A Fieldbus Simulator For Training Purposes

Diunggah oleh

Salvador LopezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Fieldbus Simulator For Training Purposes

Diunggah oleh

Salvador LopezHak Cipta:

Format Tersedia

ISA Transactions 48 (2009) 132141

Contents lists available at ScienceDirect

ISA Transactions

journal homepage: www.elsevier.com/locate/isatrans

A fieldbus simulator for training purposes

Eduardo Andr Mossin, Rodrigo Palucci Pantoni , Dennis Brando

School Engineer of So Carlos - University of So Paulo, Brazil

article

info

Article history:

Received 14 May 2008

Received in revised form

25 July 2008

Accepted 29 July 2008

Available online 30 August 2008

Keywords:

Fieldbus automation systems

Simulator

LabView

a b s t r a c t

This article presents a fieldbus simulation platform and its remote access interface that enables a

wide range of experiments, where users can configure operation sequences and procedures typical of

Foundation Fieldbus systems. The simulation system was developed using LabVIEW, with requisites of

deterministic execution, and a course management work frame web server called Moodle. The results

were obtained through three different evaluations: schedule table execution, simulator functionality

and finally, simulator productivity and achievement. The evaluation attests that this new tool is feasible,

and can be applied for fieldbus automation systems training purposes, considering the robustness and

stability in tests and the positive feedback from users.

2008 ISA. Published by Elsevier Ltd. All rights reserved.

1. Introduction

The use of automatic electronic devices in the process control

industry is nothing new. Since 1970, these devices have been

used first in direct digital control (DDC), and then in distributed

control system (DCS) or programmable logic controllers (PLC).

The spread of microcontrollers technology in the 90s enabled

the development of smart field devices, the main characteristic of

which is having their own intelligence and function [1].

Considering that the intelligence of a control system is

distributed over each smart device on the shop floor or on

the plant, the next step is interconnecting all devices, and

creating an instrument network [2], nowadays called fieldbus, with

requisites of real time systems. Fig. 1 shows the basic architecture

of a fieldbus network, composed of field devices, the fieldbus

communication channel, the controller unit(s) and specialized

engineering host stations.

The great interest in this network model led several manufactures to implement their own communication protocols, to enable communication among their devices, and during the last two

decades, some criteria were defined in order to standardize the

communication model, and enable communication among different models of devices, developed by different manufacturers.

There are several standard and widespread fieldbus protocols

available in the market, such as CAN (Control Area Network),

Interbus, DeviceNet, Hart, Modbus, AS-I (AS-Interface), Profibus

and FOUNDATION Fieldbus. This article refers to the FOUNDATION

Corresponding author. Tel.: +55 16 33739357; fax: +55 16 33739372.

E-mail address: rodrigoppantoni@yahoo.com.br (R.P. Pantoni).

Fieldbus (FF) protocol, one of the fieldbuses designed for typical

industrial process control applications.

The combination of two or more protocols on integrated

hybrid systems, as well as the use of such systems on process or

equipment with fast dynamic responses, motivates the scientific

community to evaluate the performance of networked control

systems (NCS). Such studies result in advances and optimization of

transmission media technologies, communication methods, new

smart transmitters capabilities (sensors, controllers and actuators),

as well as advanced industrial control strategies.

Although being standardized, there are complex concepts

and architectures behind these systems and, therefore, the

learning curve for this technology is slow, considering the large

amount of required professional background on the areas of

instrumentation, software engineering and digital communication.

An important aspect when considering the learning process of the

fieldbus technology is practical experience. There are considerable

safety and economical restrictions on the access of students,

researchers and plant operators on training processes, to a real

operating industrial plant. Even bypassing the need for real plant,

projecting and assembling a small plant destined only for training

purposes would certainly be considered an interesting option. This

alternative leads as well to certain restrictions, such as engineering

costs, capital expenses and the low flexibility for executing a

broad range of experiments and situations during the training or

a particular study.

In this context, the use of training simulation tools should

be also considered. By using this class of tools, researchers,

professionals and students can simulate the dynamics and the

communication of complete fieldbus networks, in order to

understand, evaluate and practice its operation on network

configuration, device commissioning, plant start up, and system

operation in automatic or manual modes.

0019-0578/$ see front matter 2008 ISA. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.isatra.2008.07.005

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

133

Fig. 1. Basic fieldbus network architecture.

Typically, simulation tools force the students, professionals

or researchers to go to a laboratory to execute their tests and

chores. Due to the increasing availability of the Internet on

academic and industrial facilities, remote access through the

Internet to simulators and plants shall be considered, because of

the possibility to separate these resources from users.

In fact, the use of simulations can be complementary to

traditional training methods and facilities, or in a second approach,

it can be considered and projected as flexible and realistic enough

to be used as a main training tool.

This paper presents a web enabled simulation tool for networked control systems, designed according to the FF specification

and aimed to be applied in industrial training programs and in academic disciplines. The proposed simulation tool is named FBSIMU,

and is focused on the user application layer, attending to requisites of realistic operation procedures and interfaces, and of real

time simulation dynamics. Its range of experience goes from fieldbus system configuration and commission, to handling events and

alarm conditions.

This paper is organized in eight sections, including this

introduction. The next section introduces some characteristics of

the FOUNDATION Fieldbus protocol and application process, used

as a model to design the FBSIMU architecture. This architecture

and the resulting simulation platform are explained later on the

section FBSIMU Architecture. The description of a typical training

application of the FBSIMU closes section three.

Section 4 is comprised of a brief state-of-the-art and examples

of remote laboratories focused on e-learning of industrial automation in a broader sense, and control systems disciplines.

The Internet access mechanism and the clientserver model

of cooperation proposed for the remote use of the FBSIMU are

presented in Section 5.

In Section 6, the practical tests and results obtained by the use

of the FBSIMU online version are presented. The analyses of the

results are discussed in the Section 7.

Finally, the authors discuss new perspectives for development

and application of the FBSIMU tool, and the identification of trends

on distance training models, dedicated to industrial automation

and distributed control systems.

2. The Foundation Fieldbus protocol

The term FOUNDATION Fieldbus indicates the protocol specified by the Fieldbus Foundation. It is a digital, serial, bidirectional,

and distributed protocol, which interconnects field devices such as

sensors, actuators and controllers. Basically, this protocol can be

classified as a LAN (Local Area Network) for instruments used in

process and industrial automation, with the ability to distribute the

control application through a network.

This protocol is based on the ISO/OSI (International Organization for Standardization/Open System Interconnection) sevenlayer reference model [3]. Although being based on the ISO/OSI

model, the FF does not use the network layer, the transport layer,

the section layer, nor the presentation layer, because it is restricted

to local applications. The entire network structure of the FF concentrates on the physical layer, the data link layer (DLL) and the application layer. Besides these three implemented layers, the protocol

defines an additional layer called User Application Layer.

The FF Physical Layer, named H1, uses a shielded twisted pair

cable as a communication medium. The H1 specifies a 31.25 kBit/s

baud rate with Manchester bit codification over a bus powered

channel. The network topology configuration is flexible: it is

typically configured with a trunk and several spurs, attending

certain physical and electrical limitations regarding maximum

length and number of transmitters.

