Manual Regulador de Velocidade Gac Esd 5111

Diunggah oleh

Paulo AlvesHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Manual Regulador de Velocidade Gac Esd 5111

Diunggah oleh

Paulo AlvesHak Cipta:

Format Tersedia

ENGINE

GOVERNING

SYSTEM

G

A

C

OVERNORS

ESD5100 Series

Speed Control Unit

Simple Installation and Adjustment

Isochronous, Droop, & Variable Speed Operation

Adjustable PID

Idle Speed Circuit

MERICA

ORP.

Auxiliary Accessory Input

10 Amp Drive Circuit

Inputs for Accessories

Introduction

The ESD5100 Series electronic speed device is designed

to control engine speed with fast and precise response to

transient load changes. This closed loop control, when connected to a proportional electric actuator and supplied with

a magnetic speed sensor signal, will control a wide variety

of engines in an isochronous or droop mode. It is designed

for high reliability and built ruggedly to withstand the engine

environment.

Simplicity of installation and adjustment was foremost in the

design. Non-interacting performance controls allow near optimum response to be easily obtained.

Other features include adjustable droop and idle operation,

inputs for accessories used in multi-engine or special applications, protection against reverse battery voltage, transient

voltages, accidental short circuit of the actuator and fail safe

design in the event of loss of speed sensor signal or battery

supply.

with the speed adjust set point input. The speed range has

a ratio of 9:1 and is adjusted with by the 25-turn SPEED potentiometer. The output from the summing circuit is the input

to the dynamic control section of the speed control unit. The

dynamic control circuit, of which the GAIN and STABILITY

adjustments are part of, has a control function that will provide isochronous and stable performance for most engine

types and fuel systems.

DESCRIPTION

Engine speed information for the speed control unit is usually received from a magnetic speed sensor. Any other signal-generating device may be used provided that the generated frequency is proportional to engine speed and meets

the voltage input and frequency range specification. The

speed sensor is typically mounted in close proximity to an

engine driven ferrous gear, usually the engine ring gear. As

the teeth of the gear pass the magnetic sensor, a signal is

generated which is proportional to engine speed.

The ESDs circuit is influenced by the GAIN and STABILITY

performance adjustments. The governor system sensitivity

is increased with clockwise relation of the GAIN adjustment.

The GAIN adjustment has a range of 33:1. The STABILITY

adjustment, when advanced clockwise, increases the time

rate of response of the governor system to match the various time constants of a wide variety of engines. The ESD is

a PID device, the D, derivative portion can be varied when

required. (See instability section in PIB1000.)

Signal strength must be within the range of the input amplifier. An amplitude of 0.5 to 50 volts RMS is required to allow the unit to function within its design specifications. The

speed signal is applied to Terminals C and D on the ESDs.

Between these terminals there is an input impedance of over

33,000 . Terminal D is internally connected to Terminal E,

battery negative. Only one end of the cable shield should be

connected.

During the engine cranking cycle, the actuator becomes fully

energized and moves to the maximum fuel position. The actuator will remain in this state during engine cranking and

acceleration. While the engine is at steady load, the actuator

will be energized with sufficient current to maintain the governor speed set point.

When a speed sensor signal is received by the ESD, the signal is amplified and shaped by an internal circuit to provide

an analog speed signal. If the speed sensor monitor does

not detect a speed sensor signal, the output circuit on the

ESD will turn off all current to the actuator.

The output circuit provides switching current at a frequency

of about 500 Hz. to drive the actuator. Since the switching

frequency is well beyond the natural frequency of the actuator, there is no visible motion of the actuator output shaft.

A summing circuit receives the speed sensor signal along

Governors America Corp., 720 Silver Street Agawam, MA 01001

phone: 413.786.5600 fax: 413.789.7736

www.governors-america.com

info@governors-america.com

1

ISO 9001

CERTIFIED

Switching the output transistors reduces its internal power

dissipation for efficient power control.

of load are applied to the engine. Engine idle speed can be

remotely selected and is adjustable.

The output circuit can provide current up to 10 Amps continuous at 25C for 12 and 24 VDC battery systems. The actuator responds to the average current to position the engine

fuel control lever.

The ESD5100 Series can accept accessory inputs (i.e.,

GACs Load Sharing Modules & Synchroners) to achieve

variable speed operation and multi-engine control. Protection against reverse battery voltage and transient voltages is

provided. The design is fail safe in the event of loss of speed

sensor signal or battery supply.

