MB0044 Slides Unit 04

Diunggah oleh

Saagar KarandeHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MB0044 Slides Unit 04

Diunggah oleh

Saagar KarandeHak Cipta:

Format Tersedia

MB0044-Production and Operations Management

Unit-4 Forecasting

Program

: MBA

Semester

: II

Subject Code

: MB0044

Subject Name

: Production and Operations Management

Unit number

:4

Unit Title

: Forecasting

Lecture Number

:4

Lecture Title

: Forecasting

1

HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Production and Operations Management

Objectives:

After studying this unit, you should be able to:

Describe forecasting

Explain the strategic importance, cost implementation and

decision making of forecasting

Classify forecasting process

List the methods of forecasting

Explain product life cycle and time series

Describe associative models of forecasting

Explain accuracy of forecasting

2

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Lecture Outline

Introduction

Strategic Importance of Forecasting

Why Forecasting is Required

Cost Implementations of Forecasting

Decision Making Using Forecasting

Classification of Forecasting Process

Methods of Forecasting

Quantitative Methods

Product Life Cycle

Associative Models of Forecasting

Accuracy of Forecasting

Summary

Check Your Learning

Activity

3

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Introduction

Forecasting is the art and science of predicting the future events.

Forecasting may involve taking historical data and projecting them

into the future with some sort of mathematical model.

Forecasting is synonymous with estimating and prediction, though

forecasting is considered to be more scientific rather than a crude or

vague guesswork.

In this session, you will learn about the importance of forecasting, the

cost implementations of forecasting, the process for decision making

using forecasting, the classifications and methods of forecasting, the

selection of the forecasting method and the associative models of

forecasting.

4

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Strategic Importance of Forecasting

Forecasting influences three key activities. They are:

Human

Resources

The number of persons required is a

function of the production output which, in

turn, depends on demand forecasting

Capacity

Capacity refers to the ability to meet the

demand in terms of resources and the

preparedness on the part of the company

Supply Chain

Management

Supply chain management refers to all the

activities that enable the right product at

the right place at the right price

5

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Why Forecasting is Required

Forecasting is required for:

Production planning

Financial planning

Personnel planning

Scheduling planning

Facilities planning

Process design and planning

Forecasting helps to:

Improve employee relations

Improve materials management

Get better use of capital and facilities

Improve customer service

6

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Cost Implementations of Forecasting

Forecasting requires special efforts and involves inputs from experts which cost a

lot to the companies. Well-trained experts and associations substantially invest in

human resources and hence charge their clients for the service rendered.

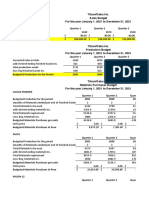

From the above figure, it is understood that to keep the total cost of

forecasting to a minimum, it is necessary that the forecasting effort has to be

raised up to a level at which certain uncertainty is acceptable and hence,

there is preparedness for some possible loss.

7

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Decision Making using Forecasting

Forecasts are always subject to uncertainty because of the changing

environment and hence, any attempt to improve the forecast accuracy only

increases the cost but not the accuracy. Keeping this in mind, the managerial

decision makers adopt the following rule:

Actual decision = Decision assuming forecasting is correct + Allowance for

forecast error

The error in forecast is calculated by:

Forecast error = Actual demand Forecast

Demand

The figure depicts the process of

forecasting and the associated factors.

8

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Classification of Forecasting Process

The different forecasting methods based on the context or focus are:

Based on

type of

database

Quantitative

Qualitative

Based on

forecast

time period

Based on

methodology

Short range

Time

methods

Medium

range

Casual

methods

Long range

Predictive

methods

9

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Methods of Forecasting

Qualitative methods

Quantitative methods

Market surveys

Time series

analysis

Causal

methods

Nominal group

testing

Moving

averages

Exponential

moving

averages

Box

Jenkins

method

Trend

projections

Fourier series

Regression

analysis

Input

output model

Leading

indicators

Simulations

model

Economic

models

Historical

analysis

Jury of executive

opinion

Life cycle

analysis

Delphi method

10

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Quantitative Methods

Quantitative methods include Time series, Nave method, Moving average

method, and Exponential smoothing method.

A time series is defined as a set of values pertaining to a variable collected

at regular intervals. The figure shown below depicts the components of a

time series.