The DLL carries the transmission control of all messages on

the fieldbus and its protocol grants to the FF network temporal

determinism. The communication is based on a masterslave

model with a central communication scheduler (master), named

Link Active Scheduler or LAS. This node performs the medium

access control (MAC).

Two types of DLL layer are standardized: Basic and Link Master.

A Basic DLL transmitter does not have LAS capabilities, it operates

passively as a communication slave. A Link Master DLL transmitter,

on the other hand, can execute LAS functions and thus, if the active

LAS node fails, become the LAS node.

The FF Data Link Layer supports two transmission policies: one

addressed to scheduled cyclic data, and another to sporadic (unscheduled) background data. These two communication policies

share the physical bus, but they are respectively segmented in

cyclic time slots or periods. In the scheduled communication period, most process variables generated by periodic processes are

transmitted cyclically according to a static global schedule table

loaded on the LAS node. This cyclic transmission mode has higher

priority over acyclic transmission modes.

A periodic process can be defined as a process initiated at

predetermined points in time, also called a time-triggered process.

The period for this class of process is typically some milliseconds,

and it is mandatory to consider that the generated data must be

delivered before the next data is available. This type of periodic

data is usually related to measurement and control variables [4].

Sporadic or unscheduled communication is used to transmit

non periodic, or aperiodic, data generated by sporadic processes

134

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

not directly related to the control loop cycles, but to configuration actions and data supervision efforts. The unscheduled transmissions are dispatched under a token pass scheme. A token that

circulates among all active nodes on the bus is used in FF protocol.

Once a transmitter receives the token, it is granted the right to send

pending aperiodic messages with a minimum priority for a specific

time period.

Non periodic (or event-triggered) processes are initiated as

soon as specific events are noted [5]. The event-triggered processes

are unpredictable and usually related to alarm notifications,

configuration data and user commands as cited before. Although

acyclic traffic is less frequent than the cyclic one, the acyclic data

should also be delivered prior to a certain time deadline, according

to the system requirements.

For a description of the MAC operation on both cyclic and acyclic

phases, refer to [68].

The FF User Layer is directly related to the process automation

tasks themselves, and it is based on distributed control or

monitoring strategies of Function Blocks. Function Blocks (FBs)

are User Layer elements that encapsulate basic automation

functions and consequently make the configuration of a distributed

industrial application modular and simplified [9]. Distributed

among the transmitters, the FBs have their inputs and outputs

linked to other blocks in order to perform distributed closed

control loop schemes. When blocks from different transmitters are

linked together, a remote link is configured and mapped to a cyclic

message. Considering that all cyclic messages should be released

in a predetermined instant defined on a schedule table, and that

they carry data generated by the FBs, it is adequate to synchronize

the execution of the FB set on the system with the referred cyclic

transmissions schedule table. This solution leads to the concept of

joint scheduling [10].

The Foundation Fieldbus standardized a set of ten basic

function blocks [11], a complementary set of eleven advanced

control blocks [12], and a special flexible function block intended

to be fully configurable, i.e., internal logic and parameter, by

the user [13]. The standard and advanced block sets provide

mathematical and engineering calculations necessary to configure

typical industrial control loop strategies, while the flexible

function block can be applied to custom or advanced controls or to

complex interlocking logics based on ladder nets. It is important to

state, however, that the standard is open at this point, permitting

the integration of user-defined custom function blocks in order

to enhance the capabilities of FF control system, and make the

integration of novel control techniques possible.

3.1. Function Block simulation

The Function Block modules are programmed into the FBSIMU

according to the FF specifications directions and, consequently, the

usage and configuration of a simulated control loop on the FBSIMU

environment is identical to a real FF system.

A VI library has been developed [15] to provide a range of

typical Foundation Fieldbus control and acquisition functions,

according to the standards. Another VI functionality facilitates

the development and integration of standard and custom FBs to

the system. These functions encapsulate different FF calculations

and data type manipulations necessary to build Function Blocks,

configuring a LabVIEW Foundation Fieldbus Tool Kit. A Function

Block seed module is also used to facilitate the process of

developing and integrating new projects. The seed has the whole

FB module structure (an empty structure) and directions to

proceed with a FB project from the design to the final test

procedures.

Each FB module is built as two different versions that share the

same FB core: stand-alone and process. The stand-alone FBs are

executed by user commands and controlled by its front panel. Its

execution can be performed independently of any other module,

so the user is able to test the FB and simulate its operation

under a controlled condition of inputs and outputs. The graphical

user interface is intuitive and enables the user to execute the FB

continually or in a step-by-step mode.

The process version of a FB, on the other hand, is controlled

remotely likewise real FBs. Each process FB has a unique

identification and its operation is controlled by the user through

the following commands:

- FB_Read: this service allows the value associated with a block

parameter to be read.

- FB_Write: this confirmed service allows the value associated

with a block parameter to be written.

- FB_Exec: this service triggers the block algorithm to be

executed.

- FB_Reset: this service allows default values associated with all

block parameters to be written.

Process FBs do not have front panels; they are instantiated by

the FBSIMU.CONF in each simulation process. The communications

between process FBs and the FBSIMU.CONF are performed

programmatically and dynamically by the LabVIEW function Call

by Reference Node. It is important to note that the industrial

transmitters are not considered in the FBSIMU architecture,

i.e., function blocks are instantiated on the simulation without

being allocated in specific virtual transmitters. The FBSIMU.CONF

module front panel for fieldbus configuration is shown in Fig. 2.

3. FBSIMU architecture

3.2. Physical plant simulations

The basic concept of the FBSIMU architecture is to map each

Function Block, as well as the plant, in an independent LabVIEW

application, also named Virtual Instrument (VI). The configuration

of the whole system is centralized in the FBSIMU.CONF module.

This modules front panel (GUI) is inspired by commercial fieldbus

configuration tools.

As mentioned before, the FBSIMU is focused on the function

block application layer and it is composed exclusively of software

according to a modular and extensible architecture. The simulator

was developed in LabVIEW using the G graphical programming

language, native language in this environment. Each FBSIMU

module or software unit simulates an element or a structure of a

real FOUNDATION Fieldbus system [14].

The plant module cyclically executes a discrete single variable

(SISO) linear ARX (Auto-Regressive with Exogenous Inputs)

mathematical structure [16]. This module is configured by the

FBSIMU.CONF and simulates the controlled plant. The adopted ARX

structure is represented by Eq. (1), where k is the discrete time

instant, Y is the output vector, U is the input vector, i is the number

of MIMO plant inputs and outputs, na is the number of output

regressors, and nb is the number of input regressors. In the current

version, i is set to 1 (one) to reflect a SISO model.

Yi1 (k) =

na

X

s=1

Asii Yi1 (k s) +

nb

X

s =1

Bsii Ui1 (k s) . (1)

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

135

Fig. 2. FBSIMU.CONF module front panel for fieldbus configuration.

Fig. 3. FBSIMU.CONF module front panel for plant configuration.

