Jacket and Coils of Agitated Vessels PDF

Diunggah oleh

lolofm25Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Jacket and Coils of Agitated Vessels PDF

Diunggah oleh

lolofm25Hak Cipta:

Format Tersedia

PHASE CONTACTING AND LIQUID-SOLID PROCESSING

can either have the impeller pump up in the draft tube and flow

down the annulus or just the reverse. If the flow is down the annulus,

then the flow has to make a 180 turn where it comes back at the bottom of the tank into the draft tube again. This is a very sensitive area,

and special baffles must be used to carefully determine how the fluid

will make this turn since many areas of constriction are involved in

making this change in direction.

When pumping down the draft tube, flow normally makes a more

troublefree velocity change to a flow going up the annulus. Since the

area of the draft tube is markedly less than the area of the annulus,

pumping up the draft tube requires less flow to suspend solids of a

given settling velocity than does pumping down the draft tube.

Another example is to eliminate the interstage pump between

mixing and settling stages in the countercurrent mixer-settler system. The radial-flow impeller typically used is placed very close to

an orifice at the bottom of the mixing tank and can develop heads

from 12 to 18 in. All the head-loss terms in the mixer and settler circuit have to be carefully calculated because they come very close to

that 12- to 18-in range when the passages are very carefully designed

and streamlined. If the mixing tank gets much above 10 ft in depth,

then the heads have to be higher than the 12- to 18-in range and special designs have to be worked on which have the potential liability

of increasing the shear rate acting on the dispersed phase to cause

more entrainment and longer settling times. In these cases, it is

sometimes desirable to put the mixer system outside the actual

mixer tank and have it operate in a single phase or to use multiple

impellers, each one of which can develop a portion of the total head

required.

Heat Transfer In general, the fluid mechanics of the film on the

mixer side of the heat transfer surface is a function of what happens at

that surface rather than the fluid mechanics going on around the

impeller zone. The impeller largely provides flow across and adjacent

to the heat-transfer surface and that is the major consideration of the

heat-transfer result obtained. Many of the correlations are in terms of

traditional dimensionless groups in heat transfer, while the impeller

performance is often expressed as the impeller Reynolds number.

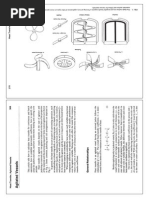

The fluidfoil impellers (shown in Fig. 18-2) usually give more flow

for a given power level than the traditional axial- or radial-flow turbines. This is also thought to be an advantage since the heat-transfer

surface itself generates the turbulence to provide the film coefficient

and more flow should be helpful. This is true to a limited degree in

jacketed tanks (Fig. 18-34), but in helical coils (Fig. 18-35), the

LIQUID-SOLID OPERATIONS AND EQUIPMENT

2 1 2 1 2 1 2

where the agitator is a disk flat-blade turbine, and the Reynolds number range is 400 to (2)(105) [Oldshue and Gretton, Chem. Eng. Prog.,

50, 615 (1954)]. The term Do is the outside diameter of the coil tube.

The most comprehensive correlation for heat transfer to vertical

baffle-type coils is for a disk flat-blade turbine over the Reynolds

number range 103 to (2)(106):

hDo

Lp2 Nr

} = 0.09 }

k

FIG. 18-35

Typical arrangement of helical coil at mixing vessel for heat transfer.

extreme axial flow of these impellers tends to have the first or second

turn in the coil at the bottom of the tank blank off the flow from the

turns above it in a way that (at the same power level) the increased

flow from the fluidfoil impeller is not helpful. It best gives the same

coefficient as with the other impellers and on occasion can cause a 5

to 10 percent reduction in the heat-transfer coefficient over the

entire coil.

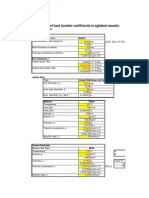

JACKETS AND COILS OF AGITATED VESSELS

Most of the correlations for heat transfer from the agitated liquid contents of vessels to jacketed walls have been of the form:

hDj

Lp2 Nr

}=a }

k

2 1}k 2 1}

2

b

1/3

(18-18)

The film coefficient h is for the inner wall; Dj is the inside diameter of

the mixing vessel. The term L p2 Nr / is the Reynolds number for mixing in which Lp is the diameter and Nr the speed of the agitator. Recommended values of the constants a, b, and m are given in Table 18-2.