Components of a Time Series

11

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Product Life Cycle

The demand for a product keeps changing as it passes through different

stages in its life cycle. The demand starts with zero value and keeps rising

as the product moves along the life cycle and gradually diminishes once the

product is outdated or obsolete. The figure depicts the product life cycle and

volume of demand graphically.

12

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Selection of Forecasting Method

Because cost, time, and skills are involved, the choice of a forecasting

method is based on several factors. They are:

Form of forecast required

Forecast horizon, period,

and interval

Data availability

Accuracy required

Behaviour of process

being forecasted

Cost of development,

installation, and operation

Case of operation

Management comprehension and

cooperation

13

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Associative Models of Forecasting

Regression and correlation techniques are means of describing

association between two or more variables. Two types of regressions

simple and multiple regression. Regression is also categorised as linear

nonlinear regression based on the severity of relationship

characteristics. The following table shows the examples.

Simple

Multiple

Linear

Y= a +b x

Y=a+bx1+cx2+dx3

Non-linear

Y= a+bx2

Y=A+BX1+CX22+DX33

the

are

and

and

The forecasting procedures using regression involves the following steps:

1. The variables are plotted along Cartesian or rectangular coordinates

2. A trend equation is developed

3. The equation is used for forecasting

4. The variables are not necessarily related on a time basis

14

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Accuracy of Forecasting

Several measures of error in forecast have been developed to examine the

issue of error in forecast. Here, we look at two widely used and popular

measure applicable to a wide variety of methods. These two measures are:

Mean Absolute

Deviation

(MAD)

MAD is often used to

measure how closely

forecast values are

matching the actual

data.

MAD = Sum of absolute

deviations for n periods

/ number of periods.

Standard Error

(SE) of

estimate

The standard error of

estimate measures the

variability or scatter of

the observed values

around the regression

line.

The formula for

calculating SE is:

15

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Summary

Forecasting is the art and science of predicting the future events.

The three activities of forecasting are Human resources, Capacity and

Supply chain management.

Forecasting basically helps to overcome the uncertainty about the

demand and thus provides a workable solution.

Forecasting requires special efforts and involves inputs from experts

which cost a lot to the companies.

Forecasting is broadly classified as quantitative and qualitative.

Qualitative methods include Market survey, Delphi method, Historical

analysis and quantitative methods include Time series analysis and

Causal methods.

The two measures of error in forecast developed to examine the issue of

error in forecast are Mean Absolute Deviation and Standard Error of

Estimate.

16

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Check Your Learning

1. Name the types of forecasting methods?

Ans: The forecasting methods can be classified into:

Quantitative

Qualitative

2. Why is forecasting required?

Ans: Forecasting is required for:

Production planning

Financial planning

Personnel planning

Scheduling planning

Facilities planning

Process design and planning

17

PREVIOUS HOME

CNEXT

onfidential

MB0044-Production and Operations Management

Unit-4 Forecasting

Activity

Assume that you are the sales manager in a company that manufactures

cars. Your company wants to manufacture a SUV for the high-end users

and has asked you to prepare a report to forecast sales of SUVs for this

segment. What are the factors that you will consider to make this report?

Which forecast method will be suitable for this purpose?

18

PREVIOUS HOME

Confidential

Anda mungkin juga menyukai

- Mb0028 Set 02 VKGDokumen12 halamanMb0028 Set 02 VKGAmbrishBelum ada peringkat

- Chap 4 - BPRDokumen49 halamanChap 4 - BPRsuradevBelum ada peringkat

- MB0044 Slides Unit 02Dokumen16 halamanMB0044 Slides Unit 02Saagar KarandeBelum ada peringkat

- Operation Management NotesDokumen30 halamanOperation Management NotesRenato WilsonBelum ada peringkat

- PAE AcFn621Ch-4a Project Alaysis and SelectionDokumen42 halamanPAE AcFn621Ch-4a Project Alaysis and SelectionProf. Dr. Anbalagan ChinniahBelum ada peringkat

- Course Pack - Operations ManagementDokumen34 halamanCourse Pack - Operations ManagementSARBIKPAUL CHOWDHURYBelum ada peringkat

- CNA Brochure FinalDokumen4 halamanCNA Brochure FinalJurun_BidanshiBelum ada peringkat