In standard operation, the ESDs performance is isochronous. Droop governing can be selected by connecting Terminals K and L and the percent of droop governing can be

varied with the DROOP adjustment control. Connecting Terminals G and H can increase the droop range. The ESD has

several performance and protection features, which enhance

the governor system. A speed anticipation circuit minimizes

speed overshoot on engine startup or when large increments

The ESD5100 Series speed control unit is compatible with

GOVERNORS AMERICA CORP. proportional electric actuators (except the 2001 Series) as well as those from other

manufacturers.

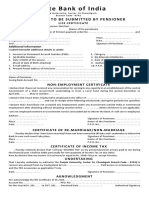

Diagram 1 System Wiring and Outline

SeLECTION CHART

5.00

(127)

LEAD CIRCUIT

JUMPER

GA

C

ESD5131, ESD5131H,

and ESD5151 only

OVERNORS

MERICA

ORP.

SPEED

SPEED CONTROL

UNIT

MODEL: ESD51xx

ON 2

SOFT COUPLING

OFF

STABILITY

CAUTION

5.00

(127)

GAIN

S/N :

MADE IN AGAWAM, MA U.S.A.

1 OFF

LEAD CIRCUIT

ON

E6

E7

DROOP

ENGINE SPEED CONTROL

COMPONENT. WHEN INSTALLING

OR SERVICING REFER TO

PRODUCT PUBLICATION.

PICK-UP - +

ACTUATOR

BATTERY

E1

E2

E3

IDLE

DEAD TIME

COMPENSATION

JUMPER

AUX 10V

A B C D E F GH J K L MN P

0.27

(6,8)

OPTIONAL ACTUATOR

CABLE SHIELDING TO

MEET CE DIRECTIVE

ACCESSORY POWER SUPPLY

ACCESSORY INPUT

ADD JUMPER TO INCREASE

DROOP RANGE

ACTUATOR

CW

MAGNETIC

PICK-UP

_

Characteristics

ESD5111

Standard Unit

ESD5111H

Hard Potted

ESD5111T

Temperature Compensated

ESD5119

EFC Reverse Acting

ESD5120

EFC Forward Acting/Light Force

ESD5120T

EFC Forward Action/Light Force/Temperature

Compensated

ESD5131

Soft Coupling Option/Speed Detection Circuit

ESD5131H

Soft Coupling Option/Hard Potted

ESD5150

4-20 mA Output

ESD5151

Soft Coupling Option/Expanded Range to 10.5K Hz

ESD5159

Expanded Adjustable Speed Range

IDLE

SPEED TRIM

BATTERY

GROUND REFERENCE

Model

S1

FUSE

15A MAX

SEE SPECIFIC ACTUATOR PUBLICATION FOR PROPER

WIRING OF ACTUATOR BASED ON BATTERY VOLTAGE

ISOCHRONOUS

DROOP

EXTERNAL SELECTOR

SWITCH

(NOT REQUIRED FOR SINGLE

SPEED ISOCHRONOUS OPERATION)

Specifications

RELIABILITY

Vibration...............................................................1G, 20-100 Hz

Testing..................................................................100% Functionally Tested

Performance

Isochronous Operation................................................ 0.25 % or better

Speed Range /Governor...........................................1K - 7.5K Hz Continuous

Speed Drift with Temperature...................................0.5% Typical

Idle Adjust CW...........Min. 1200 Hz. Below set speed

Idle Adjust CCW.....Min. 4100 Hz. Below set speed

Droop Range.....................................................................1 - 5% Regulation

Droop Adj. Max. (K-L Jumpered).................875 Hz., 75 Hz. per 1.0 A change

Droop Adj. Min. (K-L Jumpered)...................15 Hz., 6 Hz. per 1.0 A change

Speed Trim Range...........................................................................200 Hz.

Remote Variable Speed Range....................500 - 3.7 kHz. or any part thereof

Terminal Sensitivity

J..........................................-115 Hz., 15 Hz/Volt @ 5 K Impedance

L........................................-735 Hz., 60 Hz/Volt @ 65 K Impedance

N........................................-148 Hz., 10 Hz/Volt @ 1 M Impedance

P.........................................................10 VDC Supply @ 20 ma Max.

