RA 002 - LPSG Steam Pipe Hot Work in ER

Diunggah oleh

dassi99Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

RA 002 - LPSG Steam Pipe Hot Work in ER

Diunggah oleh

dassi99Hak Cipta:

Format Tersedia

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

RISK MANAGEMENT

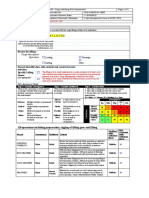

Operation / Work activity being assessed:

Generated by: Vessel

RA Code number:

LPSG Steam Pipe Hot Work in ER

Routine

Non-routine

Office

(record the name)

ALTERNATIVE WAYS TO CONDUCT THE WORK (Prior to deciding to proceed with the work always ensure that all other alternatives methods

for carrying out the job have been identified and documented )

No alternative ways to conduct this work available.

FREQUENCY CATEGORY

CONSEQUENCE CATEGORY

Frequent - Possibility of

repeated incidents

Probable - Possibility of

isolated incidents

More often than

once per voyage

Once per year

Occasional- Possibility of

occurring sometime

Once per 5 years

Remote- Not likely to occur

Once per 10 years

Very unlikely- Practically

impossible

Once per 30 years

or more

CECONSEQUEN

1

2

3

4

Human losses / fatalities

Major pollution /

Full scale response

Serious injury to

personnel

Moderate pollution/

Significant resources commitment

Number of minor

injuries / Medical

treatment for personnel

Little pollution /

Limited response of short duration

Little cost or damage

($10000 $ 100000)

Slight impact

Few minor injuries

Minimum pollution /

Little or no response needed

Minimum cost /

damage

< $10000

Zero impact

1

L (1)

L (2)

RISK MATRIX

FREQUENCY

2

3

L (2)

L (3)

M(4)

M(6)

4

M (4)

H(8)

5

M (5)

H(10)

L(3)

M(6)

H(9)

H(12)

H(15)

M(4)

H(8)

H(12)

H(16)

H(20)

Excessive/ high cost

damage >$1000000

Moderate cost or

damage

(100000 1000000$)

Major national &

international impact

Considerable

impact

High=Intolerable Risk Medium=Tolerable Risk Low=Negligible Risk

Risk Assessment

Risk Identification

No

Hazard

Leakage of O2/acetylene.

Issue No. / Date: 1 / 02.07

Risk Analysis

Potential

hazardous event

Fire explosion

Initial risk

evaluation

Existing control measures

Periodic inspection of the

O2/acetylene fixed piping system (as

per PMS).

The gas supply flexible hoses should

be inspected to confirm their good

condition (i.e. no extensive wear &

tear, no kinks, no cuts etc.).

The welding/cutting torch and

associated fittings should be

inspected to confirm their good

condition (i.e. nozzle/isolation valves

in good condition, no broken parts, no

mechanical damage etc.).

In case of temporary suspension and

Revision No. / Date: 2 / 05.14

Page 1 of 6

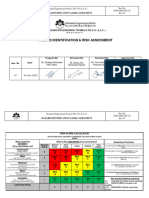

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Flame flashback in the gas piping.

Presence of flammable vapours/

combustible materials in the working area.

Issue No. / Date: 1 / 02.07

Risk Analysis

Potential

hazardous event

Fire explosion

Fire explosion

Existing control measures

after completion of the work, supply

valves on gas cylinders and gas

mains should be securely closed and

the flexible hoses de-pressurized.

Welding/cutting work (SMS 7.9.3).

It should be ensured that flashback

arresters fitted at the work station and

at the bottles storage space, are in

good order.

Hot work inside a designated space

(ISGOTT 9.4.2)

It should be ensured that the working

area is clean from any

flammable/combustible materials (i.e.

oily rags, chemical drums, waste oils

etc.).

The hot work should NOT be carried

out concurrently with any cargo/tank

cleaning/gas

freeing/purging/inerting/bunkering

operation.

The material/equipment to be

welded/cut should have been cleaned

from any combustible/flammable

residues.

Work should be carried out with shield

or curtain erected and the ventilation

switched on.

When checking the atmosphere in the

E/R, particular attention should be

given to the bilges area so as to

ensure that is less than 1% LFL.