- BA DeptDokumen14 halamanBA DeptAnirban GhoshBelum ada peringkat

- Opm549 Individual Assignment 2 - Muhd Adib Bin Daman Huri 2021239468Dokumen14 halamanOpm549 Individual Assignment 2 - Muhd Adib Bin Daman Huri 2021239468muhd adibBelum ada peringkat

- Outsourcing Strategies For Capital ProductivityDokumen9 halamanOutsourcing Strategies For Capital ProductivitySunnyVermaBelum ada peringkat

- Ch1 ME IntroductionDokumen50 halamanCh1 ME IntroductionYonas BEZUBelum ada peringkat

- Society of Workforce Planning Professionals: Workforce Management Certification ProjectDokumen6 halamanSociety of Workforce Planning Professionals: Workforce Management Certification ProjectSyed Wamiq HaiderBelum ada peringkat

- Kik Dev PresentationDokumen22 halamanKik Dev Presentationjustin29600Belum ada peringkat

- Revisi PPT4-Process StrategyDokumen32 halamanRevisi PPT4-Process StrategyAbdul GhoniBelum ada peringkat

- MB 0044 - Production and Operation ManagementDokumen8 halamanMB 0044 - Production and Operation ManagementdeepmaniarBelum ada peringkat

- Moving To CMMI Level 4 (SW/SE/IPPD) : CMMI User Conference Denver, Colorado November 2003 Sarah Bengzon, Associate PartnerDokumen17 halamanMoving To CMMI Level 4 (SW/SE/IPPD) : CMMI User Conference Denver, Colorado November 2003 Sarah Bengzon, Associate Partnerfire_mBelum ada peringkat

- Application of Six-Sigma in FinanceDokumen12 halamanApplication of Six-Sigma in Financeani198609Belum ada peringkat

- Operations Management Lesson 13Dokumen53 halamanOperations Management Lesson 13KristianBelum ada peringkat

- Production and ManagementDokumen10 halamanProduction and ManagementNageshwar singhBelum ada peringkat

- BA4204 OPERATIONS MANAGEMENT ALL UNITS 2 MARksDokumen16 halamanBA4204 OPERATIONS MANAGEMENT ALL UNITS 2 MARksKrish RavanaBelum ada peringkat

- MB 0044 - Production and Operation Management: Q1. State The Important Considerations For Locating An Automobile PlantDokumen9 halamanMB 0044 - Production and Operation Management: Q1. State The Important Considerations For Locating An Automobile PlantSaju AugustineBelum ada peringkat

- Production and Operation Management: Mba 3 SemesterDokumen27 halamanProduction and Operation Management: Mba 3 SemesterDerajuddin AhmedBelum ada peringkat

- Importance of ForecastingDokumen37 halamanImportance of ForecastingFaizan TafzilBelum ada peringkat

- Business Process Reengineering: Dhruv Mukeshkumar PrajapatiDokumen25 halamanBusiness Process Reengineering: Dhruv Mukeshkumar PrajapatiKarthi SiddhBelum ada peringkat

- POMADokumen4 halamanPOMAMuhammad Umer Anjum MirzaBelum ada peringkat

- Placement Preparation Kit - OperationsDokumen65 halamanPlacement Preparation Kit - OperationsPringles JinglesBelum ada peringkat

- Supply Chain ManagementDokumen21 halamanSupply Chain ManagementMacy AndradeBelum ada peringkat

- Information For Planning and ControlDokumen35 halamanInformation For Planning and Controlhooriya naseemBelum ada peringkat

- Operation Management NotesDokumen30 halamanOperation Management Notesthamizt72% (18)

- B.S Anangpuria Institute of Technology and Management FaridabadDokumen92 halamanB.S Anangpuria Institute of Technology and Management Faridabadwigivi4421Belum ada peringkat

- PM CreationsDokumen20 halamanPM CreationsTesfaye KebedeBelum ada peringkat

- TOPIC 11-Decision Making ProcessDokumen19 halamanTOPIC 11-Decision Making ProcessKevin RiveraBelum ada peringkat

- Total Quality Management Short NoteDokumen4 halamanTotal Quality Management Short NoteHazim IzzatBelum ada peringkat

- Assignments-Mba Sem-Ii: Subject Code: MB0028Dokumen9 halamanAssignments-Mba Sem-Ii: Subject Code: MB0028Anu AhamadBelum ada peringkat

