Improvement of Phillips Optimized Cascade Process

Diunggah oleh

Henry ZhangJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Improvement of Phillips Optimized Cascade Process

Diunggah oleh

Henry ZhangHak Cipta:

Format Tersedia

RETURN TO MAIN MENU (Click Here)

THE PHILLIPS OPTIMIZED CASCADE LNG PROCESS

A QUARTER CENTURY OF IMPROVEMENTS

by

D. L. Andress

Phillips Petroleum Company

Copyright 1996 - Phillips Petroleum Company

Nineteen ninety-four marked the 25th operating anniversary of the Phillips Petroleum Company

LNG plant located at Nikiski, Kenai, Alaska, and nearly two years later the plant continues its

exemplary performance. This plant is the first and only base-load liquefied natural gas plant

built in the Western Hemisphere solely for LNG export. It uses an early version of the Phillips

Optimized Cascade LNG Process for its liquefaction unit and has for the past quarter of a

century delivered LNG to its customers, achieving a remarkable record of product delivery.

During the past 26+ years the efficiency and throughput capabilities of the Kenai plant have

been improved by minor changes in procedures, minor equipment upgrades, and a recently

completed efficiency project. Over the same period of time, many other Phillips LNG project

studies have led to improvements and further refinements to the liquefaction process employed

at Kenai.

INTRODUCTION

The original Optimized Cascade LNG process was developed by Phillips Petroleum Company

in the 1960's. The object of this development was to devise a refrigeration cycle that could be

utilized in the liquefaction of natural gas that would permit easy startups and smooth operations

for a wide range of gas feed volumes and compositions.

Using these criteria as design parameters, computer programs were developed to calculate the

total process requirements for a cascade cycle system utilizing propane, ethylene, and methane

as the refrigerants. Propane was chosen because it is available in quantity world-wide;

ethylene because it would condense methane at a refrigerant pressure above atmospheric

pressure and could in turn be condensed by propane; and methane because it is available in

the natural gas stream. Applying the computer programs, models were created to optimize the

cycle. These models determined the optimal liquefaction train configuration to maximize

production yields of LNG.

PHILLIPS CRYOGENIC-LNG EXPERIENCE

Shortly after its founding, Phillips Petroleum Company became a leader in the gas industry,

pioneering many developments in gas and gas liquids technology. In the mid 1920s it became

the largest producer of natural gas liquids in the U.S.A., a position it maintains today. Phillips

has been active in cryogenic gas processing for over 30 years. In this time period the company

has designed, built and operated many types of cryogenic facilities such as helium recovery

plants, cryogenic NGL plants, ethylene plants, hydrogen purification systems and Kenai LNG

plant. During these years, Phillips technologists have expanded the companys cryogenic

expertise through the development of these systems.

Page 1

Republished with the permission of the Institute of Gas Technology

RETURN TO MAIN MENU (Click Here)

For 26+ years, Phillips has operated a complete LNG production system. Specific to LNG

production operations, Phillips has developed and operated the following: an offshore gas field

with its associated gas production facilities; the gas transportation system from the offshore

field to the plant; the liquefaction plant; and the storage and LNG loading facilities.

THE KENAI LNG PROJECT

Project Overview

The Kenai LNG project has its origins in the discovery of large natural gas fields in the Cook

Inlet Area of Alaska by Marathon Oil Company, Phillips Petroleum Company, and others in the

late 1950s and the early 1960s. At about the same time, Tokyo Gas Co., Ltd., and the Tokyo

Electric Power Company, Inc., came to the realization that the utilization of LNG might help

alleviate Japans air pollution problems, while at the same time providing a needed energy

supply to their county. After the offering of various proposals and a period of negotiations, an

agreement was reached whereby Phillips and Marathon would jointly participate in the export of

liquefied natural gas to Japan.

