AssignmentNoel JenningsBelum ada peringkat

- Using Bipolar Transistors As SwitchesDokumen15 halamanUsing Bipolar Transistors As SwitchesgpopeBelum ada peringkat

- Ahmed Karam Abdo REPORT 1 PDFDokumen8 halamanAhmed Karam Abdo REPORT 1 PDFdragon for pc gamesBelum ada peringkat

- HVAC Instruments: Clamp-On Ammeter VoltmeterDokumen8 halamanHVAC Instruments: Clamp-On Ammeter VoltmeterMuhammad Jamshaid KhanBelum ada peringkat

- Ameritron Al 1200 User ManualDokumen14 halamanAmeritron Al 1200 User Manualmark777markBelum ada peringkat

- MantaienanceDokumen22 halamanMantaienancePallavi PatilBelum ada peringkat

- Step Down Transformers - Having Output Voltage Is Smaller Than Input VoltageDokumen8 halamanStep Down Transformers - Having Output Voltage Is Smaller Than Input VoltageSynergy Transformers100% (1)

- Ahmed Karam Abdo REPORT 22 PDFDokumen7 halamanAhmed Karam Abdo REPORT 22 PDFdragon for pc gamesBelum ada peringkat

- Industrial Rectifier BrochureDokumen12 halamanIndustrial Rectifier Brochure666667Belum ada peringkat

- Electrical Power Generation, Transmission & Protection: Project Report OnDokumen29 halamanElectrical Power Generation, Transmission & Protection: Project Report OnAmit TripathiBelum ada peringkat

- Personal Alarm Using IC 74HC04Dokumen22 halamanPersonal Alarm Using IC 74HC04satyasampathBelum ada peringkat

- Musical Instrument Amplifiers Clubman '35, Chieftain Reverb 210, 112, 212Dokumen6 halamanMusical Instrument Amplifiers Clubman '35, Chieftain Reverb 210, 112, 212RobBelum ada peringkat

- ELECTRONIC TRANSFORMER FOR A 12V HALOGEN LAMP by P 1Dokumen10 halamanELECTRONIC TRANSFORMER FOR A 12V HALOGEN LAMP by P 1sarmivenBelum ada peringkat

- Designing Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558Dokumen15 halamanDesigning Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558PredragPeđaMarkovićBelum ada peringkat

- Motor & Thermistor FundaDokumen10 halamanMotor & Thermistor Fundajay shahBelum ada peringkat

- A Simple Solar Panel RegulatorDokumen4 halamanA Simple Solar Panel Regulatorinter2176Belum ada peringkat

- Single Phasing EffectsDokumen41 halamanSingle Phasing EffectsdiljithBelum ada peringkat

- Supplementary Components and System: Engr - Kashif IqbalDokumen21 halamanSupplementary Components and System: Engr - Kashif IqbalHassan Bin QasimBelum ada peringkat

- Bosch DynastartDokumen12 halamanBosch DynastartKkbhuvan KkBelum ada peringkat

- Major Electrical EquipmentsDokumen52 halamanMajor Electrical EquipmentsGrant Arvin SantiagoBelum ada peringkat

- A Presentation On The Working and Maintenance of Grid TransformerDokumen68 halamanA Presentation On The Working and Maintenance of Grid Transformeruday shardaBelum ada peringkat

- A Brief Introduction To Essential Substation ComponentsDokumen16 halamanA Brief Introduction To Essential Substation ComponentsMuhammed MekkiBelum ada peringkat

- E e K Wma Ranfrmrs: T So E: We Make A RNFR o Mers: T SDokumen1 halamanE e K Wma Ranfrmrs: T So E: We Make A RNFR o Mers: T SkrejishBelum ada peringkat

- Power Control Transformer Used and Advantages in IndiaDokumen6 halamanPower Control Transformer Used and Advantages in IndiaAb TransformerBelum ada peringkat

- Electrical DiplomaDokumen44 halamanElectrical DiplomaMukesh SharmaBelum ada peringkat

- JUSCO Power Distribution Project ReportDokumen23 halamanJUSCO Power Distribution Project ReportGaurav KumarBelum ada peringkat

- EMC of semiconductor devices and long cablesDokumen8 halamanEMC of semiconductor devices and long cablesEli KatzBelum ada peringkat

- Introduction To Power AmplifiersDokumen22 halamanIntroduction To Power AmplifiersGaneshVenkatachalamBelum ada peringkat

