Bolted Connections Guide

Diunggah oleh

A.k.MandalDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bolted Connections Guide

Diunggah oleh

A.k.MandalHak Cipta:

Format Tersedia

Structural Connections I

Bolted Connections

A.K.Mandal

Connections form an important part of any structure and are designed more conservatively than

members. This is because, connections are more complex than members to analyse and the

discrepancy between analysis and actual behavior is large. Moreover, in case of overloading, we

prefer the failure confined to an individual member rather than in connection, which could affect

many members. Connections account for more than half the cost of structural steelwork and so their

design and detailing are of primary importance for economy of the structure.

Just as members are classified as bending members or axially loaded members depending on the

dominant force/moment resisted, connections are also classified into idealized types while

designing. But the actual behaviour of the connection may be different and this point should always

be kept in mind so that the connection designed does not differ from the intended type. Take for

example, the connection of an axially loaded truss members at a joint. If the truss is assumed to be

pin jointed, then the members should ideally be connected by means of a single pin or bolt.

However, in practice, if the pin or bolt diameter works out to be larger than that possible, more than

one bolt is used. The truss can then be considered pin-jointed only if the bending due to self-weight

or other superimposed loads between joints is negligible.

Connection elements consist of components such as cleats, gusset plates, brackets, connecting

plates and connectors such as rivets, bolts, pins and weld. The connections provided in steel

structures can be classified as 1) riveted, 2) bolted and 3) welded connections. Riveted connections

were once very popular and are still used in some cases, but will gradually be replaced by bolted

connections. This is due to the low strength of rivets, higher installation cost and inherent

inefficiency of the connection. Welded connections have the advantage that no holes need to be

drilled in the member and consequently have higher efficiencies. However, welding in the field may

be difficult, costly and time consuming. Welded connections are also susceptible to failure by

cracking under repeated cyclic loads due to fatigue which may be due to working loads such as trains

passing over a bridge (high-cycle fatigue) or earthquakes (low-cycle fatigue). A special type of bolted

connections using High Strength Friction Grip (HSFG) bolts has been found to perform better under

such conditions than the conventional black bolts used to resist predominantly static loading. Bolted

connections are also easy to inspect and replace. The choice of using a particular type of connection

is entirely that of the designer.

Riveted Connections:

A rivet is made up of round ductile steel bar (mild or high tensile) called shank, with a head at

one end. The head can be of different shapes. The usual form of rivet head used in structural steel

construction is the snap head. The snap heads and pan heads form a projection beyond the plate

face, whereas countersunk head remains flashed with plate face.

Connections-I: Bolted Connections

The diameter of the shank is called the nominal diameter. A hole slightly greater than the

nominal diameter is drilled in the parts to be connected. The rivet is inserted and the head is formed

at the other end. The rivets may be formed in cold state or may be heated to red hot state prior to

driving. The rivets may be placed in a variety of patterns. The most common types of rivet patterns

are chain riveting and diamond riveting. Staggered patterns can also be provided.

The design of riveted connections is same as that of bolted connections with ordinary bolts with

the following differences

1. The diameter of rivet to be used in calculation is the diameter of the hole, whereas for

bolted connections it is the nominal diameter of the bolt.

2. The design stresses are different, lesser for bolts.

Bolted Connections:

Classification of connections

a)

Classification based on the type of resultant force transferred: The bolted connections are

referred to as concentric connections (force transfer in tension and compression), eccentric

connections (in reaction transferring brackets) or moment resisting connections (in beam to column

connections in frames)

Ideal concentric connections should have only one bolt passing through all the members

meeting at a joint [Fig 2 (a)]. However, in practice, this is not usually possible and so it is only

ensured that the centroidal axes of the members meet at one point [Fig 2 (b)].

The Moment connections are more complex to analyse compared to the above two types

and are shown in Fig 3 (a) and Fig 3 (b). The connection in Fig 3 (a) is also known as bracket

connection and the resistance is only through shear in the bolts.

Connections-I: Bolted Connections

The connection shown in Fig 3 (b) is often found in moment resisting frames where the

beam moment is transferred to the column. The connection is also used at the base of a column

where a base plate is connected to the foundation by means of anchor bolts. In this connection, the

bolts are subjected to a combination of shear and axial tension.

b)

Classifications based on the types of force experienced by the bolts: The bolted connections

can also be classified based on geometry and loading conditions into three types namely, shear

connections, tension connections and combined shear and tension connections.

Typical shear connections occur as a lap or a butt joint used in the tension members [Fig 4].

While the lap joint has a tendency to bend so that the forces tend to become collinear, the butt joint

requires cover plates. Since the load acts in the plane of the plates, load transmission at the joint

will ultimately be through shearing forces in the bolts.

In case of a lap joint or a single cover plate butt joint, there is only one shearing plane and so

the bolts are said to be in single shear. In case of double cover butt joint, there are two shearing

planes and so the bolts will be in double shear. It should be noted that the single cover type butt

joint is nothing but lap joints in series and also bends so that the centre of cover plate becomes

collinear with the forces. In case of single cover plate (lap) joint, the thickness of the cover plate is

chosen to be equal to or greater than the connected plates. While in double cover plate (butt) joint,

the combined thickness of the cover plates should be equal to or greater than the connected plates.

A hanger connection is shown in Fig 5 (a). In this connection, load transmission is by pure

tension in the bolts. In the connection shown in Fig 5 (b), bolts are subjected to both tension and

shear.

c)

Classification based on force transfer mechanism by bolts: The bolted connections are

classified as bearing type (bolts bear against the holes to transfer the force) or friction type (force

transfer between the plates due to the clamping force generated by the pre-tensioning of the bolts).

Connections-I: Bolted Connections

Bolts and bolting

Bolts used in steel structures are of three typesa) Unfinished bolts or black bolts (also called ordinary, common or rough bolt)

b) Turned and fitted bolts

c) High strength friction grip (HSFG) bolts.

Bolts are designated by grade x.y. In this nomenclature x indicates one-hundredth of the

nominal ultimate tensile strength of the bolt in N/mm2 and the second number y indicates one-tenth

of the ratio of yield stress to ultimate stress, expressed as percentage. Thus, grade 4.6 will have the

ultimate tensile strength of 400 N/mm2 and yield strength of 0.6 x 400 i.e., 240 N/mm2.

Black bolts are unfinished and are made from mild steel rods with square or hexagonal head and

nuts and usually of grade 4.6. Black bolts have adequate strength and ductility when used properly,

but when tightening the nut snug tight (Snug tight is defined as the tightness that exists when all

plies in a joint are in firm contact) will twist off easily if tightened too much. These bolts are used for

light structures subjected to static loads and for secondary members such as purlins, bracings etc.,

and for roof trusses. They are not recommended for connections subjected to impact load, vibration

and fatigue. These bolts are available from 5 to 36 mm diameter and designated as M5 to M36.