A wide variety of configurations exists for coils in agitated vessels.

Correlations of data for heat transfer to helical coils have been of two

forms, of which the following are representative:

TABLE 18-2

2 1 2 1 2

0.62

c

}

k

1/3

b

}

w

0.14

(18-19)

Values of Constants for Use in Eq. (18-18)

Agitator

a

Paddle

Pitched-blade turbineb

Disk, flat-blade turbinec

Propeller d

Anchor b

Anchor b

Helical ribbone

Typical jacket arrangement for heat transfer.

18-24

where the agitator is a paddle, the Reynolds number range is 300 to

4 105 [Chilton, Drew, and Jebens, Ind. Eng. Chem., 36, 510 (1944)],

and

hDo

Lp2 Nr 0.67 c 0.37 Lp 0.1 Do 0.5

(18-20)

} = 0.17 }

}

}

}

k

k

Dj

Dj

hDj

Lp2 Nt

} = 0.87 }

k

FIG. 18-34

18-23

0.36

0.53

0.54

0.54

1.0

0.36

0.633

w

w

w

w

a

w

a

0.21

0.24

0.14

0.14

0.18

0.18

0.18

Range of

Reynolds number

3003 10 5

80200

403 10 5

2 103 (one point)

10300

30040,000

810 5

a

Chilton, Drew, and Jebens, Ind. Eng. Chem., 36, 510 (1944), with constant

m modified by Uhl.

b

Uhl, Chem. Eng. Progr., Symp. Ser. 17, 51, 93 (1955).

c

Brooks and Su, Chem. Eng. Progr., 55(10), 54 (1959).

d

Brown et al., Trans. Inst. Chem. Engrs. (London), 25, 181 (1947).

e

Gluz and Pavlushenko, J. Appl. Chem. U.S.S.R., 39, 2323 (1966).

Copyright 1999 by The McGraw-Hill Companies, Inc. All rights reserved. Use of

this product is subject to the terms of its license agreement. Click here to view.

}

}

2 1}k 2 1}

D 2 1n 2 1 2

0.65

1/3

Lp

1/3

0.2

0.4

(18-21)

where nb is the number of baffle-type coils and f is the fluid viscosity

at the mean film temperature [Dunlop and Rushton, Chem. Eng.

Prog. Symp. Ser. 5, 49, 137 (1953)].

Chapman and Holland (Liquid Mixing and Processing in Stirred

Tanks, Reinhold, New York, 1966) review heat transfer to low-viscosity

fluids in agitated vessels. Uhl [Mechanically Aided Heat Transfer, in

Uhl and Gray (eds.), Mixing: Theory and Practice, vol. I, Academic,

New York, 1966, chap. V] surveys heat transfer to low- and highviscosity agitated fluid systems. This review includes scraped-wall units

and heat transfer on the jacket and coil side for agitated vessels.

LIQUID-LIQUID-GAS-SOLID SYSTEMS

This is a relatively unusual combination, and one of the more common

times it exists is in the fermentation of hydrocarbons with aerobic

microorganisms in an aqueous phase. The solid phase is a microorganism which is normally in the aqueous phase and is using the

organic phase for food. Gas is supplied to the system to make the fermentation aerobic. Usually the viscosities are quite low, percent solids

is also modest, and there are no special design conditions required

when this particular gas-liquid-liquid-solid combination occurs. Normally, average properties for the density of viscosity of the liquid

phase are used. In considering that the role the solids play in the system is adequate, there are cases of other processes which consist of

four phases, each of which involves looking at the particular properties

of the phases to see whether there are any problems of dispersion,

suspension, or emulsification.

FIG. 18-36

Laser scan.

FIG. 18-37

Laser scan.

COMPUTATIONAL FLUID DYNAMICS

There are several software programs that are available to model flow

patterns of mixing tanks. They allow the prediction of flow patterns

based on certain boundary conditions. The most reliable models use

accurate fluid mechanics data generated for the impellers in question

and a reasonable number of modeling cells to give the overall tank

flow pattern. These flow patterns can give velocities, streamlines, and

localized kinetic energy values for the systems. Their main use at

the present time is to look at the effect of making changes in mixing

variables based on doing certain things to the mixing process. These

programs can model velocity, shear rates, and kinetic energy, but

probably cannot adapt to the actual chemistry of diffusion or masstransfer kinetics of actual industrial process at the present time.