The simulated plant dynamic behavior is modeled on the dynamic

matrixes A and B. It must be observed that the number of regressors

limits the model dynamic order in the actual version it is limited

to third order systems and that all regressors must be initialized

prior to starting the simulation. A white noise generator function

adds a simulated acquisition noise to each plant output bounded

by user configurable amplitude.

As the user chooses the plant order (1st, 2nd or 3rd) and

dynamics (gain for 1st and 2nd order systems, damping ratio,

natural frequency and time constant), the selected plants Bode

Magnitude Chart, Pole-Zero Map, Root Locus Graph and the Step

Response are instantly presented on the front panel. The third

order system is composed of a first order system in series with a

second order one, both adjustable by the user, as stated.

A white noise signal can be also introduced with configurable

absolute amplitude over the plant output. Fig. 3 shows the

FBSIMU.CONF module front panel for plant configuration.

3.3. Simulation architecture

The proposed execution model for the fieldbus simulation on

FBSIMU can be considered hybrid, because some tasks are eventdriven, while other tasks are time-triggered. All tasks related to

the user interface are event-driven, they are executed after a user

action, such as selecting a new block, configuring schedule table,

saving a configuration or starting the execution.

On the other hand, the tasks related to executing FBs according

to a schedule table, plant simulation, and online monitoring of FBs

are time-triggered.

Due to the fact that all tasks are performed on a single

microprocessor, they are, naturally, concurrent. The proposed

solution for preventing unexpected delays of time-triggered

tasks (considered critical) due to executing event-driven tasks

(considered non-critical) is adopting priority levels for each task

and preemptive execution mode.

136

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

Table 1

FBSIMU task set

Module

Priority

Execution

Timeout

Determinism

GUI & User commands

FB schedule

Plant execution

Online FB parameters monitoring

Lowlow

Highhigh

High

Low

Event driven

Time triggered according to the schedule table

Periodic with configurable period

Periodic with period = 500 ms

1s

No

No

No

No

Yes

Yes

Yes

Fig. 4. FBSIMU block list.

Fig. 5. FBSIMU schedule table.

In the preemptive execution mode, a higher priority task that is

ready to execute preempts all lower priority tasks, which are also

ready to execute or actually during execution.

Table 1 summarizes the FBSIMU task set and its timing and

execution characteristics.

3.4. A typical simulation experiment

The intrinsic flexibility of simulation tools opens a wide range

of FBSIMU experiments, where users can exploit the effect of

important communication parameters and configurations found in

industrial FF systems. Practical experiments consist of comparing

given simulated fieldbus system performances over different

operation conditions. The results can be analyzed via log files or

graphically on charts.

For typical simulation training, the FB control strategy should

be defined. Then, the period of the macrocycle must be set

in milliseconds, and all the release times (in milliseconds) of

each FB execution and FB link must be defined regarding the

macrocycle start instant. Figs. 4 and 5 present an example of these

configurations on the FBSIMU.

The configuration parameters from all FBs on the schedule table

must be set in a parameter table, as shown in Fig. 6, to support

the proposed strategy (for example, Block Mode, Scaling, Gains),

exactly likewise a real block strategy configuration.

The last step is to link the input and output parameters from the

AI and AO blocks to the plant simulation module, as represented in

Fig. 7.

The connection between an Analog Output block (AO) and

the plant input (manipulated variable MV) and the connection

between the plant output (primary value PV) and the Analog

Input block (AI) are configured by the user for close loop

experiments. Alternatively, the user may connect only the plant PV

to the AI block for an open loop simulation, or manually load the

plant PV with a given numeric value.

Finally, the user downloads the configuration to each FB, and

starts executing the schedule. During the execution, it is possible

to monitor the parameter table with online parameter values and

register the parameters on text files for further analysis.

With the FBSIMU architecture, the FF operation scenarios

can be configurable and different sequences of practice training

can be defined to embrace fundamental concepts of fieldbus

control systems, as well as practical situations of alarms or

events handling. This characteristic is considered important

by the authors, because most of the traditional pilot plants

equipped with fieldbus instrumentation offer just one or a few

scenarios, whereas a full sequence of practice experiments should

be based on it. Thus, the use of a simulated fieldbus system

enables a flexible evaluation of the contribution and effect of the

communication protocol on the overall system dynamics, which

is an impossible goal considering that, in pilot plants equipped

with real instrumentation, most communication configurations

are fixed and, in most cases, inaccessible to end-users.

4. On-line laboratories in automation and industrial control

area

It is possible to identify three distinct approaches in the

literature associated with distance learning methodologies, used

in the Automation and Industrial Control area.

The first one is based on remote access to laboratories

with real instruments. The second one is the remote access to

dynamic simulators for control loops and, eventually, for industrial

instruments. The third approach, currently in disuse, is based on

on-line tutorials, where users have some information about a

subject but do not have interactive methods of learning. A simple

activity, showed in [17], can be performed through a tutorial where

a user copies commands from a web page and pastes them in

MATLAB. After executing the application, the analysis of the results

is guided by explanations contained in the on-line tutorial.

A simple comparison can be made by focusing the first two

approaches. First, it can be concluded that the advantage of the

simulation method is that it allows the user to conduct any

type of experiment without security restrictions or concerns. A

disadvantage of simulation systems is that it does not provide a

more realistic experience with industrial equipment to the users.

Considering these tools, Section 4.1 shows some examples

of laboratories with remote access to real control systems and

Section 4.2 shows examples of remote access to simulations. Then,

Section 4.3 shows the examples of remote laboratories which

provide access to pilot plants using fieldbus protocols.

4.1. Remote access to real instruments

An example of this approach is described in [18]. It is composed

of an environment for distance operation of a real testing plant

through the Internet. The plant, an inverted pendulum, is located

near the server machine. The system was developed with the

purpose of not showing the physical plant characteristics to the

user, and therefore, the system can be easily adapted to other

plants located in this laboratory. An important characteristic of this

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

137

Fig. 6. FB parameter table.

Fig. 7. Plant simulation module.

work is that professors can add different experiments by simply

editing the configuration file.

Also exemplifying didactic experiences through remote access

to real plants, a system that allows the users to access instruments

through the web is described in [19]. In this system, instructors

can configure equipments even during a class. The system

architecture is composed of a server machine connected to

different instruments (sensors, actuators, motors, power supplies),

and equipment control is performed by a LabVIEW application.

With remote access through the web, the instructor connects to

the LabVIEW to modify different instruments parameters, thus

having the ability to take different directions in his/her classes. In

this system, the user has limited access to some parameters due to

security reasons.

In [20], the remote access to a laboratory with four types of

control loops (manual and PID control, space state algorithms and

fuzzy logic) was implemented. Also, in this laboratory, it is possible

to remotely access a platform where researchers execute tests on

control algorithms. The system supplies images and sounds from

the laboratory through a camera built in a mobile platform. The

plant used in the experiment consists of coupled tanks.

4.2. Remote access to simulation tools

Experiments that involve tutorial sections, theoretical exercises

and experiments in simulated plants have been explored through

a system based on a MATLAB/Simulink plug-in for remote access,

Maple and Java applet [17]. The disadvantage of this system is that,

although the system is accessed remotely, the client machine must

have the MATLAB software installed locally.