The atmosphere in the space to be

monitored by a multi gas detection

instrument so as to ensure that is

maintained less than 1% LFL

Cargo tanks pressure should be kept

in normal operating condition and

below 180 mbr. A poster on the CCR

and Bridge, will inform the officers

that a Hot work is in progress and the

rise of the tanks pressure above 180

mlb, should not be allowed. If in any

case the cargo tanks pressure is out

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

Page 2 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Sparks/melting steel flying in the area.

Risk Analysis

Potential

hazardous event

Fire explosion

Existing control measures

Inadequate competence/experience.

Electricity hazard (during arc welding/

cutting).

Issue No. / Date: 1 / 02.07

Personal

injury/property

damage

Personal injury

of control, job will be seized.

To the extent possible, any

prefabrication work (e.g. pipework

and supports) should be carried out in

the E/R Workshop

Adequate fire-fighting equipment

must be prepared and laid out and be

ready for immediate use.

A Fire Watch must be established for

the area of Hot Work and for

adjacent, spaces where the transfer

of heat, or accidental damage might

create a hazard, e.g. damage to

hydraulic lines, electrical cables,

thermal oil lines, etc. The fire watch

should monitor the work and take

action in case of ignition of residues

or paint coatings.

No Hot Work should be carried out on

bulkheads of bunker tanks, or within

500 mm of such bulkheads, unless

that tank is cleaned to Hot Work

standard

Hot Work (SMS 7.9.3)

In addition to 3D, the portable fire

extinguishers should be readily

available for use.

Initial risk

evaluation

The person assigned by the Chief

Engineer to carry out the hot work

must be experienced and qualified.

The C/E or the 2nd Engineer (if

designated) should supervise the

work.

Welding/cutting work (SMS 7.9.3)

It should be ensured that the

insulation of the flexible electric

cables as well as of the electrode

holder is good condition (i.e. no cuts,

no kinks, no excessive wear & tear).

The earth return cable should lead

directly back to the welding machine.

The ships structure should not be

used as an earth return.

Ensure that personnel involved is

Revision No. / Date: 2 / 05.14

Page 3 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Radiation hazard (which could cause eye

injury/heat burn).

Risk Analysis

Potential

hazardous event

Personal injury

Emission of smoke during welding/cutting.

Personal injury

Heat transfer to the bulkhead

Fire explosion

10

11

High temperature in the working area

Adverse weather

Issue No. / Date: 1 / 02.07

Fire explosion

Personal

Existing control measures

properly clothed and equipped as

required (i.e. wearing welders gloves,

aprons, welding helmets and non

conducting rubber boots).

The electric cable to be used should

have the less possible length (to

avoid overheating).

Welding/cutting work (SMS 7.9.3)

The visor cover glass of the welders

helmet should be checked to confirm

its good condition (i.e. no crack, no

damage by weld spatter).

For Arc welding, the correct filter

shade should be selected according

to the welding process, wire diameter,

and operating current.

Welding/cutting work (SMS 7.9.3)

Hot Work (SMS 7.9.3)

Procedures for intentional and

temporary disconnection of a fire

detector (SMS 10.1.15.3)

Hot Work (SMS 7.9.3)

The Metal to be welded on the

welding table should not touch the

bulkhead

In case the size of the metal to be

welded is quite big then a protective

shield to be placed on the bulk head

OR the table to move at least 50 cm

further away from the bulkhead if not

possible to change location of welding

operation into the workshop

The flame should not touch the

bulkhead or the direction of the flame

should not be towards the bulkhead If

the distance is less than 50 cm

Hot Work (SMS 7.9.3)

Adequate work rest periods should be

provided and precautions against

dehydration should be taken.

Any involved personnel showing

signs of fatigue should be released

from duty and replaced at once.

Heavy Weather (SMS 7.2.13)

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

4

Page 4 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Risk Analysis

Potential

hazardous event

injury/property

damage

12

13

14

Lifting/transferring heavy objects

Personal

injury/property

damage

Personal injury

Work at height

Personal injury

Steam

Initial risk

evaluation

Existing control measures

The work should be carried out under

favorable sea conditions, In case of

weather deterioration the job should

be stopped

Lifting appliances / Lifting Operations

(SMS 7.9.11)

During lifting of heavy objects all

personnel should keep clear of the

dangerous zone

Lifting equipment/appliances to be

inspected in order their good

condition to be verified prior to their

use. Lifting equipment must have

adequate SWL for the weight of the

object handled.