Relatively uncomplicated transparent tank studies with tracer fluids

or particles can give a similar feel for the overall flow pattern. It is

important that a careful balance be made between the time and expense

of calculating these flow patterns with computational fluid dynamics

compared to their applicability to an actual industrial process. The

future of computational fluid dynamics appears very encouraging and a

reasonable amount of time and effort put forth in this regard can yield

immediate results as well as potential for future process evaluation.

Figures 18-36, 18-37, and 18-38 show some approaches. Figure

18-36 shows velocity vectors for an A310 impeller. Figure 18-37 shows

contours of kinetic energy of turbulence. Figure 18-38 uses a particle

trajectory approach with neutral buoyancy particles.

Copyright 1999 by The McGraw-Hill Companies, Inc. All rights reserved. Use of

this product is subject to the terms of its license agreement. Click here to view.

PASTE AND VISCOUS-MATERIAL MIXING

18-25

Numerical fluid mechanics can define many of the fluid mechanics

parameters for an overall reactor system. Many of the models break

up the mixing tank into small microcells. Suitable material and masstransfer balances between these cells throughout the reactor are then

made. This can involve long and massive computational requirements.

Programs are available that can give reasonably acceptable models of

experimental data taken in mixing vessels. Modeling the threedimensional aspect of a flow pattern in a mixing tank can require a

large amount of computing power.

Most modeling codes are a time-averaging technique. Depending

upon the process, a time-dependent technique may be more suitable.

Time-dependent modeling requires much more computing power

than does time averaging.

FIG. 18-38

GENERAL REFERENCES

1. J. Y. Oldshue, Mixing 89, Chemical Engineering Progress, 85(5): 3342

(1989).

2. J. C. Middleton, Proc. 3d European Conf. on Mixing, 4/89, BHRA, pp.

1536.

3. J. Y. Oldshue, T. A. Post, R. J. Weetman, Comparison of Mass Transfer

Characteristics of Radial and Axial Flow Impellers, BHRA Proc. 6th

European Conf. on Mixing, 5/88.

4. A. W. Neinow, B. Buckland, R. J. Weetman, Mixing XII Research Conference, Potosi, Mo., 8/89.

5. R. Calabrese et al., AIChE J. 32: 657, 677 (1986).

6. T. N. Zwietering, Chemical Engineering Science, 8(3): 244253 (1958).

7. J. Y. Oldshue, Chemical Engineering Progress, Mixing of Slurries Near

the Ultimate Settled Solids Concentration, 77(5): 9598 (1981).

Laser scan.

PASTE AND VISCOUS-MATERIAL MIXING

GENERAL REFERENCES: Dry Solids, Paste and Dough Mixing Equipment Testing Procedure, American Institute of Chemical Engineers, New York, 1979.

Fischer, Chem. Eng. 69(3): 52 (1962). Irving and Saxton, Mixing of High Viscosity Materials, in Uhl and Gray, Mixing Theory and Practice, vol. 2, Academic,

New York, 1967, chap. 8. Mohr, in Bernhardt, Processing of Thermoplastic Materials, Reinhold, New York, 1967, chap. 3. Parker, Chem. Eng. 71(12): 166 (1964).

Rauwendaal, Mixing in Polymer Processing, Marcel Dekker, 1991. Tadmor and

Gogos, Principles of Polymer Processing, Wiley, New York, 1979.

INTRODUCTION

Thick mixtures with viscosities greater than 10 Pas are not readily

mixed in conventional stirred pots with either propeller or turbine agitators. The high viscosity may be due to that of the matrix fluid itself,

to a high slurry concentration, or to interactions between components.

Because of the high viscosity, the mixing Reynolds number (Re =

D2N/) may be well below 100. Mixing occurs as a consequence of

laminar shearing and stretching forces, and turbulence plays no part.

Relative motion of an agitator stretches and deforms the material

between itself and the vessel wall. As a layer of fluid gets stretched into

thinner layers, the striations diminish and the shear forces tear solid

agglomerates apart until apparent homogeneity is obtained. When

solids are present, it may be necessary to reduce the particle size of the

solids, even down to submicron size, such as in pigment dispersion.

Mixers for high-viscosity materials generally have a small high shear

zone (to minimize dissipative heat effects) and rely on the impeller to

circulate all of the mixer contents past the high shear zone. It may be

necessary to take special steps to eliminate any stagnant zones or perhaps to avoid material riding around on mixing blades without being

reincorporated into the matrix.

