Putting 'Life' Into The Yaqin MS-22B

Diunggah oleh

Alicia SmithJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Putting 'Life' Into The Yaqin MS-22B

Diunggah oleh

Alicia SmithHak Cipta:

Format Tersedia

Putting LIFE into the Yaqin MS-22B and MS-23

These are the beasts that wont deliver what is expected!

But with some surgery they can be made to sound so much better!

MS22B

New edition December 2014

MS23B

Some History

Many years ago there was a British company called World Audio Design or WAD who manufactured various

amplifiers as kits for home construction. Unfortunately they ceased trading leaving a legacy of many happy customers

with high performance products using the highest quality components. The pricing was very good considering how

much one has to pay for similar high end equipment today, maybe they under-priced themselves but their disappearance

has been sadly lamented to this day. Then came the age of relatively cheap Chinese valve amplifiers, not just offering

good performance, but they looked good too. Compare the following photographs of a WAD amplifier and a Yaqin

MC10L and you will see for yourself.

Because their kits were no longer available, the Author built a copy of the WAD Phono Amplifier into a small die-cast

box and this performed really well. Many solid state designs were tried later, some using the latest operational

amplifiers but none came anywhere near to the quality of this simple little RIAA box.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 1 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

The Author was keen to obtain and evaluate the Yaqin MS22B and one came his way as part of an amplifier deal.

When he replaced his home made effort with this lovely looking piece of kit, he was very disappointed at the sound it

produced. Visitors would plead with him to take it out of circuit and put his amp back into operation, was it that bad?

Yes it really was!

So rather than put this amplifier away in a cupboard until its innards dried out, he decided to take a look at the circuit

board with the idea of transplanting the WAD circuit into the much nicer looking enclosure. The WAD circuit uses

three valves (called Tubes in some other countries) yet the Yaqin only used two with a transistor acting as a buffer.

Buffer? It is a name given to a stage that is designed to stop the effects of a following stage affecting the performance

of the previous stage. A crude analogy would be using an oven glove as a buffer so you can pick up hot things without

affecting your hand. Hope that is a bit clearer Anyway, Yaqin appears to have made a mistake on their buffer circuit

as they feed the output signal not just to the output socket but also as a feed to the RIAA circuit. In theory therefor,

different loading conditions could affect the RIAA operation? Ideally the buffer should only feed signals out to the

following amplifier and nowhere else and one of its properties is to be able to drive into the loads presented by the

following equipment. Well the WAD circuit did not like the transistor at all, as expected the RIAA curves were all over

the place so a Mosfet transistor was tried and it worked well but not as good as a third valve. So even though it means

more effort in making a hole for a third valve, it is a worthwhile improvement.

Are you experienced?

You may feel that the following work is too much for you but take heart, there are others who have successfully done

the conversion despite little knowledge of electronics or soldering. Soldering is a skill but it can easily be mastered by

practicing on old circuit boards and there are plenty of internet sites that show how to solder, cleanliness is the key,

make sure your iron tip is clean and well tinned. Avoid using lead free solder, get a small reel of 60/40 leaded flux

solder and you will make good joints.

Tools

Apart from the usual screwdrivers, cutters and pliers, a Dremel with some attachments will be found most useful, the

drill bit being a 0.8mm PCB drill. A stepped cone cutter makes short work of cutting the hole required for the extra

valve.

Some solder wick to remove unwanted solder from the circuit board is also required along with some heat shrink tubing

to cover component leads and the third valve terminals. If you dont have a heat gun then being nifty with a cigarette

lighter can give good results. Also some fine abrasive paper or a fibre glass pen to clean away the Green solder resist

from the track ready for soldering. A Multimeter for pre-switch-on and safety checks and above all, be prepared to take

your time to produce a good job.

The task looks daunting, but not if you take your time and re-check your work as you go. The rewards are most

significant!

The Author is indebted to Juha Jrvel and Mark Kerr for their contributions of other tweaks to the design and the

supply of excellent photographs to complement and even better his own.

This new edition of Putting LIFE into the Yaqin MS-22B and MS-23 goes straight into the conversion that results in

a 3 tube version and described in a way that could only be achieved after carrying out many conversions.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 2 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Electronic components you will need:

Qty.

Ref.

2

2

2

4

2

2

2

2

2

2

3

2

2

1

2

C2 & C9

RAA & RBA

R2 & R13

R5,R16,RAH & RBH

RAB & RBB

RAC & RBC

R6 & R17

RAE &RBE

R7 & R18

RAD & RBD

R3, R15, R25

RAF & RBF

RAG & RBG

D1

R10 & R21

Description

UK supplier

RS COMPONENTS

185-4347

135-847

214-1153

136-058

683-3528

754-5673

214-1478

149-048

214-1434

214-1181

214-1412

148-944

683-2755

628-9546

707-8669

100nF 400V Capacitor

1k 0.25W Resistor (chosen for small size)

1k2 1W Resistor

1M 0.25W Resistor

316k 1% 0.25W Resistor

39k2 1% 0.25W Resistor

330k 1W Resistor

180k 1% 0.25W Resistor

150k 1% 1W Resistor

2k2 1W Resistor

120k 1W Resistor

75k 0.25W Resistor

18k 0.25W Resistor

1N4007 Diode (For heater voltage lift)

1k 1W Resistor (For output RCA sockets)

100uF 350V Radial Electrolytic Capacitor.

2

C15 & C16

715-2287

Size important: 18mm Dia. 25mm High.

2

C5 & C13

8200pF 1% Silver Mica (or originals can be used *)

495-947

2

C3 & C10

200pF 1% Silver Mica (or originals can be used *)

744-1546

3uF Poly Capacitor, audio grade, 250V

2

C4 & C12

(or originals wired in parallel (2uF) can be used *)

1 off For the extra Valve V3, a B9A skirted Valve Holder with screening can e.g. Cricklewood B9AS*

http://www.cricklewoodelectronics.com/Cricklewood/home.php?cat=23com

US supplier

ALLIED

70111989

70063029

70063526

70239138

70289086

70289087

70063546

70063378

70063517

70063542

70063514

70122073

70063379

70055517

70122738

Use 68uF

70257107

70189582

70189540

* Suggestions:

The present 8200pF capacitors can be reused, but it is recommended they are replaced with 1% types to help match

channels. This should have been done by Yaqin!

Likewise, the present 100pF capacitors can be re-used or replaced with 200pF 1% types.

Needless to say, the Author has actually tried 5% Mica capacitors and the channel matching has been satisfactory, the

WAD circuit has proven to be so repeatable that you can be confident in obtaining a good RIAA characteristic even

without test equipment to verify.

Also you may consider changing C4 and C12 output capacitors with high quality audio grade 2u2F capacitors. The

Author used 3u3F 250V Audiophile MKT capacitors because they were to hand and their small physical size and gauge

of connecting leads were easy to work with. Expensive Russian paper in oil capacitors have been tried with no

detectable improvement in sound and their size makes using them rather difficult so not recommended.

