Treatment of Grey and Small Scale Industry Waste Water With The Help of Vermi-Filter

Diunggah oleh

Matthew JohnsonJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Treatment of Grey and Small Scale Industry Waste Water With The Help of Vermi-Filter

Diunggah oleh

Matthew JohnsonHak Cipta:

Format Tersedia

Civil Engineering and Urban Planning:An International Journal(CiVEJ) Vol.2,No.

1, March 2015

TREATMENT OF GREY AND SMALL SCALE INDUSTRY

WASTE WATER WITH THE HELP OF VERMI-FILTER

Pali Sahu1, Swapnali Raut2 and Sagar Mane3

1

Asst.Prof. Environmental Engineering, Civil Department, VIIT, Pune, India

2

U.G. Student, Civil Department, VIIT, Pune, India

3

U.G. Student, Civil Department, VIIT, Pune, India

Abstract

Water is becoming one of the important and limited resources available to us. Reuse and recycle is the best option

to deal with water scarcity. Therefore an attempt is made to reuse the grey and small scale industry water after

giving low cost effective treatment with the help of vermi-filter. Vermi-filtration is a new and innovative

technology in which the combined action of earthworms activity and the adsorption properties of other

materials like soil, sand and gravel particles on the organic pollutants are applied for wastewater treatment.

This study is aimed to test the suitability of vermi-filter and non-vermi-filter for the various critical parameter

namely pH, removal efficiency of BOD, COD and TSS. From the present experiment data it was found that the

efficiency of vermi-filter is much better than Non vermi-filter (normal filter). Vermi-filter is an eco-friendly

technology which does not produces sludge and is very economical.

Keywords

Earthworms, Eisenia fetida (tiger worm), Vermi-filter, Non-vermi-filter, Ingestion, Biodegradation,

Biochemical oxygen Demand (BOD), Chemical oxygen Demand (COD)

1.INTRODUCTION

Fresh water is becoming one of the most limited resources available to us. Today we are left with no

other option but to conserve reuse& recycle every drop of water that we use. Due to rapid increase in

population, industrialization and development, there is an increased opportunity for grey-water reuse in

developing countries such as India. India accounts for 2.45% of land area and 4% of water resources

of the world but represents 16% of the world population. [1]

The International Water Management Institute (IWMI) predicts that in India by 2025, one person out of

three will live in conditions of absolute water scarcity (IWMI, 2003). It is therefore very essential to reduce

surface and ground water use in all sectors of consumption, to substitute this with alternative water

resources available and to enhance water use efficiency through other options like reuse. These

alternative resources include rainwater harvesting and reuse, grey-water and waste water reuse. It is

estimated that 38355 million liters per day (MLD) of sewage is generated in major cities of India,

but the sewage treatment capacity is only of 11787 MLD. [2] This uncollected sewage is directed

to the water bodies and hence is the cause of pollution. Similarly, only 60% of industrial waste

water (large scale industries) is treated while the small scale industries discharge their waste

water directly into water bodies which ultimately pollutes the nearby river. [3]

Hence to meet the increased demand of fresh water and to reduce the pollution load on the water

bodies, an economical treatment approach is required. Reusing waste water (includes both

domestic and industrial) is a new and attractive economic alternative and helps conserve an

29

Civil Engineering and Urban Planning:An International Journal(CiVEJ) Vol.2,No.1, March 2015

essential commodity for future generations. The treatment methods should be efficient so that the

treated waste water can be reused for certain application.

Research has been done to reuse the grey water efficiently and help to reduce the demand. [4, 5]

It is also estimated that grey-water reusing can help to save 40% to 45% of the annual water

consumption.

As water for industrial application becomes less easily accessible, industry is looking for ways to recycle

and reuse. For efficient reuse of the industrial waste water, an extensive treatment system is required as the

contaminant concentration is high and toxic. Generally chemical treatment methods are adopted to treat

industrial influent; these methods incurred huge cost and require skilled maintenance. Limited literature is

available for the use of biological methods to treat and reuse the industrial waste water. [6, 7]

One such emerging technique is vermi-filter which is cost effective and efficient. The treated effluent is

suitable for may reuse application. Vermi-filtration of waste water using waste eater earthworms is a newly

conceived technology. Earthworms body works as a Bio-filter and they have been found to remove the

BOD5, COD & TSS by almost 80-90% from waste water by the general mechanism of Ingestion &

Biodegradation. [8]

A low cost treatment system with adequate efficiency is essential for small scale industries which are not able

to treat their waste water because of unavailability of funds and discharging it into water bodies and causing

water pollution. As the grey water which generates from bath-room is less contaminated as compare to other

waste water and can be treated separately to reduce the burden on the sewage treatment plants (STP).

Therefore a low cost treatment system is required to treat effluent of small scale industries and grey water to

make it fit for reuse.

