Ficha Tecnica Metacaulk Composite Sheet

Diunggah oleh

José Martín Meza CabillasDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ficha Tecnica Metacaulk Composite Sheet

Diunggah oleh

José Martín Meza CabillasHak Cipta:

Format Tersedia

July 2012

PRODUCT DATA SHEET

Metacaulk Composite Sheet

Classified Through-Penetration Firestop System Numbers:

CAJ0088, CAJ4062, CAJ8121, WL8062, WJ8032

1. Product Description

Metacaulk Composite Sheet is

a rigid fire resistive panel used to

seal penetrations and restore the

fire rating to floor/ceilings or walls

in which a large opening has been

made for the passage of penetrating

items. It is made of a reinforced,

highly intumescent material

which is bonded on one side to a

galvanized steel sheet. In addition

to sealing penetrations through large

openings, Metacaulk Composite

Sheet is also used for shielding cable

trays, conduit, and vital process

equipment from radiant heat, flame

spread and smoke. The Metacaulk

Composite Sheet functions as an

effective intermediate fire-break

within horizontal and vertical cable

tray runs and is excellent for both

new and retrofit construction. When

exposed to a fire the material forms

a refractory char that retards heat

transmission and tightly seals

penetrations against flame spread,

smoke and toxic fumes. The nominal

0.2 inch (5 mm) thick composite

sheet provides up to a 3 hour fire

rating. It is lightweight and can be

easily installed with common trade

tools.

Use Metacaulk Composite Sheet

for various applications:

Large blank openings

Cable trays

Steel pipe, EMT, Copper, PVC Cable

Bundles

Concrete floors

Concrete walls

Gypsum walls

Metacaulk Composite Sheet

Features:

Intumesces (expands with

heat) to form a refractory char

that tightly seals penetrations

against flame spread, smoke

and toxic fumes.

Easy to install using common

trade tools.

Lightweight ... easy to handle,

cut and form to desired shape.

Easy to fasten... bolt punch or

drill through. Use self-tapping

screws or anchor bolts.

Thermally conductive: allows

unwanted heat build-up to

escape.

Non-flame supporting.

UL Classified.

Cost effective, high

performance versus installed

cost.

No mixing or damming... is

clean to install.

Versatile: can be cut to fit

irregular shapes.

Re-enterable.

Normal disposal procedures.

2. Physical Properties

Sheet Size:

36" x 36"

Total Thickness: 0.150.05 inch

Nominal Weight:

1.6 lb/ft2

Cure Time:

No

Skin Over Time:

No

Freeze-Thaw:

Excellent

VOC:

None

Solvent: None

3. Applications

Metacaulk Composite Sheet is

used to seal penetrations through

fire-rated walls and floors and for

cable trays, cable, piping and large

blanks. It provides a fire resistive

smoke seal for any shape opening

in concrete block or slabs or

gypsum walls for up to 4 hours - UL

Classified.

Use Metacaulk Composite Sheet to

shield cable trays, conduit, panels,

valves and vital heat-sensitive

process equipment. The product is

effective in protecting cable dropouts, junction boxes and cabinets,

as well as providing an intermediate

firestop in horizontal and vertical

cable tray runs.

4. Installation Data

Install Metacaulk Composite Sheet

using standard sheet metal tools.

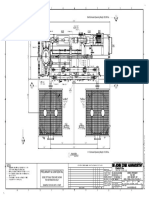

Typical blank opening installation

Step 1

Cut the Metacaulk Composite

Sheet to overlap the opening by a

minimum of 2 inches on all sides.

METACAULK Composite Sheet

CAJ0088

Step 2

Cut around penetrating iitems to

no more than a 3/8" gap. Secure

the sheet to the opening using 1/4"

x 1 1/2" steel mansonry fasteners

with steel washers. Place along the

perimeter and space a maximum 6

inches apart. Install the Composite

Sheet with its galvanized steel side

exposed (facing outward).

