Airsuspensionrdso 2009 CG Cmi 01 140912134756 Phpapp01

Diunggah oleh

Rickson Viahul Rayan CDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Airsuspensionrdso 2009 CG Cmi 01 140912134756 Phpapp01

Diunggah oleh

Rickson Viahul Rayan CHak Cipta:

Format Tersedia

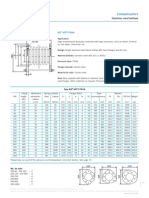

Ref: CGW 0001,Rev.

-3

Date / Month of issue:

September, 2009

Page 1 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

(For official use only)

INDIAN RAILWAYS

MAINTENANCE INSTRUCTIONS

ON

AIR SUSPENSION

FOR

MAINLINE/RAJDHANI COACHES WITH ICF

TYPE BOGIES

RDSO/2009/CG/CMI-01

September 2009

RESEARCH DESIGNS AND STANDARDS ORGANISATION

MANAK NAGAR, LUCKNOW 226011.

RDSO/Lucknow

Page-1

Ref: CGW 0001,Rev.-3

Date / Month of issue:

September, 2009

Page 2 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

SYNOPSIS

Requirement of greater passenger comfort with reduced maintenance and

have generated need for the Indian Railways to adopt air suspension for its

coaching stock.

For Indian Railways, air suspension is a new technology and hence there is a

need to impart awareness amongst officials engaged in handling of this system,

regarding its working principle, functions and details of hardware and maintenance

practices to be followed for various items.

This booklet has been prepared with above objectives in view. Any

suggestion directed towards improvement in the quality of the booklet shall be

welcome which may be sent to Executive Director Standards/Carriage or

Director/VDG/Carriage, Research Designs & Standards Organization, Manak

Nagar, Lucknow-226011.

RDSO/Lucknow

Page-2

Ref: CGW 0001,Rev.-3

Date / Month of issue:

September, 2009

Page 3 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

INDEX

Item

DESCRIPTION

Page No.

1.

INTRODUCTION

2.

WORKING PRINCIPLE OF PNEUMATIC SUSPENSION

3.

COMPARISON WITH EXISTING COIL SUSPENSION

4.

ADVANTAGES OF AIR SUSPENSION

5.

CHARACTERISTICS FEATURES OF AIR SUSPENSION

6.

CONSTRUCTION DETAILS/CHARACTERISTICS OF AIR SPRING

7.

SCHEMATIC LAYOUT OF PNEUMATIC SUSPENSION CONTROL

EQUIPMENTS

8.

MODIFICATIONS FOR AIR SPRING FITMENT

9.

OPERATING INSTRUCTIONS

10.

DISMANTLING OF AIR SPRING FROM LOWER SPRING BEAM

(CRADLE) AND BOGIE BOLSTER.

11.

INSPECTION & MAINTENANCE OF AIR SPRING

12.

INSPECTION & MAINTENANCE OF LOWER SPRING BEAM

13.

INSPECTION OF PIPE LINE

14.

MOUNTING AIR SPRING ON LOWER SPRING BEAM AND BOLSTER

15.

TEST FOR LEAKAGE

16.

PROCEDURE FOR CHECKING OF BOGIE CLEARANCES ON EMUS &

DMUSPROVIDED WITH AIR SPRING

17.

PROCEDURE FOR CENTRE BUFFER COUPLER HEIGHT ADJUSTMENT

IN WORKSHOP

INSTALLATION LEVER ADJUSTMENT

19.

CHARACTERISTICS OF AIR SPRING/PERIODICAL INSPECTION OF

AIR SPRING SYSTEM ON MAINLINE COACHES

20.

AIR SPRING SERVICE

10

21.

AIR SPRING CONTROL EQUIPMENTS SERVICE

10

18.

22.

23.

FIGURES 1 to 9

11-19

ANNEXURES A to J

RDSO/Lucknow

Page-3

Ref: CGW 0001,Rev.-3

Date / Month of issue:

September, 2009

Page 4 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

MAINTENANCE INSTRUCTIONS

ON

AIR SUSPENSION

1.

INTRODUCTION:

Railway Board had approved fitment of air spring on AC Mainline ICF coaches for the purpose

of oscillation trials. After simulation study at RDSO, design for mainline stock with air spring at

secondary suspension has been evolved. Simulation studies have revealed a significant

improvement in the quality of ride on ICF stock fitted with air springs over those fitted with

conventional coiled springs. This is particularly significant with regard to the requirement of

better riding on high speed Rajdhani and Shatabdi trains specially in Ist AC coaches.

Oscillation trials have been conducted on ICF mainline bogie coaches successfully, with good

results. Accordingly it has been decided by Railway Board to provide air springs (pneumatic

suspension) on all stainless steel shell coaches (LHB type shell) provide with ICF bogies.

The Pneumatic suspension has been proven, on DC-EMU, AC-EMU, AC-DC EMU and HHPDMU.

2.