In 1967, an LNG sales agreement was signed with Phillips and Marathon as sellers and the two

Tokyo utilities as buyers. The original sales contract was for 15 years with an extension option

for an additional five years. This was the initial step in a project that was, at the time, the

worlds largest LNG project. In addition, it was the largest project of any kind in either Phillips

.

or Marathons history

The ownership of the project is split between the two companies on a 70/30 basis: Phillips has

the 70% share interest and the responsibility for the operation of the Kenai gas liquefaction

facilities; Marathon has the 30% share interest and the responsibility for the operation of the two

LNG tankers. Both companies participate in the marketing negotiations with the Japanese LNG

buyers. Each company is responsible for its respective share of the feed gas to the plant. The

joint Phillips/Marathon operation of the project for more than 26 years along with the excellent

seller/buyer relationship with the two Japanese utilities for the same period exemplifies a

win/win relationship. An environment of mutual respect and trust among all parties in the

project has developed over the projects life.

Liquefaction Process

Kenai LNG Plant uses an early version of the Phillips Optimized Cascade LNG Process. The

cryogens used are propane, ethylene, and methane. The plant has a single liquefaction train

with parallel gas turbine/compressor sets on each refrigeration circuit. Also a gas turbine driven

fuel gas compressor was utilized to compress the flash vapors from storage and loading

facilities into the fuel system. Total installed brake horsepower of the compressors was 84,600

(63.1 mW). The original design capacity of the plant was 172.6 million standard cubic feet

(~4.9 million standard cubic metres) of gas per stream day delivered aboard ship; this is

equivalent to roughly 49,000 barrels (~7800 cubic metres of liquid) per day of LNG, as shown in

Table 1.

Page 2

Republished with the permission of the Institute of Gas Technology

RETURN TO MAIN MENU (Click Here)

Kenai Plant Capacity at Startup

Trillion Btu

Million CF/day

Barrels

Million cu m (gas)

Cu m (liquids)

Tonnes Equivalent

Plant Tailgate

Capacity

(24-Hour Average)

0.174

173

49,000

4.9

7800

3300

Each Kenai LNG

Storage Tank

0.8

800

225,000

23

36,000

15,000

Polar Alaska

Tanker

Capacity

1.6

1600

450,000

45

72,000

30,000

Table 1

Plant Capacity Increases

Kenai plant production capacity was increased during the mid-1970s, when it was thought that

LNG sales could be made to the West Coast. The plant capacity was increased to 200 million

standard cubic feet (~5.6 million standard cubic meters) per day LNG equivalent by replacing

the propane compressor rotors and enlarging the propane condensers, as shown in Table 2.

This incremental volume was to be delivered to Northwest Natural Gas Company. However,

this sale never materialized.

Kenai Plant Capacity in the Mid 1970s

Trillion Btu

Million CF/day

Barrels

Million cu m (gas)

Cu m (liquids)

Tonnes Equivalent

Plant Tailgate

Capacity

(24-Hour Average)

0.2

200

57,000

5.6

9100

3800

Each Kenai LNG

Storage Tank

0.8

800

225,000

23

36,000

15,000

Polar Alaska

Tanker

Capacity

1.6

1600

450,000

45

72,000

30,000

Table 2

By 1989, at the conclusion of the extension of the original Kenai gas supply contract a new

contract with the Japanese buyers was successfully negotiated. This contract requires the

delivery of gas from Kenai to Japan through the year 2004, with another option for extension

through the year 2009. The new contract also specified that the annual contract delivery

quantities were to be increased through the 1990's. To meet this demand modifications at the

plant to remove bottlenecks in the production process were required. Also new, larger ships

were to be utilized. In 1990, a series of plant tests and studies to define the modifications

required were initiated. These tests and studies provided several options to be considered.

Page 3

Republished with the permission of the Institute of Gas Technology

RETURN TO MAIN MENU (Click Here)

The optimum combinations of plant modifications selected were:

Install an auxiliary fuel gas compressor

Install two new cooling tower cells

Install a larger vapor blower

Minor upgrade and modifications, i.e., fan blades, control valve trim, etc.