However, in structural steel work, the most common ones are M16, M20, and M24 to M30.

Turned and fitted bolts are similar to unfinished bolts, with the difference that the shanks of

these bolts are formed from hexagonal rods. The surface of these bolts are prepared and machined

carefully to fit in the hole. Tolerances allowed are about 0.15 mm to 0.5 mm. These bolts are used

when no slippage is permitted between the connected parts and where accurate alignment of

components is required. They are mainly used in special jobs (in some machines and where there are

dynamic loads). These bolts are available from grade 4.6 to 8.8.

High strength friction grip bolts (HSFG) provide extremely efficient connection and perform well

under fluctuating/fatigue load condition. They are made from quenched and tempered alloy steel

with grades from 8.8 to 10.9. The most common are general grade of 8.8 and have medium carbon

content which makes them less ductile. The 10.9 grade have much higher tensile strength, but lower

ductility. The size of the bolts available are from M16 to M36, but bolts of sizes M16, M20, M24 and

M30 are commonly used. HSFG bolts require hardened washer to distribute the load under bolt

heads. The tension in the bolt ensures that no slip takes place under working conditions and so the

load transmission from plate to bolt is through friction and not by bearing.

The tightening of HSFG bolts can be done by either of the following methods (IS 4000):

1. Turn-of-nut tightening method: In this method the bolts are first made snug tight and then

turned by specific amounts (usually either half or three-fourth turns) to induce tension equal

to proof load.

2. Calibrated wrench tightening method: In this method the bolts are tightened by a wrench,

calibrated to produce the required tension.

3. Alternate design bolt installation: In this method special bolts are used which indicate the

bolt tension. Presently such bolts are not available in India.

4. Direct tension indicator method: In this method special washers with protrusions are used

[Fig 6]. As the bolt is tightened, these protrusions are compressed and the gap produced by

them gets reduced in proportion to the load. This gap is measured by means of a feeler

gauge, consisting of small bits of steel plates of varying thickness, which can be inserted into

the gap.

Connections-I: Bolted Connections

Since HSFG bolts under working loads, do not rely on resistance from bearing, holes larger than

usual can be provided to ease erection and take care of lack-of-fit. Typical hole types that can be

used are standard, extra large and short or long slotted. These are shown in

Fig 7. However, the

type of hole will govern the strength of the connection.

Fig 7 Hole types for HSFG bolts

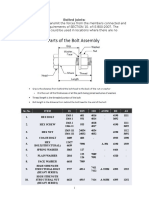

Spacing and Edge Distance of bolt holes

Pitch (p): The centre-to-centre distance between individual fasteners (i.e. bolts or rivets) in a line, in

the direction of load/stress is called pitch. The distance between any two consecutive fasteners in a

zigzag pattern of bolts, measured parallel to the direction of load/stress is called a staggered pitch.

For wide plates, pitch may be defined as the c/c distance of bolts, measured along the transverse

direction of load. A minimum spacing of 2.5 times the nominal diameter of the fastener is specified

in the code (cl. 10.2.2) to ensure that there is sufficient space to tighten the bolts, prevent

overlapping of washers and provide adequate resistance to tear-out of bolts. Similarly, the code also

specified the maximum pitch value (cl. 10.2.3).

Connections-I: Bolted Connections

Gauge distance (g): The distance between adjacent parallel line of bolts, transverse to the direction

of load/stress, or the distance between the back of the rolled section and the first bolt line or centre

to centre distance between two consecutive bolts measured along the width of the member is called

gauge distance. IS Handbook SP-1 provides gauge distance for various rolled sections.

Edge distance (e): The distance from the centre of a bolt hole to the edge of a member, measured at

right angles to the direction of load is called the edge distance. The distance in the direction of stress

from the centre of a hole to the end of the member is called end distance.

IS 800 specifies spacing and edge distance for bolt holes.

Types of Bolted Connections

a) Lap joint

b) Butt joint.

Load transfer mechanism of bolts

Depending upon the types of bolts, ordinary or high-strength bolts, the load transfer from one

connected part to another may be by shear and bearing or by friction; the former being called

bearing-type connection and the latter slip-resistance (or slip-critical) connection.

A) Bearing-type connections

In this type of connections, it is assumed that the load to be transferred is larger than the

frictional resistance caused by tightening the bolts. Consequently members slip a little over each

other and the bolts bear on the plates, placing the bolts in shear and bearing. Fig 9 shows the freebody diagram of the shear force transfer in bearing-type bolted connection. It is seen that tension in

one plate is equilibrated by the bearing stress between the bolt and the hole in the plate. Since there

is a clearance between the bolt and the hole in which it is fitted, the bearing stress is mobilized only

after the plates slip relative to one another and start bearing on the bolt. The section x-x in the bolt

is critical section for shear. Since it is a lap joint, there is only one critical section in shear (single

shear) in the bolt. In case of butt joint there would be two critical sections in shear in the bolt

(double shear), corresponding to two cover plates.

Assumptions in design of bearing bolts

a)

b)

c)

d)

e)

Friction between the plates is negligible

Shear is uniform over the cross-section of the bolt

Distribution of stress on the plates between the bolt holes is uniform

Bolts in a group subjected to direct loads share the load equally

Bending stresses developed in the bolts is neglected.

Connections-I: Bolted Connections

Design of bearing bolts

The failure of a joint can be in bolt or in plate. Thus the strength of a joint will be the minimum

of the strength of joint based on (a) strength of bolts in the joint and (b) the net tensile strength of

the plate. Since the bolt can fail either in shear or in bearing, the strength of bolts should be taken as

the minimum strength of bolts in shear and in bearing.

1.0 Shearing strength of bearing-type bolts

The resistance of a bolt to shear is called nominal capacity of bolt in shear and is denoted by

Vnsb. It depends on the ultimate tensile strength of bolt fub, the number of shear planes n, the

nominal shank area of bolt Asb and net tensile stress area of bolt through the threads Anb. If threads

do not lie in the shear plane, nominal shank area Asb is used as shear area, whereas if threads lie in

the shear plane, net tensile stress area Anb is used as shear area. Net tensile stress area is specified

in the code and is usually about 0.78 times the shank area.