WORKING PRINCIPLE OF PNEUMATIC SUSPENSION:

Air suspension is a suspension where properties of air are used for cushioning effect

(springiness). Enclosed pressurised air in a pre-defined chamber called air spring, made up of

rubber bellow & emergency rubber spring, provides various suspension characteristics including

damping. Air springs are height-controlled load levelling suspension devices. With changing

loads, air spring reacts initially by changing the distance between air spring support and vehicle

body. The height monitoring valve (called levelling valve) is in turn actuated, either taking the

compressed air pressure to the air spring or releasing air pressure from it to the atmosphere. This

process continues until the original height is restored. (See Fig.1 page No. 11). This mechanism

ensures a constant floor height on coaches provided with air springs, irrespective of the load. This

greatly reduce problems associated with low buffer / coupler heights.

3.

COMPARISON WITH EXISTING COIL SUSPENSION:

Unlike steel spring, air springs retain their height under changing loads. The low natural

frequency of air spring suspension remains virtually constant.

In case of coil spring, deflection is proportionate to the load, therefore, under high payload

situation, space constraint become critical, leading to the use of stiffer springs resulting in

unsatisfactory ride behavior and reduced speed potential.

Air springs through their control mechanism, offer a load proportionate stiffness, constant floor

height and prospects of better ride behavior with higher speed potential. (See Fig.2 page No. 12).

RDSO/Lucknow

Page-4

Ref: CGW 0001,Rev.-3

4.

6.

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

Capable to sustain Super Dense Crush Loads typical of suburban traffic.

Maintain constant floor height of coach.

Provide superior ride comfort.

Virtually Constant natural frequency from tare to full loads, reducing passenger fatigue.

Isolation of structure borne noise, this improving comfort.

Improved reliability, reduced maintenance effort.

Flexibility to chose characteristics as per requirement at design stage.

CHARACTERISTICS FEATURES OF AIR SUSPENSION:

Soft flexible characteristics in vertical direction

- Achieved by compression of air (See Fig.3 page No. 13).

Excellent lateral spring characteristics, as desired.

- Achieved by variation in effective area in lateral direction (See Fig.3 page No. 13).

Avoids excess air consumption due to instantaneous modes of vehicle oscillation or

change in air pressure.

- Achieved by designing delayed reaction levelling valve (See Fig.4 page No. 14).

CONSTRUCTION DETAILS:

7.

Page 5 of 21

ADVANTAGES OF AIR SUSPENSION:

5.

Date / Month of issue:

September, 2009

Construction details of air spring are shown in (See Fig.5 page No. 15). (air spring with

outside emergency spring), & Fig. 6 at page no.16 (air spring with inside emergency

spring).

SCHEMATIC LAYOUT OF PNEUMATIC SUSPENSION CONTROL EQUIPMENTS:

A schematic layout of pneumatic suspension control equipments has been provided in Fig.7 at

page no. 17.

8.

MODIFICATION FOR FITMENT OF AIR SPRING IF REQUIRED:

8.1

Bogie Frame & Suspension:

Air spring has been installed at secondary stage replacing steel coil springs.

A fixed lower spring beam (as cradle) to accommodate the air spring has been provided

on bogie bolster.

A lateral hydraulic damper and lateral bump stop have been provided at secondary stage.

Primary springs have been retained as steel spring.

Details are shown in Fig.8 at page no. 18

Leveling valve provided between bogie frame and bogie bolster.

RDSO/Lucknow

Page-5

Ref: CGW 0001,Rev.-3

8.2

Base plate to be used should be as per drawing No. RDSO sketch- K4018 alt 1 is

enclosed as fig.9 at page no 19.

Train Driver to maintain 7 bar pressure in compressor.

In case of heavy leakage of air from air spring system, Isolate the affected bogie and

observe speed restriction at 60 km/h up to the terminal point for maintenance.

DISMANTLING OF AIR SPRING FROM LOWER SPRING BEAM (CRADLE)

AND BOGIE BOLSTER:

11.

A pipeline is drawn from M.R pipe (feed pipe) for pneumatic suspension

One isolating cock, one non return valve, one 150 lit air reservoir (auxiliary reservoir) one

air filter and two separate isolating cocks to isolate each bogie have been provided

A schematic diagram is shown in fig.7 at page no 17.

OPERATING INSTRUCTIONS:

10.

Provision made for air inlet to air spring.

40 lit addl. Reservoir connected to each air spring is provided.

Duplex check valve is provided.

BASE PLATE:

9.

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

Under frame:

8.4

Page 6 of 21

Bogie bolster:

8.3

Date / Month of issue:

September, 2009

Remove All Body, Bogie connections

Remove duplex check valve from bolster

Remove lateral & vertical shock absorber

Remove equalizing rod connection from both ends of lower spring beam if provided.

Remove connection between arm of levelling valve & installation lever.

Remove all 4 No. Bolts and nut with the help of M16 Allen key and suitable spanner from

bottom plate of air spring & lower spring beam.

Lift bolster up to bogie frame to clear the spigot of air spring.

Slide air spring from lower spring seat.

INSPECTION & MAINTENANCE OF AIR SPRING:

Inspect for any water collection in rubber bellow of air spring

Inspect the air spring for any damage or leakage.

Inspect air spring seat and top plates for corrosion, if corrosion noticed is paint with

primer & black paint.