- Thyristor Switch Operation: Instructed By: Mr. R. JayawardenaDokumen4 halamanThyristor Switch Operation: Instructed By: Mr. R. JayawardenaRas PqrBelum ada peringkat

- 12 Steps For Designing Toroidal TransformersDokumen9 halaman12 Steps For Designing Toroidal TransformersFernando SotoBelum ada peringkat

- Thyristor Type ExcitationDokumen3 halamanThyristor Type Excitationraom_2Belum ada peringkat

- Nichrome Wire Foam CuttersDokumen6 halamanNichrome Wire Foam CuttersHeanjiaAlloys100% (1)

- Step down Transformers: Lowering Voltage EfficientlyDokumen2 halamanStep down Transformers: Lowering Voltage EfficientlyRemya R. KumarBelum ada peringkat

- Carvin Schematic - Sc2000-Sc3000Dokumen2 halamanCarvin Schematic - Sc2000-Sc3000dodBelum ada peringkat

- Carvin Schematic - s1200-s1800 - EqDokumen1 halamanCarvin Schematic - s1200-s1800 - EqdodBelum ada peringkat

- Carvin Schematic - s204000CDokumen2 halamanCarvin Schematic - s204000CdodBelum ada peringkat

- Carvin Schematic - s600 - Mixer - PsDokumen1 halamanCarvin Schematic - s600 - Mixer - PsdodBelum ada peringkat

- Carvin Schematic - s600 - EqDokumen1 halamanCarvin Schematic - s600 - EqdodBelum ada peringkat

- Carvin Schematic - s1200-s1800 - MixerDokumen1 halamanCarvin Schematic - s1200-s1800 - MixerdodBelum ada peringkat

- Carvin Schematic - s01000H-BDokumen1 halamanCarvin Schematic - s01000H-BdodBelum ada peringkat

- Carvin Schematic - KB1000 PWR Module RevEDokumen1 halamanCarvin Schematic - KB1000 PWR Module RevEdod100% (1)

- Carvin Schematic - KB100 Rev CDokumen1 halamanCarvin Schematic - KB100 Rev CdodBelum ada peringkat

- Carvin Schematic - s600 - MixerDokumen1 halamanCarvin Schematic - s600 - Mixerdod100% (1)

- Carvin Schematic - RX1200 System Master Rev D EDokumen4 halamanCarvin Schematic - RX1200 System Master Rev D EdodBelum ada peringkat

- Carvin Schematic - PA1200 PA800 System Master Rev CDokumen1 halamanCarvin Schematic - PA1200 PA800 System Master Rev CdodBelum ada peringkat

- Carvin Schematic - PA880 System Master Rev BDokumen1 halamanCarvin Schematic - PA880 System Master Rev BdodBelum ada peringkat

- Carvin Schematic - S400 Sound Mate Rev DDokumen1 halamanCarvin Schematic - S400 Sound Mate Rev DdodBelum ada peringkat

- Carvin Schematic - DCM4000 Power Supply & Amp Rev BDokumen1 halamanCarvin Schematic - DCM4000 Power Supply & Amp Rev BdodBelum ada peringkat

- Carvin Schematic - DCM2500 Rev BDokumen1 halamanCarvin Schematic - DCM2500 Rev Bdod0% (1)

- Carvin Schematic - KB1000 Rev BDokumen1 halamanCarvin Schematic - KB1000 Rev BdodBelum ada peringkat

- Carvin Schematic - RX800 System Master Rev CDokumen1 halamanCarvin Schematic - RX800 System Master Rev CdodBelum ada peringkat

- Carvin Schematic - DCM2000 4000 Input PCB Rev ADokumen1 halamanCarvin Schematic - DCM2000 4000 Input PCB Rev AdodBelum ada peringkat

- Carvin Schematic - DCM4000 Iinput and Preamp Rev BDokumen1 halamanCarvin Schematic - DCM4000 Iinput and Preamp Rev BdodBelum ada peringkat

- Carvin Schematic - 10028 Power Module FET1000Dokumen1 halamanCarvin Schematic - 10028 Power Module FET1000dodBelum ada peringkat

- Carvin Schematic - DCM2000 Rev PDokumen1 halamanCarvin Schematic - DCM2000 Rev PdodBelum ada peringkat

- Carvin Schematic - DCM2000 REV. JDokumen4 halamanCarvin Schematic - DCM2000 REV. Jdod100% (1)

- Carvin Schematic - FET1000 Rev-GDokumen1 halamanCarvin Schematic - FET1000 Rev-GdodBelum ada peringkat