A bolt subjected to a factored shear force (Vsb) shall satisfy

Vsb Vdsb

where, Vsb = factored shear force

Vdsb = design shear strength of bolt

Design shear strength of bolt (Vdsb) is given by

Vdsb = Vnsb / mb

where, Vnsb = nominal shear capacity of a bolt

mb = partial safety factor for the material of bolt

= 1.25

[Refer Table 5 of IS 800:2007]

Nominal shear capacity of a bolt (Vnsb) is given by

Vnsb =

where,

f ub

( nn Anb + ns Asb )

[cl. 10.3.3]

fub = ultimate tensile strength of a bolt

nn = number of shear planes with threads intercepting the shear plane

ns = number of shear planes without threads intercepting the shear plane

Asb = nominal plain shank area of bolt

Anb = net tensile area at thread, may be taken as area corresponding to root diameter at

thread

For bolts in single shear, either nn or ns is one and the other is zero. For bolts in double shear the

sum of nn and ns is two.

Then design strength of bolt in shear is given by

Vdsb =

f ub

3 mb

( nn Anb + ns Asb )

Reduction factors for nominal shear capacity of bolt

In long joints, the bolts farther away from the centre of the joint will carry more loads than the

bolts located close to the centre. Therefore, for joints having more than two bolts on either side of

the connection with distance between the first and last bolt exceeding 15d in the direction of load,

the shear capacity of the joint shall be reduced by the factor lj, given by cl. 10.3.3.1 as

lj = 1.075

lj

200 d

but 0.75 lj 1.0

Connections-I: Bolted Connections

where,

d = nominal diameter of bolt

lj = length of joint (equals to distance between first & last row of bolts measured in the

direction of load transfer.

Similarly, if the grip length exceeds five times the nominal diameter, the strength is reduced by a

factor lg as per cl. 10.3.3.2. The strength is also reduced if thickness of packing plate exceeds 6 mm

by a factor pk as per cl. 10.3.3.3.

So the design shear capacity of a bolt for long joint, long grip length and with packing plates (if

provided) will be modified as below.

Vdsb =

f ub

3 mb

( nn Anb + ns Asb ) lj lg pk

2.0 Bearing strength of bolt

If the connected plates are made of high strength steel, then failure of bolt can take place by

bearing of the plates on the bolt. If the plate material is weaker than the bolt material, then failure

will occur by bearing of the bolt on the plate and the hole will elongate.

The design bearing strength of a bolt on any plate Vdpb as governed by bearing is given by

Vdpb = Vnpb / mb

where, Vnpb = nominal bearing strength of a bolt & mb = 1.25

Nominal bearing strength of a bolt is given by

Vnpb = 2.5 kb d t fu

where,

kb is smaller of

3 d0

3 d0

0.25 ,

f ub

fu

and

1.0

e, p = end and pitch distances of the fastener along bearing direction

d0 = diameter of hole

fub, fu = ultimate tensile stress of the bolt and the ultimate tensile strength of the plate

respectively

d = nominal diameter of the bolt

t = summation of thicknesses of the connected plates experiencing bearing stress in

the same direction. In case the bolts are countersunk, then it should be taken as

the thickness of the plate minus half of the depth of countersinking.

Then design strength of a bolt in bearing is given by

Vdpb = 2.5 kb d t

fu

mb

NOTE: In case of butt joints, thickness of cover plate should not be less than t, where t is the

thickness of main plate.

3.0 Tensile strength of bolt

When bolts are subjected to tensile load (see Fig 5), the bolts are designed as tension member.

As per cl. 10.3.5, a bolt subjected to a factored tension force (Tb) shall satisfy

Tb Tdb

where, Tdb = design tension capacity of bolt

= Tnb / mb

where, Tnb = nominal tensile capacity of bolt & mb = 1.25

Connections-I: Bolted Connections

The nominal tensile capacity of bolt (Tnb) is calculated as

Tnb = 0.90 fub An < fyb Asb (mb / m0)

mb = 1.25 & m0 = 1.10

where, fub = ultimate tensile strength of bolt

fyb = yield stress of bolt

An = net tensile stress area of bolt

Asb = shank area of bolt.

Tension capacity of plate

The plate in a joint may fail in tension through the weakest section due to holes. The holes may

be arranged in the longitudinal direction of plate, so that the number of holes is equal in all rows

across the width [Fig 10 (a)] or staggered so that the number of holes across the width is reduced

[Fig 10 (b)]. In the first case, the plate will fail across the weakest section, whereas in the second

case the failure is along a zigzag pattern. The design tension capacity (Tdn) of plate is expressed as

Tdn = 0.9

fu

m 1

An

[cl. 6.3.1]

fu = ultimate stress of material

where,

An = net effective area of the plate

m1 = partial safety factor for failure at ultimate stress = 1.25

The net effective area of the plate (An) depends on arrangement of bolt holes.

If holes are not staggered, then An = (b n dh) t

m

b n dh + pi 2 /(4 g i ) t

For staggered holes, An =

where,

i=1

b = width of plate

n = number of holes

dh = diameter of hole

pi = staggered pitch

gi = gauge distance

Efficiency of the joint

Efficiency of the bolted joint =

Strength of bolted joint per pitch length

Combined shear and tension

strength of solid plate per pitch length

x 100

A bolt required to resist both shear and tension at the same time shall satisfy

V

where,

V sb + T b

dsb

db

1.0

Vsb = factored shear force on bolt

Vd = design shear capacity

Tb = factored tensile force on bolt

Tdb = design tension capacity

10

Connections-I: Bolted Connections

Connection with HSFG bolts

Free body diagram of an HSFG connection is shown in Fig 11. It can be seen that the pretension

in the bolt causes clamping forces between the plates even before the external load is applied.

When the external load is applied, the tendency of the two plates to slip against one another is

resisted by the friction between the plates. Until the externally applied force exceeds this frictional

resistance, the relative slip between the plates is prevented. The HSFG connections are designed

such that under service load the force does not exceed the frictional resistance so that the relative

slip is avoided during service. When the external force exceeds the frictional resistance the plates

slip until bolts come in contact with the plate and start bearing against the hole. Beyond this point

the external force is resisted by the combined action of frictional resistance and bearing resistance.