RDSO/Lucknow

Page-6

Ref: CGW 0001,Rev.-3

12.

Inspect all welding joints of the lower spring beam (cradle) and repair if required.

Inspect air spring fixing holes of lower spring beam for elongation, if elongated build

them to dia.17 mm or dia. 26 mm.

Inspect the corrosion on top surface of lower spring beam, Remove the corrosion paint

with primer and black paint.

The air spring piping may be checked for any leakage/damage by soap test and repair if

required.

MOUNTING AIR SPRING ON LOWER SPRING BEAM AND BOLSTER:

15.

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

INSPECTION OF PIPE LINE:

14.

Page 7 of 21

INSPECTION & MAINTENANCE OF LOWER SPRING BEAM:

13.

Date / Month of issue:

September, 2009

"O" rings provided on air spring spigot must be changed.

Mount air spring on lower spring beam and match the holes of bottom plate of air spring

and holes of lower spring beam.

Tight all 4 nut-bolts with the help of M16 Allen key and suitable spanner.

Place the bolster on air spring ensuring no damage to spigot of air spring.

Connect levelling valve arm with installation lever.

Mount vertical and lateral shock absorber.

Connect all flexible/fixed pipe connections of bogie

All the threaded joints of air spring be sealed with thread sealing tape to avoid air leakage.

The filter of levelling valve must be cleaned.

TEST FOR LEAKAGE:

Connect the hosepipes on the under frame piping with the levelling valves of the bogies.

Connect pressure gauges to the drain plug locations of 150-litre reservoir.

Provide packing in the gap between bolster & bogie frame.

Connect the 150-litre reservoir on the under frame to the compressed air source of

pressure 9.0 kgf/cm2.

Allow air into the air springs to a value of 9.0 kgf/cm2 in the pressure gauge by adjusting

the horizontal lever of the levelling valve and keep it in the same position.

Close the isolating cock connecting MR pipe with 150-litre reservoir.

Test all pipe joints for leakages.

Check the pressure gauge readings after one hour. The pressure drop should be within 1%

of the test pressure 9.0 kgf/cm2.

Release the air completely by dropping the horizontal lever.

Remove the packing.

RDSO/Lucknow

Page-7

Ref: CGW 0001,Rev.-3

16.

AC SG(16 T)

NON AC (13 T)

Page 8 of 21

ICF DRAWING No.

WTAC5-0-0-501

(ANNEXURE.-C)

LWGSCWAC-0-0-001

(ANNEXURE.-D)

LGS-0-0-001

(ANNEXURE.-E)

RCF DRAWING No.

CA00001(ANNEXURE.-F)

CA00002(ANNEXURE.-G)

Than the coach should be placed at leveled track.

The primary springs should be grouped as per ICF drawing no. ICF/STD-9-0-003 placed at

Annexure-H, in which the different type of primary springs is grouped for air spring bogie and

other type of bogie.

The primary springs are used for the air spring bogies as follows:

TYPE OF COACH ICF DRAWING No.

RCF DRAWING No.

AC EOG(16 T)

WTAC-0-1-202

WTAC-0-1-202

AC SG(16 T)

WTAC-0-1-202

AW01101

NON AC (13 T)

WTAC-0-1-202

CC01129

POWER CAR

WLRRM8-0-1-801

Place the proper primary springs and compensating rings in AC EOG,AC SG and NON AC

coaches with air spring bogie as per following suspension diagram:

TYPE

OF ICF DRAWING No.

COACH

AC EOG(16 T)

WTAC5-9-0-501(ANNEXURE.-I)

AC SG(16 T)

NON AC (13 T)

-

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

PROCEDURE FOR CHECKING BOGIE CLEARANCES ON AC AND NON AC

COACHES PROVIDED WITH AIR SPRINGS :

Firstly find out the type of bogie as AC EOG (16 T), AC SG (16T), or NON AC (13 T) coaches

and make RCF or ICF. List of relevant drawings are as under:

TYPE OF COACH

AC EOG(16 T)

Date / Month of issue:

September, 2009

RCF DRAWING No.

CA90001(ANNEXURE.-J)

CA90001

Than maintain the bogie corner heights as per relevant suspension diagram.

After the bogie corner height is maintained, adjust the air spring height as per relevant suspension

diagram with the help of installation lever.

17. PROCEDURE FOR CENTRE BUFFER COUPLER HEIGHT ADJUSTMENT IN WORKSHOP:

After POH and before assembling the bogie, measure the wheel diameter.

Depending upon the wheel diameter, place wooden packing of required thickness under the

flange of lower spring seat as indicated in the following table:

Average wheel dia. between the Thickness of hard packing ring (mm)

two wheels on the same bogie

889 mm to 864 mm

863 mm to 840 mm

840 mm to 820 mm

819 mm

RDSO/Lucknow

13

26

38

48

Page-8

Ref: CGW 0001,Rev.-3

Date / Month of issue:

September, 2009

Page 9 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

18. INSTALLATION LEVER ADJUSTMENT:

Adjustment of installation levers is essential for proper levelling of coach body. The adjustment

needs to be carried out in AOH/POH or intermediate dismantling of levelling valve system. The

procedure to be followed is as under:

Keep the coach on a level track.