Working Overside or Aloft (SMS

7.9.7)

Assessment of the weight of the

object that will be handled should be

made in advance according to

packing details or equipment weight

as per manufacturer.

Additional lifting/moving equipment

(i.e. trolley) to be used if the weight

cannot be handled by manpower only.

Pressure vessel / pipeline (PVP)

work (SMS 7.9.5)

Agree on the valves to be closed.

Pipe Drain to be done from drain

valves

PVP work permits must be issued in

conjunction with Company approved

"DO NOT OPERATE" tags.

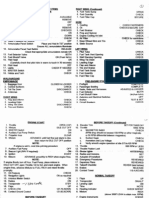

Note F: Frequency, C: Consequence, R: Risk

Notes: (1) This Form should be filed onboard in File M27 & E5.

Risk Treatment

Hazard

No.

Additional Risk Control Measures

Residual risk

evaluation

Responsible

*Action

Timeline

Note F: Frequency, C: Consequence, R: Risk

Issue No. / Date: 1 / 02.07

Revision No. / Date: 2 / 05.14

Page 5 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Contingency plans (to facilitate safe management and recovery of the situation in case of any unplanned occurrences)

Emergency case

Contingency Plans

Refer to emergency response procedures

Risk Assessment reviewed/approved by:

Name

Rank / Title

Signature

Date

Please enter below the persons who will be

involved in the job:

Remarks:

*Action timeline : Ensure the close out of the preventive actions prior to commencement of work.

Verification (Master and the Officer in Charge) that all control measure are fully implemented prior work commencing.

Name

Rank / Title

Signature

Date

Office verification reviewed/approved by:

Name

Issue No. / Date: 1 / 02.07

Rank / Title

Signature

Revision No. / Date: 2 / 05.14

Date

Page 6 of 6

Anda mungkin juga menyukai

- Conversion Table For PressureDokumen4 halamanConversion Table For Pressuredassi99Belum ada peringkat

- RA 002 - HFO Line Pressure TestDokumen4 halamanRA 002 - HFO Line Pressure Testdassi99100% (1)

- RA 002 - D.O. Tank Inspection and CleaningDokumen6 halamanRA 002 - D.O. Tank Inspection and Cleaningdassi99100% (1)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDokumen6 halamanRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99Belum ada peringkat

- Hazard Identification, Risk Assessment and Control Record Register For Offshore ActivitiesDokumen4 halamanHazard Identification, Risk Assessment and Control Record Register For Offshore Activitiespvs12684100% (2)

- Tra 002Dokumen6 halamanTra 002Bilal0% (1)

- Work at Heights PermitDokumen4 halamanWork at Heights PermitFerdinand M. TurbanosBelum ada peringkat

- Hazard Identification, Risk Assessment & Safe Working Procedure For Hazardous Area InspectionsDokumen14 halamanHazard Identification, Risk Assessment & Safe Working Procedure For Hazardous Area InspectionsAnonymous KarIDvBelum ada peringkat

- PTSB (Jsa Form)Dokumen5 halamanPTSB (Jsa Form)hanujaBelum ada peringkat

- #303 Cargo Operation - LoadingDokumen3 halaman#303 Cargo Operation - LoadingTolias EgwBelum ada peringkat

- #402 Valve Overhauling in A Cargo TankDokumen4 halaman#402 Valve Overhauling in A Cargo TankTolias EgwBelum ada peringkat

- Risk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09Dokumen2 halamanRisk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09sizwe0% (1)

- Tra ExcavationDokumen7 halamanTra ExcavationBilal50% (2)

- PSSR Checksheet - Offshore Asset - DraftDokumen6 halamanPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- #305 Tank Cleaning Operations - Cargo TanksDokumen3 halaman#305 Tank Cleaning Operations - Cargo TanksTolias EgwBelum ada peringkat