Another example is a tool that simulates a Digital Signal

Processing (DSP) laboratory [21]. The laboratory has five exercises

which cover Z-Transform theory, Frequency Response, Fourier

transform and other control topics. The tool provides web pages

that describe the proposed exercises and support programs in Java,

allowing users to develop their own system simulations.

Focusing on the teaching of theoretical bases of control systems,

a tool that covers several techniques for control systems analysis

under the classic and modern theories was created [22]. The tool

supports models represented in both state space and transfer

functions notations. The user, using a web browser, can choose the

project and analysis methods of a controller, specify the type of

control system and configure its parameters. Data is sent to a server

for numerical computation and results are sent back to the client.

On-line experiments that allow comparing the performance of

different controllers, such as PD and PID, in situations of set point

changes and disturbance, are also explored [23]. The author affirms

that simulations are excellent for theory assimilation, but they

cannot substitute a real experiment in the laboratory.

4.3. Distance learning of Fieldbus protocols

Beyond control theory, some cases of distance learning explore

the teaching of fieldbus protocols. An example of a virtual

laboratory focusing on the CAN protocol (Controller Area Network)

can be cited [24]. This laboratory, called Virtual Automation Lab, is

an interactive tool for distance learning of CAN protocol operation.

The tool can be used in two ways: first, as a real laboratory

connected to the Internet using a remote interface, where the

user operates a real device and observes characteristics of fieldbus

networks, such as communication delays, fails, etc; and second,

through simulations that allow users to get used to this type of

fieldbus system before handling real instruments. The experiment

uses a PC, one web cam, some intelligent transmitters operating

with CANopen protocol and a CAN interface board. The stages of the

course cover motivation, group objectives, educational objectives,

general vision and exercises. To complete an exercise, the devices

must be available for use (only one user can access the devices per

time) and some security restrictions must be considered.

138

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

Fig. 8. FBSIMU On-line architecture.

Using another fieldbus protocol, an experimental practice

with remote access to a pilot plant explores the basics of the

FOUNDATION Fieldbus protocol [25]. This remote access allows

the user to execute experiments and supervise a pilot plant.

This system is also used as a platform for industrial automation

research. The adopted pilot plant consists of three coupled tanks,

flow pumps and five control valves used to manipulate the

outflows of liquids in the system. It is possible to configure several

control strategies using the tank level variables, outflows and

temperatures. The system architecture follows the clientserver

model. The client is an applet that communicates with the

web server using sockets. The SCADA software is installed on

the server with an OPC interface, which receives information

from the fieldbus network. The SCADA software creates a web

page with all the necessary process data and makes them

available to the remote user. The system has also a web cam

for visual tracking of the plant dynamics. As auxiliary functions

to the training procedures, the system contains user access

control, a sub-system for scheduling experiments, a method for

monitoring the duration of practical sections and a configuration

area in which users can set some parameters from the control

system. Since the system is composed of a real pilot plant,

experiments cannot be executed by more than one user at the same

time.

5. Online FBSIMU

Aiming to provide the flexibility for users access to fieldbus

learning systems and to follow the distance learning tendency, an

online version of the FBSIMU platform is described in this section.

The online version of the simulator is based on the clientserver

model. The server executes several instances of the FBSIMU and the

clients are the users computers.

On the proposed model, two additional functions were added to

the local scheme simulation, described on the previous sections, in

order to coordinate the remote transactions. The main additional

function is related to user access control. The other functionality

is an online questionnaire that registers information related to the

users learning process for future efficiency analysis of the remote

model.

5.1. Server side

The FBSIMU server is composed of two web servers. The first

server is responsible for user access control, forums, links, and

the questionnaire. This server was developed through a Course

Management System (CMS), a configurable framework, whose goal

is to organize and speed up the creation, management, distribution

and publication of information in remote courses context. The CMS

offers features that allow the web master to execute the whole

content management process from web browsers, in a remote way.

Moreover, the CMS offers a framework with some features already

implemented, such as access permission to the system.

There are different types of CMS available in the market and

most of them are open source projects. The CMS Moodle [26] was

used in the on-line FBSIMU implementation.

Moodle is an open-source software licensed under GNU GPL

(General Public License), maintained and revised by a community

of users and developers. The software is developed with the PHP

script language; it stores data in a MySQL database and uses Apache

as its web server.

The second web server deals with remote access to the FBSIMU

environment itself. This access is performed through a native web

server embedded in the LabVIEW. It is activated by the FBSIMU

modules, i.e., the FBSIMU VIs (Virtual Instruments).

Through this web server, a user can access the VI, using a web

browser. For the web browser to access the VI, it is necessary to

install the LabView Runtime Engine in the client machine. This

software can be downloaded from the National Instruments Home

Page or the LAI Home Page (http://lai.sel.eesc.usp.br/moodle/).

Considering that LabVIEW and Moodle work with different web

servers (Moodle uses Apache while LabVIEW uses its own web

server), this section describes the integration of both servers.

The integration is achieved with a database, where user access

information for each FBSIMU instance is stored and read by both

Moodle and LabVIEW. Fig. 8 shows the basic architecture for this

system.

Following this architecture, steps i, ii and iii illustrate the

communication flow between the client workstation and the

server:

(i) Moodle validates the user who tries to log in the system. At

this moment, the user may or may not have permission to

access the FBSIMU.

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

(ii) User with permission accesses the FBSIMU link. At this

moment, the system executes a PHP code that controls which

users are operating the system. This information is stored in

the database. After executing the validation, another PHP code

generates a HTML file that will be used on the access of the

FBSIMU instance. Generated such archive, the access address

is returned transparently to the client workstation.

(iii) This address is a response to a PHP call, and when this value

is received by the client workstation, a new Web navigator

window will open, pointing to this address. Then, the accessed

HTML will link the client workstation to the FBSIMU instance.

Table 2

Schedule table configuration

Task

Release time (ms)

AI

PID

AO

AI.OUT PID.IN

PID.OUT AO.CAS_IN

PID.BKCAL_OUT AO.BKCAL_IN

Macrocycle period

0

300

600

100

400

700

1000

Table 3

Experimental timing measurements

5.2. Client side

On the client side, the first web page shows a brief description

of the experiment and the link for the user log-in page. This web

page is provided by the Moodle module through the Apache web

server.

After the user logs on the system, he/she can access the FBSIMU

tool. Access will be provided by the LabVIEW embedded web

server.

Besides the FBSIMU access, the system proposes a questionnaire, which registers information related to the users learning

process for a future efficiency analysis of the educational model,

as cited before.

6. Results

The results were obtained through three different evaluations:

schedule table execution (Section 6.1), FBSIMU functionality

(Section 6.2) and productivity and achievement (Section 3).

The schedule table execution test and the FBSIMU functionality

functional test were performed in order to verify the timing

precision, robustness and stability of the FBSIMU running over the

Internet.

On the schedule table execution test, a static schedule table was

configured and, based on this table, the test was executed under

four simulation operational conditions in order to verify the timing

precision of the schedule table dispatch mechanism, the most time

critical process in the simulator.