Connect pressure gauges to the drain plug locations of all 40-litre reservoirs in the bogie.

Place the car body on the two bogies and hook it up to the air supply (by opening the

isolating cock 1a).

First open only the isolating cock (1c0, thereby releasing the air supply for bogie 1and

affix the level control rod assembly to the valves).

On the rod assemblies (6) set the general level (-5mm) that the car body is ultimately to

have above the bogie frame and the upper edge of the bogie.

Insert the suitable block (ca 10 mm under the nominal height and preferably of hardwood)

centrally between the bogie frame and the car body and lower the car body onto the block

by removing the valve rod assembly (6).

Shut the isolating cock (1c) again, thereby interrupting the supply of air to bogie1 and

open isolating cock (1b), and thereby releasing the air supply to bogie 2.

Affix level control rod assemblies (6) to the valves (5) and set the assemblies (6) to

desired level.

Insert a suitable block (preferably hardwood) centrally between the bogie frame and the

car body and lower the car body onto block by removing the valve and assemblies (6).

Shut isolating cock (1b) again, thereby cutting off the air supply to bogie 2 and open

isolating cock (1c), and thereby releasing the air supply to bogie 1.

Attach level control rod assemblies (6) to the valves (5) and, after aeration, carefully

adjust settings on both rod assemblies (6) simultaneously (proceeding from below) until

the desired car body height has been attained.

Remove the block from bogie 1.

Reopen isolating cock (1b), thereby releasing air to bogie 2, and while at the same time

hanging the rod assembly (6) back in place in bogie 2.

Remove the block from bogie 2.

Recheck the height at all measuring points.

CAUTION:

If the difference in pressure of the air in the air springs of the same bogie is more than setting

pressure of the duplex check valve i.e. 1.5 bar, then the air will continuously escape from one air

spring to the other through the duplex check valve and then to atmosphere.

Tighten the installation lever lock nuts with the horizontal lever, so that the setting will

not be disturbed.

Repeat the above procedure for the second bogie.

Disconnect the pressure gauges and replace the drain plugs.

19.

CHARACTERISTICS OF AIR SPRING / PERIODICAL INSPECTION OF AIR SPRING

SYSTEM ON MAINLINE COACHES:

These are provided at Annexure A and B for reference and implementation.

RDSO/Lucknow

Page-9

Ref: CGW 0001,Rev.-3

20.

Date / Month of issue:

September, 2009

Page 10 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

AIR SPRING SERVICE:

For the maintenance of the air springs, the respective vendors maintenance manuals should be

followed. These maintenance manuals shall be provided by the respective vendors at the time of

delivery of air springs.

21.

AIR SPRING CONTROL EQUIPMENT SERVICE:

For the maintenance of the air springs control equipment, the respective vendors maintenance

manuals should be followed. These maintenance manuals shall be provided by the respective

vendors at the time of delivery of air spring control equipments.

-------------------------------------

RDSO/Lucknow

Page-10

Ref: CGW 0001,Rev.-3

Date / Month of issue:

September, 2009

Page 11 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

WORKING PRINCIPLE OF PNEUMATIC SUSPENSION

FIG. NO. 1

RDSO/Lucknow

Page-11

Date / Month of issue:

September, 2009

Page 12 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

FIG. No. 2

Ref: CGW 0001,Rev.-3

RDSO/Lucknow

Page-12

Date / Month of issue:

September, 2009

Page 13 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

FIG. No.3 VERTICAL AND LATERAL ACTION OF

AIR SPRING

Ref: CGW 0001,Rev.-3

RDSO/Lucknow

Page-13

Page 14 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

RDSO/Lucknow

FIG. No. 4

Date / Month of issue:

September, 2009

DELAYED REACTION OF CONTROL VALVE TO AVOID EXCESSIVE AIR CONSULATION

Ref: CGW 0001,Rev.-3

Page-14

Date / Month of issue:

September, 2009

Page 15 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

FIG. NO. 5: AIR SPRING WITH OUTSIDE

EMERGENCY SPRING

Ref: CGW 0001,Rev.-3

RDSO/Lucknow

Page-15

Date / Month of issue:

September, 2009

Page 16 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

FIG. NO. 6 : AIR SPRING WITH INSIDE EMERGENCY SPRING

Ref: CGW 0001,Rev.-3

RDSO/Lucknow

Page-16

Date / Month of issue:

September, 2009

Page 17 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

FIG.NO. 7: SCHEMATIC DIAGRAM OF AIR SUSPENSION EQUIPMENTS

Ref: CGW 0001,Rev.-3

RDSO/Lucknow

Page-17

Page 18 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

RDSO/Lucknow

FIG.No. 8 : BOGIE GENERAL ARRANGEMENT WITH AIR SPRING RETROFITMENT

Date / Month of issue:

September, 2009

CRADLE

Ref: CGW 0001,Rev.-3

Page-18

Ref: CGW 0001,Rev.-3

Date / Month of issue:

September, 2009

Page 19 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

FIG No. 9 : BASE PLATE FOR AIR SPRING

RDSO/Lucknow

Page-19

Date / Month of issue:

September, 2009

Ref: CGW 0001,Rev.-3

Page 20 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

ANNEXURE-A

GENERAL TECHNICAL DATA AS PER RDSO STR C-K509

1. STATIC VERTICAL LOADS ON AIR SPRING

Tare load -------------------------- -- 50.0 KN

Full load --------------------------- -- 140.0 KN

2. VERTICAL STIFFNESS

At dz + 20 mm and constant speed of 5mm/sec, the vertical stiffness (Cz) shall be:

Load in KN (Static)

50

115

140

Vertical stiffness Cz IN N/mm

Additional Volume 20dm3 Additional volume 40dm3

55050 N/mm

40050N/mm

87575N/mm

62575N/mm

1000100N/mm

700100N/mm

3. HORIZONTAL STIFFNESS

At dy +20 mm at constant speed of 5 mm/sec, the lateral stiffness (Cy) shall be:

Load in KN (Static)

50

115

140

Lateral stiffness Cy IN N/mm

150 25 N/mm

17525 N/mm

20025 N/mm

4. Min. height of air spring under full load with no air and without spigot - 210 mm

5. Installed height without spigot - 255+0-5 mm.

RDSO/Lucknow

Page-20

Ref: CGW 0001,Rev.-3

Date / Month of issue:

September, 2009

Page 21 of 21

Maintenance Instruction No.

CMI- RDSO/2009/CG/CMI-01

PERIODICAL INSPECTION OF AIR SPRINGS SYSTEM ON MAINLINE COACHES

EXISTING

SCHEDULE OF

INSPECTION

Primary /

Secondary

Schedule-A

Schedule -B

Schedule -C

AOH/POH

INSPECTION ON AIR SPRING SYSTEM

INSPECTION

SITE

Visual check: General conditions which includes any external damages, air leakage, infringement of any

fittings, etc.

Draining of 150-liter air reservoir of air spring

Check the position of isolating cock and drain cock, these should be on and off position respectively.

As in Primary / Secondary schedule and Draining of 40-liter reservoir.

Cleaning of leveling valve filter as per manufacturers manual. The procedure is shown at Annexure B/1.

As in Schedule -A

Checking of installation lever with inflated air spring for normal function, tightening of installation lever

nuts and protection screen nuts, tightening of bracket of all flexible hoses.

Cleaning of air filter of 150-liter reservoir.

As in Schedule -B &

Thorough checking of air spring, bulging of bellow, air leakage.

Air suspension pipe leakage check by using soap water.

Removing dust mud & oil deposit if any, on air spring and control equipment.

Thorough checking of lower spring beam for any crack and deformation.

Tightening of air spring bottom plate bolts and nuts.

Measurement of bogie clearances related to air spring.

As in Schedule - C and

Through visual check of air spring as per Annexure-C or D after dismantling as in clause 10.

Remove all valves and carry out external cleaning, overhauling and function test should be done as given

in maintenance manual supplied by respective vendors.

Checking securing arrangement of steel pipeline.

Leakage test of air springs as per clause 15.

Installation lever adjustment as per clause 18.

Lateral damper condition should be checked and replace with fresh if damaged.

Air spring bellow should not be painted.

Pit line

Page-21

Pit line

Sick line

Depot/

Work shop

ANNEXURE-B

RDSO/Lucknow

Pit line

Anda mungkin juga menyukai

- Rdso 2009 CG Cmi 01 PDFDokumen32 halamanRdso 2009 CG Cmi 01 PDFkohli91Belum ada peringkat

- Engineering Order #TC-108-7: InmediatoDokumen27 halamanEngineering Order #TC-108-7: InmediatoJóse CedanoBelum ada peringkat

- Blanik l13 - Gfa Ad-369Dokumen11 halamanBlanik l13 - Gfa Ad-369mersoigBelum ada peringkat

- Gas-Dynamic Designing of The Exhaust System For THDokumen7 halamanGas-Dynamic Designing of The Exhaust System For THSemanur ÖzdemirBelum ada peringkat

- SURAHHHHHHHHHHHDokumen6 halamanSURAHHHHHHHHHHHsuraj kumarBelum ada peringkat

- Air Compressor Flange Removal and Installation Has Been Added To The Workshop ManualDokumen4 halamanAir Compressor Flange Removal and Installation Has Been Added To The Workshop ManualChandra SutawijayaBelum ada peringkat

- 07w LandGearDokumen13 halaman07w LandGearRaees SwatiBelum ada peringkat

- 1341903547012-E chp8Dokumen109 halaman1341903547012-E chp8Vijay KumarBelum ada peringkat

- Handbook On Air Brake System For Freight StockDokumen77 halamanHandbook On Air Brake System For Freight StockSourav PaulBelum ada peringkat

- Schaku Coupler - ICF Des..Dokumen20 halamanSchaku Coupler - ICF Des..Sumit Shyamal33% (3)

- Ad 2008 08 10Dokumen9 halamanAd 2008 08 10bnolascoBelum ada peringkat

- 7.0 Pavement DataDokumen25 halaman7.0 Pavement DataMunarwand AhmadBelum ada peringkat