Connections-I: Bolted Connections

1.0

11

Shear strength of HSFG bolts

HSFG bolts will come into bearing only after slip takes place. So if slip is critical (i.e., if slip cannot

be allowed), then slip resistance is to be calculated which will govern the design. However, if slip is

not critical, and limit state method is used, then bearing failure can occur at the limit state of

collapse and needs to be checked. Even in the limit state method, since HSFG bolts are designed to

withstand working load without slipping, slip resistance has to be checked anyway as a serviceability

limit state.

a) Slip reistance: Design for friction type bolting in which slip is required to be limited, a bolt

subjected only to a factored design shear force Vsf in the interface of connections shall satisfy the

following [cl. 10.4.3]Vsf Vnsf / mf

The design slip resistance or nominal shear capacity of a bolt as governed by slip for friction type

connection is calculated as

Vnsf = f ne Kh Fo

where,

f = coefficient of friction (slip factor) [as specified in Table 20, page 77 of IS 800]

ne = number of effective interfaces offering frictional resistance to slip

Kh = 1.0 for fasteners in clearance holes

= 0.85 for fasteners in oversized & short slotted holes and for fasteners in long

slotted holes loaded perpendicular to the slot

=0.7 for fasteners in long slotted holes loaded parallel to the slot

mf = 1.10 (if slip resistance is designed at service load)

= 1.25 (if slip resistance is designed at ultimate load)

Fo = minimum bolt tension (proof load) at installation (= Anb fo)

Anb = net area of bolt at threads

fo = proof stress = 0.70 fub

fub = ultimate tensile stress of bolt

b) Bearing strength of HSFG bolts: HSFG bolts will come into bearing only after slip takes

place. So if slip is not critical and limit state method is used, bearing is to be checked at ultimate limit

state. The design bearing capacity of bolt can be determined using the same formula used for

bearing-type i.e., ordinary (or black) bolts

Vdpb = Vnpb / mb

and Vnpb = 2.5 kb d t fu

c) Tensile strength of HSFG bolts: The design tensile strength of HSFG bolt is similar to that of

bearing-type i.e., ordinary (or black) bolts and is given by

Tnf = 0.90 fub An < fyb Asb (m1 / m0)

where, fu is the ultimate tensile stress of the bolt and An is the net tensile area of the bolt and may

be taken as the area at the root of the threads. Asb is shank area of the bolt, m1 is the partial safety

factor for material resistance governed by ultimate stress = 1.25, m0 is the partial safety factor for

material resistance governed by yielding = 1.10, and fyb is the yield stress of the bolt.

As per IS 800, HSFG bolt subjected to a factored tension force Tf should satisfy

Tf Tnf / mb

where, mb = partial safety factor for material of the bolt = 1.25.

12

Connections-I: Bolted Connections

d) Combined shear and tension in HSFG bolt: The following equation should be satisfied V

V sf + T f

dsf

df

1.0

where, Vsf is applied factored shear at design load, Vdsf is design shear strength, Tf is externally

applied factored tension at design load and Tdf is design tensile strength.

Examples:

P-1: Find the efficiency of the lap joint shown in the figure. Given: M20 bolts of grade 4.6 and

Fe 410 plates are used.

Ans:

For M20 bolt of grade 4.6,

Diameter of bolt, d = 20 mm

Diameter of bolt hole, d0 = 22 mm

Ultimate strength, fub = 400 N/mm2

Partial safety factor, mb = 1.25

For Fe 410 plate

Ultimate strength, fu = 410 N/mm2

Partial safety factor, m1 = 1.25

[refer table 19 of IS 800]

[refer table 5 of IS 800]

[refer table 1 of IS 800]

[refer table 5 of IS 800]

Strength of bolts

(i) Design strength in shear

Bolts will be in single shear.

Considering shear plane at threads, nn = 1 and ns = 0

Anb = 0.78 x d2 = 0.78 x

x 202 = 245.04 mm2

Strength of a single bolt in shear

Vdsb =

f ub

3 mb

( nn Anb + ns Asb ) =

400

3 x 1.25

( 1 x 245.04 + 0 ) = 45,272 N = 45.272 kN

Design strength of joint in shear = number of bolts x Vdsb

= 6 x 45.272 = 271.632 kN

. . . . . (1)

Connections-I: Bolted Connections

13

(ii) Design strength in bearing

Vdpb = 2.5 kb d t

kb is least of

e

30

=

3 d0

3 x 22

p

0.25

3 d0

f ub

400

=

=

fu

410

a)

b)

c)

fu

mb

= 0.4545

=

60

3 x 22

0.25 = 0.6591

0.9756

d) 1.0

kb = 0.4545

Design strength of a single bolt in bearing

Vdpb = 2.5 kb d t

fu

410

= 2.5 x 0.4545 x 20 x 20 x

mb

1.25

= 149,076 N = 149.076 kN

Design strength of joint in bearing = number of bolts x Vdpb

= 6 x 149.076 = 894.456 kN . . . . .

Hence strength of bolts = lesser of (1) and (2)

= 271.632 kN

.....

(2)

(3)

Strength of plates

Net tensile strength of plate is

Tdn = 0.9

fu

m 1

An = 0.9 x

410

1.25

x (180 3 x 22) x 20

= 673,056 N = 673.056 kN

.....

(4)

Hence strength of the given bolted joint = lesser of (3) and (4)

= 271.632 kN

Strength of solid plate = 0.9

fu

A = 0.9 x

m 1

410

1.25

x (180 x 20)

= 1062,720 N = 1062.72 kN

Strength of bolted joint

Efficiency of the bolted joint =

=

strength of solid plate

271.632

1062 .720

x 100

x 100 = 25.56 %

P-2: Find the efficiency of the joint, if in the above example (P-1) instead of lap, butt joint is made

using two cover plates each of 12 mm thick and 6 numbers of bolts on each side.

Thickness of main plate is less than sum of thicknesses of cover plates. So, in this case strength

of plates and strength of bolts in bearing are same as in example P-1. However strength of bolts in

shear will be different.

Strength of bolts in shear

Bolts are in double shear. Consider one shear plane at root of threads and the other at shank of

bolt.

Asb =

x d2 =

Anb = 0.78 x

x 202 = 314.16 mm2

x d2 = 0.78 x

x 202 = 245 mm2

14

Connections-I: Bolted Connections

nn = 1

and ns = 1

Vdsb =

f ub

3 mb

( nn Anb + ns Asb ) =

= 103,306 N = 103.306 kN

400

3 x 1.25

( 1 x 245 + 1 x 314.16)

Hence design strength of bolts in shear = 6 x 103.306 = 619.836 kN . . . . . (1)

Design strength of bolts in bearing = 894.456 kN [from example P-1] . . . . . (2)

Hence design strength of bolts = lesser of (1) and (2)

= 619.836 kN

. . . . . (3)

Net tensile strength of plate = 673.056 kN [from example P-1] . . . . . (4)

Design strength of joint = lesser of (3) and (4)

= 619.836 kN

Design strength of solid plate = 1062.720 kN [from example P-1]

Efficiency =

Strength of bolted joint

strength of so lid plate

619.836

x 100 =

1062 .720

= 58.33 %

x 100

P-3: Two plates 10 mm and 18 mm thick are to be jointed by a double cover butt joint. Assuming

cover plates of 8 mm thickness, design the joint to transmit a factored load of 500 kN. Assume

Fe 410 plate and 4.6 grade of bolts.

Ans:

Assume diameter of bolt, d = 20 mm

Diameter of bolt hole, d0 = 22 mm

For Fe 410 grade of steel, fu = 410 N/mm2 and m1 = 1.25

For bolts of grade 4.6, fub = 400 N/mm2 and mb = 1.25

Thickness of plate from bearing consideration will be least of 10 mm, 18 mm and 16 mm (2 x8)

and hence t = 10 mm.