On the FBSIMU functionality test, the robustness and the

stability of the FBSIMU online version were tested, when accessed

by a group of five concomitant users. This group of students

executed a test routine where all system features were evaluated.

The use of the distance education methodology is sufficiently

spread out, and its effectiveness has been already proven [27].

In order to evaluate the users productivity and their achievement on the learning process with the use of the FBSIMU on

a remote scheme, a class of 25 undergraduate industrial automation students executed a regular FBSIMU experiment and

answered a questionnaire. Another questionnaire was used to

evaluate the instructors impression about the tool (productivity and achievement test). These questionnaires are published at the Industrial Automation Laboratorys Moodle website

(http://lai.sel.eesc.usp.br/moodle/) with access constraints.

6.1. Schedule table execution evaluation

These tests were performed with five students from the

Industrial Automation Laboratory.

For this test, a PID Control strategy composed of three Function

Blocks (AI-PID-AO) was configured, and a schedule table was

proposed for its execution. The schedule table and the macrocycle

period configuration are presented in Table 2.

The LabVIEW system clock value was registered at the release

instant of each task at the scheduling table. The macrocycle period

139

Average period

Standard deviation

Max. value

Min. value

Number of samples

Cond. 1

Cond. 2

Cond. 3

Cond. 4

999.99

0.51

1002

998

500

1000.01

0.74

1002

998

485

1000.00

0.37

1002

999

510

1000.01

0.37

1004

996

450

can be measured, therefore, by calculating the difference in time

between each task release time for instant k and k 1, for k = 1

to n, where n is the number of release time samples.

The same test was conducted under four operational conditions:

1.

2.

3.

4.

Schedule execution alone;

Schedule execution with online FB monitoring;

Schedule execution with plant simulation and visualization;

Schedule execution with FB monitoring and plant simulation and

visualization.

The Table 3 presents the results obtained from executing the

FBSIMU on a Pentium Centrino Duo computer equipped with an

Intel T2400@1.83 GHz processor and 1.5 Gbytes RAM. The time unit

on Table 3 for the average period, standard deviation, maximum

and minimum values is milliseconds.

6.2. FBSIMU functional evaluation

The expected result from the first test with five users was meant

to verify:

- Which resources had not been foreseen for the ideal functioning

of the system?

- Which problems could appear during the system regular

operation?

- Does the proposed architecture permit a parallel remote access

to the FBSIMU for multiple users?

Summarizing, the test plan was created in order to provide

a scenario as close as possible to the real FBSIMU online use.

This scenario is composed of five users that execute their experiments concomitantly and independently, from five remote

stations. To reproduce the exact use of the tool, each user has

executed all the steps from the beginning. Firstly, each user

sent an e-mail to the administrator (this e-mail address is published at the Industrial Automation Laboratorys Moodle website:

http://lai.sel.eesc.usp.br/moodle/) requesting registration. With

the five accounts created, a confirmation e-mail was sent back to

the users. The next step for each user was to access the private area

at the Moodle website where the online FBSIMU is hosted, and then

access the FBSIMU itself. The FBSIMU web server correctly identified and informed the users connected at the access moment.

For each of the five instances of the FBSIMU remote panel

opened in five client workstations, the users executed simulations

as described on Section 3.4, saved logs and configurations files,

and logged out from the system. Since all experiments were saved,

the users would have many opportunities afterwards to access the

system again, loading the saved files and then continuing his/her

experiments with the saved configuration.

140

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

Table 4

Topic evaluated for grade (Students)

Topic

Grade (15)

Satisfaction

Easy to use

Without technical problems

Easy to access

Student Learning

4

3

5

3

4

Table 5

Topic evaluated for grade (Instructors)

Topic

Grade (15)

Satisfaction

Students interaction

Easy to evaluate the students

Easy to manage

Student Learning

4

4

3

5

4

6.3. Productivity and achievement evaluation

Once the tool functionality was successfully validated, the

next test evaluated productivity and achievement of users and

instructors. The 25 students accessed the online FBSIMU and

executed the same experiment detailed on the first test in this

section. A questionnaire was elaborated, and made available online

for the students, and another questionnaire was elaborated for the

instructor.

The consolidated results obtained from the students filled

questionnaires are shown in Table 4. The second evaluation involved the instructors feedback after completing the experiment.

Table 5 shows the consolidated results obtained through the analysis of the instructors questionnaire. For both tables the grade

represents: 1 (poor), 2 (not good), 3 (satisfactory), 4 (good) and 5

(excellent).

7. Analyses of the results

Related to the schedule table execution test results (Tables 2

and 3), the adoption of a hybrid simulation model on the FBSIMU,

composed of concurrent event-driven task and time-triggered

task, all inserted on a priority based preemptive execution, gave

the simulation platform a high degree of realism and a satisfactory

timing precision operation. However, it is noted that a theoretical

deterministic behavior is not possible to be obtained, as presented

on Table 3, because of the non-deterministic nature of the

Windows operational system, and because of the concurrence of

many other computer processes besides the simulation. In order to

interpret the results, it is necessary to consider that all the timing

calculation and the dispatching mechanisms are bounded in the

FBSIMU by the 1 ms resolution LabVIEW system clock. In spite of

the non-deterministic nature of the Windows operational system,

it is concluded that the simulation tool is able to reproduce the

real network fieldbus time behavior (time delays are satisfactory).

Thus, this test was successful.

In the FBSIMU functionality test (Section 6.2), the system

worked properly for all proposed test cases, therefore the online

platform functionality was validated. The conclusion is that the

tool stability is sufficiently good and this test was successful.

Considering the productivity and achievement evaluation

(Section 6.3) some facts can be noted about the results obtained

from the users (students and instructors) filled questionnaires.

In general, the users impression (Tables 4 and 5) are good (the

grade of most of the Topics is greater than 3) and characterizes

the general evaluation as successful. In addition, the proposed tool

reacted with robustness and stability in the tests.

Concerning the Topic Easy to use of students (Table 4), a

satisfactory grade was obtained. A better grade was not obtained

due to the FOUNDATION fieldbus configuration complexity. To

improve the system usability, a stronger help support could be

implemented in future versions of the FBSIMU.

Related to the Topic Easy to access of students (Table 4), a

better grade was not obtained due to LabVIEW Runtime Engine

installation when the user logs in the system. As cited before, to

enable running the online FBSIMU remotely, this engine must be

installed, and the download time to do that is substantial. The use

of JavaScript interfaces integrated to the LabVIEW web server is

a promising technology to overcome the use of Runtime Engines.

This solution is being investigated by the authors.

Analyzing the results obtained from the instructors filled

questionnaire (Table 5), it can be noticed that the methods for

student evaluation (Topic Easy to evaluate the students) need to

be improved to achieve an excellent grade. In the current version,

this evaluation was done exclusively through configuration files

and log files saved by the students.

8. Conclusions

The online system architecture can be considered simple to

manage and the use of a complete CMS framework gave the system

a valuable means to promote an efficient communication channel

between users and instructors.