These various modifications were implemented over a two year period, completion being

achieved during the early summer of 1993. In August, 1993, a full scale plant test was

conducted at Kenai plant to confirm that the efficiency project objectives were met. The new

plant capacity based on the results of the plant test is presented in Table 3.

Kenai Plant Capacity in 1994

Trillion Btu

Million CF/day

Barrels

Million cu m (gas)

Cu m (liquids)

Tonnes Equivalent

Plant Tailgate

Capacity

(24-Hour Average)

0.22

220

64,000

6.2

9900

4299

Each Kenai

LNG

Storage Tank

0.8

800

225,000

23

36,000

15,000

Polar Eagle

Tanker Capacity

2

2000

550,000

55

88,000

3700

Table 3

So, over the years the plant has had its capacity increased from the initial LNG production

volume of 172.6 million standard cubic feet (~4.9 million standard cubic metres) per day LNG

equivalent to todays 220+ million standard cubic feet (~6.2 million standard cubic metres) per

day LNG equivalent. An approximate 28% increase in LNG production capacity has been

achieved by simply debottlenecking the plant at various times and with no modification to the

cryogenic section of the liquefaction train.

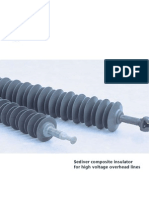

THE PHILLIPS OPTIMIZED CASCADE LNG PROCESS - 1996

Over the past quarter of a century, many improvements to the Phillips Optimized Cascade LNG

Process have been made. One change that has been incorporated in the LNG process over

the years is the modification of the methane refrigerant circuit such that it is now an open circuit

or a feed-flash system rather than the original closed circuit as used at Kenai. The major

advantage of this modification is that it eliminates the separate fuel gas compressor. Also

storage vapors and vapors from tanker loading are recovered and fed back to the liquefaction

train and reliquefied rather than being routed directly to fuel or flare, thereby increasing LNG

production (see Figure 1).

Other modifications to the basic Kenai plant configuration that could be considered are the

replacement of the dual gas turbines/compressors used on each refrigerant, as at Kenai, with a

single gas turbine/compressor on each refrigerant, particularly if two or more liquefaction trains

are to be installed at the site. Also, if the feed gas has significant amounts of C2+ hydrocarbons

Page 4

Republished with the permission of the Institute of Gas Technology

RETURN TO MAIN MENU (Click Here)

a hydrocarbon liquid draw system would be included. There are still other modifications that can

be incorporated in the Phillips Optimized Cascade LNG Process that would increase its

operational effectiveness in LNG production.

Over the years since 1969 LNG projects have been studied from the original Kenai plant size of

1.2 million metric tons of LNG production per liquefaction train per year to 3.5 million metric

tons of LNG production per liquefaction train per year. With the Phillips Optimized Cascade

LNG Process very large LNG trains can be constructed due to the manner in which the

liquefaction trains can be configured using plate-fin type heat exchangers.

Phillips Optimized Cascade LNG Process

Process Schematic

Carbon

Filter

Scrubber

Amine Treater

Inlet Scrubber

Dehydrator

Inlet Meter

Inlet

Raw Gas

Dry Gas

Filter

Propane Chiller

Air Fin Heat

Exchanger

Air Fin Heat

Exchanger

Plant Fuel

Gas

Turbine

Gas

Turbine

Methane

Compressor

Ethylene

Compressor

Gas

Turbine

Propane

Compressor

Air Fin Heat

Exchanger

Propane

Surge

LNG

Heat Exchangers,

Flash Tanks, and

Pressure Letdown Valves

Heat Exchangers

Ethylene

Surge

Heat Exchangers

Ship Vapor Blower

Tank Vapor Blower

Storage Tanks

and Loading

Pumps

Vapors From

Ship When Loading

To Ship Loading

Facilities

Transfer Pump

Figure 1

Page 5

Republished with the permission of the Institute of Gas Technology

RETURN TO MAIN MENU (Click Here)

Special Features of the Phillips Optimized Cascade LNG Process

Among the special features of the Phillips Optimized Cascade LNG Process are:

1.