The bolts are in double shear and bearing. Since two plates to be joined are of 10 mm and 18

mm thick, packing plate of 18 10 = 8 mm thick will be required. Since thickness of packing plate

is more than 6 mm, shear strength of bolts has to be reduced by a factor pkg whose value is

pkg = 1 0.0125 x tpkg = 1 0.0125 x 8 = 0.9

Now, bolt strength in double shear per pitch length will be

Vdsb =

f ub

3 mb

( nn Anb + ns Asb ) x pkg

Considering one shear plane at root of threads and the other at shank of bolt,

Asb =

x d2 =

Anb = 0.78 x

nn = 1

and ns = 1

x 202 = 314.16 mm2

x d2 = 0.78 x

x 202 = 245 mm2

Connections-I: Bolted Connections

f ub

Vdsb =

3 mb

( nn Anb + ns Asb ) x pkg =

= 92,980 N = 92.98 kN

400

3 x 1.25

15

( 1 x 245 + 1 x 314.16) x 0.9

Since pitch of bolt is not known, the factor kp and thus bearing strength of bolt can not be

determined now. However, since in general shear controls the strength of bolts, not the bearing,

we can calculate number of bolts on the basis of strength in shear of the bolt [ in other words,

assuming strength of bolt in bearing to be more than that in shear, no of bolts can be

calculated].

So, number of bolts required =

500

92.90

= 5.38

Provide 6 bolts, 3 in a line. Since there will be 2 bolts per pitch length, strength of joint per pitch

length on the basis of shearing strength of bolts = 2 x 92.98 = 185.96 kN.

Now equating strength of bolt in shear per pitch length to the net tensile strength of plate per

pitch length, we find pitch (p) of the bolts.

Tdn = 0.9

or,

fu

(p n x d0) x t = 185.96 x 103

m 1

0.9 x

410

1.25

x (p 1 x 22) x 10 = 185.96 x 103

or,

p = 84.99 mm

Provide pitch of 80 mm > 50 mm ( = 2.5 d)

Consider end distance, e = 1.7 x d0 = 1.7 x 22 = 37.4 mm

[cl. 10.2.4.2]

Provide e = 40 mm.

kb is least of

a)

b)

c)

e

40

=

3 d0

3 x 22

p

0.25

3 d0

f ub

400

=

=

fu

410

= 0.61

=

80

3 x 22

0.9756

d) 1.0

kb = 0.61

0.25 = 0.96

Design strength of bolt in bearing per pitch length

Vdpb = 2.5 kb d t

fu

mb

= 2.5 x 0.61 x 20 x 10 x

410

1.25

= 100,040 N

= 100.04 kN > 92.98 kN

Hence there is no need to increase end distance. Provide additional two bolts of 20 mm dia on

the packing plate as shown.

NOTE: End distance causes value of kb to be the least among other values of kb. So if Vdpb comes out

to be less than Vdsb, value of e can be increased and consequently the bearing strength.

16

Connections-I: Bolted Connections

P-4: A member of a truss consists of two angles ISA 75 x 75 x 6 placed back to back. It carries an

ultimate tensile load of 150 kN and is connected to a gusset plate 8 mm thick placed in between the

two connected legs. Determine the number of 16 mm diameter 4.6 grade ordinary bolts required for

the joint. Assume fu of plate as 410 MPa.

Ans:

For M16 bolt of grade 4.6,

Diameter of bolt, d = 16 mm

Diameter of bolt hole, d0 = 18 mm

Ultimate strength, fub = 400 N/mm2

Partial safety factor, mb = 1.25

For gusset plate

Ultimate strength, fu = 410 N/mm2

Partial safety factor, m1 = 1.25

[refer table 19 of IS 800]

[refer table 5 of IS 800]

[refer table 1 of IS 800]

[refer table 5 of IS 800]

Strength of bolts

(i) strength of bolt in shear

Bolts are in double shear. Consider one shear plane at root of threads and the other at shank of

bolt.

Asb =

x d2 =

Anb = 0.78 x

= 0.78 x

x 162 = 201.06 mm2

x d2

x 162 = 156.83 mm2

nn = 1

and ns = 1

Vdsb =

f ub

3 mb

( nn Anb + ns Asb )

400

3 x 1.25

( 1 x 156.83 + 1 x 201.06)

= 66,121 N = 66.121 kN

(ii) strength of bolt in bearing

Assume pitch, p = 2.5 d = 2.5 x 16 = 40 mm

[cl. no. 10.2.2]

end distance, e = 1.5 d0 = 1.5 x 18 = 27 mm

[ cl. no. 10.2.4.2]

30 mm

Thickness of plate from bearing consideration will be minimum of 8 mm and 2 x 6 = 12 mm.

So t = 8 mm.

kb is least of

a)

b)

c)

30

=

3 0

3 18

p

0.25

3 d0

f ub

400

=

=

fu

410

d) 1.0

kb = 0.49

= 0.56

=

40

3 x 18

0.9756

0.25 = 0.49

Connections-I: Bolted Connections

17

Design strength of bolt in bearing per pitch length

Vdpb = 2.5 kb d t

fu

mb

= 2.5 x 0.49 x 16 x 8 x

410

1.25

= 51,430 N = 51.43 kN

Hence strength of bolt = minimum of strength in shear and in bearing = 51.43 kN

No of bolts required = 150 / 51.43 = 2.92

So provide 3 nos of bolts as shown in the fig.

NOTE: Also study Example 5.8, page 203 of SK Duggal or Example 5.13, page 405 of

N Subramanian.

P-5: Design a single bolted double cover butt joint to connect boiler plates of thickness 12 mm for

maximum efficiency. Use M16 bolts of grade 4.6. Boiler plates are of Fe 410 grade. Also find the

efficiency of the joint.

Ans:

Strength of bolts

Design strength in shear

d = 16 mm

d0 = 18 mm

Asb =

d2 =

Anb = 0.78 x

x

4

2

d

4

162 = 201.06 mm2

= 0.78 x

x 182 = 156.83 mm2

Bolts will be in double shear. Considering one shear plane at threads and the other at shank,

nn = 1 and ns = 1

Strength of a single bolt in shear

Vdsb =

f ub

3 mb

( nn Anb + ns Asb ) =

400

3 x 1.25

( 1 x 156.83 + 1 x 201.06 )

= 66,121 N = 66.121 kN

Assuming strength of bolts in bearing will be more than strength of bolts in shear,

Design strength of bolts per pitch length = 66.121 kN

For maximum efficiency of the joint, net tensile strength of the plate per pitch length must be

equal to strength of bolts per pitch length.