Since the beginning of fieldbus protocols adopted by the

industrial community, there has been a large interest in research

related to the different aspects and functionalities of this

technology. Several research tools for simulation have been

developed to assist training programs and test routines. Besides its

low cost, when compared with real instruments and systems, an

additional advantage of simulation tools is the intrinsic flexibility

and safety, which allows the execution of a broad range of

experiments without security restrictions.

Due to the increasing presence of the Internet in and outside

industrial sites, an evident tendency for using remote access to

simulation tools or even to fieldbus systems with real instruments

is expected.

Considering the implementation architecture of the FBSIMU

simulation tool and its remote access, it has been demonstrated

that it is possible to consider realistic fieldbus simulations, in

an efficient way, by using a CMS system interacting with a local

simulation application in a remote clientserver model over the

Internet. The proposed interaction model between LabVIEW and

Moodle introduces certain complexities once two web servers

(Apache for Moodle and the LabVIEW web server for the FBSIMU

tool) must collaborate locally during simulations. The proposed

collaboration model for this application was successfully tested

and approved.

The satisfaction and the learning experience of the users are

positive results to be noted. This fact can be explained by the

high compatibility degree of the FBSIMU Function Blocks and

scheduling policy with the FF standards, and the intentional

similarity of its GUI to real fieldbus configuration software.

According to the result analysis section, this new tool is feasible

and can be applied for fieldbus automation systems training

purposes, considering the robustness and stability in the tests and

the positive feedback from users.

Acknowledgments

The authors gratefully acknowledge the Brazilian agency

FAPESP for the financial support received through the Kyatera

project, and the academic support and research structure from the

Engineering School of So Carlos - University of So Paulo. The

authors also acknowledge the important technical contributions

from Smar International Corporation.

E.A. Mossin et al. / ISA Transactions 48 (2009) 132141

References

[1] Berge J. Fieldbus for process control: Engineering, operation, and maintenance.

Research Triangle Park: ISA Books. 2002.

[2] Smar International Corporation. Fieldbus tutorial: A FOUNDATION fieldbus

technology overview. Sertozinho: Brazil. 2004.

[3] International organization for standardization. ISO/IEC 7498-1: Information

technology open systems interconnection basic reference model: The basic

model. Switzerland. CD-ROM. 1994.

[4] Cavalieri S, Di Stefano A, Mirabella O. Optimization of acyclic bandwidth

allocation exploiting the priority mechanism in the fieldbus data link layer.

IEEE Transactions on Industrial Electronics 1993;40(3):297306.

[5] Pop T, Eles P, Peng Z. Holistic scheduling and analysis of mixed time/eventtriggered distributed embedded systems. In: 10th international symposium

on Hardware/software codesign. 2002.

[6] Hong SH, Ko SJ. A simulation study on the performance analysis of the data

link layer of IEC/ISA fieldbus. Simulation 2001;76(2):10918.

[7] Wang Z, Yue Z, Chen J, Song Y, Sun Y. Realtime characteristic of FF

like centralized control fieldbus and its state-of-art. In: IEEE international

symposium on industrial electronics. 2002.

[8] Petalidis N, Gill DS. The formal specification of the fieldbus foundation link

scheduler in E-LOTOS. In: International conference on formal engineering

methods. 1998.

[9] Chen J, Wang Z, Sun Y. How to improve control system performance using FF

function blocks. In: IEEE international conference on control application. 2002.

[10] Ferreiro Garcia R, Vidal Paz J, Pardo Martinez XC, Coego Botana J. Fieldbus:

Preliminary design approach to optimal network management. In: IEEE

international workshop on factory communication systems. 1997.

[11] Fieldbus Foundation. FF-890-1.3: Foundation specification function block

application process, part 1. Austin, USA. 1999.

[12] Fieldbus Foundation. Foundation specification function block application

process Part 3: FF-892 FS1.4. Austin, USA. 1999.

[13] Fieldbus Foundation. Foundation specification function block application

process Part 5: FF-894 DPS0.95. Austin, USA. 1999.

[14] Brando D. Ferramenta de simulao para projeto, avaliao e ensino de redes

fieldbus, Doctorate thesis. Escola de Engenharia de So Carlos, USP. 2005.

141

[15] Pinotti Jr M, Brando D. A flexible fieldbus simulation platform for distributed

control systems laboratory courses. The International Journal of Engineering

Education 2005;21(6):10508. Dublin.

[16] Ljung L. System identification- theory for the user. Englewood Cliffs: Prentice

Hall; 1999.

[17] Luntz J, Messner W, Tilbury D. Web technology for controls education.

In: Proceedings of the IEEE conference on decision and control. 1997.

[18] Snchez J, Morilla F, Dormino S, Aranda J, Ruiprez P. Virtual control lab using

Java and Matlab: A qualitative approach. IEEE Control Systems Magazine 2002;

820.

[19] Liou S, Soelaeman H, Leung P. Distance learning power engineering laboratory.

Computer Applications in Power 1999;12(1):516.

[20] Ko CC, Chen BM, Chen J, Zhuang Y, Tan KC. Development of a webbased laboratory for control experiments on a coupled tank apparatus. IEEE

Transactions on Education 2001;44:7686.

[21] Clausen A, Spanias A, Xavier A, Tampi M. A Java signal analysis tool for signal

processing experiments. In: Acoustics, speech, and signal processing, ICASSP

98. Proceedings of the 1998 IEEE international conference, vol. 3. p. 184952.

[22] Qingcang YU, Chen B, Cheng HH. Web based control system design and

analysis. Control Systems Magazine, IEEE 2004;24(3):4557.

[23] Exel M, Gentil S, Michau F, Rey D. Simulation workshop and remote laboratory:

Two Web-based training approaches for control. In: Proceedings American

control conference, vol. 5. 2000. p. 346872.

[24] Buhler D, Kuchlin W, Grubler G, Nusser G. The virtual automation Lab-Web

based teaching of automation engineering concepts. Engineering of computer

based systems. In: Proceedings. Seventh IEEE international conference and

workshop. 2000. ECBS, p. 15664.

[25] Zeilmann RP, Gomes da Silva JJM, Bazanella AS, Pereira CE. Web-based control

experiments on a foundation fieldbus pilot plant. In: 5th IFAC international

conferences on fieldbus and their applications. 2003.

[26] Homepage, MOODLE. Free Support [Online]. Available at: http://moodle.org/

course/view.php?id=5.

[27] Irvine SE, Hein TL, Laughlin D. Different degrees of distance: The impact

of the technology-based instructional environment on student learning.

In: ASEE/IEEE Frontiers in Education Conference, 29, San Juan. Proceedings.

New York: IEEE; 1999. p. 13c-713c-12.