Step 3

Seal the overlap onto the floor/wall

using Metacaulk Putty, Metacaulk

Putty Pads or Metacaulk 1000.

Step 4

Apply a 1/2" diameter bead of

Metacaulk Putty or Metacaulk 1000

at the interface of the penetrating

item and Composite Sheet.

5. Testing Data

For specific test criteria, refer to the

UL's Fire Resistance Directory or

call RectorSeal.

Metacaulk Composite Sheet was

tested at positive pressure with a

minimum 0.01 (2.5 Pa) inch water

and in accordance with ASTM E814

(UL1479).

6. Storage and Handling

Metacaulk Composite Sheet

should be stored in a clean, dry

place.

7. Availability

Metacaulk Composite Sheet comes

3 hr. system shown

2 hr. system Composite Sheet installed on only

the top surface

Composite Sheet

Composite Sheet

1/4" x 1 1/4" steel

anchor screws w/

min. 1 1/4" steel

fender washers

1/2" wide strip of

Metacaulk Putty

in a 36 inch by 36 inch square

sheet. They are available through

RectorSeal distributors both

domestically and internationally.

fax: 713-263-7577 or 1-800-441-0051

RECTORSEAL

2601 SPENWICK DRIVE HOUSTON, TEXAS 77055

WWW.RECTORSEAL.COM

8. Limitations

Metacaulk Composite Sheet is not

designed to be used in the areas

under continuous immersion or in

areas which would be continuously

wet. Metacaulk Composite Sheets

should not be used against a hot

uninsulated surface above 300F.

9. Cautions

FOR CHEMICAL EMERGENCY, SPILL, LEAK,

FIRE, EXPOSURE OR ACCIDENT, CALL

CHEMTREC-DAY OR NIGHT 1-800-424-9300.

PRECAUTIONS: Do not take internally. May

be harmful if swallowed. FIRST AID: For any

overexposure, get immediate medical attention

after first aid is given. Eyes- Flush 15 minutes

with clean water. Skin-Wash with soap and water.

Ingestion-Only if conscious, give large amounts

of water and INDUCE VOMITING. STORAGE

AND HANDLING: Store away from heat sources.

KEEP OUT OF REACH OF CHILDREN.

For additional information, refer to Material Safety Data Sheet.

For additional technical service,

call: 713-263-8001 or 1-800-231-3345

9. LIMITED WARRANTY

RectorSeal makes the Limited Express Warranty that when the instructions for storage and handling of our products are followed we warrant our products to be free from defects. THIS LIMITED

EXPRESS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND OF ANY OTHER OBLIGATION ON THE PART OF RECTORSEAL. The sole remedy for breach of the Limited Express Warranty shall be the refund of the purchase price.

All other liability is negated and disclaimed, and RectorSeal shall not be liable for incidental or consequential damages.

Suggestions and recommendations covering the use of our products are based on our past experience and laboratory findings. However, as we have no control as to the methods and conditions

of application, we only assume responsibility for the uniformity of our products within manufacturing tolerances.

G-12

Anda mungkin juga menyukai

- Maintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksDokumen441 halamanMaintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksMigue Angel Rodríguez Castro100% (2)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- System 9000 Resilient Blanket Insulation Spec SheetDokumen4 halamanSystem 9000 Resilient Blanket Insulation Spec SheetSethuraman Saravanakumar100% (1)

- MBCC Masterseal 345 Tds v4Dokumen2 halamanMBCC Masterseal 345 Tds v4shashikantBelum ada peringkat

- Fire Barrier IC 15WB Sealant: Retardants IncDokumen4 halamanFire Barrier IC 15WB Sealant: Retardants Inctony6868Belum ada peringkat

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDokumen2 halamanRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaBelum ada peringkat

- Lumber Lock PDSDokumen2 halamanLumber Lock PDSasummerfeldtBelum ada peringkat

- Product Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneDokumen3 halamanProduct Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneVaittianathan MahavapillaiBelum ada peringkat