For those on a tight budget, you could try leaving all four of the original 1uF capacitors in place; they are already

electrically wired on one side. All you have to do is add a wire link so that the capacitors are effectively in parallel with

each other on each channel. (See page 8)

Prewire the valve holder with 250mm long wires, the Author uses colour codes for easy identification.

Red for Anodes (Plates) at Pins 1 and Pin 6, Green for control Grids at Pins 2 and 7, Black for Cathodes at Pins 3 and 8

and a twisted pair of any colour for the heaters at Pins 4 and 5.

The solder tags run from Pin 1 to Pin 9 clockwise from the keyway gap, looking at the tag side of course.

The connections (including the unused pin 9)

should be covered with suitable heat shrink

tubing as shown. Do not bend the tags at this

time as it makes mounting the holder difficult.

When the holder has been mounted to the top

side of the chassis, then the tags should be

carefully bent to the horizontal to allow

replacement of the board with no danger of

short circuiting to the board components.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 3 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Basically, you will be converting the circuitry from the feedback arrangement used by Yaqin (called a Yin Yang

circuit) to the straight filter technique as shown in block form below.

Whilst you are doing these changes, you will also add a diode to the heater regulator to give the heater voltage a lift of

approximately 0.7V and take it from 11.8V to the more ideal 12.6V.

You will also be doing some changes at the RCA jacks that will remove the hum loop that has given owners such a

headache; of course you may have already done this.

It is the Authors opinion that any small residual hum that still remains is due to the magnetic fields from the mains

transformer acting upon the metal parts of the input triodes of each channel. Real high end RIAA amplifiers use a

remote power supply to get over such problems, however the level is so small that it cannot be heard at normal listening

levels on the main amplifier.

HOWEVER! PLEASE CHECK THAT THE POWER INPUT IS REMOVED BEFORE

STARTING!

AS YOU PROCEED THERE ARE DIFFERENCES BETWEEN THE 22B AND THE 23B WHICH

HAVE TO BE OBSERVED.

Nothing too severe, the circuit is the same; just the mechanics have altered slightly.

MS23B changes will be highlighted in Blue as you go through the conversion.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 4 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Taking apart.

You have to completely remove the circuit board to get totally free access to the components that require deletion

and/or changing but first you need to get into the Beast using a cross head screwdriver and a small hex driver.

It is strongly advised to apply some wide sticky tape or kitchen towel across the top and sides of the transformer cover

to prevent any scratches that may be accidentally picked up during the conversion work.

Best to pull the two valves out now and place in a safe place.

The Yellow indicated screws are 6mm machine thread screws.

The Light Blue are 8mm self tap and the Purple are 10mm self tap screws.

On some MS23s all screws are 6mm machine thread screws.

The cover should now slide slightly towards the front to disengage the rear lip after which the cover can be lifted away.

The Author found this slightly difficult due to a foot screw fouling on the internal screening frame. In this respect it will

be found helpful to also remove the top right hand foot as shown in the above picture. This is not a problem on

MS23s that use a different type of foot.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 5 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Now before commencing on the board, make sure the internal capacitors are fully discharged! These can be discharged

by holding a suitable low value resistor (one of your new 1k2 1W should do) across + and of C17 for 20 seconds.

Check with your Multimeter switched to DC Volts that the capacitors are all but discharged.

The front panel is detached by removing two Torx screws on the amplifier top side.

As you withdraw the front panel you will see a connector providing supply to the front panel LED assembly, disconnect

this connector to allow the front panel to be totally removed.

Now detach the four white plugs from the circuit board connectors, dont worry, they are easy to identify when it comes

to re-assembly.

Just to ease your mind for when it comes to re-assembly, the Author has made a note for you!

Left Channel INPUT (White inner) to XS1

Right Channel INNER (Red inner) to XS2

Left Channel OUTPUT (White inner) from XS3

Right Channel OUTPUT (Red inner) from XS4.

Now unsolder the central Earth STAR connection(s) shown above on the printed circuit board (Not necessary with

some versions of the MS23) and remove the 4 countersunk screws holding the board to the metal frame.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 6 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Now unsolder the two White wires (on later MS23B models this may be a 2 pin plug), the two Yellow wires and the

Earth wire going to the circuit board at the position marked G2. On the MS23 there are two black wires on G2 and

not a Yellow/Green wire as shown. In fact there have been a number of production variations so make a note of

where the Ground wires have been attached. Some will go to G2, some to the STAR Point, some use a connection

to the left of the STAR (hidden by the Yellow twisted wires) and some units even have a connection on the

ground track that connects to the lower electrolytic capacitors C15 and C16. It seems Yaqin have tried many

ways to reduce hum in these units whereas a mu-metal shield around the power transformer may have yielded

some improvement.

The circuit board can now be slid from the chassis; the board being the next focus of attention means you can put aside

the main chassis for now.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 7 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

The Electronic conversion.

On the Left Hand channel, remove components C2 (10nF), R11 (560 Ohms), C3a and C3b (100pF each, carefully for

re-use), R2 (2k Ohms), R3 (100k Ohms), R8 (680k Ohms), C5 (8n2 carefully for possible re-use), R9 (30k), C6 (2n2),

R10 (1k carefully for re-use), R5 (2M Ohms), R7 (82k Ohms), R6 (100k Ohms), C4 and C7 (1uF unless you are

saving them - see note below) and Transistor V3?!.

On the Right Hand channel, remove components C9 (10nF), R14 (560 Ohms), C10a and C10b (100pF each, carefully

for re-use), R13 (2k Ohms), R15 (100k Ohms), R19 (680k Ohms), C13 (8n2 carefully for possible re-use), R20 (30k),

C14 (2n2), R21 (1k carefully for re-use), R16 (2M Ohms), R18 (82k Ohms), R17 (100k Ohms), C11 and C12 (1uF

unless like C4 and C7 you are saving them) and Transistor V4.

Remove the Yellow link wire that skirts around V2 (already done in the photo).

Now remove the short wire link marked as 5MM which is presently connected to pin 1 of V2,

You DO NOT want this! On the MS23 this is shown as a 6MM link!

Use some solder wick to clear all solder pads for re-use followed by a wash and scrub with Isopropyl Alcohol (IPA)

and a small stubby brush.

All the Yellow starred components are no longer needed unless you intend to re-use the Blue block capacitors which

should be left in place. The Green starred components may be re-used if required so put to one side in a safe place.

Although Yellow starred for redundancy, C4, C7, C11 and C12 can be re-used, as previously stated, by placing them in

parallel to give 2uF output on each channel. The position of the linking wires will be shown later when the board is

mostly complete. If you are fed up with being blinded by the Blue LEDs, applicable mainly to the MS23, then also

remove R25 (820 Ohms). This is shown to the left of the heat sink and can be replaced with a 120k 1W later.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 8 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

If you are fitting replacement output capacitors your board should look like this:-

Heater Diode.