PRODUCTION FLEXIBILITY. As the composition of feed gas changes, withdrawal

points for optimum production of LNG and NGL change. Multiple-stage processing

lends itself to making withdrawals as necessary to minimize the cost of producing NGL

products.

2.

NITROGEN REMOVAL. Removal of nitrogen from the feed gas minimizes the power

requirements per million Btu of product and lowers marine transportation costs.

Nitrogen is removed in a unique rejection scheme. Also, fuel is provided in a manner

that eliminates the need for a separate fuel gas compressor.

3.

VAPOR RECOVERY. Storage tank vapor is returned to the methane refrigeration

system to recover both the vapor and its refrigeration. No special equipment other than

a vapor blower is required to recover the vapor and its refrigeration since the vapor is

processed through existing liquefaction equipment.

4.

RATE FLEXIBILITY. Liquefaction unit operation is possible over a range of near zero to

one hundred percent of capacity. Recycle capability is designed into the compressors to

permit operation completely independent of actual feed gas load. Heat exchangers

operate smoothly at all load levels. This allows smooth operation of the total plant during

start-up, shutdown and periods of reduced throughput.

5.

MINIMAL SPACE REQUIREMENTS. Compact plate-fin type heat exchangers are used

extensively in this process. The use of this type of equipment allows construction of a

compact, easily modularized plant.

6.

EASE OF OPERATION. The process utilizes pure component refrigerants of essentially

constant molecular weight. This fact greatly simplifies the operation of the compression

)

systems . Considering the basic liquefaction plant, this point is well expressed in the

words of a former Kenai Plant Operations Superintendent, who said, Its the simplest

operating design in the world.

ACKNOWLEDGMENTS

The author expresses his appreciation to Ellen Inman and Linda Odum for typing and editorial

assistance and to the management of Phillips Petroleum Company for permission to present

this paper.

Page 6

Republished with the permission of the Institute of Gas Technology

RETURN TO MAIN MENU (Click Here)

REFERENCES

1. Alaska Still the New Frontier for Energy Development,

pp 8-12.

Philnews, November, 1982,

2. Barber, H. W., et al., Current LNG Technology, Proceedings of Fiftieth Annual Convention

of Natural Gas Processors Association, 1976, pp 92-97.

3. Barber, H. W., et al., Optimized Cascade Process Works Well for LNG Plants, Oil & Gas

Journal, April 17, 1972, pp 86-94.

4. The Big Look in Alaska, Philnews, April, 1969, pp 16-20.

5. Culbertson, L., et al., Liquefaction Plant Experience at Kenai, paper presented at the 3rd

International Conference and Exhibition on Liquefied Natural Gas, Washington, D.C.,

September 24-8, 1972.

6. Harper, E. A., et al., Trouble Free LNG, Chem. Eng. Progr, 71, 11 (November 1975),

pp 75-9.

7. Horn, John, et al., Alaska to Japan LNG Project - Kenai Revisited, paper presented at the

4th International Conference and Exhibition on Liquefied Natural Gas, Algiers, Algeria,

June 24-27, 1974.

8. Phillips Petroleum Company, Kenai Liquefied Natural Gas Operations, Bartlesville,

Oklahoma: Phillips Petroleum Company, First Edition, n.d.

9. Phillips Petroleum Company, Kenai Liquefied Natural Gas Operations, Bartlesville,

Oklahoma: Phillips Petroleum Company, Second Edition, n.d.

10. Phillips Petroleum Company, LNG Showpiece After 20, Years of Operation, Performance,

May/June, 1990, Number 103, pp 19-20.

11. Krusen, L. C., Propane Refrigeration System Upgrades at the Kenai LNG Plant, paper

presented at the 10th International Conference on Liquefied Natural Gas, Kuala Lumpur,

Malaysia, May 25-28, 1992.

12. Phillips Petroleum Company, Liquid Natural Gas, Bartlesville, Oklahoma: Phillips Petroleum

Company, n.d.

