10 Chapter 4

Diunggah oleh

Ankit MehtaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

10 Chapter 4

Diunggah oleh

Ankit MehtaHak Cipta:

Format Tersedia

86

Chapter 4

Accelerometer Testing

4.1 Introduction

The accelerometer designed and realized so far is intended for an

aerospace application. Detailed testing and analysis needs to be

conducted to qualify the product for the end use and establish the

suitability of the product for the intended use. These tests can take many

different forms including chip level probing for electrical characterization,

sensitivity estimation, bias stability, performance evaluation under

thermal and dynamic environments. Details of performance testing

procedure of commercially available accelerometers are presented by

number of researchers [47-49].

MEMS pendulous accelerometers have already demonstrated good

performance in automobile and other commercial applications. The

challenge of using of this technology in aerospace inertial navigation is

about, significantly improving the bias stability, cross-axis sensitivity,

temperature

sensitivity

and

detailed

measured

performance

demonstration for the intended application.

The accelerometer was tested using procedure and data analysis

methods similar to the practices in defence departments which are

87

broadly adopted from IEEE STD 337-1972 [50]. This describes the test

procedures for linear, single axis pendulous analog, torque balance

accelerometer.

The test procedure consists of observing the output of the test

device to input acceleration using Earths gravitation field or an external

excitation source.

The objective of the test is to characterize the accelerometer

Bias stability

Linearity

Hysteresis

Cross- axis sensitivity

Temperature sensitivity

Bandwidth.

Shock response

It was presumed that physical sources of the errors described in the

reference [50] remain valid for the micromachined accelerometer also. In

both micromachined and conventional accelerometers, the temperature

sensitivity of performance is an important parameter. However, due to

the small scale of MEMS device, temperature is expected to play a larger

role.

The

error

model

components

selected

for

micromachined

accelerometers are bias, scale factor, non-linearity, cross-axis sensitivity

and temperature. The effect of misalignment of the input axis is not

investigated.

88

The equation relating different error model components to the final

overall error expressed in % of FSO is as follows.

Average output = E1 + E2 + E3 + E4 x T + E5.

E1 Bias drift

E2 Non linearity

E3 Cross- axis sensitivity

E4 Temperature sensitivity of bias drift

E5 Misalignment of input axis.

T change in device temperature during testing.

4.2 Chip level probing

The primary aim of the chip level probing is to validate the wafer

fabrication process and to certify the device functionality for further

packaging and integration operations.

Fig 4.1 Test set-up for electrical probing.

A standard Cascade make probe station is integrated with Agilent LCR

meter and is used for measuring the chip level electrical parameters. This

89

set-up can measure capacitance from 10 atto Farads to 10 Farads with

an accuracy of 0.05%.

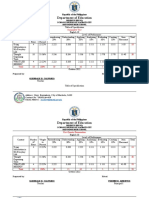

Ten number of accelerometers are selected for probing to verify the

consistency of the results. The average nominal capacitance values of

Co1 (capacitance between top electrode and proof-mass) and Co2

(capacitance between bottom electrode and proof-mass) are tabulated in

table - 4.1

Sl.No

Average nominal

Average nominal capacitance

capacitance [Co1]pF

[Co2]pF

3.0102

3.1124

Table 4.1 Measured values of average nominal capacitance.

Observations and comments:1. The average nominal capacitance between electrodes and proofmass measured is around 3 pF which is very close to the simulated

value of 2.5 pF. The discrepancy in nominal capacitance may be

due to stray capacitance caused by electrical routing & pads and

also due to fine difference in air gap on both sides.

2. However the variation in nominal capacitances Co1 and Co2 is

small hence can be balanced using internal trim capacitors of the

ASIC during electronic integration.

90

3. Finally the probing results proves that the device is successfully

realized as per the design without any stiction or shorts and the

gap between proofmass and electrodes is same on both sides and

is cleared for further electronic integration and testing.