Environmental

Ambient Operating Temperature Range......-40 to +185F (-40 to +85C)

Relative Humidity........up to 95%

All Surface Finishes.........................Fungus proof and corrosion resistance

RoHS Regulation...........................................................................Compliant

Input POWER

DC Supply...........................................12 or 24 20% VDC Battery Systems

(Transient and Reverse Voltage Protected)

Polarity......................................................Negative Ground (case isolated)

Power Consumption......................................100 mA (No actuator current)

Speed Signal Range..................................................................0.5 50 VAC

Actuator Current Range @ 77F (25C)........................10 Amps continuous

Physical

Dimensions.......................................................See DIAGRAM 1

Weight............1.2 lb. (0.545 kg)

Mounting.........................Any Position, vertical preferred

COMPLIANCE / STANDARDS

Agency...........................................................................CE Requirements

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

2

PTI1000 C

Anda mungkin juga menyukai

- ST-125 CONTROL SYSTEM FOR STANADYNE DB-4 SERIES PUMPS-woodwardDokumen26 halamanST-125 CONTROL SYSTEM FOR STANADYNE DB-4 SERIES PUMPS-woodwardManuel Otero100% (3)

- R448 Leroy Somer Manual enDokumen4 halamanR448 Leroy Somer Manual enJohn GarnetBelum ada peringkat

- Avr Conversion Instructions: FITTING KIT 45-0054 FOR USE WITH SX440 AVR Part No. E000-24030Dokumen2 halamanAvr Conversion Instructions: FITTING KIT 45-0054 FOR USE WITH SX440 AVR Part No. E000-24030Jose Pirulli100% (1)

- DG 00 006-E 06-09 PANDAROS I PDFDokumen54 halamanDG 00 006-E 06-09 PANDAROS I PDFLuis Jesus100% (1)

- Manual Generador ENGGADokumen20 halamanManual Generador ENGGAmanuel100% (2)

- Governor Controller (GAC ESD5111) - DatasheetDokumen5 halamanGovernor Controller (GAC ESD5111) - Datasheetazhan77Belum ada peringkat

- KG6 04 PDFDokumen4 halamanKG6 04 PDFAhmed Sherif CupoBelum ada peringkat

- SBI - Certificate To Be Submitted by Pensioner - ChandigarhDokumen1 halamanSBI - Certificate To Be Submitted by Pensioner - ChandigarhMsinghBelum ada peringkat

- 3500 and 3500B Generator With MUI and EUI Engines Electrical SystemDokumen4 halaman3500 and 3500B Generator With MUI and EUI Engines Electrical Systemkrisari90% (1)

- Navajo Hearing ProgramDokumen3 halamanNavajo Hearing Programjamesmith100000% (1)

- Avr Conversion InstructionsDokumen2 halamanAvr Conversion InstructionsJose PirulliBelum ada peringkat

- VR6 Voltage Regulator - Pruebas y Ajustes - CATERPILLARDokumen30 halamanVR6 Voltage Regulator - Pruebas y Ajustes - CATERPILLARCesar Alfonso Saldivar MontoyaBelum ada peringkat

- LCG2 PDFDokumen35 halamanLCG2 PDFchakrouneBelum ada peringkat

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDokumen3 halamanDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteBelum ada peringkat

- User Manual: HGM6100U Series Automatic Control ControllersDokumen32 halamanUser Manual: HGM6100U Series Automatic Control Controllersnhocti007100% (1)

- 15A Universal 1/2 Wave Self Excited AVRDokumen2 halaman15A Universal 1/2 Wave Self Excited AVRHerbertBelum ada peringkat

- Wiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Dokumen6 halamanWiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Jose FavaBelum ada peringkat

- Kg16-04+Sfbg Speed Control BoxDokumen4 halamanKg16-04+Sfbg Speed Control Boxehsan haleemBelum ada peringkat

- Regulador Woodward 8290-184Dokumen4 halamanRegulador Woodward 8290-184kinosi100% (1)

- 2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFDokumen13 halaman2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFSamir KhanBelum ada peringkat

- Speed Control GAC ESD5500Dokumen8 halamanSpeed Control GAC ESD5500Manuel Otero80% (5)

- Risk Management Report SummaryDokumen61 halamanRisk Management Report SummaryIamCcj100% (1)

- InteliVision 5 Reference GuideDokumen45 halamanInteliVision 5 Reference Guidexuyen tranBelum ada peringkat

- Harsen GU611A-EN0724 PDFDokumen34 halamanHarsen GU611A-EN0724 PDFSteven J Baynes100% (2)

- EVC600C User Manual (English)Dokumen6 halamanEVC600C User Manual (English)dhany reza100% (1)

- WEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRDokumen50 halamanWEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRJuan I. Meza Lozano100% (1)

- User Manual: HGM6200K Series Automatic Control ModuleDokumen31 halamanUser Manual: HGM6200K Series Automatic Control Modulenhocti007100% (1)

- Easygen-3000Xt Series: ManualDokumen904 halamanEasygen-3000Xt Series: Manualincore1976Belum ada peringkat

- Manual Smartgen HGM 6320 - Ced 100ksDokumen35 halamanManual Smartgen HGM 6320 - Ced 100ksddedaniel80% (5)