Thickness of cover plates = t = x 12 = 7.5 mm

Provide 2 cover plates of 8 mm thick.

Then sum of thicknesses of cover plates (2 x 8 =16 mm) > thickness of plate (=12 mm). Hence

O.K.

Net tensile strength of plate per pitch length is

Tdn = 0.9

fu

m 1

An = 0.9 x

410

1.25

1.25

x (p 1 x 18) x 12

where p = pitch of bolts

Equating it with strength of bolts,

0.9 x

410

x (p 1 x 18) x 12 = 66.121 x 103

or, p = 36.67 mm

Provide pitch of 40 mm 2 d (2.5 x 16 = 40 mm)

Now, we have to check the strength of bolts in bearing.

Let e = 30 mm ( > 1.5 d0 = 1.5 x 18 = 27 mm)

18

Connections-I: Bolted Connections

kb is least of

a)

c)

e

3 d0

f ub

fu

=

=

3040

3 x 18

400

410

= 0.5556

b)

= 0.9756

kb = 0.4907

p

3 d0

0.25 =

d) 1.0

40

3 x 18

0.25 = 0.4907

Design strength of bolt in bearing per pitch length

Vdpb = 2.5 kb d t

fu

410

= 2.5 x 0.4907 x 16 x 12 x

mb

1.25

= 77,256 N

= 77.256 kN > 66.121 kN

Hence our assumption of bearing strength is more than shear strength is ok and so there is no

need to revise the design.

Draw the sketch of connection.

Now, we shall check the efficiency of the joint.

Design strength of solid plate per pitch length = 0.9

= 141,696 N = 141.696 kN

Efficiency of the bolted joint =

fu

m 1

A = 0.9 x

Strength of bolted joint per pitch length

strength of solid plate per pitch length

66.121

141.696

410

1.25

x (40 x 12)

x 100

x 100 = 46.66 %

P-6: An ISA 100 x 100 x 10 mm carries a factored tensile force of 100 kN. It is to be jointed with a

12 mm thick gusset plate. Design a high strength bolted joint when (a) no slip is permitted, (b) when

slip is permitted. Steel of grade Fe 410.

Ans:

Let us provide HSFG bolts of grade 8.8S and diameter 16 mm.

2

For 8.8S grade bolts: fub = 800 N/mm

Anb = 0.78 x x 162 = 157 mm2

For Fe 410 grade of steel: fu = 410 N/mm2

When slip is not permitted, the joint will be a slip-critical connection and when the sections

jointed are allowed to slip, the joint will be a bearing-type connection.

(a) Slip-critical connection:

Proof load (i.e. minimum bolt tension at installation) = Anb x 0.7 fub = 157 x 0.7 x 800 x 10-3

= 87.9 kN

Slip resistance or design shear capacity of bolt, Vdsf = f ne Kh Fo/mf

Here,

f = 0.5 (assuming)

ne = number of effective interfaces offering frictional resistance to slip = 1

mf = 1.25 at ultimate load

kh = 1.0 (assuming bolt in clearance holes)

Slip resistance of bolt = 0.5 x 1 x 1 x

Number of bolts required =

100

35.16

87.9

1.25

= 35.16 kN

= 2.84 3

So, provide 3 nos 16 mm diameter 8.8S grade HSFG bolts.

Connections-I: Bolted Connections

19

(b) Bearing-type connection

Strength of bolt in single shear, assuming shear plane in threaded area (nn = 1, ns = 0)

Vdsb =

f ub

3 mb

( nn Anb + ns Asb ) =

Strength of bolt in bearing,

Vdpb = 2.5 kb d t

fu

mb

400

3 x 1.25

= 2.5 x 1 x 16 x 10 x

Hence strength of bolt = 58 kN

Number of bolts required =

100

58

x 1 x 157 x 10-3 = 58 kN

410

1.25

x 10-3 = 131.2 kN [assuming kb = 1]

= 1.72 2

Provide 2 nos 16 mm diameter HSFG bolts of grade 8.8S.

P-7: The connection shown in the figure uses 20 mm dia

10.9S grade bolts with threads in the shear plane to

connect an ISF 150 x 12 mm with gusset plate. Determine

the strength of the joint, if

(a) Slip is not permitted

(b) Slip is permitted.

Block shear strength of the joint need not be considered.

Ans:

For Fe 410 grade of steel: fu = 410 N/mm2

For 10.9S grade bolts:

2

fub = 1040 N/mm

Anb = 0.78 x x 202 = 245 mm2

(a) Slip-critical connection (slip is not permitted)

Proof load = F0 = Anb x 0.7 fub = 245 x 0.7 x 1040 x 10-3 = 178.36 kN

Slip resistance of bolt, Vdsf = f ne Kh Fo/mf

Assuming, f = 0.5, Kh = 1, n = 1 & mf = 1.25 (at ultimate load)

Slip resistance of bolt = 0.5 x 1 x 1 x 178.36/1.25 = 71.34 kN

Hence, strength of connection = no of bolts x slip resistance = 4 x 71.34 = 285.36 kN

(b) Bearing-type connection (slip is permitted)

Strength of bolt in single shear (nn =1, ns = 0),

Vdsb =

f ub

3 mb

( nn Anb + ns Asb ) =

Strength of bolt in bearing,

Vdpb = 2.5 kb d t

fu

mb

1040

3 x 1.25

= 2.5 x 1 x 20 x 12 x

x 1 x 245 x 10-3 = 117.68 kN

410

1.25

x 10-3 = 196.8 kN [assuming kb = 1]

So, strength of bolts = 117.68 kN [minimum of strength of bolt in shear and bearing]

Hence, strength of connection = no of bolts x strength of bolt = 4 x 117.68 = 470.72 kN.

Prying Forces

In the design of HSFG bolts subjected to tensile forces, an additional force, called prying force is

to be considered. This additional force is mainly due to flexibility of connected plates. Consider the

connection of a T-section to a plate as shown in the Fig 12, subjected to tensile force 2Te. As tensile

force acts, the flange of T-section bends in the middle portion and presses connecting plate near

20

Connections-I: Bolted Connections

bolts. It gives rise to additional contact forces known as prying forces. IS 800 2007 has given the

following expression for the prying force Q (cl. no. 10.4.7 of code) -

Q =

lv

2l e

Te

f0 b e t4

27 l e l v 2

....

(1)

where, lv = distance from the bolt centerline to the toe of fillet weld or to half the root radius

for a rolled section

le = distance between prying force and bolt centerline and is minimum of either end

distance or the value given by

f0

le = 1.1 t f

= 2 for non pre-tensioned bolt and 1 for pre-tensioned bolt

= 1.5

be = effective width of flange per pair of bolts

f0 = proof stress

t = thickness of end plate.