Anda mungkin juga menyukai

- Model Driven Development for Embedded Software: Application to Communications for Drone SwarmDari EverandModel Driven Development for Embedded Software: Application to Communications for Drone SwarmBelum ada peringkat

- Industrial Sensors and Controls in Communication Networks: From Wired Technologies to Cloud Computing and the Internet of ThingsDari EverandIndustrial Sensors and Controls in Communication Networks: From Wired Technologies to Cloud Computing and the Internet of ThingsBelum ada peringkat

- Unit 5: NetworkingDokumen96 halamanUnit 5: NetworkingthamizmaniBelum ada peringkat

- Networked Embedded Systems - Example Applications in The Educational EnvironmentDokumen27 halamanNetworked Embedded Systems - Example Applications in The Educational EnvironmentDespina GreeceBelum ada peringkat

- Design Automation of Cyber-Physical SystemsDari EverandDesign Automation of Cyber-Physical SystemsMohammad Abdullah Al FaruqueBelum ada peringkat

- Rapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationDari EverandRapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationBelum ada peringkat

- Openmtc: M2M Solutions For Smart Cities and The Internet of ThingsDokumen7 halamanOpenmtc: M2M Solutions For Smart Cities and The Internet of Thingsgame___overBelum ada peringkat

- Adaptive Internet Integration of Field Bus Systems: Stephan EberleDokumen9 halamanAdaptive Internet Integration of Field Bus Systems: Stephan EberleSathish KumarBelum ada peringkat

- Preprints: 11th International Workshop On REAL Time Networks RTN'12Dokumen37 halamanPreprints: 11th International Workshop On REAL Time Networks RTN'12hoalongcongphap95Belum ada peringkat

- Experiment No.8:: TitleDokumen6 halamanExperiment No.8:: TitleAyush ShahBelum ada peringkat

- SimuLTE Springer OpenAccessVersionDokumen18 halamanSimuLTE Springer OpenAccessVersionhancu georgeBelum ada peringkat

- Plant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationDari EverandPlant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationBelum ada peringkat

- PowerFactory Applications for Power System AnalysisDari EverandPowerFactory Applications for Power System AnalysisFrancisco M. Gonzalez-LongattBelum ada peringkat

- Open Radio Access Network (O-RAN) Systems Architecture and DesignDari EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignBelum ada peringkat

- (294100910) Art - 3A10.1007 - 2Fs11265-013-0767-xDokumen10 halaman(294100910) Art - 3A10.1007 - 2Fs11265-013-0767-xAdriana Saltos IbarraBelum ada peringkat

- Spe-195629-Ms Openlab: Design and Applications of A Modern Drilling Digitalization InfrastructureDokumen22 halamanSpe-195629-Ms Openlab: Design and Applications of A Modern Drilling Digitalization InfrastructureSave NatureBelum ada peringkat

- Open MPI: Goals, Concept, and Design of A Next Generation MPI ImplementationDokumen9 halamanOpen MPI: Goals, Concept, and Design of A Next Generation MPI Implementationcongnguyen201089Belum ada peringkat

- Designing Embedded Systems with PIC Microcontrollers: Principles and ApplicationsDari EverandDesigning Embedded Systems with PIC Microcontrollers: Principles and ApplicationsPenilaian: 2 dari 5 bintang2/5 (1)

- Web Services For Sensor Node AccessDokumen10 halamanWeb Services For Sensor Node AccessVinodhini GanesanBelum ada peringkat

- Field BusDokumen27 halamanField BusStef DriessensBelum ada peringkat

- Building Wireless Sensor Networks: Application to Routing and Data DiffusionDari EverandBuilding Wireless Sensor Networks: Application to Routing and Data DiffusionBelum ada peringkat

- The Track & TraceDokumen11 halamanThe Track & TraceReddy ManojBelum ada peringkat

- Multicopter Design and Control Practice: A Series Experiments based on MATLAB and PixhawkDari EverandMulticopter Design and Control Practice: A Series Experiments based on MATLAB and PixhawkBelum ada peringkat

- Computer Science Self Management: Fundamentals and ApplicationsDari EverandComputer Science Self Management: Fundamentals and ApplicationsBelum ada peringkat

- Comparison of Management and Orchestration Solutions For The 5G EraDokumen18 halamanComparison of Management and Orchestration Solutions For The 5G EranareshBelum ada peringkat

- Remote Khamis AR 2003 PsDokumen15 halamanRemote Khamis AR 2003 PshuvillamilBelum ada peringkat

- ICSAI2019 OPCUAPub Sub Implementationand ConfigurationDokumen7 halamanICSAI2019 OPCUAPub Sub Implementationand ConfigurationStephan ElliottBelum ada peringkat

- Industrial Process Automation Systems: Design and ImplementationDari EverandIndustrial Process Automation Systems: Design and ImplementationPenilaian: 4 dari 5 bintang4/5 (10)

- Process Fault-Tolerance: Semantics, Design and Applications For High Performance ComputingDokumen11 halamanProcess Fault-Tolerance: Semantics, Design and Applications For High Performance ComputingSalil MittalBelum ada peringkat

- HSE Brazil ArticlefinalDokumen13 halamanHSE Brazil ArticlefinalAkoKhalediBelum ada peringkat

- Approach For Implementing Object-Oriented Real-Time Models On Top of Embedded TargetsDokumen7 halamanApproach For Implementing Object-Oriented Real-Time Models On Top of Embedded Targetsanandkumarrs6Belum ada peringkat

- CIGRE 2018: 21, Rue D'artois, F-75008 PARISDokumen9 halamanCIGRE 2018: 21, Rue D'artois, F-75008 PARISLindo PatoBelum ada peringkat

- Application Challenges Fieldbus SystemDokumen14 halamanApplication Challenges Fieldbus SystemMericatBelum ada peringkat

- Wireless Communications Framework For An Industry For Enabling IoT Based SolutionsDokumen7 halamanWireless Communications Framework For An Industry For Enabling IoT Based SolutionsMudit AgrawalBelum ada peringkat

- Long Term Evolution Simulator - A SurveyDokumen5 halamanLong Term Evolution Simulator - A SurveyzakiBelum ada peringkat

- Cps in AutomationDokumen6 halamanCps in AutomationMichelle SamuelBelum ada peringkat

- One Day Tutorials On SDR and CRDokumen1 halamanOne Day Tutorials On SDR and CRM Madan GopalBelum ada peringkat

- Bluetooth Hotspots For Smart Spaces InteractionDokumen4 halamanBluetooth Hotspots For Smart Spaces InteractionAltair JuniorBelum ada peringkat

- Petrinet - Tutorial PDFDokumen17 halamanPetrinet - Tutorial PDFsubramanya1982Belum ada peringkat

- Tema 1-5 Parcial Redes IndustrialesDokumen22 halamanTema 1-5 Parcial Redes IndustrialesDavid GutiérrezBelum ada peringkat

- Redes Industriales FinalDokumen78 halamanRedes Industriales FinalDavid GutiérrezBelum ada peringkat

- Evolution of Communication Systems Within Industrial EnviromentDokumen9 halamanEvolution of Communication Systems Within Industrial EnviromentAhmad Elsayed MohammedBelum ada peringkat

- Protocolo Iec 61850Dokumen89 halamanProtocolo Iec 61850Eliecer CastilloBelum ada peringkat

- High-Performance Embedded Computing: Applications in Cyber-Physical Systems and Mobile ComputingDari EverandHigh-Performance Embedded Computing: Applications in Cyber-Physical Systems and Mobile ComputingBelum ada peringkat