The first thing to do is to raise the heater voltage. Cut the track going to the centre leg of the 12V regulator and insert a

diode, any in the 1N400x family will be OK.

The end of the diode with the silver band (Cathode) goes to C19.

1. Clear away solder resist.

2. Cut track with Dremel or a craft knife.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 9 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

3. Drill board

BEFORE

4. Mount Diode.

AFTER

In this picture the Diode Cathode, indicated

by a silver band, is mounted uppermost.

Wasnt too bad was it? Now for the rest of the circuit, references will still point to the original Yaqin component

numbers but where new parts are added, a letter system is used to avoid any confusion. Component references like

RAA, RAB, RAC etc. refer to the Left Channel whereas their counterparts on the Right channel will be called RBA,

RBB, RBC etc.

One thing to remember! When you are working on the printed circuit side of the board, the Left channel is on the Right

Hand side as you look at it! The Author has been caught out a few times by this

Views of the actual circuit boards may differ due to production changes, particularly the change in Valve Holders and

the addition of slots between valve pins on later models.

The remaining Track Cuts and Drilling

There are 4 track cuts to do around each valve, starting with V1 which is the Right Hand valve base viewed from the

print side. The components RAA, RAB, RAD and RAE are fitted at the same time but this can be deferred until later if

desired. In the photos you may see other mounted components not yet fitted on your board; ignore these for the moment

as these will all be addressed later.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 10 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

RAA

Note that a fixing nut and insulating washer has been removed, it can help when trying to get the Dremel cutting at the

desired angle or to give better access.

PREPARATION

TRACK DRILLING

TRACK CUT

MOUNTING OF RAA 1k 0.125W (Brown/Black/Red)

RAB

PREPARATION

TRACK CUT

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 11 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

RAB (continued)

TRACK DRILLING

MOUNTING OF RAB 316k 1% (Orange/Brown/Blue/Orange)

RAD

PREPARATION

TRACK CUT

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 12 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

RAD (continued)

TRACK DRILLING

MOUNTING OF RAD 2k2 1W (Red/Red/Red)

RAE

PREPARATION AND TRACK CUT

There is only one area requiring

preparation and this is at V1 Pin 6.

The other end of RAE will make use

of the old transistor V3 Base pad. The

track cut is simply placed at any point

between the main pad of V1 Pin 6 and

the Base connection.

IMPORTANT When you mount

RAE leave a good 5mm length of lead

showing at the end connected to old

transistor V3 Base pad, i.e. do not

crop close to the board. This will

allow connection of pin 2 of the extra

buffer valve and the RAF/RAG/C3

EQ network later.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 13 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

TRACK DRILLING

MOUNTING OF RAE

Note how RAE 180k is mounted, the

long bare lead may be covered with thin

sleeving if desired.

As mentioned before, ignore presence of

R6 and other components which will be

mounted after all track cuts have been

completed.

RAE may have the colours

Brown/Grey/Black/Orange or possibly

Brown/Grey/Yellow.

Now we turn our attention to the Right Channel track cuts and their associated components, all surrounding V2.

The author makes no apology for reminding you once again that this is the left hand valve holder viewed from the print

side of the printed circuit board.

RBA

PREPARATION

NOTE: NUT AND WASHER REMOVED AS AN AID

TRACK CUT

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 14 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

RBA (continued)

TRACK DRILLING

MOUNTING OF RBA 1k 0.25W (Brown/Black/Red)

RBB

PREPARATION

TRACK CUT

Do you notice something? The small link is shown still fitted, marked as 6mm on the

MS23 (as above) or 5mm on MS22s. This MUST be removed before fitting RBB!

DRILLING

MOUNTING OF RBB 316k 1% (Orange/Brown/Blue/Orange)

NOT YET!

This resistor will be piggy backed

over RBE as we shall see later!

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 15 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

RBD

PREPARATION (Highlighted by *)

TRACK DRILLING

TRACK CUT

MOUNTING OF RBD 2k2 1W (Red/Red/Red)

Note how RBD 2k2 is mounted, like

RAE the long bare lead may be covered

with thin sleeving if desired.

As mentioned before, ignore presence

of other components which will all be

mounted soon.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 16 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

RBE

OK, with RBE we will also be mounting RBB in piggy back fashion and adding a wire link.

PREPARATION (Highlighted by *)

TRACK DRILLING ONLY ONE PLACE

MOUNTING OF RBE 180k (colours as for RAE)

IMPORTANT When you mount RBE leave a

good 5mm length of lead showing at the end

connected to old transistor V4 Base pad, i.e. do

not crop close to the board. This will allow

connection of pin 7 of the extra buffer valve and

the RBF/RBG/C10 EQ network later.

NOW PIGGY BACK RBB 316k

PHOTO ALSO SHOWS WHERE OTHER

END OF LINK GOES. KEEP A TINY AIR

GAP BETWEEN THE TWO RESISTORS.

Insert a 100nF capacitor at C2 and C9 positions.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 17 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Insert a 1M Resistor at R5 and R16 positions.

Insert a 330k Ohm 1W resistor at R6 and R17 positions.

Insert a 120k Ohm 1W resistor at R3 and R15 positions.

Insert a 150k Ohm 1W resistor at R7 and R18 positions. Note that if you mount R7 on the print side

of the board it gives more room on the component side for the new output capacitor C4 when it is

fitted later.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 18 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Insert 1k2 1W resistor at R2 and R13 positions.

Fit new output capacitors at C4 and C12 positions

If you have retained the original 1uF capacitors at all positions, i.e. C4, C7, C11 and C12, then

parallel them together with the wire links shown.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 19 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

The replacement HT (B+) capacitors C15 and C16 can now be fitted.

Make sure you have the correct 25mm maximum height capacitor types and that these are mounted

the right way round with their negative tags towards the front edge of the board.

Now for those wishing to reduce the almost eye damaging glow of the front panel Blue LEDs, here

is the answer.

Remove R25 and replace with a 120k 1W resistor.

Thats it! You can now put the board to one side and start the mechanical work.

However, the author likes to build the EQ Networks ready for installation at the final stage of

completion and these are described on the following pages.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 20 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

There are two of each type comprising:1) C5 and RAC

2) C13 and RBC

3) RAF/RAG and C3

4) RBF/RBG and C10

We will start with C5/RAC and C13/RBC which are identical so the build instructions for one will

suffice for the other.

Unfortunately there is no photo of these EQs but the view of one fitted should allow you to see

what is required. The photo depicts a silver mica capacitor but you could use the original 8200pF if

you have previously put this to one side for re-use. RAC (39k2) is soldered to one leg of the

capacitor C5 and then covered in Heat Shrinkable sleeving. Make a similar unit for C13/RBC and

the photo gives one a good idea on how to fit both EQs later, after the board has been re-fitted. A

more detailed fitting procedure will be presented when the time comes to do it.

RAF/RAG and C3

The following photos make use of the saved 100pF Capacitors but you can substitute with a 200pF

silver mica type should you wish to do so.