Hence in the present work, experimental setup of a vermi-filter was prepared and the efficiency of

treatment was studied for industrial waste water and grey water. Also efforts were made to

compare a vermi-filter with a Non vermi-filter (normal filter).The comparison was made based on

critical parameters like pH, BOD, COD, TSS.

2. METHODS AND MATERIALS

2.1 Experimental set up

A vermi-filter and a non vermi-filter were prepared by using the locally available material. Figure

1 shows the earthworm used in the present study and Figure 2 describe the schematic layout of a

vermi-filter. The filter consists of four layers. The bottom-most layer was made of gravel

aggregate of size 20mm and it fills up to the depth of 40mm. Above this lies the layer of

aggregate of 10mm size filling up to depth of 30mm.On the top of 10 mm aggregate, the sand

passing through 2.36 mm I.S sieves were placed up to a depth of another 30mm. The top most

layer consist of a mixture of soil & cow dung in 1:3 proportion and were placed at the top of sand

layer up to depth of 120mm in which the earthworms Eisenia fetida (tiger worm), were also

released.

30

Civil Engineering and Urban Planning:An International Journal(CiVEJ) Vol.2,No.1, March 2015

Figure 1: Earth Worms used in the vermin filter

In the vermi-filtration system, suspended solid particles get trapped on top of the vermi-filter and,

after getting processed by the earthworms present in the mixture of soil and cow dung, are fed to

the soil microbes immobilized in the vermi-filter. The organic and inorganic solids which are in

dissolved and suspended form get trapped by adsorption and stabilized through complex

biodegradation processes which occur in the living soil inhabited by earthworm and the aerobic

microbes. Aggregation of soil processes and aeration by earthworms and the resultant soil

stabilization makes the complete filtration system very effective, while reducing the overall space

requirement compared to a conventional filtration system. [9-11]

Figure 2:Vermi-filter kit

A non-vermi-filter is a filter without earthworms and hence the only difference is in the top most

layer, rest all the layers were same as the layers of a vermi-filter (fig. 3). The top most-layer does

not contain the earthworms and only contain the soil. This filter works on the adsorption

mechanism where the impurities are adsorbed by the soil and sand layers and hence removal

takes place.

31

Civil Engineering and Urban Planning:An International Journal(CiVEJ) Vol.2,No.1, March 2015

Figure 3: Non-Vermi-filter kit

1.2 Experimental method used in vermi-filter& Non-Vermi-filter:

The influent from dairy and paper and pulp industry and grey water from canteen of the college campus was

collected. The influent (5 litres) was stored in a plastic bucket of 7 litres capacity. These buckets were kept on

an elevated platform just near the vermi-filter for maintaining proper flow. The buckets had tap at the bottom

to which irrigation system was attached. The waste water distribution system consist of simple 0.5 inch

flexible pipe with holes for trickling water that allowed uniform distribution of waste water on the soil surface

(figure 4). The waste water is percolated through various layers of filter bed & at the end it was collected in a

chamber at the bottom of the kit. Same day this treated water from both the filter is analyzed for pH, BOD,

COD & TSS.

Figure 4: Experimental setup

1.3 Analytical methods used in laboratory:

Analysis of mixed waste water (Grey water and small scale industry waste water) was carried out

in the Environmental Laboratory of the Civil Engineering Department, VIIT College, Pune. It

was done to analyze all the critical parameters pH, BOD, COD and TSS value of the influent and

effluent waste water obtained from vermi-filter & non-vermi-filter. (Lab test are performed as per

IS3025 Part 44:1993).

32

Civil Engineering and Urban Planning:An International Journal(CiVEJ) Vol.2,No.1, March 2015

3. Results & Discussion:

3.1 Biological Oxygen Demand

Figure 5: BOD of influent and effluent

It can see from figure 5 that the percentage reduction of BOD in vermi-filter ranges from 87% to

90% while in non-vermi-filter it was found to be 33% to 37%.

3.2 Chemical Oxygen Demand:

Figure 6: COD of influent and effluent

Figure 6 shows that the percentage of reduction COD in vermi-filter ranges from 70% to 90%.

This reduction in COD may be due to earthworms that secrete the enzymes which help in the

degradation and decomposition of several other chemical which cannot be decomposed by

microbes. The COD reduction in non vermi-filter was found to be 16% to 20%. This may be due

to increase the formation of biofilms of decomposers microbes in geological system. Biological

process and filtration are mechanism to remove COD.

33

Civil Engineering and Urban Planning:An International Journal(CiVEJ) Vol.2,No.1, March 2015

3.3 Total Suspended Solids:

Figure 7: TSS of influent and effluent

The percentage reduction in concentration of TSS of waste water by vermi-filter ranges from 90%

to 99% (figure 7) whereas in non-vermi-filter it was found to be 80% to 90%.