4.3 Packaging & electronics integration

The fabricated wafers are diced and the individual chips are die

bonded on a ceramic carrier in LCC package as shown in plate 4.1. Gold

layout is patterned on the ceramic substrate in such a way so as to

accommodate both the sensor chip and all other required electronic

components. The chip is wire bonded with 1 mil gold wire. The wire

bond is tested for its pull strength to ensure quality wire bond.

The interface circuit for converting the variation in capacitance to

voltage is implemented using a standard capacitance to voltage

conversion ASIC, MS3110 from Irvine Sensors. MS3110 is a general

purpose, ultra noise CMOS IC that requires only a single +5V DC supply

and some decoupling components. It has gain & DC offset trim functions

and on chip EEPROM for storage of program coefficients. The circuit

gives a DC bias of 2.5V at 0 g, which is also equal to the reference

voltage of the ASIC.

The fabricated accelerometer chip shows a deviation in nominal

capacitance values from the designed values and hence the capacitance

91

bridge is not balanced at zero g. As a result there is an initial offset in

the output voltage when at zero g. The offset is nullified by using the

internal capacitances in the ASIC. In case where the offset is much more

than the limit of the internal capacitances, provision is made to add an

external capacitor of suitable value in parallel with the lower capacitance

in the bridge. Provision is made in the interface circuit board for the

tuning of the ASIC coefficients after the final assembly of the components

to cater for packaging effects also.

Plate 4.1 Packaged sensor with electronics.

4.4 Scale factor test

Scale factor or sensitivity of an accelerometer is the ratio of the

sensor electrical output to mechanical input typically rated in mV /g.

This is the fundamental parameter to specify a sensor and forms the

92

basis for further detailed performance testing. The test method block

diagram is shown in fig 4.2

Fig 4.2 Test set-up for scale factor measurement.

The

accelerometer

sensor

is

mounted

on

an

automatic

accelerometer calibrator and connected to power supply and the output

is monitored using precision digital oscilloscope. The calibrator generates

a physical excitation signal of magnitude 1 g at a frequency of 159Hz.

The screen shot of the oscilloscope captured during testing is presented

in fig 4.3

93

Fig 4.3 Sensitivity of accelerometer

It can be seen from the oscilloscope output that the sensitivity of the

accelerometer measured is 62 mV/g in both directions.

Observations and remarks:The

sensitivity

of

the

accelerometer

is

62

mV/g

at

room

temperature. Change in sensitivity can be obtained by programming the

gain of the ASIC. The sensor is programmed to have an offset voltage of

2.5 V at zero g. The maximum output at +30 g is 4.5V and at -30 g it

is 0.5V. Hence

the maximum sensitivity that can be obtained is

66mV/g. With measured sensitivity of 62mV/g the sensor yields 3.1 mV

for 50 milli g resolution, which can be detected easily.

94

4.5 Hysteresis test

A sensor should be capable of following the changes of the input

parameter regardless of which direction the change is made, hysteresis is

the measure of this property. An example of hysteresis within an

accelerometer is the presence of residual deflection/strain within the

sensor's spring after acceleration has been applied and then removed. In

the presence of hysteresis, an accelerometer will not be able to

successfully repeat its null position; this will lead to unstable bias.

Hysteresis is expressed as % of FSO.

Fig 4.4 Block diagram of Hysteresis testing

As shown in the fig 4.4, the sensor is mounted on a centrifuge in such

a way that the sensing axis is in radial direction. The sensor is suitably

rotated at different speeds to obtain upto + 30 g acceleration

in

steps.

The

output

measured

at

different

accelerations

95

applied from 0 g to 30 g and while returning from 30 g to 0 g are

plotted in fig 4.5 and the output values are given in table 4.2.