- MB0044 Assignment Spring 2013Dokumen7 halamanMB0044 Assignment Spring 2013sandy065Belum ada peringkat

- OpMan and TQM Chapter 3Dokumen17 halamanOpMan and TQM Chapter 3Kadmiel CarlosBelum ada peringkat

- Operation Management Notes 130126072649 Phpapp02 PDFDokumen30 halamanOperation Management Notes 130126072649 Phpapp02 PDFBalu ABelum ada peringkat

- PM 7Dokumen27 halamanPM 7Ahmed SaeedBelum ada peringkat

- Project Monitoring, Evaluation, and Control: Establishing StandardsDokumen13 halamanProject Monitoring, Evaluation, and Control: Establishing StandardsClement Ader SekouBelum ada peringkat

- Operational Efficiency Sample OnlyDokumen5 halamanOperational Efficiency Sample OnlyhellowodBelum ada peringkat

- Q.1 What Do You Understand by Vendor-Managed Inventory (VMI) ?Dokumen21 halamanQ.1 What Do You Understand by Vendor-Managed Inventory (VMI) ?Amar GiriBelum ada peringkat

- TQM ToolsDokumen29 halamanTQM Toolsविवेक शर्माBelum ada peringkat

- TQM Chapter 4 Process FocusDokumen37 halamanTQM Chapter 4 Process Focusreyeselis0823Belum ada peringkat

- Integration ManagementDokumen32 halamanIntegration ManagementAct VjBelum ada peringkat

- Useful Key Performance Indicators For MaintenanceDokumen6 halamanUseful Key Performance Indicators For MaintenanceAtul BurangeBelum ada peringkat

- Ibf Conference Shanghai Mar11Dokumen11 halamanIbf Conference Shanghai Mar11sagarsononiBelum ada peringkat

- Operation Management NotesDokumen29 halamanOperation Management NotesAbhishek PathakBelum ada peringkat

- Capacity Planning Imp TopicsDokumen9 halamanCapacity Planning Imp TopicsAryan RaiBelum ada peringkat

- Chapter 3 - Demand ForecastingDokumen43 halamanChapter 3 - Demand ForecastingHello WorldBelum ada peringkat

- Demand and Supply ManagementDokumen31 halamanDemand and Supply Managementbelanineha5Belum ada peringkat

- Two Marks BA9221.Dokumen9 halamanTwo Marks BA9221.sanmira_geetha5271Belum ada peringkat

- Preparing Your Production PlanDokumen9 halamanPreparing Your Production PlanwentropremBelum ada peringkat

- Engineering Management KNR 4553 / KNL 4603: Topic 3 - PlanningDokumen23 halamanEngineering Management KNR 4553 / KNL 4603: Topic 3 - PlanningrpjongBelum ada peringkat

- MB0044 Production and Opn MRMTDokumen7 halamanMB0044 Production and Opn MRMTMohammed IsmailBelum ada peringkat

- Om 11Dokumen16 halamanOm 11गब्बर जाटBelum ada peringkat

- Day 15 - BUS212 2Dokumen15 halamanDay 15 - BUS212 2Amrit SainiBelum ada peringkat

- Operation Management ReviewerDokumen10 halamanOperation Management ReviewerMebelle LoronoBelum ada peringkat

- Banking: An Introduction: December 2013Dokumen2 halamanBanking: An Introduction: December 2013Happy Surjya DaimaryBelum ada peringkat

- Monday Tuesday Wednesday Breakfast Lunch Snacks DinnerDokumen3 halamanMonday Tuesday Wednesday Breakfast Lunch Snacks DinnerSaagar KarandeBelum ada peringkat

- Oracle Banking Payments: US CHIPS User Guide Release 14.4.0.0.0Dokumen42 halamanOracle Banking Payments: US CHIPS User Guide Release 14.4.0.0.0Saagar KarandeBelum ada peringkat

- Dell Emc Poweredge R740 and R740Xd: Technical GuideDokumen56 halamanDell Emc Poweredge R740 and R740Xd: Technical GuideSaagar KarandeBelum ada peringkat

- Important+Instructionsfrom Valid SirDokumen4 halamanImportant+Instructionsfrom Valid SirSaagar KarandeBelum ada peringkat

- Manual: Training - Debugger BasicsDokumen164 halamanManual: Training - Debugger BasicsSaagar KarandeBelum ada peringkat