- Product Data 232 Ceilcote FlakelineDokumen3 halamanProduct Data 232 Ceilcote FlakelineMohd MustafhaBelum ada peringkat

- Rockwool 3Dokumen28 halamanRockwool 3deerajksBelum ada peringkat

- Rectorseal Metacaulk Box GuardDokumen3 halamanRectorseal Metacaulk Box Guardrbucholz0% (1)

- High-performance epoxy coating data sheetDokumen2 halamanHigh-performance epoxy coating data sheetamadan64Belum ada peringkat

- Conbextra EP75Dokumen4 halamanConbextra EP75Venkata Raju KalidindiBelum ada peringkat

- Henk Loctite Gasket Seal 2 TdsDokumen1 halamanHenk Loctite Gasket Seal 2 TdsGabo TellezBelum ada peringkat

- Windows: DoorsDokumen8 halamanWindows: Doorsansal mtechBelum ada peringkat

- MASTERSEAL 550 v6Dokumen2 halamanMASTERSEAL 550 v6Mohiuddin MuhinBelum ada peringkat

- Elastocrete P8J Waterproofing Kit Technical Data SheetDokumen3 halamanElastocrete P8J Waterproofing Kit Technical Data SheetZèlia FláviaBelum ada peringkat

- Boscoseal Torch OnDokumen3 halamanBoscoseal Torch OnjbonvierBelum ada peringkat

- Semco PR-855Dokumen4 halamanSemco PR-855Reginald D. De GuzmanBelum ada peringkat

- Sika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneDokumen3 halamanSika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneSouvik DasBelum ada peringkat

- Loctite 567 Thread Sealant Data SheetDokumen3 halamanLoctite 567 Thread Sealant Data SheetJoseph BernardBelum ada peringkat

- Electrical TapeDokumen2 halamanElectrical TapemmartincikBelum ada peringkat

- EN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFDokumen6 halamanEN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFermusatBelum ada peringkat

- Chill-In Insulation KitsDokumen4 halamanChill-In Insulation KitsAuburnMfgBelum ada peringkat

- HVAC Thermal Insulation GuideDokumen33 halamanHVAC Thermal Insulation GuideNath BoyapatiBelum ada peringkat

- 2703 UltramasticIIIsuperwhite GB NoRestrictionDokumen4 halaman2703 UltramasticIIIsuperwhite GB NoRestrictionFloorkitBelum ada peringkat

- M4 Ep PDFDokumen2 halamanM4 Ep PDFjunaid112Belum ada peringkat

- Proofex Torchseal (PE)Dokumen2 halamanProofex Torchseal (PE)kalidindivenkatarajuBelum ada peringkat

- 0091 Amercoat 91 PDS May 08Dokumen2 halaman0091 Amercoat 91 PDS May 08donaldoguerreroBelum ada peringkat

- 13 - Tds - Emaco s43 NTDokumen3 halaman13 - Tds - Emaco s43 NTmanil_5Belum ada peringkat

- QTs EcoSeriesDokumen22 halamanQTs EcoSeriesasrihamidBelum ada peringkat

- Jining QiangkeDokumen35 halamanJining QiangkeCobu LamBelum ada peringkat

- Cde-1493 R0 PDFDokumen2 halamanCde-1493 R0 PDFAli GurselBelum ada peringkat

- HysolDokumen2 halamanHysoljorgequijanoBelum ada peringkat

- Masterflow - 410 PC T - v1Dokumen2 halamanMasterflow - 410 PC T - v1kavi_prakash6992Belum ada peringkat

- Recotec Rotafil enDokumen16 halamanRecotec Rotafil enJordan RileyBelum ada peringkat

- Emaco S88C TDSDokumen2 halamanEmaco S88C TDSMerdan JumagylyjovBelum ada peringkat

- Plexus Selector GuideDokumen8 halamanPlexus Selector GuideLodewykbronnBelum ada peringkat