Hysterisis

4500.00

4000.00

Output V (mV)

3500.00

3000.00

2500.00

2000.00

Up

1500.00

Down

1000.00

500.00

Acceleration g

0.00

-30

-20

-10

10

20

30

Fig. 4.5 Hysteresis test result

Acceleration (g)

UP (mV)

Down (mV)

-30

320.00

322.00

-18

1063.00

1064.00

-6

1800.00

1802.00

2181.00

2180.00

2548.00

2550.00

18

3294.00

3297.00

30

4041.00

4041.00

Table - 4.2 Accelerometer output at different g

96

Observation and remarks:From the readings presented it can be seen that the maximum deviation

in output is at 18 g. The hysteresis is given as

(y)/2 X 100 = 0.08 % of FSO

FSO

The measured value of hysteresis is 0.08%, which is much less than the

specified value of 0.15 % of FSO.

4.6 Bias stability or drift

Bias stability is specified as a percentage of FSO at constant temperature

over a specified time period.

Fig 4.6 Test set-up for bias stability measurement.

The accelerometer is positioned in such a way that its sensitive axis (Z) is

perpendicular to the earth gravitation vector. In this way the sensor is

not subjected to any acceleration. The sensor output is connected to a

data logger. The offset variation is measured using a digital multi meter

(DMM) and logged over a period of two hours and plotted as in Fig 4.7.

97

Drift Testing of SE03 for 2 Hours

2.1900

Output(V)

2.1850

2.1800

2.1750

2.1700

0

20

40

60

80

100

120

time(Min)

Fig 4.7 Bias stability with time.

Observations and comments

Long term bias stability measurements have demonstrated an

overall measured value of 0.5mV over a period of 120minutes. This

works out to be 0.025% of FSO, which is well within the requirement of

0.15% of FSO.

4.7 Linearity test

The transfer function of the sensor (input/output relationship) is

not perfectly linear. Non-linearity is expressed as the ratio of maximum

deviation of output voltage from a best fit straight line to full scale output

of the device. This is expressed as a percentage of FSO and the equation

is given below.

98

Non linearity = Maximum Deviation(Volts) X 100 %

Full Scale Output(Volts)

Non-linearity is one of the major sources of error in aerospace class of

accelerometers and shall be limited to less than 1% of the FSO.

Fig 4.8 Block diagram of linearity test

To conduct the test, Modalshop make automatic accelerometer

calibration workstation is used. The system uses back to back

comparison calibration method as per ISO 16063-21 [51] and generates

test reports automatically. It can apply a peak acceleration of 20 g at

a reference frequency of 100Hz. Hence the test range is limited to 20 g

instead of full range of 30 g.

99

The Accelerometer is mounted on the shaker with its sensitive axis

(Z- axis) along the shaker excitation axis. The sensor is subjected to g

sweep from 1 g to 20 g progressively at a reference frequency of

100 Hz. The g output from the sensor at different g values is compared

with that of a standard acceleration sensor and report generated

automatically as shown in Fig 4.9.

100

Fig 4.9 Linearity test result (calibrator output)

101

Observations and remarks

From fig 4.9 it can be seen that the linearity error of the sensor is

0.32% of FSO, which is well within the specified value of 1%.

4.8 Cross-axis sensitivity test

Aerospace systems experience acceleration forces along all three axes

i.e. pitch, roll and yaw. Accelerometer with its sense axis mounted along

a particular direction shall sense acceleration in that direction only and

shall be immune to the accelerations applied on other axes.

Cross-axis sensitivity is the output that is obtained on the sensing

axis for an acceleration applied on a perpendicular axis. This is

expressed as a percentage of the full scale output sensitivity. The sensor

has two cross-axis sensitivities and . The first subscript is the

sense axis and the second subscript is the off-axis direction. Cross-axis

sensitivity is given by

100

100

102

Fig 4.10 Cross-axis testing block diagram

The sensor is mounted on a precision centrifuge in such a way that

its sensitive axis (Z) is along the Earths gravitational vector. This method

of mounting eliminates both radial and tangential components of

acceleration acting on the sense direction. The sensor output for 1g

acting due to gravity is nullified and set to zero in the DMM. Now by

suitably rotating the centrifuge at appropriate speed the required cross

axis acceleration is applied on the accelerometer and output of the

sensor is recorded through a data logger.