Fig 12 Prying action

Neglecting second term of eqn (1), which is relatively small, we get

Q =

T e lv

2 le

The thickness of end plate to avoid yielding of plate is obtained by equating the moment in the

plate at bolt centre and at a distance lv from it to the plastic moment capacity of plate Mp. Thus, we

get

MA = Q le and MC = Te lv - Q le

MA = MC = Te lv / 2 = Mp

2

Taking Mp = (fy/1.1) (be t /4), the minimum thickness of end plate is obtained as

tmin = 4.4 Mp /fy be

P-8: Design a hanger joint as shown to carry a factored load of 300 kN. Use an end plate of size 250

mm x 150 mm and appropriate thickness, M24 HSFG bolts (2 nos) and Fe 410 steel for end plate (fy =

250 MPa).

Ans:

We shall consider grade of HSFG bolt as 8.8

[Note: grade of 8.8 is commonly used]

Connections-I: Bolted Connections

21

For Fe 410 grade of steel fu = 410 N/mm2, fy = 250 N/mm2

2

fub = 800 N/mm

For bolt of grade 8.8,

2

2

For 24 mm diameter bolt, Asb = /4 x 24 = 452 mm ,

Anb = 0.78 x /4 x 242 = 353 mm2

do = 30 + 3 = 33 mm

2

2

Proof stress, fo = 0.7 fub = 0.7 x 800 = 560 N/mm = 0 .56 kN/mm

For pre-tensioned bolt, = 1

Assuming an 8-mm fillet weld between hanger

and end plate and an end distance of 40 mm, the

distance from centre line of bolt to the toe of the

fillet weld is

lv = (250/2) 10 8 40 = 67 mm

For minimum thickness,

Mp = Telv / 2 = (300/2) x 67/2

= 5025 kNmm

and

tmin = 4.4 Mp /fy be

= [(4.4 x 5025 x 103 )/(250 x 150)] = 24.28 mm 25 mm

f0

= 1.1 x 25 x

lv

2l e

Te

le = 1.1 t

f

1 x 560

250

= 41.158 mm

le is lesser of 41.158 mm and 40 mm (end distance). So le = 40 mm

Prying force, Q =

f0 be t4

27 l e l v 2

67

2 x 40

1 x 1.5 x 0.56 x 150 x 25 4

27 x 40 x 67 2

150

Total load on bolt = Te + Q = 150 + 117 = 267 kN

Tension capacity of bolt, Tdb = Tnb / mb

= 117 kN

-3

Tnb = 0.9 Anb fub = 0.9 x 353 x 800 x 10 = 254 kN

-3

Asb fyb mb / m0 = 452 x 640 x 1.25 / 1.10 x 10

= 329 kN

Hence, Tdb = 254 / 1.25 = 203 kN < 267 kN. So, it is unsafe.

To reduce prying force, let us provide a thicker plate.

Assume 45 mm thick plate.

Tensile force in bolt = 150 kN

Tension capacity of bolt = 203 kN

So, prying force that can be allowed = 203 150 = 53 kN

Moment at toe of weld = Te lv Q le = 150 x 67 - 53 x 40 = 7930 kNmm

Moment capacity =

So, ok.

Prying force, Q =

fy

1.1

lv

2l e

Hence design is O.K.

be t2

4

Te

250

1.1

150 x 45 2

4

f0 be t4

27 l e l v

67

x 10-3 = 17,258 kNmm > 7930 kNmm

= 2 x 40 150

1 x 1.5 x 0.56 x 150 x 45 4

27 x 40 x 67 2

* * * * *

= 36.37 kN < 53 kN

Anda mungkin juga menyukai

- Anchor Bolt DesignDokumen60 halamanAnchor Bolt DesignS.s. LeeBelum ada peringkat

- Stiffened Seat ConnectionDokumen4 halamanStiffened Seat ConnectionUttam Kumar Ghosh0% (1)

- BCN 3224 - Exam 3 ReviewDokumen34 halamanBCN 3224 - Exam 3 Reviewmgwin17Belum ada peringkat

- Stiffner Design For Beam Column ConnectionsDokumen84 halamanStiffner Design For Beam Column ConnectionsfabnameBelum ada peringkat

- Design Slip-Critical Steel ConnectionDokumen9 halamanDesign Slip-Critical Steel ConnectionKUROBelum ada peringkat

- 1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualDokumen3 halaman1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualBobbi Jo Bach-Oachs50% (2)

- Anchor Bolt Base PlateDokumen51 halamanAnchor Bolt Base Platedeepak394Belum ada peringkat

- Chapter 2 Bolted ConnectionsDokumen29 halamanChapter 2 Bolted ConnectionsKishan Purohit100% (1)

- Moment Resisting Connections - SteelconstructionDokumen13 halamanMoment Resisting Connections - SteelconstructionAniket Dube100% (2)

- Bolted Beam Column ConnectionsDokumen16 halamanBolted Beam Column Connectionslael00Belum ada peringkat

- Beam To Beam ConnectionsDokumen9 halamanBeam To Beam ConnectionskarthiksampBelum ada peringkat

- Chapter 4 SteelDokumen52 halamanChapter 4 SteelHtet Myat AungBelum ada peringkat

- Factors Designing Structural Joint ConnectionsDokumen23 halamanFactors Designing Structural Joint ConnectionsCharlton CabagingBelum ada peringkat

- Design a 3m Jib Crane to Lift 5000NDokumen25 halamanDesign a 3m Jib Crane to Lift 5000NMuhammad Fadzil100% (1)

- Friction Type Connections FullDokumen64 halamanFriction Type Connections FullmohammedBelum ada peringkat

- Joints in Steel Construction - Simple Connections - Part 17 PDFDokumen22 halamanJoints in Steel Construction - Simple Connections - Part 17 PDFkakem61Belum ada peringkat

- Project Title: TBA: Client: ContractorDokumen4 halamanProject Title: TBA: Client: ContractorIzza Halim100% (2)

- Soil Exploration Methods & TechniquesDokumen6 halamanSoil Exploration Methods & TechniquesA.k.MandalBelum ada peringkat

- Soil Exploration Methods & TechniquesDokumen6 halamanSoil Exploration Methods & TechniquesA.k.MandalBelum ada peringkat

- Design of Fillet and Butt WeldsDokumen29 halamanDesign of Fillet and Butt WeldsDarsHan MoHanBelum ada peringkat

- Bolted Connections GuideDokumen21 halamanBolted Connections GuideA.k.MandalBelum ada peringkat

- Bolted Connections GuideDokumen21 halamanBolted Connections GuideA.k.MandalBelum ada peringkat

- Bolted Connections (Prying Force)Dokumen16 halamanBolted Connections (Prying Force)Ivan Hadzi BoskovicBelum ada peringkat