- Mitchell Capt AndrewDokumen150 halamanMitchell Capt AndrewOSDocs2012Belum ada peringkat

- SP1010 HSE Specification - Environmental Noise and VibrationDokumen12 halamanSP1010 HSE Specification - Environmental Noise and Vibrationcall_mustafas2361Belum ada peringkat

- #201 Navigation in Heavy Marine Traffic ChannelDokumen4 halaman#201 Navigation in Heavy Marine Traffic ChannelTolias EgwBelum ada peringkat

- STC5 Risk Management and Safe Work ProcedureDokumen36 halamanSTC5 Risk Management and Safe Work ProcedureDenise Isebella LeeBelum ada peringkat

- HSEQ-HQ-09-01-00 Incident and Accident Investigation PDFDokumen13 halamanHSEQ-HQ-09-01-00 Incident and Accident Investigation PDFAHMED AMIRABelum ada peringkat

- Title: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBDokumen1 halamanTitle: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBBharat PatilBelum ada peringkat

- 1 RA Water Works (Revised)Dokumen21 halaman1 RA Water Works (Revised)Muhammad Shahid Iqbal0% (1)

- CM 03 - Cargo Handling Risk AssessmentDokumen3 halamanCM 03 - Cargo Handling Risk AssessmentDmitriy100% (1)

- SP-1010 - Specification For Environmental Noise and VibrationDokumen11 halamanSP-1010 - Specification For Environmental Noise and VibrationLeo BartonBelum ada peringkat

- 120021-Hse-004 - Risk Assessment Procedure 001Dokumen28 halaman120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- SMP For Calibration of Gauges & TransmittersDokumen3 halamanSMP For Calibration of Gauges & Transmitterspradeep1987coolBelum ada peringkat

- AOD Isolation Risk Assessment Rev D2Dokumen17 halamanAOD Isolation Risk Assessment Rev D2api-3745449Belum ada peringkat

- LOPA and Human Factors 2Dokumen26 halamanLOPA and Human Factors 2sandhyakasturiBelum ada peringkat

- Attachment B - BCC RISK ANALYSIS REGISTER - Piping PreservationDokumen1 halamanAttachment B - BCC RISK ANALYSIS REGISTER - Piping PreservationJohn Vem BansagBelum ada peringkat

- Hazard, Hazid, Hazan and Hazop - Part of Safety and Risk Management - IspatGuru PDFDokumen9 halamanHazard, Hazid, Hazan and Hazop - Part of Safety and Risk Management - IspatGuru PDFnaren_013100% (1)

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Dokumen6 halamanRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008Belum ada peringkat

- GM Saf 006a (Hazid)Dokumen27 halamanGM Saf 006a (Hazid)Edwin Nuñez FlorezBelum ada peringkat

- Safety Plan For Chemical PlantDokumen7 halamanSafety Plan For Chemical PlantM Amir Haris100% (1)

- #107 Manual Handling - Deck DeptDokumen6 halaman#107 Manual Handling - Deck DeptTolias EgwBelum ada peringkat

- Detector SelectionDokumen149 halamanDetector Selectionssriram2003Belum ada peringkat

- HIRAC (Potential of Major Accident Hazard (MAH) )Dokumen8 halamanHIRAC (Potential of Major Accident Hazard (MAH) )hendraBelum ada peringkat

- Job Safety Analysis (JSA)Dokumen4 halamanJob Safety Analysis (JSA)Wisnu WicaksonoBelum ada peringkat

- #404 Emergency Fire Pump Maintenance (Revised)Dokumen4 halaman#404 Emergency Fire Pump Maintenance (Revised)Tolias EgwBelum ada peringkat

- Risk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Dokumen1 halamanRisk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Devi Ratna Pratiwi0% (1)

- Pdo Risk Assessment FormDokumen2 halamanPdo Risk Assessment FormPazhamalai RajanBelum ada peringkat

- #406 Maintenance On Main EngineDokumen3 halaman#406 Maintenance On Main EngineTolias Egw100% (1)

- Hazard Identification 2. Risk Evaluation 3. Risk ControlDokumen4 halamanHazard Identification 2. Risk Evaluation 3. Risk ControlCarmilyn Joy TapelBelum ada peringkat