- Mackenzie Mountains: Jump To Navigationjump To SearchDokumen3 halamanMackenzie Mountains: Jump To Navigationjump To SearchSaagar KarandeBelum ada peringkat

- Presentation To Analysts and Investors: Merchant BankingDokumen20 halamanPresentation To Analysts and Investors: Merchant BankingSaagar KarandeBelum ada peringkat

- Tasty Chips Electronics ECR-1/ECR+ User ManualDokumen13 halamanTasty Chips Electronics ECR-1/ECR+ User ManualSaagar KarandeBelum ada peringkat

- Python History and InformationDokumen12 halamanPython History and InformationSaagar KarandeBelum ada peringkat

- Open On-Chip Debugger: Openocd User'S Guide: For Release 0.11.0+dev 25 July 2022Dokumen219 halamanOpen On-Chip Debugger: Openocd User'S Guide: For Release 0.11.0+dev 25 July 2022Saagar KarandeBelum ada peringkat

- Shakespear in MindDokumen1 halamanShakespear in MindSaagar KarandeBelum ada peringkat

- Chips 3 0 Wireless Helmet Headphones ManualDokumen6 halamanChips 3 0 Wireless Helmet Headphones ManualSaagar KarandeBelum ada peringkat

- Mackenzie RiverDokumen1 halamanMackenzie RiverSaagar KarandeBelum ada peringkat

- AutobiographyDokumen2 halamanAutobiographySaagar KarandeBelum ada peringkat

- Published Journals On North PassageDokumen1 halamanPublished Journals On North PassageSaagar KarandeBelum ada peringkat

- The Non ExistenceDokumen1 halamanThe Non ExistenceSaagar KarandeBelum ada peringkat

- Lunar Module Eagle: Apollo 11 50th Anniversary Commemorative CoinsDokumen1 halamanLunar Module Eagle: Apollo 11 50th Anniversary Commemorative CoinsSaagar KarandeBelum ada peringkat

- Tirthankara Kayotsarga Shankha Garbhagriha Ardhamandapa Mahamandapa Ranga Mandapa Shikhara Manasthamba Yakshas YakshiniDokumen1 halamanTirthankara Kayotsarga Shankha Garbhagriha Ardhamandapa Mahamandapa Ranga Mandapa Shikhara Manasthamba Yakshas YakshiniSaagar KarandeBelum ada peringkat

- Alexander Mackenzie (Explorer) : Jump To Navigation Jump To SearchDokumen5 halamanAlexander Mackenzie (Explorer) : Jump To Navigation Jump To SearchSaagar KarandeBelum ada peringkat

- Autobiography of A Versatile YogiDokumen4 halamanAutobiography of A Versatile YogiSaagar KarandeBelum ada peringkat

- DictatorDokumen3 halamanDictatorSaagar KarandeBelum ada peringkat

- Dramatically Simple and Proven Device Security ManagementDokumen1 halamanDramatically Simple and Proven Device Security ManagementSaagar KarandeBelum ada peringkat

- The Northwest PassageDokumen1 halamanThe Northwest PassageSaagar KarandeBelum ada peringkat

- Abascus UnlimitedDokumen4 halamanAbascus UnlimitedSaagar KarandeBelum ada peringkat

- Ready To Replace An Old Switch?: Compares To Older Models Cisco Active Advisor Trade-In Your Old Switch and Save!Dokumen11 halamanReady To Replace An Old Switch?: Compares To Older Models Cisco Active Advisor Trade-In Your Old Switch and Save!Saagar KarandeBelum ada peringkat

- Shakespear InsightsDokumen2 halamanShakespear InsightsSaagar KarandeBelum ada peringkat

- Tl-wr741nd v5 User GuideDokumen118 halamanTl-wr741nd v5 User GuideZajciBelum ada peringkat

- Numbe R Port Speed Numb Er of Ports Uplinks Softwa Re Image When To BuyDokumen9 halamanNumbe R Port Speed Numb Er of Ports Uplinks Softwa Re Image When To BuySaagar KarandeBelum ada peringkat

- Product Overview: Switch ConfigurationsDokumen26 halamanProduct Overview: Switch ConfigurationsSaagar KarandeBelum ada peringkat