Most paste and high-viscosity mixtures are nonnewtonian, with viscosity dropping with shear rate. Consequently, increasing impeller

speed may be counterproductive, as the transmitted shear drops

rapidly and an isolated hole may be created in the central mass without circulation of the bulk material in the remainder of the vessel.

The relative viscosities of the materials being mixed can be very

important. Karam and Bellinger [Ind. Eng. Chem. Fund. 7: 576

(1981)] and Grace [Engr. Fndn. Mixing Research Conf. Andover,

N.H., 1973] have shown that there is a maximum viscosity ratio ( dispersed/ continuous equal to about 4) above which droplets can no

longer be dispersed by shear forces. The only effective dispersing

mechanism for high-viscosity-ratio mixtures is elongational flow.

Equipment for viscous mixing usually has a small clearance

between impeller and vessel walls, a relatively small volume, and a

high power per unit volume. Intermeshing blades or stators may be

present to prevent material from cylindering on the rotating impeller.

Blade shape can have a significant impact on the mixing process. A

scraping profile will be useful if heat transfer is important, whereas a

smearing profile will be more effective for dispersion. Ease of cleaning and ease of discharge may also be important.

BATCH MIXERS

Change-Can Mixers Change-can mixers are vertical batch mixers

in which the container is a separate unit easily placed in or removed

from the frame of the machine. They are available in capacities of about

4 to 1500 L (1 to 400 gal). The commonest type is the pony mixer. Separate cans allow the batch to be carefully measured or weighed before

being brought to the mixer itself. The mixer also may serve to transport

the finished batch to the next operation or to storage. The identity of

each batch is preserved, and weight checks are easily made.

Change cans are relatively inexpensive. A good supply of cans

allows cleaning to be done in a separate department, arranged for efficient cleaning. In paint and ink plants, where mixing precedes milling

or grinding and where there may be a long run of the same formulation and color, the cans may be used for an extended period without

cleaning, as long as no drying out or surface oxidation occurs.

In most change-can mixers, the mixing elements are raised from the

can by either a vertical lift or a tilting head; in others, the can is

Copyright 1999 by The McGraw-Hill Companies, Inc. All rights reserved. Use of

this product is subject to the terms of its license agreement. Click here to view.

Anda mungkin juga menyukai

- TankjktDokumen57 halamanTankjktAnonymous 20VAru100% (2)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDokumen2 halamanDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaBelum ada peringkat

- K Value of FittingsDokumen4 halamanK Value of FittingsJoydip Misra100% (6)

- ECE 2416 JKUAT 2021 - Lecture NotesDokumen52 halamanECE 2416 JKUAT 2021 - Lecture NotesThomasBelum ada peringkat

- Tank Coils - Design and UseDokumen7 halamanTank Coils - Design and UseMartin DanzeBelum ada peringkat

- Heat Transfer in Jacketed VesselDokumen2 halamanHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Jacketed VesselDokumen4 halamanJacketed Vesselnithansa100% (1)

- Agitated VesselsDokumen24 halamanAgitated VesselsAnuj Kumar100% (1)

- Finned Tube Heat ExchangerDokumen2 halamanFinned Tube Heat ExchangerjnmanivannanBelum ada peringkat

- Heat Transfer Design Methods by John MC Ketta PDFDokumen607 halamanHeat Transfer Design Methods by John MC Ketta PDFAlberto LazzarettiBelum ada peringkat

- Dose Calc - Practice ProblemsDokumen3 halamanDose Calc - Practice Problemsapi-484630324Belum ada peringkat

- Agitated Vessel Heat Transfer (K.J. Carpenter)Dokumen9 halamanAgitated Vessel Heat Transfer (K.J. Carpenter)Clarence AG Yue100% (2)

- Agitated Vessel Heat TransferDokumen6 halamanAgitated Vessel Heat TransferkitofanecoBelum ada peringkat

- Dimple Jacket Heat Transfer EstimationDokumen3 halamanDimple Jacket Heat Transfer EstimationicingrockBelum ada peringkat

- Half Pipe CalculationDokumen3 halamanHalf Pipe CalculationCaptainTonies0% (1)

- Agitated Vessel Heat Transfer PDFDokumen6 halamanAgitated Vessel Heat Transfer PDFMuthuKumar ArunachalamBelum ada peringkat