3.4 pH:

Figure 8: pH of influent and effluent

Earthworms are sensitive to change the pH. The prefer condition is neutral reaction. The pH of

waste water in the initial stage was 5.5 to 6.5 (acidic nature). But as the degradation started in

vermi-filter the pH range was found to be 7.2 to 7.4 (alkaline) while pH remains same in effluent

as in influent in non-vermi-filter.

4.Conclusion:

From the experimental data, it was found that vermi-filter is more efficient than non- vermi-filter

in removal efficiency of BOD, COD TSS, pH.

The major conclusions drawn from the project for vermi-filter are given below:

34

Civil Engineering and Urban Planning:An International Journal(CiVEJ) Vol.2,No.1, March 2015

1.Zero sludge produce.

2.Efficiency is achieved up to 90%.

3.Convenient to use.

4.It has an in-built pH buffering ability and hence can accept waste water within a pH range 4 to 9

without any pH adjustment.

5.Economical & Eco-friendly.

6.The vermi-filtered water is clean and can be recycled in many industrial plants for production

processes & various secondary uses.

7.Filtered water can also be used for irrigation.

REFERENCES:

[1]

[2]

[3]

[4]

UNEP: Clearing the Waters ,A focus on water quality solutions

R Kaur SP Wani: Wastewater production, treatment and use in India.

S.K.Garg & B.C.Punmia: water supply & waste water engg.

Mehta, M et al. 2009: In the Public Interest: Landmark Judgements & Orders of the Supreme Court of

India on Environmental & Human Rights (Volume I).Prakriti Publications

[5] Tomar, P., & Suthar, S.2011: Urban wastewater treatment using vermi-biofiltration

system.Desalination Vol 28 no.2, 95-103

[6] Musaida Mercy Manyuchi et al 2013:Application of Vermi-filter-based Effluent Treatment Plant

(Pilot scale) for Biomanagement of Liquid Effluents from the Gelatine Industry

[7] Ghatnekar et al. 2010: Zero discharge of waste water from juice making industry by vermifiltration

technology:

[8] RohitPathania et al. 2012:A review of vermifiltration and related low cost alternatives for waste

water management :

[9] Prasad Amit Kumar et al 2013:International Journal of Scientific Research and Review Vertical Sub

Surface Flow Constructed Vermi-filter;

[10] Gajalakshmi et al. 2004: Earthworm and Vermi composting, Indian Journal of Biotechnology Vol.3.

[11] NamdarAparna et al.: Vermiculture Biotechnology, Geosense www.google .

35

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Civil Engineering and Urban Planning: An International Journal (CIVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CIVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CIVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CIVEJ)Matthew JohnsonBelum ada peringkat

- Exploration of Forming An Ecological Eco-Environment Protection Planning System: Taking The Suining City As An ExampleDokumen20 halamanExploration of Forming An Ecological Eco-Environment Protection Planning System: Taking The Suining City As An ExampleMatthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CIVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CIVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Call For Paper - Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCall For Paper - Civil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen1 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Call For Paper CIVEJDokumen2 halamanCall For Paper CIVEJMatthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen1 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen1 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen1 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CIVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CIVEJ)Matthew JohnsonBelum ada peringkat

- Call For Paper - Civil Engineering and Urban Planning: An International Journal (CiVEJ)Dokumen2 halamanCall For Paper - Civil Engineering and Urban Planning: An International Journal (CiVEJ)Matthew JohnsonBelum ada peringkat

- Civil Engineering and Urban Planning: An International JournalDokumen2 halamanCivil Engineering and Urban Planning: An International JournalMatthew JohnsonBelum ada peringkat

- International Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)Dokumen2 halamanInternational Journal On Soft Computing, Artificial Intelligence and Applications (IJSCAI)Matthew JohnsonBelum ada peringkat

- IjmpictDokumen2 halamanIjmpictWspcfp WireillaBelum ada peringkat

- Civil Engineering and Urban Planning: An International Journal (CIVEJ)Dokumen2 halamanCivil Engineering and Urban Planning: An International Journal (CIVEJ)Matthew JohnsonBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- CIDB MyCESMM Library of Standard DescriptionsDokumen173 halamanCIDB MyCESMM Library of Standard Descriptionskiet eelBelum ada peringkat

- Research Article Typology of Municipal Wastewater Treatment Technologies in Latin AmericaDokumen7 halamanResearch Article Typology of Municipal Wastewater Treatment Technologies in Latin AmericaMarcela JaimesBelum ada peringkat

- Xii Biology Case Study Based Q ADokumen12 halamanXii Biology Case Study Based Q APraphul Pulkit GiriBelum ada peringkat

- Env 20 BodDokumen14 halamanEnv 20 BodMsMME123Belum ada peringkat

- Research On Effluent-Oxidation PondDokumen6 halamanResearch On Effluent-Oxidation PondCHIN FelleBelum ada peringkat