- Woodward EGCP-3 Installation ManualDokumen120 halamanWoodward EGCP-3 Installation Manualgregbennett00_scBelum ada peringkat

- EDI1300Dokumen24 halamanEDI1300Mahmoud Khattab100% (2)

- Generator Automatic Voltage Regulator Operation ManualDokumen6 halamanGenerator Automatic Voltage Regulator Operation Manualanwarkj100% (1)

- Break Free - Nathaniel BrandenDokumen16 halamanBreak Free - Nathaniel Brandennbckudxtkudkuf50% (2)

- AVR - DSR Manual Rev02 PDFDokumen32 halamanAVR - DSR Manual Rev02 PDFAhmed Kotb50% (2)

- Robust Electric Actuator STG16-01Dokumen2 halamanRobust Electric Actuator STG16-01Paulo MandingaBelum ada peringkat

- VOLVO Speed Governor ESD 5500E Technical InformationDokumen10 halamanVOLVO Speed Governor ESD 5500E Technical Informationdaniel_ting_1Belum ada peringkat

- DKG 307 User ManualDokumen29 halamanDKG 307 User ManualTani100% (2)

- Smart Tech ShogunDokumen7 halamanSmart Tech ShogunBruno Mariano100% (1)

- Controllers For Stanadyne Pumps Using DC-70025 Integrated Actuators PDFDokumen16 halamanControllers For Stanadyne Pumps Using DC-70025 Integrated Actuators PDFO mecanicoBelum ada peringkat

- 2301 Speed ControlDokumen4 halaman2301 Speed ControlCarlos SantosBelum ada peringkat

- DC30D Configuration and Instructions Ver1.0Dokumen8 halamanDC30D Configuration and Instructions Ver1.0JaimeCoello100% (2)

- Regulador de Voltaje GAVR8AhDokumen2 halamanRegulador de Voltaje GAVR8AhcrecosiroBelum ada peringkat

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDokumen7 halamanEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomBelum ada peringkat

- DNV Rules For Electrical Instal at IonsDokumen80 halamanDNV Rules For Electrical Instal at Ionsnzjohn100% (3)

- D Formation Damage StimCADE FDADokumen30 halamanD Formation Damage StimCADE FDAEmmanuel EkwohBelum ada peringkat

- Multilizer PDF Translator Free version limits translations to 3 pagesDokumen23 halamanMultilizer PDF Translator Free version limits translations to 3 pagesmarcosluna6857% (7)

- QC4003 ESF Zaragoza Application Datasheet EN 2954567001 LTODokumen2 halamanQC4003 ESF Zaragoza Application Datasheet EN 2954567001 LTOmoises100% (1)

- Gu601a En0507 PDFDokumen30 halamanGu601a En0507 PDFChhoan Nhun100% (2)

- Altronics DISN800C IOM 11-1997 PDFDokumen18 halamanAltronics DISN800C IOM 11-1997 PDFSMc67% (3)

- EA16 Generator Automatic Voltage Regulator Operation ManualDokumen6 halamanEA16 Generator Automatic Voltage Regulator Operation Manualabuzer1981Belum ada peringkat

- Paralleling PCC 2100 in Droop Mode Using Aux101 ModuleDokumen2 halamanParalleling PCC 2100 in Droop Mode Using Aux101 ModuleGeneral Projects and Electric, C.A GEPECABelum ada peringkat

- DST4602 enDokumen255 halamanDST4602 enMarcos BrandãoBelum ada peringkat

- My 1306 1300 EDi Genset - Data List - 2Dokumen1 halamanMy 1306 1300 EDi Genset - Data List - 2Khaled Kamel100% (1)

- Gu301 ADokumen3 halamanGu301 AJosé Da Silva MataBelum ada peringkat

- TWD1643GE: Volvo Penta Genset EngineDokumen2 halamanTWD1643GE: Volvo Penta Genset Enginemohsen_cumminsBelum ada peringkat

- Instruction Manual: FOR DGC-2020HD Digital Genset ControllerDokumen404 halamanInstruction Manual: FOR DGC-2020HD Digital Genset ControllerTakis KipurosBelum ada peringkat

- Diagram LCG2Dokumen1 halamanDiagram LCG2Edgar De50% (2)

- PowerWizard Configuration of InputsDokumen2 halamanPowerWizard Configuration of Inputssfantu_29Belum ada peringkat

- PCC 1301 DG PDFDokumen2 halamanPCC 1301 DG PDFmohsen_cummins100% (1)