- Sikacrete 114 AEDokumen4 halamanSikacrete 114 AEMicheal B HaizenBelum ada peringkat

- Rooftex BrochureDokumen2 halamanRooftex BrochureTRAG ProjectsBelum ada peringkat

- Novolac ScreedDokumen4 halamanNovolac Screedmd_kureshiBelum ada peringkat

- Sika ProofDokumen2 halamanSika Proofthe pilotBelum ada peringkat

- Sikaflex TS Plus PDSDokumen4 halamanSikaflex TS Plus PDSMark CousinsBelum ada peringkat

- SikaTop Armatec 110 EpoCemDokumen3 halamanSikaTop Armatec 110 EpoCemseagull70Belum ada peringkat

- Sto Therm Classic BrochureDokumen12 halamanSto Therm Classic BrochureМомчило МитићBelum ada peringkat

- BASF MasterSeal M 790 TdsDokumen9 halamanBASF MasterSeal M 790 TdsAmar WadoodBelum ada peringkat

- Basf Masterseal m808 TdsDokumen8 halamanBasf Masterseal m808 TdsOkan KalendarBelum ada peringkat

- Elasto Cool.Dokumen2 halamanElasto Cool.Sunny Singh100% (1)

- Titanium UDL-50 BROCHURE PDFDokumen2 halamanTitanium UDL-50 BROCHURE PDFHRroofingBelum ada peringkat

- TDS - Protectosil CITDokumen3 halamanTDS - Protectosil CITVenkata RaoBelum ada peringkat

- 232 Ultrabond Eco 380 UkDokumen4 halaman232 Ultrabond Eco 380 UkFloorkitBelum ada peringkat

- Euro Therma TR27 2ppDokumen2 halamanEuro Therma TR27 2ppbakkakraljBelum ada peringkat

- Comflex Expansion Joints GuideDokumen8 halamanComflex Expansion Joints Guideterencejustine100% (1)

- For Electrical & Communications Products: Solution GuideDokumen43 halamanFor Electrical & Communications Products: Solution GuideBromax DandanBelum ada peringkat

- Elastuff 102Dokumen3 halamanElastuff 102pravi3434Belum ada peringkat

- 95 44Dokumen2 halaman95 44Vivek VenugopalBelum ada peringkat

- TDS - Masterflow 980Dokumen4 halamanTDS - Masterflow 980Venkata RaoBelum ada peringkat

- Aspen Aerogels Pyrogel XT PDFDokumen4 halamanAspen Aerogels Pyrogel XT PDFBTconcordBelum ada peringkat

- Conbextra EP10TGDokumen2 halamanConbextra EP10TGBambang SasikiranaBelum ada peringkat

- Rocklite FireproofingDokumen3 halamanRocklite FireproofingRahul AwaghadeBelum ada peringkat

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsDari EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsBelum ada peringkat

- Water Tank Interior Ladder Manual PDFDokumen2 halamanWater Tank Interior Ladder Manual PDFJosé Martín Meza CabillasBelum ada peringkat

- CaneriasDokumen3 halamanCaneriasJosé Martín Meza CabillasBelum ada peringkat

- Plano 3Dokumen1 halamanPlano 3José Martín Meza CabillasBelum ada peringkat

- VRU - Mediana y PequeñaDokumen1 halamanVRU - Mediana y PequeñaJosé Martín Meza CabillasBelum ada peringkat

- Layout ModelDokumen1 halamanLayout ModelJosé Martín Meza CabillasBelum ada peringkat

- Reducing Coupling PDFDokumen2 halamanReducing Coupling PDFJosé Martín Meza CabillasBelum ada peringkat

- PIP STF05501 Fixed Ladders and CagesDokumen11 halamanPIP STF05501 Fixed Ladders and CagesHowo4Die86% (7)

- A13 - 1 - Distr - Boq Anillo TQ-1 - 2Dokumen1 halamanA13 - 1 - Distr - Boq Anillo TQ-1 - 2José Martín Meza CabillasBelum ada peringkat

