Black Specks

Diunggah oleh

Steven ChengHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Black Specks

Diunggah oleh

Steven ChengHak Cipta:

Format Tersedia

BLACK SPECKS

sensitive (like PVC). It is not a good

idea to empty the barrel for every shot

because more time will be required to

bring the next mass of material up to

proper heat and degradation may occur.

TRAPPED MATERIAL

BlSpeck

Black specks can be defined as small

dark particles or spots

on the surface of an opaque injection

molding part or within a transparent

part.

MACHINE

EXCESSIVE RESIDENCE TIME IN

BARREL

Explanation: Under the best conditions,

a shot size should represent 50% of the

capacity of the injection cylinder (barrel).

This will result in processing the

material for one cycle while preparing

the material for the next cycle. Thus, a

mold requiring a four-ounce shot should

be run in a machine that has a barrel

with an eight-ounce capacity. The more

material left in the barrel between shots,

the greater the likelihood of thermal

degradation. This degradation is what

causes the black specks.

Solution: Strive for a 50% shot-to-barrel

ratio. This is ideal but can go as low as

20%, if the material is not too heat

sensitive (like polypropylene) and up to

80% if the material is extremely heat

Explanation: If any molten resin is

trapped along the flow path (most

notably in the heating cylinder), it will

stay there until it degrades. When this

happens, the degraded material becomes

carbonized, then chars and becomes

brittle. At that point, it will flake away

from the area of entrapment and enter

the melt stream appearing as black

specks or streaks.

Solution: Inspect the barrel liner, nozzle,

non-return valve, and check ring for

nicks, cracks, rough surfaces, peeled

plating or stuck resin. Then, stone and

polish as required, replace any damaged

mechanisms, and inspect the main and

secondary runners, as well as the sprue

bushing, for nicks, rough surfaces or

sharp corners. Round off sharp corners

and radius corners where possible to

minimize material trapping and shear

points.

CONTAMINATION IN INJECTION

BARREL

Explanation: Any type of contamination

in the injection barrel may be the cause

of streaks, spots, and specks. It may be

in the form of dust particles that fell

from the ceiling into an open hopper,

pellets from other materials, residual

resin from an improper changeover, or

even pieces of food that accidentally fell

www.plasticmoulds.net

into a container of material ready to be

placed in the hopper.

loose and enters the melt stream,

appearing as specks or streaks.

Solution: To remove this type of

contamination it may be necessary to

increase the temperature of the injection

barrel and, using a purging material with

a wide melt range, purge the

contaminate(s) from the system.

Solution: Inspect the injection unit for

cracks and nicks in the walls. Sometimes

damaged cylinder walls can be welded

but it is usually more effective to replace

the cylinder liner. Pitted screws must be

welded, ground and replated, or replaced

with new stock.

UNCONTROLLED HEATER BANDS

OR THERMOCOUPLES

Explanation: Improperly sized or loose

heater bands or thermocouples can cause

localized degradation of the material by

exposing it to extreme heat. They may

be calling for more heat than normal due

to malfunction or improper sizing. Even

a heater band that is not working can be

the cause of such overheating. The

reason is that adjacent heater bands must

increase heat to compensate for the

nonworking band.

Solution: Check each heat zone to

ensure that all heater bands are working

properly, are properly controlled,

properly sized, and are tight against the

barrel. A conductive sealant should be

used to ensure full contact with the

barrel. Be sure to replace bands with the

proper size, voltage, and wattage

requirements as stated in the machine

manual.

DAMAGED BARREL OR SCREW

Explanation: A cracked injection

cylinder or pitted screw is a cause of

material hang-up and degradation.

Eventually this degraded material breaks

OIL LEAKS

Explanation: Hydraulic components or

fittings that are in the proximity of the

injection cylinder may leak. This

leakage may get into raw material

storage containers and find its way into

the material hopper. The oil will burn at

the temperatures needed for molding and

will degrade and char. This degraded

material is a source for streaks and

specks.

Solution: Eliminate all hydraulic leaks

as soon as possible after they occur.

MOLD

SPRUE BUSHING IS NICKED,

ROUGH, OR NOT SEATING

Explanation: A damaged sprue may

cause material to stick and be held in

residence at elevated temperature until it

degrades and decomposes. At that point,

it will break loose and enter the melt

stream as streaks or specks.

Solution: Inspect the internal surfaces of

the sprue bushing. Remove any nicks or

other imperfections. The tapered hole

should be highly polished. Check the

sprue bushing-to-nozzle seal with thin

www.plasticmoulds.net

paper or bluing ink to ensure that the

nozzle is centered to the bushing and

that the hole and radius dimensions are

compatible for the nozzle and the

bushing.

IMPROPER VENTING

Explanation: Air is trapped in a closed

mold and incoming molten plastic will

compress this air until it auto-ignites.

This burns the surrounding plastic and

results in charred material in the form of

spots and specks.

Solution: Vent the mold by grinding thin

(0.0005-0.002) pathways on the

shutoff area of the cavity blocks. Vents

should take up a minimum of 30% of the

perimeter of the molded part. Vent the

runner, too. Any air that is trapped in the

runner will be pushed into the part.