13. Phillips Petroleum Company, Liquefied Natural Gas, Bartlesville, Oklahoma: Phillips

Petroleum Company, n.d.

Page 7

Republished with the permission of the Institute of Gas Technology

RETURN TO MAIN MENU (Click Here)

14. Phillips Petroleum Company, Phillips Optimized Cascade Cycle for Liquefaction of Natural

Gas, 1993.

15. Phillips Petroleum Company, Phillips Optimized Cascade LNG Process, Bartlesville,

Oklahoma: Phillips Petroleum Company, n.d.

16. Krusen, L.C., The Kenai LNG Plant Efficiency Project: Making A Good Thing Even Better,

paper prepared for LNG 11, Birmingham, England, July 3-6, 1995.

Page 8

Republished with the permission of the Institute of Gas Technology

Anda mungkin juga menyukai

- Catalogo CAT 1Dokumen500 halamanCatalogo CAT 1Elmer Lagua Malpaso100% (2)

- 5672 RGA Manual TehnicDokumen48 halaman5672 RGA Manual TehnicOarga CalinBelum ada peringkat

- Webinar Engineering Study The Future of Chilled Water Plants and Waterside Economizers FinalDokumen44 halamanWebinar Engineering Study The Future of Chilled Water Plants and Waterside Economizers FinalShawn MelvilleBelum ada peringkat

- Let Me Explain Issues Related To LNG in Question and Answer FormDokumen23 halamanLet Me Explain Issues Related To LNG in Question and Answer Formashdimri100% (6)

- Welding Process Work InstructionDokumen6 halamanWelding Process Work InstructionmkcsekarBelum ada peringkat

- Peru LNGDokumen42 halamanPeru LNGEmma Truett100% (1)

- Pounder's Marine Diesel Engines and Gas TurbinesDari EverandPounder's Marine Diesel Engines and Gas TurbinesPenilaian: 4 dari 5 bintang4/5 (15)

- Developments in LNG Storage Overview of LNG Storag PDFDokumen14 halamanDevelopments in LNG Storage Overview of LNG Storag PDFpasir_waktuBelum ada peringkat

- CWB Guide to Welding Certification RequirementsDokumen8 halamanCWB Guide to Welding Certification RequirementsKhemaraj PathBelum ada peringkat

- Liquified Natural GasDokumen12 halamanLiquified Natural Gasprathesh prasadBelum ada peringkat

- BO1001-41120-EEC102 - 448220633 - Cable Trays and Conduits Technical Specification - ESEDokumen31 halamanBO1001-41120-EEC102 - 448220633 - Cable Trays and Conduits Technical Specification - ESEfernando romeroBelum ada peringkat

- Fluor's Technologies for LNG Regasification and Power GenerationDokumen20 halamanFluor's Technologies for LNG Regasification and Power GenerationMahesh DivakarBelum ada peringkat

- HurskyDokumen10 halamanHurskydipawangsaBelum ada peringkat

- Sabine Pass LNG World's First Import-Export Facility (2017) (BECHTEL)Dokumen24 halamanSabine Pass LNG World's First Import-Export Facility (2017) (BECHTEL)David PierreBelum ada peringkat

- Refrigeration Compressor Driver SelectionDokumen27 halamanRefrigeration Compressor Driver SelectionsppramBelum ada peringkat

- History of The Development of LNG - DR Chen-Hwa Chiu (Chevron)Dokumen5 halamanHistory of The Development of LNG - DR Chen-Hwa Chiu (Chevron)Yamuna NarasimhanBelum ada peringkat

- Scale UpDokumen4 halamanScale UpMohamed RadwanBelum ada peringkat

- Liquid Flow Meter Proving and LACT UnitsDokumen4 halamanLiquid Flow Meter Proving and LACT UnitsDayo IdowuBelum ada peringkat

- Operation of The Kiln Line: TrainingDokumen32 halamanOperation of The Kiln Line: TraininglafecapoBelum ada peringkat