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDokumen9 halamanHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeBelum ada peringkat

- Jacketed VesselsDokumen2 halamanJacketed VesselsImamRNBelum ada peringkat

- Calculation and Design of Speed and Power AgitatorDokumen4 halamanCalculation and Design of Speed and Power Agitatorkamlesh luharBelum ada peringkat

- Agitated Vessel Heat Transfer DesignDokumen3 halamanAgitated Vessel Heat Transfer Designvasudevanrv9405Belum ada peringkat

- Design of AgitatorDokumen3 halamanDesign of AgitatorManish PatelBelum ada peringkat

- NT42 Calculation Heat Transfer of Storage Tank Rail TankDokumen2 halamanNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHBelum ada peringkat

- Jacketed Reactor Vessel PDFDokumen1 halamanJacketed Reactor Vessel PDFSH1961Belum ada peringkat

- Design Calculations of Pitch Blade TurbineDokumen6 halamanDesign Calculations of Pitch Blade TurbineAyaz_HasanjiBelum ada peringkat

- Radiation and Convection Heat TransferDokumen5 halamanRadiation and Convection Heat TransfergsdaundhBelum ada peringkat

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDokumen3 halamanDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaBelum ada peringkat

- Calculation and Design of Critical Speed and Power AgitatorDokumen4 halamanCalculation and Design of Critical Speed and Power AgitatorFrendy RianBelum ada peringkat

- Limpet Coil DesignDokumen10 halamanLimpet Coil Designmaheshspawar0% (1)

- Design of Agitator 8 Batch Volume PDFDokumen3 halamanDesign of Agitator 8 Batch Volume PDFakash kumarBelum ada peringkat

- Agitator Vessel (Design&Costing)Dokumen34 halamanAgitator Vessel (Design&Costing)imrancenakk100% (2)

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDokumen8 halamanHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiBelum ada peringkat

- Calculation Overall Heat TransferDokumen4 halamanCalculation Overall Heat TransferDavid LambertBelum ada peringkat

- Dimpled Jacket 2Dokumen4 halamanDimpled Jacket 2grincheu7050% (2)

- Chapter - 9-Heat Transfer in Agitated VesselsDokumen44 halamanChapter - 9-Heat Transfer in Agitated VesselsSata Ajjam100% (2)

- Reactor WeightsDokumen2 halamanReactor WeightsleekiangyenBelum ada peringkat

- Jacketed Vessel Design CalculusDokumen4 halamanJacketed Vessel Design Calculusmaspiqdo100% (1)

- Design of AgitatorDokumen12 halamanDesign of AgitatorPatil HemantBelum ada peringkat

- Agitator Vessel Design CostingDokumen20 halamanAgitator Vessel Design CostingneelBelum ada peringkat

- 9.1 Overview: 9 Wiped Film EvaporatorDokumen12 halaman9.1 Overview: 9 Wiped Film EvaporatorNoman AslamBelum ada peringkat

- Calculation of Scrubber DiameterDokumen44 halamanCalculation of Scrubber DiameterRamakrishna SomuBelum ada peringkat

- Insulation For SCI ReactorDokumen12 halamanInsulation For SCI ReactorJogender DhayalBelum ada peringkat

- Agitated VesselDokumen8 halamanAgitated VesselBharatShethBelum ada peringkat

- AgitatorDokumen6 halamanAgitatorSung Woong MoonBelum ada peringkat

- Jacketed Vessel DesignDokumen5 halamanJacketed Vessel Designfunkkkky100% (1)

- Limpet Coil CalculationDokumen1 halamanLimpet Coil Calculationkirandas_mullassery100% (1)

- Jacketed Vessel PDFDokumen6 halamanJacketed Vessel PDFbroedenBelum ada peringkat

- DheerajDokumen7 halamanDheerajSaksham KakarBelum ada peringkat

- Method of Heat Exchanger Sizing (Kern Method)Dokumen11 halamanMethod of Heat Exchanger Sizing (Kern Method)Hani Kirmani80% (5)

- Design of Heat ExchangersDokumen23 halamanDesign of Heat ExchangersKhalid Turki100% (2)

- Agitator Design: HP CalculationDokumen32 halamanAgitator Design: HP CalculationJose Heli Vallejos CoronadoBelum ada peringkat

- Limpet Coil Reactor - 28-05Dokumen3 halamanLimpet Coil Reactor - 28-05AJAY138150% (2)