103

Cross-axis sensivitty

sensor output (Volts)

2.1900

2.1850

2.1800

2.1750

2.1700

2.1650

2.1600

0

10

15

20

25

cross-axis acceleration applied (g)

Fig 4.11 Cross-axis sensitivity plot

Cross axis

acceleration

0

Output (V)

2.1812

2.1823

10

2.1834

15

2.1845

20

2.1855

25

2.1866

30

2..1874

Table 4.3 Cross-axis sensitivity output

30

35

104

Observations and remarks

Since the sensor is symmetrical along X-axis and Y-Axis the crossaxis test is done along one direction only.

The measured value of cross-axis sensitivity is 0.313% of FSO,

which is well within the specified value of 1% of FSO. However it is

more than the simulated value of 0.01% of FSO. This may be due

to the initial deflection present in the accelerometer because of the

Earths gravity, fabrication error in positioning the beams at the

centre and due to sensor mounting misalignment in the package.

4.9 Temperature sensitivity test

Aerospace systems, during their operational period are exposed to

harsh environmental conditions, which includes vibration and wide

operational range of temperatures. The two most important performance

parameters that need to be studied for their temperature effects are bias

stability and offset variation. The temperature sensitivity of the

accelerometer is the sensitivity of a given performance characteristic to

operating temperature. It is expressed as the change of the characteristic

per degree of temperature change, typically in ppm/C for scale factor

and mg/C for bias. This figure is useful for the estimation of maximum

sensor error with temperature as a variable while modelling.

105

4.9.1 Temperature sensitivity of offset value:

Temperature sensitivity of zero g offset is, the variation in the zero

g offset value over the operating temperature range. The offset variation

is measured by placing the accelerometer in a thermal chamber fig 4.12

and subjecting it to different operating temperatures. The accelerometer

is mounted in such a way that its sense axis is perpendicular to the

Earths gravitational axis. The output is noted down using a precision

DMM which in turn is connected to a data logger.

Fig 4.12 Temperature sensitivity of offset test block diagram

offset variation (Volts)

2.1880

2.1860

2.1840

2.1820

2.1800

2.1780

2.1760

-20

20

40

60

Temperature deg C

Fig 4.13 Temperature sensitivity of offset

80

106

Temp (C)

Nominal output

(V)

-20

2.1773

2.1786

20

2.1812

40

2.1837

60

2.1860

80

2.1871

Table 4.4

Temperature sensitivity of offset

The zero g offset voltage is measured at -20, 0, 20, 40, 60, 80C.

The zero g offset voltage at -20C is subtracted from the value obtained

at 80C. The resulting value obtained is divided by the accelerometer's

FSO to express the change in output in terms of % of FSO or alternately

it can be expressed as ppm also.

Observations and remarks:

From Table 4.4, it can be seen that over the operating temperature

range - 20C to + 80C

the maximum change in zero g output is

9.8mV. Hence the temperature sensitivity of zero g error works

out to be 0.52% of FSO (or) alternately this can be expressed as

1.58mg/C (at 62mV/g sensitivity).

107

The offset variation is fairly linear with temperature, hence by

implementing suitable temperature compensation techniques, the

effect can be reduced considerably.

4.9.2 Temperature sensitivity of the scale factor:

Temperature sensitivity of the scale factor is the change in the

sensitivity of the accelerometer from the room temperature sensitivity as

the temperature changes. The variation is measured using special test

set-up in which accelerometer is placed on one end of an arm which is

inside the thermal chamber and the other end is outside and is

connected to a precision rotary table. Now the accelerometer is subjected

to the temperatures -20, 0, 20, 40, 60, 80C. By rotating the rotary table

the accelerometer is subjected to 1 g acceleration and the scale factor

value is noted down at different temperatures as shown in fig 4.14. After

the testing is complete, the data is analyzed. The sensitivity at 25C is

subtracted from each of the measurements. The resulting maximum

change in sensitivity is divided by the accelerometer's sensitivity at 25C

to express the change in output in terms of ppm change in scale factor.