- Project ReportBanty Kumar VermaDokumen126 halamanProject ReportBanty Kumar VermagunjanBelum ada peringkat

- Mandy Craven: Career ObjectiveDokumen2 halamanMandy Craven: Career ObjectiveMandy CravenBelum ada peringkat

- Ashishgupta3554 ResumeDokumen1 halamanAshishgupta3554 ResumeAshish GuptaBelum ada peringkat

- Analysis On Apollo Tyres LTDDokumen43 halamanAnalysis On Apollo Tyres LTDCHAITANYA ANNEBelum ada peringkat

- Test Bank For Financial Reporting and Analysis 13th Edition Charles H GibsonDokumen36 halamanTest Bank For Financial Reporting and Analysis 13th Edition Charles H Gibsonbdelliumtiliairwoct100% (42)

- Problem: Regular Model Advanced Model Deluxe ModelDokumen8 halamanProblem: Regular Model Advanced Model Deluxe ModelExpert Answers100% (1)

- Database PanteneDokumen4 halamanDatabase PanteneYahya CahyadiBelum ada peringkat

- Example of RFP For Credit ScoringDokumen4 halamanExample of RFP For Credit ScoringadaquilaBelum ada peringkat

- Form Restoran Sederhana Masakan PadangDokumen30 halamanForm Restoran Sederhana Masakan PadangLuthfi's Mzakki'sBelum ada peringkat

- w9 - L2 - Review For Lecture Midterm 2Dokumen14 halamanw9 - L2 - Review For Lecture Midterm 2Rashid AyubiBelum ada peringkat

- Report On Corporate Communication Strategy Analysis ofDokumen38 halamanReport On Corporate Communication Strategy Analysis ofNAFISA ISLAMBelum ada peringkat

- Accounting Standard 5-8Dokumen36 halamanAccounting Standard 5-8Aseem1Belum ada peringkat

- INTERN 1 DefinitionsDokumen2 halamanINTERN 1 DefinitionsJovis MalasanBelum ada peringkat

- Constitutional Provisions For Labor Law PhilippinesDokumen1 halamanConstitutional Provisions For Labor Law PhilippinesAgnes GamboaBelum ada peringkat

- Bookkeeping Problems Batch 1Dokumen2 halamanBookkeeping Problems Batch 1lanz kristoff racho100% (1)

- Factory Audit ReportDokumen33 halamanFactory Audit ReportMudit Kothari100% (1)

- What Are Key Performance IndicatorsDokumen13 halamanWhat Are Key Performance IndicatorsKharieh Comb's100% (1)

- 5s Audit Check SheetDokumen1 halaman5s Audit Check SheetDevendra Singh100% (1)

- Gain Sheet - 2020 - FormatDokumen5 halamanGain Sheet - 2020 - FormatMohd MazidBelum ada peringkat

- Workplace Housekeeping: Training Slides OnDokumen42 halamanWorkplace Housekeeping: Training Slides Onamit yadavBelum ada peringkat

- Sps Oco V Limbaring DigestDokumen1 halamanSps Oco V Limbaring DigestReena MaBelum ada peringkat

- Frauds in Indian Banking SectorDokumen5 halamanFrauds in Indian Banking SectorPayal Ambhore100% (1)

- Leadership & Innovation BrochureDokumen10 halamanLeadership & Innovation BrochureFiona LiemBelum ada peringkat

- Mid Term Exam 1 - Fall 2018-799Dokumen3 halamanMid Term Exam 1 - Fall 2018-799abdirahmanBelum ada peringkat

- Kabushi Kaisha Isetan Vs IacDokumen2 halamanKabushi Kaisha Isetan Vs IacJudee Anne100% (2)

- Labour Rights in Vietnam: Unilever's Progress and Systemic ChallengesDokumen76 halamanLabour Rights in Vietnam: Unilever's Progress and Systemic ChallengesOxfamBelum ada peringkat

- EXPORTDokumen99 halamanEXPORTdhruv81275Belum ada peringkat

- Acctg 202 Di Pa FinalDokumen10 halamanAcctg 202 Di Pa FinalJoshua CabinasBelum ada peringkat

- One Point LessonsDokumen27 halamanOne Point LessonsgcldesignBelum ada peringkat

- ADS Landscape RecommendationsDokumen7 halamanADS Landscape Recommendationslkumar_inBelum ada peringkat