- 05 Foam Chambers Install. and MA2Dokumen3 halaman05 Foam Chambers Install. and MA2Matthew BennettBelum ada peringkat

- FMDS 03 10 - Installation & Maintenance of Fire Service MainsDokumen59 halamanFMDS 03 10 - Installation & Maintenance of Fire Service MainsNazri Nawi100% (1)

- Lightweight Flexible Coupling PDFDokumen2 halamanLightweight Flexible Coupling PDFJosé Martín Meza CabillasBelum ada peringkat

- TFP1580 11 2007 PDFDokumen16 halamanTFP1580 11 2007 PDFambition1340cnBelum ada peringkat

- 30 81 PDFDokumen19 halaman30 81 PDFJosé Martín Meza CabillasBelum ada peringkat

- E 90 21 - Fire PDFDokumen2 halamanE 90 21 - Fire PDFJosé Martín Meza CabillasBelum ada peringkat

- FM DS 07-12 - Plantas Concentradoras PDFDokumen120 halamanFM DS 07-12 - Plantas Concentradoras PDFJosé Martín Meza CabillasBelum ada peringkat

- 05 Foam Chambers Install. and MA2Dokumen3 halaman05 Foam Chambers Install. and MA2Matthew BennettBelum ada peringkat

- 05 Foam Chambers Install. and MA2Dokumen3 halaman05 Foam Chambers Install. and MA2Matthew BennettBelum ada peringkat

- Sodium Ethoxide MSDS: Section 1: Chemical Product and Company IdentificationDokumen6 halamanSodium Ethoxide MSDS: Section 1: Chemical Product and Company IdentificationJosé Martín Meza CabillasBelum ada peringkat

- Ansul: Extinguishing Agent Data SheetDokumen2 halamanAnsul: Extinguishing Agent Data SheetJosé Martín Meza CabillasBelum ada peringkat

- Catalogo Rejilla IrvingDokumen20 halamanCatalogo Rejilla IrvingGeorgeMty100% (1)

- PC 165 PC 235 PC 310: Bell Lengths and Reference Marks May Vary Up To +/ - "Dokumen1 halamanPC 165 PC 235 PC 310: Bell Lengths and Reference Marks May Vary Up To +/ - "José Martín Meza CabillasBelum ada peringkat

- Pressure Vacuum VentDokumen1 halamanPressure Vacuum VentJosé Martín Meza CabillasBelum ada peringkat

- PQS Standard MultipropositoDokumen2 halamanPQS Standard MultipropositoJosé Martín Meza CabillasBelum ada peringkat

- P&ID JockeyDokumen1 halamanP&ID JockeyJosé Martín Meza CabillasBelum ada peringkat

- Aurora Fire Pump SpecsDokumen16 halamanAurora Fire Pump SpecsJosé Martín Meza CabillasBelum ada peringkat

- Beam Clamps: MaterialsDokumen20 halamanBeam Clamps: Materialsgreg_n5Belum ada peringkat

- Himsac-500gpm-175 Psi - C02-98535-4Dokumen1 halamanHimsac-500gpm-175 Psi - C02-98535-4José Martín Meza CabillasBelum ada peringkat

- Valvula de Diluvio Horiozntal 6inDokumen4 halamanValvula de Diluvio Horiozntal 6inJosé Martín Meza CabillasBelum ada peringkat

- Valvula de Diluvio Horiozntal 4inDokumen4 halamanValvula de Diluvio Horiozntal 4inJosé Martín Meza CabillasBelum ada peringkat

- Final Page Size: A5 (148mm X 210mm)Dokumen20 halamanFinal Page Size: A5 (148mm X 210mm)RJ BevyBelum ada peringkat

- Electric Rolling Bridge, Scientific American 24 August 1889 p120Dokumen2 halamanElectric Rolling Bridge, Scientific American 24 August 1889 p120Rm1262Belum ada peringkat