First, the resistors RAF (75k) and RAG (18k) are wired in parallel, i.e. together side by side.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 21 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Cover in Heat Shrinkable sleeving and then crop the lead at one end and solder to the capacitor(s)

C3. The reclaimed 100pF capacitors shown here are also wired in parallel to make the value of

200pF.

Make a similar unit for RBF/RBG and C10.

We can now turn our attention to the chassis modifications.

Below is a simple template for you to make from thin card or stout paper, using this template you

can position the mounting hole correctly for the extra valve V3. Readers with copies of the original

instruction manual will know that there were two templates, one for the MS22 and another for the

MS23 because of the valve guard fitted to this model.

The author has decided to describe the template for the MS23 only, as it serves both models and

avoids the situation where someone accidentally uses the wrong template!

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 22 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

After making to the sketch, place the template onto the underside of the chassis using the present

large holes as a guide to placement. Simply centre mark the required position for the pilot hole and

then cut the panel for the valve holder.

There is caution here! Some valve holders, particularly the skirted type, require a larger hole than

depicted. The safe solution here is to carefully cut the hole until the new valve holder fits

comfortably into it.

Be careful of machining operation swarf when cutting the large hole for the extra valve. It helps to

keep the amplifier body tilted forward slightly during these operations to prevent metal particles

finding their way into the power transformer cover.

The holder should be retained with suitable screws, shake proof washers and nuts; the author

recommends that the keyway gap faces the power transformer.

This of course may not be possible with some valve holders as there is no design standard.

Now we will do some changes to the rear panel. The addition of extra grounding is to follow

accepted safety standards and is highly recommended, particularly if you are converting a unit for

somebody else.

Remove the two 6mm long Torx headed screws and the central cross head screw (marked with

asterisks), the latter secures an internal screening frame.

At the OUTPUT RCA Jacks, if you find the two Ground tags soldered together then separate the

tags and Black wires. These will already be separated on the Mark.2 or some MS23 Models.

Reconnect the respective Black wires to their own independent tags.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 23 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

On both of the OUTPUT RCA jacks do the following:The White Left Channel centre connection is temporarily removed and a 1k Ohm resistor R10 is

inserted. Heat shrink tubing comes in handy here. When soldering back to the centre connection,

apply at the same time a 1M Ohm resistor (RAH) between the centre connection and the Ground

Tag with its Black wire. Dont get these two resistors mixed up or you will have very low output!

The Red Right Channel centre connection is now

temporarily removed and another 1k Ohm

resistor R21 is inserted as was done for the Left

Channel. Likewise the 1M Ohm resistor (RBH)

should be installed between the centre

connection and the Ground Tag with its Black

wire.

At the INPUT RCA Jacks, check that the

Ground Tags are isolated too, separate if

necessary and ensure you connect the correct

Black wires to them.

These should already be separated on the

Mark.2 or MS23 Models.

The errant soldering together of these Ground

Tags has been the main source of unwanted

hum.

The diversity of Ground/Earthing schemes tried by Yaqin clearly shows the endeavours they have

made to try to solve the hum problem.

Example: The author found a single Yellow/Green Earth wire going from the supply input IEC connector to the solder

tag that grounds the transformer cage. Then two Black wires to connect with the insulated rear Ground terminal and the

other to the Ground point on the rear edge of the printed circuit board. Here there was another Black wire that went up

into the transformer enclosure to earth the power transformer.

On one MS23 a single Earth wire went from the IEC connector to a chassis solder tag. On another

tag mounted close by there was one Black wire which went to the GND terminal on the PCB edge.

The Black wire coming from the power transformer connected to a new Earth terminal close to the

Star point on the PCB. The rear panel Ground post connected to a new Earth terminal located near

C15 and C16, with its interconnecting wire wrapped around the twisted Yellow heater wires.

These wire loop Ground points can be seen on the board view of Page 28.

All these changes seemed to be an endeavour to find a way to eradicate the small amount of hum

that just would not go away but now, thankfully, reduced to a satisfactory level. In all conversions

that the author does, he Grounds to this new wiring build standard but also retains his own ground

safety scheme for the rear and bottom panels.

Solder two extra earthing wires (striped Green/Yellow) to the Earth Connection of the Power Input

Connector. One needs to locate to a dedicated earth point on the rear panel and should be fitted with

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 24 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

an eyelet tag. There is no connection at present and a 3mm clearance hole should be drilled at a

central position between the voltage selector switch and the shield surrounding the RCA sockets.

Make sure all anodising is cleared on the inside of the panel or a bad Earth connection will result.

The other earth wire should be about 150mm and also furnished with an eyelet tag. This should be

mounted later to the bottom cover; a 3mm clearance hole should be drilled in the cover to take the

tag. A convenient point can be found above the empty space behind the IEC connector.

For those wishing to fit the optional Normal/+6dB Boost switch, another hole needs to be drilled as

shown.

The author has no measurements for this but use of a sub miniature double pole switch should make

it capable of being fitted.

The small safety warning now obscured is replaced later by the more preferred Black on Yellow

safety label on the bottom cover. The old label can be masked by either painting over or making a

new label.

Something like:-

Suitably scaled of course, covered with non-yellowing Scotch Crystal tape with some double sided

tape applied to the underside.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 25 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Each pole of the switch should be fitted with single core screened lead that is long enough to reach

the front corners of the chassis. The leads are wired such that the screened lead inner conductor is

shorted to the outer screen when the switch is set to +6dB.

You are almost there! Almost in vinyl heaven! All you need to do now before re-fitting the circuit

board is to drill some holes for the extra valve connecting leads.

The following photographs were taken from much earlier conversions when some components were

mounted onto the print side. Hopefully your board will look much neater with most components

now hidden out of the way.

In his first conversions, the author drilled three 5.5mm holes in the circuit board where no

components resided but he now uses six 2.5mm holes for the single V3 wires and one 3.5mm hole

for the V3 twisted pair. The photographs on the following pages show the locations. Carefully feed

the wires through these holes from the component side and if you colour coded the wires then this

should be easy to do.

Once the board is in position and the wires pulled through then they can be terminated as required.

If you have decided to use all four original output capacitors then an alternative place to drill the

hole will be required for the Black Cathode resistor wires.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 26 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

This is an early photograph; the Red Anode wires should now be routed further up the board to

connect with the solder pads at the other ends of R22 and R23 (see next page).

With the board now fixed in place, reconnect the Yellow and White pairs of supply wires to the

board edge connectors and connect the grounding wires as required.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 27 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

This photograph gives another view, this time with similar coloured wires but shows exactly where

the wires are terminated on the board. It also shows the positions for mounting the 200pF EQ

networks which can now be soldered in together with the Grid wires of V3. The other end of the

networks, ending with the capacitors, should be soldered to the Ground strip that runs almost the

full width of the board.

IMPORTANT! Despite being covered in heat shrinkable sleeving, leave a tiny gap between the

resistors RAF/RAG and RBF/RBG as the tracks that lie beneath them carry full HT (B+) voltage.