- Calculations On An Adiabatic Continuous DryerDokumen11 halamanCalculations On An Adiabatic Continuous DryerCaleb Somai0% (1)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86Dari EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86Belum ada peringkat

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Dari EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Penilaian: 5 dari 5 bintang5/5 (1)

- Handbook for Transversely Finned Tube Heat Exchanger DesignDari EverandHandbook for Transversely Finned Tube Heat Exchanger DesignBelum ada peringkat

- Semester No: 4: Name of The Discipline: Chemical EngineeringDokumen18 halamanSemester No: 4: Name of The Discipline: Chemical EngineeringSk jahidul IslamBelum ada peringkat

- Bi-Phase SeparatorDokumen19 halamanBi-Phase Separator1mmahoneyBelum ada peringkat

- Pages From Chapter 10 Mixing and AgitationDokumen4 halamanPages From Chapter 10 Mixing and AgitationDaniel PadillaBelum ada peringkat

- Hydrodynamic Study of Fixed Beds With Cocurrent Upflow and DownflowDokumen6 halamanHydrodynamic Study of Fixed Beds With Cocurrent Upflow and DownflowAbdelhamid OughanemBelum ada peringkat

- Process Transients AnalysisDokumen25 halamanProcess Transients AnalysisOtis ArmsBelum ada peringkat

- Sie Krishna RevChemEng 1998 Part 3Dokumen50 halamanSie Krishna RevChemEng 1998 Part 3Huzefa CalcuttawalaBelum ada peringkat

- Agitators: Robert L. Bates, President Chemineer, IncDokumen24 halamanAgitators: Robert L. Bates, President Chemineer, InctenshinomiyukiBelum ada peringkat

- Frictional Losses For Turbulent FlowDokumen1 halamanFrictional Losses For Turbulent Flowlolofm25Belum ada peringkat

- Europass CV Instructions enDokumen5 halamanEuropass CV Instructions enSaverio GrisorioBelum ada peringkat

- 1-Heat Transfer Design Methods (McKetta) PDFDokumen12 halaman1-Heat Transfer Design Methods (McKetta) PDFlolofm250% (1)

- Jacket Vessels. Overall CoefficientsDokumen1 halamanJacket Vessels. Overall Coefficientslolofm25Belum ada peringkat

- Roughness Reference PDFDokumen27 halamanRoughness Reference PDFlolofm25Belum ada peringkat

- Jeedyna PDFDokumen25 halamanJeedyna PDFlolofm25Belum ada peringkat

- Process Plant Layout and Piping DesignDokumen460 halamanProcess Plant Layout and Piping Design~E~97% (32)

- Liquid Line SizingDokumen12 halamanLiquid Line Sizinglolofm25Belum ada peringkat

- Piping Workbook PIDesignDokumen73 halamanPiping Workbook PIDesignUrsula MoeringsBelum ada peringkat

- Roughness Reference PDFDokumen27 halamanRoughness Reference PDFlolofm25Belum ada peringkat

- c22 c01Dokumen14 halamanc22 c01Robert Fortuny PonsBelum ada peringkat

- Catalitzadors Per A La Reacció IPA AcetonaDokumen14 halamanCatalitzadors Per A La Reacció IPA Acetonalolofm25Belum ada peringkat

- Pipe Segment-Swage PDFDokumen1 halamanPipe Segment-Swage PDFlolofm25Belum ada peringkat

- An Industrial Design Control Study For VAC Monomer Process PDFDokumen11 halamanAn Industrial Design Control Study For VAC Monomer Process PDFPY YouBelum ada peringkat

- An Industrial Design Control Study For VAC Monomer Process PDFDokumen11 halamanAn Industrial Design Control Study For VAC Monomer Process PDFPY YouBelum ada peringkat

- c22 c01Dokumen14 halamanc22 c01Robert Fortuny PonsBelum ada peringkat

- An Industrial Design Control Study For VAC Monomer Process PDFDokumen11 halamanAn Industrial Design Control Study For VAC Monomer Process PDFPY YouBelum ada peringkat

- Square Wave SimulinkDokumen10 halamanSquare Wave SimulinkEysha qureshiBelum ada peringkat

- Analysis of Failure Criteria Applied To Woo - 2013 - Engineering Failure AnalysiDokumen10 halamanAnalysis of Failure Criteria Applied To Woo - 2013 - Engineering Failure AnalysiArimateia SoaresBelum ada peringkat