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Dokumen3 halamanTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreBelum ada peringkat

- Partial Stroke Testing - R3Dokumen8 halamanPartial Stroke Testing - R3Gabo Montaño MendozaBelum ada peringkat

- Emergency Response Plan: Berrima Cement WorksDokumen44 halamanEmergency Response Plan: Berrima Cement WorksDanu HenantyoBelum ada peringkat

- #304 Cargo Operation - DischargingDokumen3 halaman#304 Cargo Operation - DischargingTolias EgwBelum ada peringkat

- Risk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderDokumen5 halamanRisk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderOvais FarooqBelum ada peringkat

- Safety Toolbox Meeting FormDokumen19 halamanSafety Toolbox Meeting FormTuntun TatBelum ada peringkat

- Fork Lift Truck-Risk Assessment - Date: R A - S A /SDokumen2 halamanFork Lift Truck-Risk Assessment - Date: R A - S A /SJalagandeeswaran KalimuthuBelum ada peringkat

- SCS 2019 Presentation-Mark Skelton-Risk Based Decision Making and ALARP-How Low Is Low EnoughDokumen25 halamanSCS 2019 Presentation-Mark Skelton-Risk Based Decision Making and ALARP-How Low Is Low EnoughkhaleedsyedBelum ada peringkat

- Habonim SIL CertificationDokumen7 halamanHabonim SIL Certificationjamil vora0% (1)

- Risk Assessment FormDokumen4 halamanRisk Assessment Formbeshoy100% (2)

- Risk Assesment Fab - Rev-07Dokumen71 halamanRisk Assesment Fab - Rev-07Nikhil PuthiryBelum ada peringkat

- HSE PresentationDokumen46 halamanHSE Presentationshan123455555555Belum ada peringkat

- Lecture 3 - Process SafetyDokumen79 halamanLecture 3 - Process SafetyDivyashini MohanBelum ada peringkat

- AE-SWM - 12B-LG-Marine-Rev-02Dokumen61 halamanAE-SWM - 12B-LG-Marine-Rev-02Planning C7100% (1)

- JSA Chemicals CleaningDokumen2 halamanJSA Chemicals CleaningVijay RajaindranBelum ada peringkat

- Specification For Biodiversity: Petroleum Development Oman L.L.C. Health Safety Environment & Sustainable DevelopmentDokumen11 halamanSpecification For Biodiversity: Petroleum Development Oman L.L.C. Health Safety Environment & Sustainable DevelopmentHari Prakash GrandheyBelum ada peringkat

- Nomenclature and Terminology For Extension-Type Variable Area Meters (Rotameters)Dokumen10 halamanNomenclature and Terminology For Extension-Type Variable Area Meters (Rotameters)Fernando Bustos MuñozBelum ada peringkat

- RA 002 - BunkeringDokumen5 halamanRA 002 - Bunkeringdassi99Belum ada peringkat

- RA 002 - BunkeringDokumen5 halamanRA 002 - Bunkeringdassi99Belum ada peringkat

- JAN 701B HandoutsDokumen22 halamanJAN 701B Handoutsdassi990% (1)

- Piezoelectricity:: Principle Knock SensorsDokumen1 halamanPiezoelectricity:: Principle Knock Sensorsdassi99Belum ada peringkat

- 4.10.1 Ramp Up-Ramp Down Plan-AsclepiusDokumen1 halaman4.10.1 Ramp Up-Ramp Down Plan-Asclepiusdassi99100% (1)

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Dokumen16 halaman06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- WISE Cargo User Manual - Ver 6 (A4)Dokumen36 halamanWISE Cargo User Manual - Ver 6 (A4)dassi9950% (2)

- Owners' Damages For Repudiation by CharterersDokumen16 halamanOwners' Damages For Repudiation by Charterersdassi99Belum ada peringkat

- The Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding ContractDokumen3 halamanThe Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding Contractdassi99Belum ada peringkat

- Calculating Damages by Clive AstonDokumen10 halamanCalculating Damages by Clive Astondassi99100% (1)

- C172R (180hp) ChecklistDokumen7 halamanC172R (180hp) Checklisterik_xBelum ada peringkat