- The Syntroleum Process of Converting Natural Gas Into Ultraclean HydrocarbonsDokumen10 halamanThe Syntroleum Process of Converting Natural Gas Into Ultraclean HydrocarbonsBharavi K SBelum ada peringkat

- LNG Chain: Transporting Natural Gas GloballyDokumen11 halamanLNG Chain: Transporting Natural Gas Globallytsar mitchelBelum ada peringkat

- LNG Terminal Flow SheetDokumen11 halamanLNG Terminal Flow SheetHari Krishna Raju100% (1)

- LNG Reliquefaction Systems2Dokumen14 halamanLNG Reliquefaction Systems2123habib123fikriBelum ada peringkat

- Underground Gas Storage Facilities: Design and ImplementationDari EverandUnderground Gas Storage Facilities: Design and ImplementationBelum ada peringkat

- Storage and Transportation LNGDokumen5 halamanStorage and Transportation LNGSanil Kuriakose100% (1)

- Benefits of Integrating NGL Extraction and LNG RecoveryDokumen8 halamanBenefits of Integrating NGL Extraction and LNG RecoveryEdgar HuancaBelum ada peringkat

- Are Floating LNG Facilities ViableDokumen8 halamanAre Floating LNG Facilities Viableihllhm100% (1)

- Comparison of Liquefaction Processes PDFDokumen4 halamanComparison of Liquefaction Processes PDFGeoffreyHunter100% (1)

- Re Liquefaction System EcoRel - Cryostar Magazine 10Dokumen12 halamanRe Liquefaction System EcoRel - Cryostar Magazine 10Narayan Marndi100% (1)

- Nathalie MillotDokumen10 halamanNathalie MillotAnastasia YuandyBelum ada peringkat

- Comparison of Present Day Peakshaving Liquefaction TechnologiesDokumen18 halamanComparison of Present Day Peakshaving Liquefaction Technologiesfericoolabiss100% (1)

- A High Capacity Floating LNG Design by Barend - PekDokumen15 halamanA High Capacity Floating LNG Design by Barend - PekShaka Shalahuddin Shantika PutraBelum ada peringkat

- Slide Set 3 - Role of LNG, GTL, CNGDokumen71 halamanSlide Set 3 - Role of LNG, GTL, CNGRAJIB DEBNATHBelum ada peringkat

- Catalysts Catafin HEDokumen4 halamanCatalysts Catafin HEsashaBelum ada peringkat

- 10 06 Jeff Beale PresentationDokumen38 halaman10 06 Jeff Beale PresentationCharles AshmanBelum ada peringkat

- Aeroderivative Gas Turbine FinalDokumen16 halamanAeroderivative Gas Turbine Finaldylan_dearing@hotmail.comBelum ada peringkat

- Gas Value Chain Explained-1Dokumen10 halamanGas Value Chain Explained-1UJJWALBelum ada peringkat

- Design Improvements in LNG Carriers: by Jacques Dhellemmes, Chairman & C.E.O, G & T FranceDokumen18 halamanDesign Improvements in LNG Carriers: by Jacques Dhellemmes, Chairman & C.E.O, G & T FranceMarcelo Varejão CasarinBelum ada peringkat

- Overview of LNG Industry: History, Value Chain and Base Load LNGDokumen13 halamanOverview of LNG Industry: History, Value Chain and Base Load LNGAnil KumarBelum ada peringkat

- Petsoc 99 13 35 PDokumen8 halamanPetsoc 99 13 35 PPeralta LeannyBelum ada peringkat

- XojomixedawokukuvisavaneDokumen2 halamanXojomixedawokukuvisavanehamdi maidisonBelum ada peringkat

- Ge Combust 1 05Dokumen3 halamanGe Combust 1 05Nazrul IslamBelum ada peringkat

- LNG Brochure PDFDokumen12 halamanLNG Brochure PDFrezarizqi09Belum ada peringkat