- Air SuspentionDokumen42 halamanAir Suspentionbhaskar098100% (1)

- Subject: Aircraft Tire Maintenance and Operational Practices Date: 4/18/05 Initiated By: AFS-306 AC No.: 20-97B ChangeDokumen10 halamanSubject: Aircraft Tire Maintenance and Operational Practices Date: 4/18/05 Initiated By: AFS-306 AC No.: 20-97B ChangeDavid Samaniego PánchezBelum ada peringkat

- Standard 625 Appendix CDokumen7 halamanStandard 625 Appendix CBakerviewBelum ada peringkat

- Lock InstallationDokumen3 halamanLock InstallationAhmet CalisBelum ada peringkat

- Design and Wind-Tunnel Analysis of A Fully Adaptive Aircraft ConfigurationDokumen9 halamanDesign and Wind-Tunnel Analysis of A Fully Adaptive Aircraft ConfigurationRicardo MinetteBelum ada peringkat

- Vietnam Power Development Plan 8 - 2024Dokumen7 halamanVietnam Power Development Plan 8 - 2024qdzungBelum ada peringkat

- Toyo 1-55Dokumen435 halamanToyo 1-55Yuda Satria100% (1)

- Project Report Rdso TRG Aman Pal JeDokumen4 halamanProject Report Rdso TRG Aman Pal JeAman PalBelum ada peringkat

- A Project Report ON " ": Air Brake SystemDokumen35 halamanA Project Report ON " ": Air Brake SystemChandan Kumar SharmaBelum ada peringkat

- Landinggear Strut and Oleo - ServicingDokumen6 halamanLandinggear Strut and Oleo - ServicingOSCAR RODRIGUEZBelum ada peringkat

- Service Bulletin: TitleDokumen12 halamanService Bulletin: TitleLuis EnriqueBelum ada peringkat

- Project PPT Pneumatic SystemDokumen25 halamanProject PPT Pneumatic SystemPankaj BhangareBelum ada peringkat

- Special Considerations in Configuration Lay-OutDokumen31 halamanSpecial Considerations in Configuration Lay-Outalagarg137691Belum ada peringkat

- Fatigue Analysis and Design of Different Compressor Rotor BladeDokumen16 halamanFatigue Analysis and Design of Different Compressor Rotor BladeAmbrish SinghBelum ada peringkat

- A Project Report On Air Brake System 2 NewDokumen92 halamanA Project Report On Air Brake System 2 NewSunny ThomasBelum ada peringkat

- Development of An Experimental Setup For Analyzing The Influence of Magnus Effect On The Performance of AirfoilDokumen9 halamanDevelopment of An Experimental Setup For Analyzing The Influence of Magnus Effect On The Performance of AirfoilDiptoBelum ada peringkat

- Steam Jet Ejectors in Pilot and Production PlantsDokumen5 halamanSteam Jet Ejectors in Pilot and Production PlantsPrabhakar KattulaBelum ada peringkat

- Ensuring integrally-geared-compressor-reliability-API-617Dokumen12 halamanEnsuring integrally-geared-compressor-reliability-API-617AbhijitBelum ada peringkat

- 15419Dokumen29 halaman15419tushar11singhBelum ada peringkat

- CompressorDokumen10 halamanCompressorArjun Shantaram ZopeBelum ada peringkat

- A Seminar-Report: Topic Air Brake System of Indian RailwaysDokumen9 halamanA Seminar-Report: Topic Air Brake System of Indian RailwaysVineet Yadav100% (1)

- DrumDokumen10 halamanDrumSaeedAkbarzadehBelum ada peringkat

- APROJECT REPORTONAIRBRAKESYSTEM2new PDFDokumen92 halamanAPROJECT REPORTONAIRBRAKESYSTEM2new PDFPravinBelum ada peringkat

- Rolls Royce Comp. GuideDokumen33 halamanRolls Royce Comp. Guideewillia13100% (1)

- Air SpringsDokumen40 halamanAir Springscts kgpBelum ada peringkat

- Reverse RsDokumen3 halamanReverse RsccoyureBelum ada peringkat

- AC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesDokumen12 halamanAC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesUjang SetiawanBelum ada peringkat

- Exec 90 Maintenance Manual 3 03Dokumen95 halamanExec 90 Maintenance Manual 3 03najmul100% (1)

- Air Brake Proportional To Load: Saeed Abu Alyazeed AlbatlanDokumen5 halamanAir Brake Proportional To Load: Saeed Abu Alyazeed AlbatlandeepakBelum ada peringkat

- Project Report PDFDokumen30 halamanProject Report PDFsaateh100% (3)

- Compressor Performance TestDokumen9 halamanCompressor Performance TestPartha Pratim GhoshBelum ada peringkat

- Solutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas IndustryDokumen7 halamanSolutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas Industryzeinab_jahani5799Belum ada peringkat

- A320 Carbon BrakesDokumen11 halamanA320 Carbon BrakesSpass100% (1)

- Influence of Elastic Foundation Structures On The Rotor DynamicsDokumen8 halamanInfluence of Elastic Foundation Structures On The Rotor DynamicsVodanh Tieutot100% (1)