108

sensitivity mv/g'

62.04

62.02

62

61.98

61.96

61.94

61.92

61.9

-20

20

40

60

80

temperature C

Fig 4.14 Temperature sensitivity of the scale factor

Temp (C)

Sensitivity (mV/ g)

-20

61.906

61.923

20

61.948

40

61.965

60

61.989

80

62.006

Table 4.5 Temperature sensitivity of scale factor

109

Observations and remarks:

From Table 4.5 it can be seen that the scale factor variation over

the temperature range is a maximum of 0.1mV. Hence the scale

factor stability is 1612 ppm. This stability figure is adequate for

control class aerospace applications.

By adopting closed loop control techniques, scale factor variation

can be reduced considerably and more precise accelerometers can

be realized.

110

4.10. Bandwidth test

The bandwidth is defined as the useful frequency range, in which

the output of the sensor is within 3dB of the nominal value. The test

set-up block diagram is shown in fig 4.15.

Fig 4.15 Test set-up for bandwidth measurement.

The accelerometer is mounted on Modalshop make automatic

dynamic shaker. In this system, the output of the accelerometer under

test is compared with an inbuilt reference accelerometer output and the

performance is compared. A sine sweep signal of 1 g magnitude is

applied from a frequency of 10 Hz to 10000 Hz taking the output at 100

Hz as the reference value. The deviation in amplitude response as a

function of frequency is shown in fig 4.16.

111

Fig 4.16 Frequency sweep output of accelerometer

Observations and remarks

From fig 4.16 amplitude response vs. frequency plot it can be seen that,

3dB deviation in output is occurring at 800Hz. Hence the sensor meets

the operational bandwidth of 100Hz.

112

4.11 Shock test

Accelerometers used in aerospace applications are subjected to high

shocks during the operation. The sensor shall withstand the shock and

exhibit normal performance after the shock is withdrawn.

Power

Supply

Accelerometer

Data

Logger

Shock

Tester

Fig 4.17 Block diagram of shock testing

As shown in the fig 4.17 the sensor is mounted on a shock tester in

such a way that the sensing axis is along the shock input axis. A half

sine shock signal

of 50 g magnitude is applied for a duration of

11msec. Fig. 4.18 gives the input shock spectrum and fig. 4.19 is the

response shock spectrum of the accelerometer, the graph plots the

response of three different accelerometers with different sensitivities. Also

the shock response spectrum provides a measure of response time of the

sensor.

113

Fig 4.18 Input shock spectrum

- Sensor 1

- Sensor 2

- Sensor 3

Fig 4.19 Response shock spectrum

114

Observations and remarks:

From the test results, it can be seen that, all the three

accelerometers have responded in a similar way to the applied

shock and the response is along the lines of input shock.

It can be seen that the accelerometers have very fast response of

less than 1msec.

4.12 Results & discussion

The sensitivity of the sensor measured is 62 mV/g.

The sensor demonstrated linearity error and cross-axis sensitivity

less than 1% of FSO as designed.

The hysteresis and bias stability values measured are less than

0.15% of FSO and meet the sensor specifications.

The temperature sensitivity of zero g error or offset error is 0.52%

of FSO (or) 1.58mg/C (at 62mV/g sensitivity) and is fairly linear

over the temperature range.

The scale factor stability over the operational temperature range is

1612 ppm.

The operational bandwidth of the sensor is >100Hz as designed.

Sensor response time measured from shock test is less than

one msec.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- IntroductionDokumen20 halamanIntroductionAnkit MehtaBelum ada peringkat

- Shang Et Al-Annalen Der PhysikDokumen7 halamanShang Et Al-Annalen Der PhysikAnkit MehtaBelum ada peringkat

- How To Access Your School Files From HomeDokumen2 halamanHow To Access Your School Files From HomeAnkit MehtaBelum ada peringkat

- Solutions ManualDokumen260 halamanSolutions ManualEISALMANKHAN91% (11)

- AMEMS Course+Outline W2015Dokumen6 halamanAMEMS Course+Outline W2015Ankit MehtaBelum ada peringkat