- 10 1 1 168 59 PDFDokumen11 halaman10 1 1 168 59 PDFanshuman432Belum ada peringkat

- Cool Water Coal Gasification Program 1982Dokumen164 halamanCool Water Coal Gasification Program 1982Patricio LeonardoBelum ada peringkat

- Catalytic Coal Gasification Emerging Technology SNGDokumen30 halamanCatalytic Coal Gasification Emerging Technology SNGkaramniaBelum ada peringkat

- Teoria Vs Realidad Acido NitricoDokumen4 halamanTeoria Vs Realidad Acido NitricoAdelaida PeñalozaBelum ada peringkat

- Pearl GTL: Making Liquids Out of Gas on a Grand ScaleDokumen3 halamanPearl GTL: Making Liquids Out of Gas on a Grand ScaleLeonardo AmpueroBelum ada peringkat

- Subsea Pipeline Design For Natural Gas Transportation: A Case Study of Cote D'ivoire's Gazelle FieldDokumen15 halamanSubsea Pipeline Design For Natural Gas Transportation: A Case Study of Cote D'ivoire's Gazelle FieldAfrial KamilBelum ada peringkat

- 9 STG Gas To Liquids GTLDokumen6 halaman9 STG Gas To Liquids GTLDiego Bascope MaidaBelum ada peringkat

- Rejuvenating Libya's Brega LNG Plant and Developing New CapacityDokumen17 halamanRejuvenating Libya's Brega LNG Plant and Developing New CapacitythawdarBelum ada peringkat

- ST Albert Kick Around UnitDokumen7 halamanST Albert Kick Around UnitMike ChernichenBelum ada peringkat

- 017 Lngtruckloading PDFDokumen49 halaman017 Lngtruckloading PDFHERON HERRERA URBANOBelum ada peringkat

- Qatar Petroleum Signs Deal for Mega-LNG ExpansionDokumen19 halamanQatar Petroleum Signs Deal for Mega-LNG ExpansionSandesh Tukaram GhandatBelum ada peringkat

- ATT 1460622217101 Full-Paper 429Dokumen13 halamanATT 1460622217101 Full-Paper 429Pawan ChaturvediBelum ada peringkat

- Japan's First LNG SatelliteDokumen13 halamanJapan's First LNG SatellitethawdarBelum ada peringkat

- Cygnus Energy LNG News Weekly 27th November 20Dokumen10 halamanCygnus Energy LNG News Weekly 27th November 20Sandesh Tukaram GhandatBelum ada peringkat

- Oxygen For Clean Energy - Cryostar - MagazineDokumen12 halamanOxygen For Clean Energy - Cryostar - MagazineNarayan MarndiBelum ada peringkat

- Abu Dhabi Key To Uae Growth Upstream and DownstreamDokumen5 halamanAbu Dhabi Key To Uae Growth Upstream and DownstreamVassilios KelessidisBelum ada peringkat

- Overview of Shell Global Solutions' Worldwide Gasification DevelopmentsDokumen7 halamanOverview of Shell Global Solutions' Worldwide Gasification DevelopmentsAdwait ParanjpeBelum ada peringkat

- Flow Assurance in Subsea Pipeline Design - A Case Study of Ghana's Jubilee and TEN FieldsDokumen15 halamanFlow Assurance in Subsea Pipeline Design - A Case Study of Ghana's Jubilee and TEN FieldsJuan Yerko SandovalBelum ada peringkat

- Liu, X., Falcone, G. and Alimonti, C. (2018) A Systematic Study of Harnessing Lowtemperature Geothermal Energy From Oil and Gas Reservoirs. Energy, 142, Pp. 346-355Dokumen17 halamanLiu, X., Falcone, G. and Alimonti, C. (2018) A Systematic Study of Harnessing Lowtemperature Geothermal Energy From Oil and Gas Reservoirs. Energy, 142, Pp. 346-355Diego ChamorroBelum ada peringkat

- Conversion of GasDokumen23 halamanConversion of Gasanyak1167032Belum ada peringkat