- LHB Handbook On Maintof Air Brake System in LHB Coaches (FTIL Type)Dokumen120 halamanLHB Handbook On Maintof Air Brake System in LHB Coaches (FTIL Type)Rakesh Jainwal100% (4)

- Airflex Constricting Type Clutches and BrakesDokumen100 halamanAirflex Constricting Type Clutches and Brakesrony adonay sandovalBelum ada peringkat

- Awbtsg0001 9Dokumen28 halamanAwbtsg0001 9EleazarBelum ada peringkat

- A Project Report On Air Brake System 2 NewDokumen92 halamanA Project Report On Air Brake System 2 NewAvinash ArjunBelum ada peringkat

- Project Pedal and Pneumatic Actuator Operated Air CompressorDokumen6 halamanProject Pedal and Pneumatic Actuator Operated Air CompressorMehtaMilanBelum ada peringkat

- Internship ReportDokumen40 halamanInternship Report310- KiranBelum ada peringkat

- The Aircraft Engineer June 19, 1931Dokumen7 halamanThe Aircraft Engineer June 19, 1931Mark Evan SalutinBelum ada peringkat

- Flow Analysis of Upstream Fluid Flow Using Simulation For Different Positions of Optimized Inlet Guide Vane in Centrifugal Air CompressorDokumen9 halamanFlow Analysis of Upstream Fluid Flow Using Simulation For Different Positions of Optimized Inlet Guide Vane in Centrifugal Air CompressorAJER JOURNALBelum ada peringkat

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityDokumen3 halamanAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityAlexTLSBelum ada peringkat

- Study On Design of Casing of Steam TurbineDokumen3 halamanStudy On Design of Casing of Steam Turbinesevero97Belum ada peringkat

- Cleveland Wheel & Brakes Technician Service Guide AWBTSG0001Dokumen28 halamanCleveland Wheel & Brakes Technician Service Guide AWBTSG0001Richard MayBelum ada peringkat

- 737 Performance Reference Handbook - EASA EditionDari Everand737 Performance Reference Handbook - EASA EditionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachDari EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachBelum ada peringkat

- Ship YardsDokumen9 halamanShip YardsRickson Viahul Rayan CBelum ada peringkat

- 92Dokumen3 halaman92Rickson Viahul Rayan CBelum ada peringkat

- 88Dokumen3 halaman88Rickson Viahul Rayan CBelum ada peringkat

- 91Dokumen3 halaman91Rickson Viahul Rayan CBelum ada peringkat

- 89Dokumen3 halaman89Rickson Viahul Rayan CBelum ada peringkat

- 90Dokumen3 halaman90Rickson Viahul Rayan CBelum ada peringkat

- 97Dokumen3 halaman97Rickson Viahul Rayan CBelum ada peringkat

- 96Dokumen3 halaman96Rickson Viahul Rayan CBelum ada peringkat

- 95Dokumen3 halaman95Rickson Viahul Rayan CBelum ada peringkat

- 94 PDFDokumen3 halaman94 PDFRickson Viahul Rayan CBelum ada peringkat

- Ship EquipmentDokumen3 halamanShip EquipmentviahulBelum ada peringkat

- 98Dokumen2 halaman98Rickson Viahul Rayan CBelum ada peringkat

- Flareless Bite Type FittingsDokumen24 halamanFlareless Bite Type FittingsRickson Viahul Rayan CBelum ada peringkat

- Hoses and Accessories: RX KS-HP Pn40Dokumen1 halamanHoses and Accessories: RX KS-HP Pn40Rickson Viahul Rayan CBelum ada peringkat

- ErmetoDokumen28 halamanErmetoRickson Viahul Rayan C100% (1)

- Bulb Flats1Dokumen2 halamanBulb Flats1Constantine KtzmnBelum ada peringkat

- 01-Hexagon Head BoltDokumen1 halaman01-Hexagon Head BoltTony AbrahamBelum ada peringkat

- Ermeto CouplingDokumen9 halamanErmeto CouplingRickson Viahul Rayan CBelum ada peringkat

- Hoses and Accessories: RX KBF Ss/Ss Pn16Dokumen1 halamanHoses and Accessories: RX KBF Ss/Ss Pn16Rickson Viahul Rayan CBelum ada peringkat

- Compensators: RX KSU PN2,5 - Exhaust Gas BellowDokumen1 halamanCompensators: RX KSU PN2,5 - Exhaust Gas BellowRickson Viahul Rayan CBelum ada peringkat

- Hoses and Accessories: RX KS-HP Pn40Dokumen1 halamanHoses and Accessories: RX KS-HP Pn40Rickson Viahul Rayan CBelum ada peringkat

- Hoses and Accessories: RX KSG Pn16Dokumen2 halamanHoses and Accessories: RX KSG Pn16Rickson Viahul Rayan CBelum ada peringkat

- Compensators: RX KFFT Pn16Dokumen1 halamanCompensators: RX KFFT Pn16Rickson Viahul Rayan CBelum ada peringkat