- GX - 340 - Manual STAMFORD SERIE 3 PART 450-11700Dokumen11 halamanGX - 340 - Manual STAMFORD SERIE 3 PART 450-11700Manuel Otero100% (2)

- General: Technical Data TAD721GEDokumen8 halamanGeneral: Technical Data TAD721GEbaljeetjatBelum ada peringkat

- Pti1000 Esd5100 SeriesDokumen2 halamanPti1000 Esd5100 SeriesRamon Thales DomeniconiBelum ada peringkat

- Gac Esd5500Dokumen7 halamanGac Esd5500christramBelum ada peringkat

- Esd5111 enDokumen4 halamanEsd5111 enRicardo MonteroBelum ada peringkat

- Esd5111 enDokumen4 halamanEsd5111 enMahdi Dehghankar100% (1)

- Manual Regulador de Velocidade Gac Esd 5111 PDFDokumen2 halamanManual Regulador de Velocidade Gac Esd 5111 PDFGugui68100% (1)

- DOC023.97.80076 - 3ed Sensores ORPDokumen148 halamanDOC023.97.80076 - 3ed Sensores ORPAlejandroBelum ada peringkat

- 1 The Fifth CommandmentDokumen10 halaman1 The Fifth CommandmentSoleil MiroBelum ada peringkat

- Flexible and Alternative Seating: in ClassroomsDokumen5 halamanFlexible and Alternative Seating: in ClassroomsweningBelum ada peringkat

- App 17 Venmyn Rand Summary PDFDokumen43 halamanApp 17 Venmyn Rand Summary PDF2fercepolBelum ada peringkat

- Ficha Tecnica StyrofoamDokumen2 halamanFicha Tecnica StyrofoamAceroMart - Tu Mejor Opcion en AceroBelum ada peringkat

- EDSP Quantitative and Qualitative FormDokumen2 halamanEDSP Quantitative and Qualitative FormTalal SultanBelum ada peringkat

- ĐỀ THI THU TNTHPT SỐ 17Dokumen4 halamanĐỀ THI THU TNTHPT SỐ 17Nguyên Hà NguyễnBelum ada peringkat

- PTA Resolution for Donation to School WashroomDokumen2 halamanPTA Resolution for Donation to School WashroomMara Ciela CajalneBelum ada peringkat

- Accuracy of Real-Time Shear Wave Elastography in SDokumen10 halamanAccuracy of Real-Time Shear Wave Elastography in SApotik ApotekBelum ada peringkat

- RJ Bensingh Pub Composites CoatingsDokumen5 halamanRJ Bensingh Pub Composites CoatingsFakkir MohamedBelum ada peringkat

- Specialized Connective TissueDokumen15 halamanSpecialized Connective TissueSebBelum ada peringkat

- Homework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)Dokumen5 halamanHomework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)CARLOS DIDIER GÓMEZ ARCOSBelum ada peringkat

- Borri Ups b9000 Ups Service Manual - CompressDokumen180 halamanBorri Ups b9000 Ups Service Manual - CompressArun SBelum ada peringkat

- The Truth About EtawahDokumen4 halamanThe Truth About EtawahPoojaDasgupta100% (1)

- Bespoke Fabrication Systems for Unique Site SolutionsDokumen13 halamanBespoke Fabrication Systems for Unique Site Solutionswish uBelum ada peringkat

- Rajasthan PET Chemistry 1997 Exam with Detailed SolutionsDokumen34 halamanRajasthan PET Chemistry 1997 Exam with Detailed SolutionsYumit MorwalBelum ada peringkat

- Gsis - Ra 8291Dokumen33 halamanGsis - Ra 8291RoySantosMoralesBelum ada peringkat

- 4Dokumen130 halaman4Upender BhatiBelum ada peringkat

- MTD CalculationsDokumen50 halamanMTD CalculationsLeny HrBelum ada peringkat

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDokumen2 halamanVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainBelum ada peringkat

- Fiitjee JEE Adv p1 Phase II SolDokumen10 halamanFiitjee JEE Adv p1 Phase II SolPadamBelum ada peringkat

- Treating Thyroid Emergencies: Myxedema Coma and Thyroid StormDokumen17 halamanTreating Thyroid Emergencies: Myxedema Coma and Thyroid StormMarlon UlloaBelum ada peringkat

- Role of Homeostasis in Human Physiology A ReviewDokumen5 halamanRole of Homeostasis in Human Physiology A ReviewNathaly ZiékteBelum ada peringkat

- MPQ2908 - 48V Buck Converter Automotive Reference DesignDokumen4 halamanMPQ2908 - 48V Buck Converter Automotive Reference DesignShubham KaklijBelum ada peringkat