- Royal Institution of Naval Architects paper on ship design methodsDokumen24 halamanRoyal Institution of Naval Architects paper on ship design methodsSilvio MeloBelum ada peringkat

- Description of the Process of Manufacturing Coal Gas: For the Lighting of Streets Houses, and Public BuildingsDari EverandDescription of the Process of Manufacturing Coal Gas: For the Lighting of Streets Houses, and Public BuildingsBelum ada peringkat

- Malampaya An OverviewDokumen12 halamanMalampaya An OverviewHujiLoko100% (1)

- Gas and Oil Engines, Simply Explained An Elementary Instruction Book for Amateurs and Engine AttendantsDari EverandGas and Oil Engines, Simply Explained An Elementary Instruction Book for Amateurs and Engine AttendantsBelum ada peringkat

- Politeknik Negeri Bandung Chemical Process DiagramsDokumen5 halamanPoliteknik Negeri Bandung Chemical Process DiagramsNovianti NoviBelum ada peringkat

- Manager Mechanical Maintenance BOPDokumen4 halamanManager Mechanical Maintenance BOPjust_4_u_dear_in9549Belum ada peringkat

- MSC CDP GuidlineDokumen51 halamanMSC CDP GuidlineAurobindo SahuBelum ada peringkat

- General Instructions: PhysicsDokumen5 halamanGeneral Instructions: PhysicsSACHIDANANDA SBelum ada peringkat

- Recruitment and Selection at Shree CementDokumen122 halamanRecruitment and Selection at Shree CementSmartydr100% (1)

- Haldor Topsoe A-S - Promoting Medium-Temperature CO Shift Catalysts PDFDokumen1 halamanHaldor Topsoe A-S - Promoting Medium-Temperature CO Shift Catalysts PDFzorro21072107Belum ada peringkat

- Exicom BuildupDokumen35 halamanExicom BuildupchvsmanyamBelum ada peringkat

- Front Page For MM1 Group Project TaskDokumen2 halamanFront Page For MM1 Group Project Taskparika khannaBelum ada peringkat

- Crown Regency Resort Paradise BoholDokumen3 halamanCrown Regency Resort Paradise BoholWi WiBelum ada peringkat

- Presentation June 2018Dokumen67 halamanPresentation June 2018Vijay KumarBelum ada peringkat

- Asia Motor Work (AMW) ProjectDokumen29 halamanAsia Motor Work (AMW) ProjectAbhishekJumwalBelum ada peringkat

- VENTUS Born in The USA - CatalogueDokumen23 halamanVENTUS Born in The USA - CataloguekksajjanamBelum ada peringkat

- Kti Chemtrading Icpo Oilprod 2022-10 27Dokumen9 halamanKti Chemtrading Icpo Oilprod 2022-10 27Bujor SergiuBelum ada peringkat

- Exide - GNB Flooded Classic NXT Batteries SpecsDokumen9 halamanExide - GNB Flooded Classic NXT Batteries SpecscifthasekipasaBelum ada peringkat

- Final Rpeort (Jakson)Dokumen82 halamanFinal Rpeort (Jakson)Vikas SolankiBelum ada peringkat

- Rhino Steel Building Brochure PDFDokumen16 halamanRhino Steel Building Brochure PDFmutton moonswamiBelum ada peringkat

- Kompositisolatorer PDFDokumen6 halamanKompositisolatorer PDFJose AlirioBelum ada peringkat

- Product Features: Control ModeDokumen6 halamanProduct Features: Control ModeYudha J MalmsteenBelum ada peringkat

- Iaea Status Low ReactorsDokumen46 halamanIaea Status Low ReactorsBARBOSA RAFFAELLIBelum ada peringkat

- 2022-11-10 19 30 51 Morning-NoteDokumen8 halaman2022-11-10 19 30 51 Morning-Notevikalp123123Belum ada peringkat

- Lecture 3 Process ModellingDokumen50 halamanLecture 3 Process Modellinghayelom gebremikaelBelum ada peringkat