CONTAMINATION FROM

LUBRICANTS

Explanation: Excessive use of mold

release will clog vents. The trapped air

cannot be evacuated and burns. Also,

grease that is used for lubricating cams,

slides, ejector pins, etc., can seep into

the mold cavity and contaminate the

molded part.

Solution: The remedy is to keep the

mold as clean as possible and clean the

vents if they become clogged. A white

ash will be present if the vents are

clogged. Also, make every effort to

eliminate the use of external mold

releases.

MOLD TOO SMALL FOR MACHINE

SIZE

Explanation: If the mold is placed in too

large of a machine, the chances are that

the heating cylinder of that machine will

be large enough to result in extensive

residence time of the raw material in the

heated cylinder. This will result in

degraded material that will be injected

into the mold causing streaks and

specks.

Solution: Place all molds in properly

sized machinery. A rule-of-thumb states

that the machine should inject between

20% and 80% of its capacity every shot.

MATERIAL

CONTAMINATED RAW MATERIAL

Explanation: The most common causes

of black specks and streaks are molding

compound contaminants. Such

contamination is usually the result of

dirty regrind, improperly cleaned

hoppers or granulators, open or

uncovered material containers, and poor

quality virgin material supplied by the

manufacturer.

Solution: This type of contamination can

be minimized by dealing with high

quality, reputable suppliers and by using

good housekeeping practices. Properly

trained material handlers will also help

reduce contamination.

OPERATOR

INCONSISTENT PROCESS CYCLE

Explanation: It is possible that the

machine operator is the cause of delayed

or inconsistent cycles. This will result in

www.plasticmoulds.net

excessive residence time of the material

in the injection barrel. If such a

condition exists, heat sensitive materials

will degrade, resulting in black specks or

streaks.

Solution: If at all possible, run the

machine on automatic cycle, using the

operator only to interrupt the cycle if an

emergency occurs. Use a robot if an

operator is really necessary. And,

instruct all employees on the importance

of maintaining consistent cycles.

www.plasticmoulds.net

Anda mungkin juga menyukai

- Injection Molding ProcessDokumen3 halamanInjection Molding ProcessSteven ChengBelum ada peringkat

- Causes of Wear and Damage of Plastic MoldDokumen8 halamanCauses of Wear and Damage of Plastic MoldSteven ChengBelum ada peringkat

- Color Change For The Same MaterialDokumen6 halamanColor Change For The Same MaterialSteven ChengBelum ada peringkat

- Plastic Part DesignDokumen11 halamanPlastic Part DesignSteven ChengBelum ada peringkat

- Injection Molding ProcessDokumen12 halamanInjection Molding ProcessSteven ChengBelum ada peringkat

- It Can Be Complicated To Buy A Mold PDFDokumen1 halamanIt Can Be Complicated To Buy A Mold PDFSteven ChengBelum ada peringkat

- How To Identify Faults in Injection MoldingDokumen3 halamanHow To Identify Faults in Injection MoldingSteven ChengBelum ada peringkat

- Pricing The Plastic MoldDokumen4 halamanPricing The Plastic MoldSteven ChengBelum ada peringkat

- The Designer of Plastics ToolingDokumen2 halamanThe Designer of Plastics ToolingSteven ChengBelum ada peringkat

- Clamping Tonnage Vs Shot WeightDokumen1 halamanClamping Tonnage Vs Shot WeightSteven ChengBelum ada peringkat

- Practical Points in Mold Design and ConstructionDokumen9 halamanPractical Points in Mold Design and ConstructionSteven ChengBelum ada peringkat

- Safety Rules For Injection MoldingDokumen1 halamanSafety Rules For Injection MoldingSteven ChengBelum ada peringkat

- Injection Moulding ProcessDokumen3 halamanInjection Moulding ProcessSteven ChengBelum ada peringkat

- Injection Moulding ProcessDokumen5 halamanInjection Moulding ProcessSteven ChengBelum ada peringkat

- The Mould Design Guide-Modificated-1Dokumen3 halamanThe Mould Design Guide-Modificated-1charliesquibbzywlBelum ada peringkat

- Plastic Moulding ProcessDokumen4 halamanPlastic Moulding ProcessSteven ChengBelum ada peringkat

- Injection Machine OperationDokumen2 halamanInjection Machine OperationSteven ChengBelum ada peringkat

- Black SpecksDokumen3 halamanBlack SpecksSteven ChengBelum ada peringkat

- Troublshooting For PET PreformDokumen5 halamanTroublshooting For PET PreformSteven Cheng75% (4)

- Plastic Mold TryoutDokumen2 halamanPlastic Mold TryoutSteven ChengBelum ada peringkat

- Safety Rules For Molding DepartmentDokumen2 halamanSafety Rules For Molding DepartmentSteven ChengBelum ada peringkat

- GLOSS (Low) Low Gloss Can Be Defined As A Dulling of TheDokumen3 halamanGLOSS (Low) Low Gloss Can Be Defined As A Dulling of TheSteven Cheng100% (1)