- Arcademis: A Framework For Object Oriented Communication Middleware DevelopmentDokumen19 halamanArcademis: A Framework For Object Oriented Communication Middleware DevelopmentthaidiemBelum ada peringkat

- A Bluetooth Solution For Public Information Systems - Marsanu, CiobanuDokumen11 halamanA Bluetooth Solution For Public Information Systems - Marsanu, Ciobanu_qabriel_Belum ada peringkat

- 1Dokumen9 halaman1Fares ChetouhBelum ada peringkat

- Pattern-Based Architecture For Building Mobile Robotics Remote LaboratoriesDokumen6 halamanPattern-Based Architecture For Building Mobile Robotics Remote LaboratoriesCamilo DuqueBelum ada peringkat

- Fggy KKL SkyDokumen14 halamanFggy KKL SkyFahd SaifBelum ada peringkat

- Comparison Between Different Wireless Sensor Simulation ToolsDokumen7 halamanComparison Between Different Wireless Sensor Simulation ToolsInternational Organization of Scientific Research (IOSR)0% (1)

- Final ReportDokumen33 halamanFinal Reportyousef tamerBelum ada peringkat

- OPNET LTE Simulator Project PDFDokumen2 halamanOPNET LTE Simulator Project PDFAli Mahmoud0% (2)

- A Versatile Demonstrator For Distributed RealDokumen4 halamanA Versatile Demonstrator For Distributed Realpriyanka1229Belum ada peringkat

- Using Artificial Neural Networks for Analog Integrated Circuit Design AutomationDari EverandUsing Artificial Neural Networks for Analog Integrated Circuit Design AutomationBelum ada peringkat

- Developing Trend of Industrial Fieldbus Control SystemDokumen4 halamanDeveloping Trend of Industrial Fieldbus Control SystemFarukh AzizzBelum ada peringkat

- Pipelined Processor Farms: Structured Design for Embedded Parallel SystemsDari EverandPipelined Processor Farms: Structured Design for Embedded Parallel SystemsBelum ada peringkat

- LTE Self-Organising Networks (SON): Network Management Automation for Operational EfficiencyDari EverandLTE Self-Organising Networks (SON): Network Management Automation for Operational EfficiencySeppo HämäläinenBelum ada peringkat

- DVCon Europe 2015 TA4 2 PaperDokumen8 halamanDVCon Europe 2015 TA4 2 PaperJon DCBelum ada peringkat

- 2018MC53 Assignment 1Dokumen17 halaman2018MC53 Assignment 1Muntha AslamBelum ada peringkat

- FMI StandardDokumen27 halamanFMI StandardDialloABD2021Belum ada peringkat

- Algorithmique Et Programmation en C: Cours Avec 200 Exercices CorrigésDokumen298 halamanAlgorithmique Et Programmation en C: Cours Avec 200 Exercices CorrigésSerges KeouBelum ada peringkat

- LMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesDokumen2 halamanLMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesRobert MateoBelum ada peringkat

- Sophia Program For Sustainable FuturesDokumen128 halamanSophia Program For Sustainable FuturesfraspaBelum ada peringkat

- Channel Tables1Dokumen17 halamanChannel Tables1erajayagrawalBelum ada peringkat

- Specialty Arc Fusion Splicer: FSM-100 SeriesDokumen193 halamanSpecialty Arc Fusion Splicer: FSM-100 SeriesSFTB SoundsFromTheBirdsBelum ada peringkat

- Peoria County Jail Booking Sheet For Oct. 7, 2016Dokumen6 halamanPeoria County Jail Booking Sheet For Oct. 7, 2016Journal Star police documents50% (2)

- SPH4U Assignment - The Wave Nature of LightDokumen2 halamanSPH4U Assignment - The Wave Nature of LightMatthew GreesonBelum ada peringkat

- Tivoli Performance ViewerDokumen4 halamanTivoli Performance ViewernaveedshakurBelum ada peringkat

- United Nations Economic and Social CouncilDokumen3 halamanUnited Nations Economic and Social CouncilLuke SmithBelum ada peringkat

- Year 9 - Justrice System Civil LawDokumen12 halamanYear 9 - Justrice System Civil Lawapi-301001591Belum ada peringkat

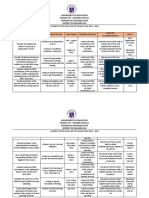

- Professional Regula/on Commission: Clarita C. Maaño, M.DDokumen31 halamanProfessional Regula/on Commission: Clarita C. Maaño, M.Dmiguel triggartBelum ada peringkat

- On CatiaDokumen42 halamanOn Catiahimanshuvermac3053100% (1)

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesDokumen13 halamanThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6Belum ada peringkat

- 6 V 6 PlexiDokumen8 halaman6 V 6 PlexiFlyinGaitBelum ada peringkat

- Unit-5 Shell ProgrammingDokumen11 halamanUnit-5 Shell ProgrammingLinda BrownBelum ada peringkat

- DesalinationDokumen4 halamanDesalinationsivasu1980aBelum ada peringkat

- Working Capital ManagementDokumen39 halamanWorking Capital ManagementRebelliousRascalBelum ada peringkat

- TLE - IA - Carpentry Grades 7-10 CG 04.06.2014Dokumen14 halamanTLE - IA - Carpentry Grades 7-10 CG 04.06.2014RickyJeciel100% (2)

- Subqueries-and-JOINs-ExercisesDokumen7 halamanSubqueries-and-JOINs-ExerciseserlanBelum ada peringkat

- Difference Between Mountain Bike and BMXDokumen3 halamanDifference Between Mountain Bike and BMXShakirBelum ada peringkat

- Linux For Beginners - Shane BlackDokumen165 halamanLinux For Beginners - Shane BlackQuod Antichristus100% (1)

- Action Plan Lis 2021-2022Dokumen3 halamanAction Plan Lis 2021-2022Vervie BingalogBelum ada peringkat

- Bajaj Allianz InsuranceDokumen93 halamanBajaj Allianz InsuranceswatiBelum ada peringkat

- ST JohnDokumen20 halamanST JohnNa PeaceBelum ada peringkat

- Ishares Core S&P/TSX Capped Composite Index Etf: Key FactsDokumen2 halamanIshares Core S&P/TSX Capped Composite Index Etf: Key FactsChrisBelum ada peringkat

- Epidemiologi DialipidemiaDokumen5 halamanEpidemiologi DialipidemianurfitrizuhurhurBelum ada peringkat

- G.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARDokumen2 halamanG.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARTheodore DolarBelum ada peringkat

- Activity Description Predecessor Time (Days) Activity Description Predecessor ADokumen4 halamanActivity Description Predecessor Time (Days) Activity Description Predecessor AAlvin LuisaBelum ada peringkat

- Cam Action: Series: Inch StandardDokumen6 halamanCam Action: Series: Inch StandardVishwa NBelum ada peringkat

- Discover Mecosta 2011Dokumen40 halamanDiscover Mecosta 2011Pioneer GroupBelum ada peringkat