- Hoses and Accessories: RX KBF Ss/Ss Pn16Dokumen1 halamanHoses and Accessories: RX KBF Ss/Ss Pn16Rickson Viahul Rayan CBelum ada peringkat

- Hoses and Accessories: RX KS2T PN16Dokumen1 halamanHoses and Accessories: RX KS2T PN16Rickson Viahul Rayan CBelum ada peringkat

- Compensators: RX Kff2T Pn16Dokumen1 halamanCompensators: RX Kff2T Pn16Rickson Viahul Rayan CBelum ada peringkat

- Hoses and Accessories: RX KST Pn16Dokumen1 halamanHoses and Accessories: RX KST Pn16Rickson Viahul Rayan CBelum ada peringkat

- Compensators: RX KBFL Pn16Dokumen1 halamanCompensators: RX KBFL Pn16Rickson Viahul Rayan CBelum ada peringkat

- Aire Valley Railway SeriesDokumen61 halamanAire Valley Railway SeriesTom Bell100% (1)

- PRESENTATION of IR LOCOMOTIVE BOGIESDokumen38 halamanPRESENTATION of IR LOCOMOTIVE BOGIESAMAN GUPTABelum ada peringkat

- HTC Equipment List PDFDokumen6 halamanHTC Equipment List PDFSahanBelum ada peringkat

- BOBRNDokumen18 halamanBOBRNManoj KumarBelum ada peringkat

- BOBR Wagon DetailsDokumen4 halamanBOBR Wagon DetailsZahoor AhmedBelum ada peringkat

- ESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockDokumen57 halamanESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockRafael SchelbauerBelum ada peringkat

- Draft Maintenance Manual For WagonsDokumen574 halamanDraft Maintenance Manual For WagonsMd Arifullah100% (1)

- BT Ixion Swe 120iDokumen4 halamanBT Ixion Swe 120iIker BasqueAdventureBelum ada peringkat

- Fiat Bogie PresentationDokumen54 halamanFiat Bogie Presentationkr_abhijeet7235658783% (6)

- Project Report of Internship For Inventory ManagementDokumen88 halamanProject Report of Internship For Inventory Managementmakwanagaurav185779100% (1)

- Noise Technical Measures CatalogueDokumen63 halamanNoise Technical Measures CatalogueAdela TomaBelum ada peringkat

- 1552989005406-Question Bank On LHB Design Coaches PDFDokumen32 halaman1552989005406-Question Bank On LHB Design Coaches PDFKashul Kumar90% (10)

- Dictionar Feroviar RO-EnDokumen216 halamanDictionar Feroviar RO-EnMonica BumbăcelBelum ada peringkat

- Rollfeder EnglischDokumen3 halamanRollfeder EnglischKristoffer MosshedenBelum ada peringkat

- Summer Internship ReportDokumen57 halamanSummer Internship ReportPREMBelum ada peringkat

- Dictionar Feroviar RO-ENDokumen222 halamanDictionar Feroviar RO-ENonesunnyday100% (1)

- Bogie Mounted Brake System, Indian Railways.Dokumen18 halamanBogie Mounted Brake System, Indian Railways.Srinivas Avutapalli50% (2)

- Yale End Truck Brochure Y-ET-B-0915Dokumen6 halamanYale End Truck Brochure Y-ET-B-0915Brad BorgesBelum ada peringkat

- Indian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Dokumen15 halamanIndian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Pratap Singh GangwarBelum ada peringkat

- Question Bank For SCOR - TI HQRS Final - 26Dokumen99 halamanQuestion Bank For SCOR - TI HQRS Final - 26Jeetendra Singh ChauhanBelum ada peringkat

- Fontaine Flip Neck MatrixDokumen3 halamanFontaine Flip Neck MatrixPete ABelum ada peringkat

- Bombardier Zefiro Technical Description enDokumen15 halamanBombardier Zefiro Technical Description ennickerlesstezla100% (1)

- Handbook On Bogie Mounted Brake System of ICF CoachesDokumen54 halamanHandbook On Bogie Mounted Brake System of ICF CoachesVijay Anand0% (1)

- Fontaine Flip Axle MatrixDokumen3 halamanFontaine Flip Axle MatrixPete ABelum ada peringkat

- CNC LTS EdpDokumen35 halamanCNC LTS EdpZishan KhanBelum ada peringkat

- MMMUT PPT TemplateDokumen17 halamanMMMUT PPT TemplateÀnkit MishràBelum ada peringkat

- Sky BusDokumen26 halamanSky BusDevidas SapkaleBelum ada peringkat

- Hand Pallet Truck-VL25Dokumen2 halamanHand Pallet Truck-VL25sutanuprojectsBelum ada peringkat

- Sect 13 LOCOMOTIVES Incl New AS Id1 PDFDokumen81 halamanSect 13 LOCOMOTIVES Incl New AS Id1 PDFRizki Fajar NovantoBelum ada peringkat

- FR8 WP4 D Ac2 022 03 - FR8 WP4 D KTH - DLR - TVP 021 03Dokumen186 halamanFR8 WP4 D Ac2 022 03 - FR8 WP4 D KTH - DLR - TVP 021 03Gabriel CaraveteanuBelum ada peringkat