Another example where silver mica 200pF

capacitors were fitted.

Note the Green Grid and Black Cathode

wires emanating from holes in the board

ready for connection. This unit did not

have resistors mounted in specially drilled

holes hence the view of the 180k resistor

RBE (this being the Right Channel).

The presence of the fixing nut and washer

however serves as a reminder for you to

check that you have re-fitted any you may

have removed.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 28 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Now for the last EQ networks to be fitted. This should of course be on a board that you have

refitted into the chassis but is shown out of chassis for better visuals. It will give you some idea of

lead lengths which you can try anyway before final cropping of wires. The right hand EQ (shown

on the left of course) goes between Ground and Pin 2 of V2. The Left channel shown on the right,

goes between Ground and Pin 7 of V1. Ignore the presence of the resistors at the valve holders as

this is an early photograph.

If you have fitted the +6db boost switch, then connect the two screened leads to the pads associated

with the vacant 560 Ohm resistors situated just above the 220uF/16V capacitors. Connect the

screens to the outermost pads, that is the one connected to the Positive terminal of the 220uF

capacitors.

Refit the front panel.

You can now connect the four plugs to the board and temporarily replace the bottom cover with just

two holding screws. If you have a digital Multimeter to hand, then it is a good idea to do some

cold checks on the circuitry before powering up. Temporarily fitting the bottom cover will save

you undoing all of those screws should you find anything wrong?

Just a reminder - valve pins are numbered 1 to 9 clockwise looking from UNDERNEATH. If you

are looking INTO the socket where the valve actually goes, then you have to count the pins in an

anti-clockwise direction, pin 1 in this case being the first pin after the gap.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 29 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

It helps to do the measurements if you make up some special leads for locating into the small holes

of the valve sockets.

If the unit has been powered up at all then verify that the HT rail is fully discharged before

carrying out the following tests. This can be verified using pin 1 and/or pin 6 of the new valve

V3 and the GROUND Terminal.

These can be discharged, as described earlier, by holding a 1k2 1W resistor between the charged

valve holder pin and either chassis or GROUND terminal for 20 seconds. Check with your

Multimeter switched to DC Volts that the capacitors are all but discharged.

The following tests are also condensed as a quick check list in a following table form, resistance

tests are to +/-5% tolerance.

HT Checks:

a) Connect the Multimeter between Pin 1 of V3 and Pin 1 of V1. The resistance measured should

be around 140k Ohms. (Checks R22 and R3)

b) Transfer the probe on V1 Pin 1 to Pin 6 of V1, to be 350k Ohms. (Checks R22 and R6)

c) Connect the Multimeter to the other Anode (Pin 6) of V3 and measure to Pin 6 of V2 to be 140k

Ohms. (Checks R23 and R15)

d) Transfer the probe on V2 Pin 6 to Pin 1 of V2, to be 350k Ohms. (Checks R23 and R6)

Signal input checks:

e) Connect the Multimeter between the L/H Phono Input and V1 Pin 2, to be 1k Ohms.

(Checks RAA)

f) Connect the Multimeter between the R/H Phono Input and V2 Pin 7, to be 1k Ohms.

(Checks RBA)

Ground Checks:

Connect the Multimeter between the rear panel GROUND terminal and the following points.

g) L/H Phono Input to be 47k Ohms. (Checks R1)

h) R/H Phono Input to be 47k Ohms. (Checks R12)

i) V1 pin 3 to be approximately 1k2 Ohms. (Checks R2)

j) V1 pin 7 to be approximately 1316k Ohms. (Checks R5 and RAB)

k) V1 pin 8 to be approximately 2k2 Ohms. (Checks RAD)

l) V3 Pin 3 to be approximately 150k Ohms. (Checks R7)

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 30 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

m) V3 Pin 8 to be approximately 150k Ohms. (Checks R18)

n) V2 pin 8 to be approximately 1k2 Ohms. (Checks R13)

o) V2 pin 2 to be approximately 1316k Ohms. (Checks R16 and RBB)

p) V2 pin 3 to be approximately 2k2 Ohms. (Checks RBD)

Signal output checks:

q) L/H Phono Output to be approximately 1M Ohms. Checks RAH)

r) R/H Phono Output to be approximately 1M Ohms. Checks RBH)

Valve interconnects:

s) V1 pin 6 to V3 Pin 2 to be approximately 180k Ohms. If you measure something much higher

dont panic, you are on the wrong Grid of V3 so move the Multimeter probe from Pin 2 to Pin 7.

(Checks RAE)

t) Connect the Multimeter to the other Grid of V3 (i.e. if you were on Pin 7 go to Pin 2 or visa

versa) and measure to V2 Pin 1 to be approximately 180k Ohms. (Checks RBE)

u) A resistance test between V3 Pins 1 and 6 should show a virtual short circuit and proves that

both halves of the valve are connected to the B+ (HT) line. It might be prudent at this point to do a

quick check between these two valve pins and Ground to check that no short circuit exists.

CHECK LIST IN TABLE FORM

Test point

Min Value

Max Value

Actual Value

a) V3 Pin 1 to V1 Pin 1

133k

147k

b) V3 Pin 1 to V1 Pin 6

332.5k

367.5k

c) V3 Pin 6 to V2 Pin 6

133k

147k

d) V3 Pin 6 to V2 Pin 1

332.5k

367.5k

e) LEFT Phono Input to V1 Pin 2

950

1050

f) RIGHT Phono Input to V2 Pin 7

950

1050

g) LEFT Phono Input to Ground

44.65k

49.35k

h) RIGHT Phono Input to Ground

44.65k

49.35k

i) V1 Pin 3 to Ground

1.140k

1.260k

j) V1 Pin 7 to Ground

1250.2k

1381.8k

k) V1 Pin 8 to Ground

2.090k

2.310k

l) V3 Pin 3 to Ground

142.5k

157.5k

m) V3 Pin 8 to Ground

142.5k

157.5k

n) V2 Pin 8 to Ground

1.140k

1.260k

o) V2 Pin 2 to Ground

1250.2k

1381.8k

p) V2 Pin 3 to Ground

2.090k

2.310k

q) LEFT Phono Output to Ground

950k

1050k

r) RIGHT Phono Output to Ground

950k

1050k

s) V1 Pin 6 to V3 Pin 2

171k

189k

t) V2 Pin 1 to V3 Pin 7

171k

189k

u) V3 Pin 1 and V3 Pin 6

n/a

n/a

Short Circuit

AS WITH ALL WORK CARRIED OUT ON CLASS 1 EQUIPMENT, DO AN

INSTRUMENT PAT TEST OR EQUIVALENT ON THE POWER CONNECTOR,

CHECKING FOR A GOOD ALL ROUND EARTH BOND NOT GREATER THAN 100

milli-Ohms AND AN INSULATION NOT LESS THAN 100Meg Ohms AT 500V.

If all tests are OK then you can fully fit the bottom cover into place.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 31 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

VERY IMPORTANT!