- Ejemplos Resueltos 2020aDokumen39 halamanEjemplos Resueltos 2020aJardannyBelum ada peringkat

- Observation of Quantum Corrections To Conductivity Up To Optical FrequenciesDokumen8 halamanObservation of Quantum Corrections To Conductivity Up To Optical FrequenciesCarlos FazBelum ada peringkat

- D7425D7425M 13Dokumen3 halamanD7425D7425M 13diego rodriguez100% (1)

- Reinforcement of PlateDokumen33 halamanReinforcement of PlateUmer FarooqBelum ada peringkat

- Interpretation of DSC Curves in Polymer Analysis 2000 - ToledoDokumen0 halamanInterpretation of DSC Curves in Polymer Analysis 2000 - ToledoyrecoverBelum ada peringkat

- Idemitsu - Mechanic Oil SeriesDokumen2 halamanIdemitsu - Mechanic Oil SeriesarieprachmanBelum ada peringkat

- Residual Stresses in Weld JointsDokumen8 halamanResidual Stresses in Weld Jointshayder1920Belum ada peringkat

- BEC701 - Fibre Optic Communication PDFDokumen201 halamanBEC701 - Fibre Optic Communication PDFMax DurendBelum ada peringkat

- Fluid Properties LabDokumen18 halamanFluid Properties LabsilasBelum ada peringkat

- Solved Problems in PhysicsDokumen22 halamanSolved Problems in Physicsvasudevan m.vBelum ada peringkat

- 7 Review of Fundamentals - Heat and Mass TransferDokumen20 halaman7 Review of Fundamentals - Heat and Mass TransferPRASAD326100% (2)

- Almansoori Inspection Services: Travelling Block AssemblyDokumen2 halamanAlmansoori Inspection Services: Travelling Block AssemblyRanjithBelum ada peringkat

- ISU - Ilagan Module Foundation EngineeringDokumen7 halamanISU - Ilagan Module Foundation EngineeringRanie boy CabanillaBelum ada peringkat

- Norma MAT2004Dokumen12 halamanNorma MAT2004Marcelo Carvalho100% (1)

- Module 2 - Rectilinear MotionDokumen33 halamanModule 2 - Rectilinear MotionRozel100% (2)

- Analysis of The Bell-Type Inequalities On The IBM's Open-Access Quantum ComputerDokumen5 halamanAnalysis of The Bell-Type Inequalities On The IBM's Open-Access Quantum ComputerYulied Porras RamírezBelum ada peringkat

- Imaging Techniques in Biomedical Engineering (Thermal Imaging)Dokumen67 halamanImaging Techniques in Biomedical Engineering (Thermal Imaging)Karminder SinghBelum ada peringkat

- Group 2 Notes (Sem 2)Dokumen7 halamanGroup 2 Notes (Sem 2)Geethanjali SivakumarBelum ada peringkat

- Temperature ControlDokumen60 halamanTemperature ControlKmilo Giraldo100% (4)

- Acoustic Emission Monitoring During Resistance Spot-WeldingDokumen6 halamanAcoustic Emission Monitoring During Resistance Spot-WeldingROHITBelum ada peringkat

- Ejersicios Cap2Dokumen14 halamanEjersicios Cap2Jaime AguilarBelum ada peringkat

- Innovative Push Launching Technique For Long Span BridgeDokumen8 halamanInnovative Push Launching Technique For Long Span BridgeAnkit GuptaBelum ada peringkat

- Observing Microorganisms Through A MicroscopeSV PDFDokumen3 halamanObserving Microorganisms Through A MicroscopeSV PDFFelipe Andrés JorqueraBelum ada peringkat

- Random Document of Physics Definitions For LC 2024Dokumen12 halamanRandom Document of Physics Definitions For LC 2024bobby alexanderBelum ada peringkat

- Flexural Design of Reinforced Concrete Beam SectionsDokumen15 halamanFlexural Design of Reinforced Concrete Beam SectionsAamir HaideriBelum ada peringkat

- A Slurry Consolidation Approach To Reconstitute Low-Plasticity Silt Specimens For Laboratory Triaxial TestingDokumen9 halamanA Slurry Consolidation Approach To Reconstitute Low-Plasticity Silt Specimens For Laboratory Triaxial TestingFrancyBelum ada peringkat