- Telecommunications Systems Lab # 9 TCP Analysis Using WiresharkDokumen3 halamanTelecommunications Systems Lab # 9 TCP Analysis Using WiresharkAnkit MehtaBelum ada peringkat

- Nelson Physics 11Dokumen586 halamanNelson Physics 11Jeff An90% (10)

- Scientific Investigation Skills Intro and Career ExplorationDokumen22 halamanScientific Investigation Skills Intro and Career ExplorationAnkit MehtaBelum ada peringkat

- Scientific Investigation Skills Intro and Career ExplorationDokumen22 halamanScientific Investigation Skills Intro and Career ExplorationAnkit MehtaBelum ada peringkat

- Transmission Properties of Lossy Single-Negative MaterialsDokumen6 halamanTransmission Properties of Lossy Single-Negative MaterialsAnkit MehtaBelum ada peringkat

- Manual - NiUSRP Hands On 19 Sept 2013Dokumen78 halamanManual - NiUSRP Hands On 19 Sept 2013Ankit MehtaBelum ada peringkat

- Transway 1C Transway 1C: All Trips Accessible All Trips AccessibleDokumen3 halamanTransway 1C Transway 1C: All Trips Accessible All Trips AccessibleGurjot SinghBelum ada peringkat

- NCERT Class 11 MathematicsDokumen470 halamanNCERT Class 11 MathematicsAnkit MehtaBelum ada peringkat

- PNP PR Tracking 2015/2016/2017Dokumen7 halamanPNP PR Tracking 2015/2016/2017Ankit MehtaBelum ada peringkat

- Transmission Properties of Lossy Single-Negative MaterialsDokumen6 halamanTransmission Properties of Lossy Single-Negative MaterialsAnkit MehtaBelum ada peringkat

- Transmission Properties of Lossy Single-Negative MaterialsDokumen6 halamanTransmission Properties of Lossy Single-Negative MaterialsAnkit MehtaBelum ada peringkat

- Marilia Lab1Dokumen2 halamanMarilia Lab1Ankit MehtaBelum ada peringkat

- Given EquationsDokumen1 halamanGiven EquationsAnkit MehtaBelum ada peringkat

- Fabrication of Semiconductor Devices: Guard Ring Junction Contact OxideDokumen18 halamanFabrication of Semiconductor Devices: Guard Ring Junction Contact OxideakkaranniBelum ada peringkat

- Accelerometer Theory & Design Chapter Explains Working PrincipleDokumen46 halamanAccelerometer Theory & Design Chapter Explains Working Principlefarlara100% (1)

- Shang Et Al-Annalen Der PhysikDokumen7 halamanShang Et Al-Annalen Der PhysikAnkit MehtaBelum ada peringkat

- Lab 1Dokumen4 halamanLab 1Ankit MehtaBelum ada peringkat

- Panjab UniversityDokumen29 halamanPanjab UniversityAnkit MehtaBelum ada peringkat

- Chapter 12:security For RFID TagsDokumen27 halamanChapter 12:security For RFID TagsAnkit MehtaBelum ada peringkat

- Hardware Implementation of Hash FunctionsDokumen13 halamanHardware Implementation of Hash FunctionsAnkit MehtaBelum ada peringkat

- T Rec X.509 198811 S!!PDF eDokumen34 halamanT Rec X.509 198811 S!!PDF eAnkit MehtaBelum ada peringkat

- Testing Techniques For Hardware Security: Abstract-System Security Has Emerged As A Premier DesignDokumen10 halamanTesting Techniques For Hardware Security: Abstract-System Security Has Emerged As A Premier DesignMehdiForoughiBelum ada peringkat

- FlashGet DownloadsDokumen40 halamanFlashGet DownloadsAnkit MehtaBelum ada peringkat

- Form Verification of MarksDokumen2 halamanForm Verification of MarksRanveer Raj BhatnagarBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Saline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshDokumen6 halamanSaline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalBelum ada peringkat