- Degaussing N Magnetic MinesDokumen3 halamanDegaussing N Magnetic MinesGus MellonBelum ada peringkat

- Introduction To CAL ProgrammingDokumen198 halamanIntroduction To CAL ProgrammingSalam Mohamed RiyadBelum ada peringkat

- GE Con Perkins Más StamfordDokumen2 halamanGE Con Perkins Más Stamfordjim perdigonBelum ada peringkat

- ZMD402AT-CT Technical DataDokumen7 halamanZMD402AT-CT Technical DataCarlos SandersBelum ada peringkat

- Assessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryDokumen38 halamanAssessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryAbhishek Kumar0% (1)

- Simatic Hmi Wincc V7.0 Sp3 Setting Up A Message SystemDokumen123 halamanSimatic Hmi Wincc V7.0 Sp3 Setting Up A Message Systemalrighting619Belum ada peringkat

- EC2151 Electric Circuit Important QuestionsDokumen47 halamanEC2151 Electric Circuit Important QuestionschitragowsBelum ada peringkat

- John Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)Dokumen16 halamanJohn Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)zhuangfuqian31Belum ada peringkat

- 02 - Heat ExchangersDokumen88 halaman02 - Heat ExchangerssanjaysyBelum ada peringkat

- Classic Petrol 35 SDokumen10 halamanClassic Petrol 35 S5432167890OOOOBelum ada peringkat

- Project-BOQ - (Excluding VUP, LVUP)Dokumen127 halamanProject-BOQ - (Excluding VUP, LVUP)Shivendra KumarBelum ada peringkat

- Optimal Transformer Tap Changing SettingDokumen7 halamanOptimal Transformer Tap Changing Settingtrust4joshBelum ada peringkat

- PM IS - 12818 June2021Dokumen10 halamanPM IS - 12818 June2021Mahendra AhirwarBelum ada peringkat

- SPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityDokumen18 halamanSPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityYovaraj KarunakaranBelum ada peringkat

- ECOSYS M6526cdn Fax SetupDokumen204 halamanECOSYS M6526cdn Fax SetupAnonymous gn8qxxBelum ada peringkat

- Sublimation of CaffeineDokumen3 halamanSublimation of CaffeineNabil ShaikhBelum ada peringkat

- Pass4sure 200-120 PDF DownloadDokumen8 halamanPass4sure 200-120 PDF DownloadEleanor19Belum ada peringkat

- Hdpe Alathon H5520 EquistarDokumen2 halamanHdpe Alathon H5520 EquistarEric Mahonri PereidaBelum ada peringkat

- PraveenKumar - Java Developer - Broadridge - HydDokumen4 halamanPraveenKumar - Java Developer - Broadridge - HydAllagadda Mahesh BabuBelum ada peringkat

- Alcatel U3 - Alcatel U3 User GuideDokumen53 halamanAlcatel U3 - Alcatel U3 User Guideoswaldomarangoni5295100% (11)

- Ganz Hydro-Power: Over 150 Years of ExperienceDokumen1 halamanGanz Hydro-Power: Over 150 Years of ExperiencepalanaruvaBelum ada peringkat

- p6 ReportDokumen19 halamanp6 ReportAnonymous yrcU1kBelum ada peringkat

- TNK500P Taneko Industrial Generator (TNK JKT)Dokumen2 halamanTNK500P Taneko Industrial Generator (TNK JKT)Rizki Heru HermawanBelum ada peringkat

- Beam and Slab DesignDokumen41 halamanBeam and Slab DesignSridhara MunimakulaBelum ada peringkat

- Mohr's Circle Analysis of Rock Failure Under StressDokumen26 halamanMohr's Circle Analysis of Rock Failure Under StressNitishBelum ada peringkat

- DIN EN 10213 - 2008 - Fundidos em AçoDokumen29 halamanDIN EN 10213 - 2008 - Fundidos em AçoLeonardo MartinsBelum ada peringkat