If the supplied Yaqin power cable has a plug with a sleeved Earth Pin, or a fuse that is not clearly

seen, it is unsafe and illegal, cut it up and dispose of it. This really is a fire starter as it contains no

fuse at all; the wire colours do not comply with UK legislation and worse still, the Live and Neutral

connections have been found reversed inside the Plug!

DO NOT

USE!

Fit a new IEC cable and Plug, fused at 3 Amps though 5 will be acceptable.

Cut out a copy of above labels and stick to bottom cover using double sided tape.

One Earth symbol label should be placed by the new Earth point fixing screws to remind you that it

is a safety Earth and should not be disturbed.

So is there anything we can do with the original MSS23B valve cover that is now ready for the

scrap bin? Yes there is! Read on.

Fellow Yaqin enthusiast Mark Kerr had his MS23B converted but decided to modify the original

tube cover for further use. Here is his write up on the work he did.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 32 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

This mod is to allow the shield to be replaced after

carrying out the 'Les Box' mod on the Yaqin MS-23B.

With the rear of the shield facing towards you using a pencil and a steel ruler mark two lines 7mm

in from the edge of the upright section so they are parallel to the outside edge and extend from

the fold to the curve to the top surface. Extend the lines from the curved edge so they meet the

outer edges of the oblong cut-out in the centre.

Hopefully the image should explain the outline required.

Using a junior hacksaw with a sharp blade, cut down this line from the centre cut-out to the crease

being careful to not go over the outer edge of the line nor past the crease at the base (yes my

example in the next photo shows what happens if you do, thankfully as it faces the rear it is

slightly forgiving).

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 33 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Cover the flat portion at the rear with the two screw holes in tape and secure in a vice or similar

Gently flex/wiggle the cut portion to and fro above the crease and it should break off with metal

fatigue.

Dress the edges with a file and sandpaper (fine grit), then clean and remove all particles before re

attaching.

With many thanks to Les Carpenter for the mod

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 34 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

Here is a fully converted MS23B photo from Juha Jrvel

And thats it apart from a good session with your

favourite vinyl to discover the magic that is now there!

Happy Listening. Lez at ntlworld dot com

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 35 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

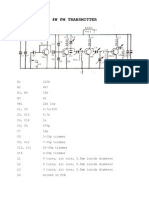

The circuit after conversion.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 36 of 37

Putting LIFE into the Yaqin MS-22B and MS-23

The power supply.

Les Carpenter_G4CNH 2014

May be copied without consent provided the contents are not used for commercial purposes or financial gain of any kind. Based on

the excellent WAD design, all rights reserved.

Page 37 of 37

Anda mungkin juga menyukai

- Aion Refractor Centaur DocumentationDokumen8 halamanAion Refractor Centaur Documentationpmacs10Belum ada peringkat

- R392 R648 Misc Notes PDFDokumen120 halamanR392 R648 Misc Notes PDFDave AustermanBelum ada peringkat

- Dynamull Driver Board St-70: Classic Valve DesignDokumen13 halamanDynamull Driver Board St-70: Classic Valve DesignyehkanghuiBelum ada peringkat

- DynaMull Docs PDFDokumen13 halamanDynaMull Docs PDFmohamadazareshBelum ada peringkat

- 200W Leach AmpDokumen12 halaman200W Leach AmpАлексей Андрияш100% (1)

- A Look at The Yaqin MC100BDokumen24 halamanA Look at The Yaqin MC100BRoi Rey100% (1)

- Art AcpDokumen12 halamanArt AcpTrungKiênTrầnBelum ada peringkat

- DIYAudio DIYAB Honey Badger Build Guide v1.0Dokumen30 halamanDIYAudio DIYAB Honey Badger Build Guide v1.0Danh Pro100% (1)

- ART Tube MP ModificationDokumen14 halamanART Tube MP Modificationtitov33Belum ada peringkat

- KAT-KIT Deacy Amp Assembly and Test InstructionsDokumen22 halamanKAT-KIT Deacy Amp Assembly and Test InstructionsAntony Sebastián Villalobos CataldoBelum ada peringkat

- 80M 40M Receiver Manual FinalDokumen19 halaman80M 40M Receiver Manual FinalcasagrandeBelum ada peringkat

- Tube Phono Preamp - NotesDokumen15 halamanTube Phono Preamp - NotesStelios PanarasBelum ada peringkat

- Valv e Tizer V15aDokumen6 halamanValv e Tizer V15aDaniel AyosaBelum ada peringkat

- Ignition Igniter For Suzuki GS1000GT 1980Dokumen17 halamanIgnition Igniter For Suzuki GS1000GT 1980migBelum ada peringkat

- WWW Usefulcomponents ComDokumen8 halamanWWW Usefulcomponents Comjg94419625Belum ada peringkat

- LM3875 Gainclone DIY Amp Building GuideDokumen49 halamanLM3875 Gainclone DIY Amp Building GuideJaco HerholdtBelum ada peringkat

- "Dynamutt" Driver Board: For The Dynaco St-70Dokumen15 halaman"Dynamutt" Driver Board: For The Dynaco St-70azornBelum ada peringkat

- Pira FM Transmitter ManualDokumen29 halamanPira FM Transmitter Manualmcbneto5470Belum ada peringkat

- ADA MN3007 Rev5 Jan2010 Documentation Rev20120225Dokumen12 halamanADA MN3007 Rev5 Jan2010 Documentation Rev20120225ismaelsleiferBelum ada peringkat

- Superlacht280 WrmsDokumen5 halamanSuperlacht280 WrmsgustavoBelum ada peringkat

- Otalgiafx: "Overdrive Based On The Vox V1901 Overdrive"Dokumen8 halamanOtalgiafx: "Overdrive Based On The Vox V1901 Overdrive"Hans stroffelBelum ada peringkat

- ADA MP-1 Mod 3.666Dokumen24 halamanADA MP-1 Mod 3.666Andrei PopaBelum ada peringkat

- The Gristleizer Assembly GuideDokumen11 halamanThe Gristleizer Assembly GuideEMLBelum ada peringkat

- LM3886 Gain Clone Amplifier DIY From XYDokumen26 halamanLM3886 Gain Clone Amplifier DIY From XYnaufalBelum ada peringkat

- "Dynamutt" Driver Board: For The Dynaco St-70Dokumen16 halaman"Dynamutt" Driver Board: For The Dynaco St-70azornBelum ada peringkat

- Divine Fuzz Building Instructions V1.0Dokumen7 halamanDivine Fuzz Building Instructions V1.0ultratumbaBelum ada peringkat

- Diesel Sound Generator PCB ProjectsDokumen11 halamanDiesel Sound Generator PCB ProjectsΔημητριος ΣταθηςBelum ada peringkat

- Lich King ChorusDokumen34 halamanLich King ChorussugenkBelum ada peringkat

- Blues Crusher SchematicDokumen28 halamanBlues Crusher Schematiczeus maxBelum ada peringkat