- Carvin Schematic - DCM1204 RevBDokumen1 halamanCarvin Schematic - DCM1204 RevBdodBelum ada peringkat

- Carvin Schematic X30 X60 1987Dokumen1 halamanCarvin Schematic X30 X60 1987dodBelum ada peringkat

- Carvin Schematic - b2000Dokumen2 halamanCarvin Schematic - b2000dod0% (1)

- Carvin Schematic DCM150 REV BDokumen1 halamanCarvin Schematic DCM150 REV Bdod100% (1)

- Hi-Fi tone control circuit using low noise transistorsDokumen8 halamanHi-Fi tone control circuit using low noise transistorsMuhammad YousafBelum ada peringkat

- Colpitts Oscillator: Electronic CircuitDokumen5 halamanColpitts Oscillator: Electronic CircuitAntonio DiazBelum ada peringkat

- LM386-Aplicacion General NationalDokumen10 halamanLM386-Aplicacion General NationalfcabreraibanezBelum ada peringkat

- JamMan Express XT ManualDokumen15 halamanJamMan Express XT ManuallistentomerijnBelum ada peringkat

- Closed Loop Angular Position Control of Stepper Motor Using Parallel Port on PCDokumen11 halamanClosed Loop Angular Position Control of Stepper Motor Using Parallel Port on PCJose LunaBelum ada peringkat

- Linear Integrated Circuits Lab Viva VoceDokumen8 halamanLinear Integrated Circuits Lab Viva Voceselvi0412100% (12)

- Civil services-GOWRIDokumen60 halamanCivil services-GOWRIPraveen Nayak BhukyaBelum ada peringkat

- Service Manual: Minidisc ChangerDokumen38 halamanService Manual: Minidisc ChangerAnonymous Lfgk6vygBelum ada peringkat

- IIIT Surat Curriculum ECEDokumen21 halamanIIIT Surat Curriculum ECEKrishna MishraBelum ada peringkat

- Harris Ridge Condos Panel Submittal REV ADokumen367 halamanHarris Ridge Condos Panel Submittal REV AspcoaustinBelum ada peringkat

- Tpa3112D1 25-W Filter-Free Mono Class-D Audio Power Amplifier With Speakerguard™Dokumen33 halamanTpa3112D1 25-W Filter-Free Mono Class-D Audio Power Amplifier With Speakerguard™djebinBelum ada peringkat

- Heart beat measurement using PIC18 microcontrollerDokumen5 halamanHeart beat measurement using PIC18 microcontrollerRian MalikBelum ada peringkat

- Tga 2597Dokumen14 halamanTga 2597chandra kiranBelum ada peringkat

- Ameritron AL-811 ALC QuestionDokumen4 halamanAmeritron AL-811 ALC QuestionTaufiq Fahlifi YfzerobrrBelum ada peringkat

- Compensador TermoparesDokumen12 halamanCompensador Termoparesazaelg_5Belum ada peringkat

- On The Linearity of Open Loop FluxgateDokumen4 halamanOn The Linearity of Open Loop FluxgateilkBelum ada peringkat

- Stereo Hi-Fi Tube Amp:: Remake of The Dynaco ST-70Dokumen16 halamanStereo Hi-Fi Tube Amp:: Remake of The Dynaco ST-70wellingtonBelum ada peringkat

- Troubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)Dokumen22 halamanTroubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)Carlos Aguilar MontemayorBelum ada peringkat

- WPT From Near-Field To Far-FieldDokumen11 halamanWPT From Near-Field To Far-FieldS SahBelum ada peringkat

- Manual Drive NC-1 NordsonDokumen19 halamanManual Drive NC-1 NordsonHeber MagdielBelum ada peringkat

- 15 Watt FET FM Amp Rev 2 Assembly InstructionsDokumen7 halaman15 Watt FET FM Amp Rev 2 Assembly InstructionsStephen Dunifer100% (4)

- Measurement Systems For Electrical Machine Monitoring: Mario Vrazic, Ivan Gasparac and Marinko KovacicDokumen19 halamanMeasurement Systems For Electrical Machine Monitoring: Mario Vrazic, Ivan Gasparac and Marinko Kovacicpredic1Belum ada peringkat

- Sugden Audio 50-Year Anniversary (1967-2017)Dokumen8 halamanSugden Audio 50-Year Anniversary (1967-2017)Neophonics®Belum ada peringkat

- Data Table 1: Readings For BJT AmplifierDokumen2 halamanData Table 1: Readings For BJT AmplifierSanjid ElahiBelum ada peringkat