- National Surface Water Classification CriteriaDokumen33 halamanNational Surface Water Classification Criteriawaheed2286Belum ada peringkat

- CTB3365x W1d Slides PDFDokumen15 halamanCTB3365x W1d Slides PDFChamuk_ZpxBelum ada peringkat

- Doctoral Dissertation Final Draft - Travis Waldemar BrownDokumen139 halamanDoctoral Dissertation Final Draft - Travis Waldemar BrownJesus Jimenez SaenzBelum ada peringkat

- OISD-GDN 199: Oil Industry Safety DirectorateDokumen32 halamanOISD-GDN 199: Oil Industry Safety Directoratemasoud132Belum ada peringkat

- Determination of Metals Concentrations and Water Quality Status Along Ulu Jempul River (Siti Norhafiza Mohd Khazaai) PP 26-34Dokumen9 halamanDetermination of Metals Concentrations and Water Quality Status Along Ulu Jempul River (Siti Norhafiza Mohd Khazaai) PP 26-34upenapahangBelum ada peringkat

- Assessment of Physico Chemical Parameters and Correlation Coefficient of The River Ganga Water at Budhanath Ghat of Bhagalpur BiharDokumen5 halamanAssessment of Physico Chemical Parameters and Correlation Coefficient of The River Ganga Water at Budhanath Ghat of Bhagalpur BiharEditor IJTSRDBelum ada peringkat

- Isbn 978 1 57766 605 9 PDFDokumen12 halamanIsbn 978 1 57766 605 9 PDFegb93Belum ada peringkat

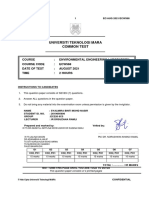

- Universiti Teknologi Mara Common TestDokumen5 halamanUniversiti Teknologi Mara Common TestSyalmira LovetobelovedBelum ada peringkat

- 0.12siph + 0.16siss + 0.15sian + 0.16sicod + 0.19sibod + 0.22sido WqiDokumen34 halaman0.12siph + 0.16siss + 0.15sian + 0.16sicod + 0.19sibod + 0.22sido WqiMudin DinBelum ada peringkat

- Sip TemplateDokumen60 halamanSip TemplateJhun Lerry TayanBelum ada peringkat

- BS 7874Dokumen11 halamanBS 7874Fenner ElectromechanicalBelum ada peringkat

- Training Manual MBBRDokumen84 halamanTraining Manual MBBRTahirJabbar100% (3)

- CE144 - A1 - Alejo - Sample ProblemsDokumen14 halamanCE144 - A1 - Alejo - Sample ProblemsAnonymous 7G5CejBelum ada peringkat

- Thesis FinalDokumen16 halamanThesis FinalabcdefBelum ada peringkat

- Water Use in Food IndustryDokumen8 halamanWater Use in Food IndustryHisExcellencyBelum ada peringkat

- BOD Lab Report PDFDokumen17 halamanBOD Lab Report PDFIzzatul Syahira Binti ZakariaBelum ada peringkat

- Water Conditioning and Waste Water Treatment In: Food IndustryDokumen6 halamanWater Conditioning and Waste Water Treatment In: Food IndustryFatma Eda AYDOĞANBelum ada peringkat

- Project Report: Small Sewage Treatment PlantDokumen58 halamanProject Report: Small Sewage Treatment PlantAnurag Dixit100% (1)

- Jurnal Ahmad MusafakDokumen14 halamanJurnal Ahmad MusafakAderizky PratamaBelum ada peringkat

- Full Thesis PDFDokumen166 halamanFull Thesis PDFMasnun Rahman83% (6)

- Concept of Zero DischargeDokumen4 halamanConcept of Zero DischargeShesharam Chouhan67% (3)

- 432 ProjectDokumen19 halaman432 ProjectjnmanivannanBelum ada peringkat

- CE 402 - Module 2Dokumen62 halamanCE 402 - Module 2lakshmi dileep100% (1)

- Bukhari Et Al.. 2020. Enzymatic Hydrolysate of Palm Oil Mill Effluent As Potential Substrate For Bioflocculant BM-8 ProductionDokumen13 halamanBukhari Et Al.. 2020. Enzymatic Hydrolysate of Palm Oil Mill Effluent As Potential Substrate For Bioflocculant BM-8 ProductionAzb 711Belum ada peringkat

- NT - TR - 537 - Ed3 - 1 - English - Handbook For Calculation of Measurement Uncertainty in Environmental LaboratoriesDokumen52 halamanNT - TR - 537 - Ed3 - 1 - English - Handbook For Calculation of Measurement Uncertainty in Environmental LaboratoriesCorina StanculescuBelum ada peringkat