- Low-Cost HF Amplifier Board and Filter ModsDokumen14 halamanLow-Cost HF Amplifier Board and Filter ModsaugustinetezBelum ada peringkat

- Sharp LC 19d1erd+lc 19d1eDokumen12 halamanSharp LC 19d1erd+lc 19d1erictronix5586Belum ada peringkat

- 175 DocDokumen107 halaman175 DocjoeBelum ada peringkat

- FM Ogre - BOM & Build InfoDokumen6 halamanFM Ogre - BOM & Build InfoDan LBelum ada peringkat

- Philips CD 650 ModsDokumen10 halamanPhilips CD 650 ModsspikebitBelum ada peringkat

- Behringer TD-3 Modifications Guide Sound and Performance ModificationsDokumen20 halamanBehringer TD-3 Modifications Guide Sound and Performance ModificationsRomain Beatlejuice DucBelum ada peringkat

- QRP Labs Ultimate 3S QCU Rev 3 Kit - Assembly ManualDokumen22 halamanQRP Labs Ultimate 3S QCU Rev 3 Kit - Assembly ManualjohnBelum ada peringkat

- MUFFN v2Dokumen6 halamanMUFFN v2Iñaki ToneMonsterBelum ada peringkat

- A Beginners Guide To Effects Pedal Components-1Dokumen25 halamanA Beginners Guide To Effects Pedal Components-1Richard Godin100% (2)

- Adcanced VHF Power MeterDokumen6 halamanAdcanced VHF Power MeterFrancisco J. Aguilera HiguereyBelum ada peringkat

- H440 InstructionsDokumen28 halamanH440 InstructionsAnonymous WgpXi9ABelum ada peringkat

- Dla 2 ADokumen7 halamanDla 2 AHugues ValotBelum ada peringkat

- Aikido LVDokumen13 halamanAikido LVepascaruBelum ada peringkat

- 208ToolBox - Build Notes - Batch4Dokumen4 halaman208ToolBox - Build Notes - Batch4klinikBelum ada peringkat

- Diy Sony Vfet Amplifier Os2-1Dokumen9 halamanDiy Sony Vfet Amplifier Os2-1alex_81_Belum ada peringkat

- Micro80D Builders Guide-Ver3Dokumen18 halamanMicro80D Builders Guide-Ver3knujdloBelum ada peringkat

- Mini FM Transmitter Kit: Hear Sounds Up to a Mile AwayDokumen6 halamanMini FM Transmitter Kit: Hear Sounds Up to a Mile AwayGoncalo EscusaBelum ada peringkat

- Build Double Bazooka PDFDokumen11 halamanBuild Double Bazooka PDFAtin surelawatinBelum ada peringkat

- Sharp LC 37a37mDokumen38 halamanSharp LC 37a37mnikola1660100% (3)

- 4w FM TransmitterDokumen9 halaman4w FM TransmitterMantas PauliukonisBelum ada peringkat

- 220 MHZ All-Mode TransverterDokumen6 halaman220 MHZ All-Mode TransverterJoao PedroBelum ada peringkat

- A Beginners Guide To Effects Pedal Components PDFDokumen25 halamanA Beginners Guide To Effects Pedal Components PDFWellington CordeiroBelum ada peringkat

- The DIY ACA Mini AmplifierDokumen17 halamanThe DIY ACA Mini AmplifierkartikaymsharmaBelum ada peringkat

- Quad 606 MK I II 707 and 909 Upgrade Revision Manual V2.6Dokumen13 halamanQuad 606 MK I II 707 and 909 Upgrade Revision Manual V2.6Edwin Petallar ApareceBelum ada peringkat

- 81 Comp 1.1Dokumen7 halaman81 Comp 1.1Anonymous kYtP6mpBelum ada peringkat

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDari EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsPenilaian: 3 dari 5 bintang3/5 (2)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDari EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileBelum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Max 49Dokumen24 halamanMax 49Alicia SmithBelum ada peringkat

- Am 73Dokumen34 halamanAm 73Alicia SmithBelum ada peringkat

- IP Hikvision DS-KD8023-E6Dokumen3 halamanIP Hikvision DS-KD8023-E6Alicia SmithBelum ada peringkat

- Wine Enthusiast Magazine - August 2017Dokumen140 halamanWine Enthusiast Magazine - August 2017Alicia SmithBelum ada peringkat

- Smanos k2 Smart Hub User ManualDokumen16 halamanSmanos k2 Smart Hub User ManualAlicia SmithBelum ada peringkat

- Security Alarm System: Printed in China PA: L020-UM-EN/FR/ES/PT-V1.0 © 2015 SMANOS HOLDING LTD. All Rights ReservedDokumen58 halamanSecurity Alarm System: Printed in China PA: L020-UM-EN/FR/ES/PT-V1.0 © 2015 SMANOS HOLDING LTD. All Rights ReservedAlicia SmithBelum ada peringkat

- Dds 80Dokumen54 halamanDds 80Alicia SmithBelum ada peringkat

- Assemble RFLink-WiFi Breakout BoardDokumen14 halamanAssemble RFLink-WiFi Breakout BoardAlicia SmithBelum ada peringkat

- Harman Kardon AVR 300 Owners ManualDokumen40 halamanHarman Kardon AVR 300 Owners ManualAnibal Jacek Quirós P.Belum ada peringkat

- Pulse Oximeter Perfusion Index InfoDokumen1 halamanPulse Oximeter Perfusion Index InfoAlexandru PredenciucBelum ada peringkat

- PCVW510GDokumen129 halamanPCVW510GAlicia SmithBelum ada peringkat

- Bitdefender 2020 Consumer Threat Landscape ReportDokumen56 halamanBitdefender 2020 Consumer Threat Landscape ReportAlicia SmithBelum ada peringkat

- XV-EV61 XV-EV31 S-EV61V S-EV31V: Stereo DVD Cassette Deck ReceiverDokumen100 halamanXV-EV61 XV-EV31 S-EV61V S-EV31V: Stereo DVD Cassette Deck ReceiverAlicia SmithBelum ada peringkat

- Assembly and Operation OpenTherm Gateway V2.3 GuideDokumen12 halamanAssembly and Operation OpenTherm Gateway V2.3 GuideAlicia SmithBelum ada peringkat

- Sagem Dual Radio 700 ManualDokumen3 halamanSagem Dual Radio 700 ManualAlicia SmithBelum ada peringkat

- k-27478 Productoverview enDokumen4 halamank-27478 Productoverview enAlicia SmithBelum ada peringkat

- Sound & Vision - June 2015 USA PDFDokumen78 halamanSound & Vision - June 2015 USA PDFAlicia Smith100% (1)

- Nuremberg Info enDokumen16 halamanNuremberg Info enAlicia SmithBelum ada peringkat

- Harman Kardon AVR 300 Owners ManualDokumen40 halamanHarman Kardon AVR 300 Owners ManualAnibal Jacek Quirós P.Belum ada peringkat