- Brief of Mold MaintenenceDokumen3 halamanBrief of Mold MaintenenceSteven ChengBelum ada peringkat

- Brief of Mold MaintenenceDokumen3 halamanBrief of Mold MaintenenceSteven ChengBelum ada peringkat

- Brief of Mold MaintenenceDokumen3 halamanBrief of Mold MaintenenceSteven ChengBelum ada peringkat

- Injection Molding DesignDokumen6 halamanInjection Molding DesignSteven ChengBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Wires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFDokumen11 halamanWires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFShubham Kumar JhaBelum ada peringkat

- HBSC3203 - V2 (Chemistry Ii) AssignmentDokumen20 halamanHBSC3203 - V2 (Chemistry Ii) AssignmentLester Randy RubintinusBelum ada peringkat

- Flowserve Oil and Gas Upstream and Pipeline PDFDokumen20 halamanFlowserve Oil and Gas Upstream and Pipeline PDFmesplamaxBelum ada peringkat

- G20 Business Letter We Mean Business CoalitionDokumen26 halamanG20 Business Letter We Mean Business CoalitionComunicarSe-ArchivoBelum ada peringkat

- Vacuum System: Plant Engineer OleochemicalDokumen55 halamanVacuum System: Plant Engineer OleochemicalMahendra Puguh100% (2)

- In Case of EmergencyDokumen352 halamanIn Case of EmergencyYgor JesusBelum ada peringkat

- Regulator Capacitor Manual PDFDokumen8 halamanRegulator Capacitor Manual PDFKyle StairBelum ada peringkat

- CT Saturation and Its Influence On Protective Relays: Roberto Cimadevilla, Ainhoa FernándezDokumen22 halamanCT Saturation and Its Influence On Protective Relays: Roberto Cimadevilla, Ainhoa FernándezANTONIO SOLISBelum ada peringkat

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Dokumen2 halamanSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaBelum ada peringkat

- Safety Rule Book For Persons in Charge of Work On Mechanical Systems Associated With JSP 375 Volume 3 Chapter 4Dokumen43 halamanSafety Rule Book For Persons in Charge of Work On Mechanical Systems Associated With JSP 375 Volume 3 Chapter 4Dimkovski Sase KazakBelum ada peringkat

- Gates em Ingles 2010Dokumen76 halamanGates em Ingles 2010felipeintegraBelum ada peringkat

- W SeatDokumen2 halamanW SeatwalleyranBelum ada peringkat

- ST 2DDokumen257 halamanST 2Dsaul100% (1)

- StandardsDokumen76 halamanStandardsSohaib ZafarBelum ada peringkat

- Dual Cab Locomotive HandbookDokumen80 halamanDual Cab Locomotive HandbookRah Mli80% (5)

- Cambridge International AS Level: Environmental Management 8291/12Dokumen12 halamanCambridge International AS Level: Environmental Management 8291/12zohaibBelum ada peringkat

- Arlan Alvar: Compex Certified E&I Ex Inspector (Qa/Qc) Available For New OpportunityDokumen3 halamanArlan Alvar: Compex Certified E&I Ex Inspector (Qa/Qc) Available For New OpportunityDo naBelum ada peringkat

- Brazil Chapter 12: Agriculture, Minerals, Industries & TradeDokumen8 halamanBrazil Chapter 12: Agriculture, Minerals, Industries & TradeHaseebullahBelum ada peringkat

- New One Role of Forests in Sustainable DevelopmentDokumen6 halamanNew One Role of Forests in Sustainable DevelopmentAbhijit NayakBelum ada peringkat

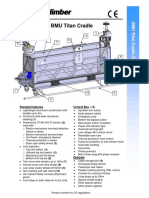

- BMU Titan Cradle: Standard Features Control BoxDokumen2 halamanBMU Titan Cradle: Standard Features Control BoxKashyapBelum ada peringkat

- L7 Voltage Regulator, Half Wave Rectifier S2 1617Dokumen20 halamanL7 Voltage Regulator, Half Wave Rectifier S2 1617Bhagyalaxmi patilBelum ada peringkat

- Green Building Rating Systems ExplainedDokumen42 halamanGreen Building Rating Systems ExplainedJake CerezoBelum ada peringkat

- Starting - Rav4 Sxa1Dokumen19 halamanStarting - Rav4 Sxa1Christian Linares AbreuBelum ada peringkat

- Automotive Application Guide 2014 - BR PDFDokumen60 halamanAutomotive Application Guide 2014 - BR PDFbnc1100% (1)

- Spe 131758 Ms - GL and EspDokumen11 halamanSpe 131758 Ms - GL and EspSamuel VmBelum ada peringkat

- Improved procedures for separating crystals from the meltDokumen10 halamanImproved procedures for separating crystals from the meltAna Mariel VenturaBelum ada peringkat

- HMCDokumen8 halamanHMCmahmoud nafieBelum ada peringkat

- Fermentor TypesDokumen33 halamanFermentor TypesFahad MukhtarBelum ada peringkat

- IR CompressorDokumen30 halamanIR CompressorkingofngayeBelum ada peringkat