- Evidence My Favorite PlayerDokumen2 halamanEvidence My Favorite PlayerReynel Soir0% (1)

- RAGHAV Sound DesignDokumen16 halamanRAGHAV Sound DesignRaghav ChaudhariBelum ada peringkat

- Table of Specification ENGLISHDokumen2 halamanTable of Specification ENGLISHDonn Abel Aguilar IsturisBelum ada peringkat

- 10 1016@j Ultras 2016 09 002Dokumen11 halaman10 1016@j Ultras 2016 09 002Ismahene SmahenoBelum ada peringkat

- DELA PENA - Transcultural Nursing Title ProposalDokumen20 halamanDELA PENA - Transcultural Nursing Title Proposalrnrmmanphd0% (1)

- NX569J User ManualDokumen61 halamanNX569J User ManualHenry Orozco EscobarBelum ada peringkat

- Two Monuments by C Mann 1493 Copy - PDF - OcredDokumen23 halamanTwo Monuments by C Mann 1493 Copy - PDF - OcredStephania FrancoBelum ada peringkat

- Dompet Digital Di Kota SemarangDokumen10 halamanDompet Digital Di Kota SemarangRikson TandelilinBelum ada peringkat

- Pedestrian Safety in Road TrafficDokumen9 halamanPedestrian Safety in Road TrafficMaxamed YusufBelum ada peringkat

- 1-7 Least-Square RegressionDokumen23 halaman1-7 Least-Square RegressionRawash Omar100% (1)

- Malla Reddy Engineering College (Autonomous)Dokumen17 halamanMalla Reddy Engineering College (Autonomous)Ranjith KumarBelum ada peringkat

- SiargaoDokumen11 halamanSiargaomalouBelum ada peringkat

- Upstream Color PDFDokumen16 halamanUpstream Color PDFargentronicBelum ada peringkat

- BUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyDokumen34 halamanBUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyThe Bartlett Development Planning Unit - UCLBelum ada peringkat

- Signal Processing Problems Chapter 12Dokumen20 halamanSignal Processing Problems Chapter 12CBelum ada peringkat

- Activity Design ScoutingDokumen10 halamanActivity Design ScoutingHoneyjo Nette100% (9)

- Science 10 3.1 The CrustDokumen14 halamanScience 10 3.1 The CrustマシロIzykBelum ada peringkat

- (MCQ) - Arithmetic ProgressionDokumen5 halaman(MCQ) - Arithmetic Progressionrahul aravindBelum ada peringkat

- Excellence Range DatasheetDokumen2 halamanExcellence Range DatasheetMohamedYaser100% (1)

- Roadmap For SSC CGLDokumen11 halamanRoadmap For SSC CGLibt seoBelum ada peringkat

- Embedded Systems - RTOSDokumen23 halamanEmbedded Systems - RTOSCheril MehtaBelum ada peringkat

- A Method For Identifying Human Factors Concerns During The HAZOP Process - Dennis AttwoodDokumen5 halamanA Method For Identifying Human Factors Concerns During The HAZOP Process - Dennis AttwoodAlvaro Andres Blanco GomezBelum ada peringkat

- Shaft design exercisesDokumen8 halamanShaft design exercisesIvanRosellAgustíBelum ada peringkat

- Grillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종Dokumen8 halamanGrillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종tyuBelum ada peringkat

- Instruction Manual For National Security Threat Map UsersDokumen16 halamanInstruction Manual For National Security Threat Map UsersJan KastorBelum ada peringkat

- Servo Magazine 01 2005Dokumen84 halamanServo Magazine 01 2005dangtq8467% (3)

- Gpredict User Manual 1.2Dokumen64 halamanGpredict User Manual 1.2Will JacksonBelum ada peringkat

- Chapter 4 Matrices Form 5Dokumen22 halamanChapter 4 Matrices Form 5CHONG GEOK CHUAN100% (2)

- D5435 PDFDokumen6 halamanD5435 PDFZamir Danilo Morera ForeroBelum ada peringkat