- User Guide: Raven Xe HspaDokumen37 halamanUser Guide: Raven Xe HspaElinton De Jesus SarmientoBelum ada peringkat

- Arcam rDac Service Manual Input and Output CircuitsDokumen14 halamanArcam rDac Service Manual Input and Output CircuitsAlicia SmithBelum ada peringkat

- Configure a repeating Home Assistant automation to turn on a Sonoff POW every 5 minutesDokumen5 halamanConfigure a repeating Home Assistant automation to turn on a Sonoff POW every 5 minutesAlicia SmithBelum ada peringkat

- Medieval Swords PDFDokumen64 halamanMedieval Swords PDFAlicia Smith50% (2)

- MC352 Power AmplifierDokumen4 halamanMC352 Power AmplifierAlicia SmithBelum ada peringkat

- Roborock Robot Vacuum Cleaner ENDokumen13 halamanRoborock Robot Vacuum Cleaner ENDaniel Criado RedondoBelum ada peringkat

- WIRED - June 2015 UK PDFDokumen188 halamanWIRED - June 2015 UK PDFAlicia SmithBelum ada peringkat

- Sagem Dual Radio 700 ManualDokumen3 halamanSagem Dual Radio 700 ManualAlicia SmithBelum ada peringkat

- DS Adam-457220141027134400 PDFDokumen2 halamanDS Adam-457220141027134400 PDFRanaIfteeBelum ada peringkat

- What Hi-Fi Sound and Vision 2011 PDFDokumen172 halamanWhat Hi-Fi Sound and Vision 2011 PDFAlicia SmithBelum ada peringkat

- XV-EV61 XV-EV31 S-EV61V S-EV31V: Stereo DVD Cassette Deck ReceiverDokumen100 halamanXV-EV61 XV-EV31 S-EV61V S-EV31V: Stereo DVD Cassette Deck ReceiverAlicia SmithBelum ada peringkat

- APC Symmetra PX-2Dokumen8 halamanAPC Symmetra PX-2drastir_777Belum ada peringkat

- Methods of Protection - Flameproof ExdDokumen2 halamanMethods of Protection - Flameproof ExdSyam DevBelum ada peringkat

- Expt No.10Dokumen6 halamanExpt No.10Rithika 318030Belum ada peringkat

- Sharp Lc32bd6x LCD TV SMDokumen212 halamanSharp Lc32bd6x LCD TV SMkothuraBelum ada peringkat

- 1 Electric Charge and Field - 020053 - 102918Dokumen20 halaman1 Electric Charge and Field - 020053 - 102918Amit VashistBelum ada peringkat

- Product Data Sheet: Easy UPS 3S 40 kVA 400 V 3:3 UPS For External BatteriesDokumen3 halamanProduct Data Sheet: Easy UPS 3S 40 kVA 400 V 3:3 UPS For External BatteriesMeh DiBelum ada peringkat

- PM800 User GuideDokumen122 halamanPM800 User Guidebobi156Belum ada peringkat

- Coleco Av Mod HowtoDokumen9 halamanColeco Av Mod HowtoOscar Arthur KoepkeBelum ada peringkat

- MPPT Using Sepic ConverterDokumen109 halamanMPPT Using Sepic ConverterSandhya RevuriBelum ada peringkat

- Adani BessDokumen45 halamanAdani Bessdan_geplBelum ada peringkat

- To Design and Simulate Priority EncoderDokumen6 halamanTo Design and Simulate Priority EncoderShubham GargBelum ada peringkat

- Op-Amp Imperfections: Autozeroing, Correlated Double Sampling, and Chopper StabilizationDokumen31 halamanOp-Amp Imperfections: Autozeroing, Correlated Double Sampling, and Chopper StabilizationAndres MauricioBelum ada peringkat

- 415V LT Motors Technical SpecificationDokumen13 halaman415V LT Motors Technical SpecificationJKKBelum ada peringkat

- WWW - Manaresults.Co - In: (Common To Ece, Eie, Etm)Dokumen2 halamanWWW - Manaresults.Co - In: (Common To Ece, Eie, Etm)Anil Kumar BBelum ada peringkat

- AH 480 DeviceList 20210719Dokumen456 halamanAH 480 DeviceList 20210719Yu FelixBelum ada peringkat

- MA Protocols Guide: FDMA, TDMA, CDMA ComparedDokumen28 halamanMA Protocols Guide: FDMA, TDMA, CDMA ComparedRashedkoutayniBelum ada peringkat

- EE 09 605 Electrical Engineering Drawing APR 2015Dokumen2 halamanEE 09 605 Electrical Engineering Drawing APR 2015علي عائشةBelum ada peringkat

- Accident Detection Using IOT Project Report FinalDokumen51 halamanAccident Detection Using IOT Project Report Finalchinju mdasBelum ada peringkat

- Chapter 13: Multiplexing and Multiple-Access Techniques: True/FalseDokumen7 halamanChapter 13: Multiplexing and Multiple-Access Techniques: True/FalseChristopher Inoval ParilBelum ada peringkat

- STCE/RTU Communication ProtocolsDokumen24 halamanSTCE/RTU Communication ProtocolsJung Boo JangBelum ada peringkat

- Nichiyu Fb10 30p Dc70 Series TrsDokumen83 halamanNichiyu Fb10 30p Dc70 Series TrsJuli Nugroho SuSanto100% (1)

- LSLVG 100Dokumen343 halamanLSLVG 100Yohanes TriatmojoBelum ada peringkat

- Btech Ec 3 Sem Fundamentals of Electronics Devices Eec 301 2018 19Dokumen1 halamanBtech Ec 3 Sem Fundamentals of Electronics Devices Eec 301 2018 19Vishesh Kumar SinghBelum ada peringkat

- Advantage GCS Modbus Protocol Support 6v8Dokumen117 halamanAdvantage GCS Modbus Protocol Support 6v8Friends foreverBelum ada peringkat

- RangeLink UHF LRS Manual v1.3Dokumen17 halamanRangeLink UHF LRS Manual v1.3lgenniferBelum ada peringkat

- Electrical Commissioning ChecklistDokumen2 halamanElectrical Commissioning Checklistalban ramabajaBelum ada peringkat

- Instruction Manual-Instruction Manual TurbiGuard In-Line Turbidity Monitor For Medium To High Turbidity (11028E3-13920-E)Dokumen36 halamanInstruction Manual-Instruction Manual TurbiGuard In-Line Turbidity Monitor For Medium To High Turbidity (11028E3-13920-E)Jose A. LamaBelum ada peringkat

- Chapter 5 - Gas Shielded Metal Arc Welding PDFDokumen16 halamanChapter 5 - Gas Shielded Metal Arc Welding PDFVasco Jardim0% (1)

- CTK-711EX: IndexDokumen37 halamanCTK-711EX: IndexEdison CamargoBelum ada peringkat

- Static Exciter Aux Fed Vs Terminal FedDokumen6 halamanStatic Exciter Aux Fed Vs Terminal Fedavikrisad100% (1)