- SOP For Bomb ThreatDokumen18 halamanSOP For Bomb ThreatJacBelum ada peringkat

- Water Rescue PDFDokumen68 halamanWater Rescue PDFRachmat Wihandana AgasiBelum ada peringkat

- Explanation TextDokumen6 halamanExplanation TextNur ArinaBelum ada peringkat

- Fire Safty in Public BuildingDokumen40 halamanFire Safty in Public BuildingSamirsinh ParmarBelum ada peringkat

- Man at SeaDokumen1 halamanMan at SeaTPKtpkTPKBelum ada peringkat

- FDNY Report On Fatal Fire, June 4, 1999Dokumen13 halamanFDNY Report On Fatal Fire, June 4, 1999City Limits (New York)100% (1)

- 12 Things You Must Do Before Operating Ship's CO2 Fire Extinguishing SystemDokumen6 halaman12 Things You Must Do Before Operating Ship's CO2 Fire Extinguishing SystemDaniel CastilloBelum ada peringkat

- 2 - Simulation Test - Fire AlarmDokumen4 halaman2 - Simulation Test - Fire Alarmtjacabenian26Belum ada peringkat

- Checklist MaintenanceDokumen5 halamanChecklist Maintenancewarnet ilhamBelum ada peringkat

- Fire Guard: Automatic Fire Detection & Alarm SystemDokumen2 halamanFire Guard: Automatic Fire Detection & Alarm SystemPardeep RajanBelum ada peringkat

- 1346351847.bobcat S185 Skid Steer PDFDokumen194 halaman1346351847.bobcat S185 Skid Steer PDFPedro Carvalho50% (4)

- Konbit Sante August 2009 NewsletterDokumen4 halamanKonbit Sante August 2009 NewsletterKonbit SanteBelum ada peringkat

- Msds Hvu Hilti (En)Dokumen8 halamanMsds Hvu Hilti (En)Victor MacoveiBelum ada peringkat

- HFC 125 Instructional SignsDokumen2 halamanHFC 125 Instructional SignsfreddyBelum ada peringkat

- NFPA13RDokumen28 halamanNFPA13RAnoj ApBelum ada peringkat

- Piper Alpha Disaster SlidesDokumen20 halamanPiper Alpha Disaster SlidestokkxylahBelum ada peringkat

- Labour Colony Inspection Report - August 2023Dokumen11 halamanLabour Colony Inspection Report - August 2023shamshad ahamedBelum ada peringkat

- 2013 Myanmar Fire Dept Draft Guideline & CommentsDokumen6 halaman2013 Myanmar Fire Dept Draft Guideline & CommentsLu Cifer100% (19)

- Backdraft Response StrategiesDokumen6 halamanBackdraft Response StrategiesShan RaffelBelum ada peringkat

- FO1 Journal 10000Dokumen43 halamanFO1 Journal 10000Alta Tierra FssBelum ada peringkat

- Menara Kuala Lumpur Kepong (KLK) : Basement 1 Floor PlanDokumen21 halamanMenara Kuala Lumpur Kepong (KLK) : Basement 1 Floor PlanAsir kotawdekarBelum ada peringkat

- Schools Conduct Simultaneous Nationwide Earthquake and Fire DrillDokumen3 halamanSchools Conduct Simultaneous Nationwide Earthquake and Fire DrillKarlai TabiminaBelum ada peringkat

- Safe Work Procedure, Gem MaintenanceDokumen46 halamanSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- FMDS0326Dokumen12 halamanFMDS0326احمد الجزار2007Belum ada peringkat

- FSSS Logic SystemDokumen51 halamanFSSS Logic SystemAshwani Dogra100% (4)

- PRELIM Fire Technology and Arson InvestigationDokumen6 halamanPRELIM Fire Technology and Arson InvestigationIgnacio Burog RazonaBelum ada peringkat

- Fire Report FinalDokumen5 halamanFire Report FinalQuentin DidierBelum ada peringkat

- Article - Preventive SafetyDokumen18 halamanArticle - Preventive SafetyDin ScrubBelum ada peringkat

- Glycerin MSDSDokumen5 halamanGlycerin MSDSBill RichardsonBelum ada peringkat