- Structural Steel Design Project: Calculation SheetDokumen14 halamanStructural Steel Design Project: Calculation SheetJoey Johnson100% (2)

- CIVDES2 Lecture Notes - 13 Bolted ConnectionDokumen26 halamanCIVDES2 Lecture Notes - 13 Bolted ConnectionVivian RositaBelum ada peringkat

- Fillet Weld DesignDokumen2 halamanFillet Weld Designsaj0205037Belum ada peringkat

- Absolute-Pressure Sensors: Micromechanics, Hybrid DesignDokumen3 halamanAbsolute-Pressure Sensors: Micromechanics, Hybrid Designc20get100% (2)

- Bolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryDokumen1 halamanBolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña VelasquezBelum ada peringkat

- Column SpliceDokumen2 halamanColumn SpliceMdShahbazAhmedBelum ada peringkat

- Design of Bolted Steel ConnectionsDokumen24 halamanDesign of Bolted Steel ConnectionsDjordjeDj100% (1)

- COLUMN EFFECTIVE LENGTH - Yura1971q2Dokumen6 halamanCOLUMN EFFECTIVE LENGTH - Yura1971q2ellisbl100% (1)

- Bolts TheoryDokumen30 halamanBolts TheoryIbrahim Mesfin100% (1)

- Design of Bolted Connections in Steel StructuresDokumen4 halamanDesign of Bolted Connections in Steel StructuresHarish T S Gowda0% (1)

- Simple Steel ConnectionsDokumen7 halamanSimple Steel ConnectionsShams Abbas NaqviBelum ada peringkat

- WF To HSS Moment Connections R1 - FINAL PDFDokumen7 halamanWF To HSS Moment Connections R1 - FINAL PDFrene_angel1Belum ada peringkat

- Ly and LZ Concept DiscussedDokumen2 halamanLy and LZ Concept DiscussedalayshahBelum ada peringkat

- Bolted Connections For Steel StructuresDokumen11 halamanBolted Connections For Steel Structuresramu karriBelum ada peringkat

- Chapter - 7 Part II STDDokumen43 halamanChapter - 7 Part II STDBelkacem AchourBelum ada peringkat

- Bolted Joints:: Lecture Notes: CRB/CIV/MSECDokumen7 halamanBolted Joints:: Lecture Notes: CRB/CIV/MSECrameshbabu_1979Belum ada peringkat

- DESIGN OF INTERMEDIATE SPAN SIDE GIRTDokumen2 halamanDESIGN OF INTERMEDIATE SPAN SIDE GIRTSantosh BapuBelum ada peringkat

- Bolted ConnectionsDokumen3 halamanBolted ConnectionsandreiroscaBelum ada peringkat

- Design Bolted & Welded Connections Baja 1Dokumen115 halamanDesign Bolted & Welded Connections Baja 1furqan yunarBelum ada peringkat

- Connecting: Making Connections With HSS Members Is Easier Than You Might Think!Dokumen4 halamanConnecting: Making Connections With HSS Members Is Easier Than You Might Think!PauloAndresSepulvedaBelum ada peringkat

- Bolted connection design principlesDokumen47 halamanBolted connection design principlesayush kumarBelum ada peringkat

- Design of Steel Bolted ConnectionsDokumen34 halamanDesign of Steel Bolted ConnectionsManjunath Tontanal0% (1)

- Riveted/Bolted Connections TypesDokumen9 halamanRiveted/Bolted Connections TypesAeron Xavier PimentelBelum ada peringkat

- Bolted ConnectionDokumen35 halamanBolted ConnectionAnonymous MxoHi8Belum ada peringkat

- Connections-Bolted 1Dokumen46 halamanConnections-Bolted 1sachin.meenaBelum ada peringkat

- Steel Cap Plate Connections DesignDokumen18 halamanSteel Cap Plate Connections DesignVinoth KumarBelum ada peringkat

- Design of Steel Structure - Connection DesignDokumen33 halamanDesign of Steel Structure - Connection DesignshingkeongBelum ada peringkat

- Directly Welded Flange FR Moment ConnectionsDokumen1 halamanDirectly Welded Flange FR Moment ConnectionssuperpiojooBelum ada peringkat

- Column SpliceDokumen6 halamanColumn SplicedudoodooBelum ada peringkat

- Machine Design AssignmentDokumen9 halamanMachine Design AssignmentMuhammad Fahad Khan 51-FET/BSCMET/F19Belum ada peringkat

- Connections I V2.1.0.a1Dokumen49 halamanConnections I V2.1.0.a1gissel vicencioBelum ada peringkat

- IS 800-2007 Provisions SummaryDokumen30 halamanIS 800-2007 Provisions SummarySachin MeenaBelum ada peringkat

- Beam Beam Connection DesignDokumen2 halamanBeam Beam Connection Designsrk bhaiBelum ada peringkat

- Connection DesignDokumen33 halamanConnection DesignSri KalyanBelum ada peringkat

- Steel ColumnDokumen33 halamanSteel Columnelect aksBelum ada peringkat

- Tension MemberDokumen58 halamanTension MemberD SRINIVASBelum ada peringkat

- Bolted ConnectionsDokumen23 halamanBolted ConnectionsNaresh ReddyBelum ada peringkat

- Design of Steel StructureDokumen16 halamanDesign of Steel Structuresuraj kumarBelum ada peringkat

- Steel Connections: Research in Building Tech 3Dokumen10 halamanSteel Connections: Research in Building Tech 3Angelica Marie AzucenaBelum ada peringkat

- Bolted Beam Splice: (A) Conventional SpliceDokumen11 halamanBolted Beam Splice: (A) Conventional SpliceKimberly Binay-anBelum ada peringkat

- Course Name: CE 3130: Steel Structures DesignDokumen25 halamanCourse Name: CE 3130: Steel Structures Designcarlomonsalve1Belum ada peringkat

- Modulo 4 CM 19 09 2020Dokumen25 halamanModulo 4 CM 19 09 2020carlomonsalve1Belum ada peringkat

- Joining Steel MembersDokumen1 halamanJoining Steel MemberstierradiegoyahooesBelum ada peringkat

- Course Content A) Bolted ConnectionsDokumen18 halamanCourse Content A) Bolted Connectionsram894uBelum ada peringkat

- iB-WRA150N2 - User Manual PDFDokumen85 halamaniB-WRA150N2 - User Manual PDFA.k.MandalBelum ada peringkat

- Net Area in Staggered ArrangementDokumen2 halamanNet Area in Staggered ArrangementA.k.MandalBelum ada peringkat

- Stability of ColumnsDokumen10 halamanStability of ColumnsA.k.MandalBelum ada peringkat

- Deflection of BeamDokumen3 halamanDeflection of BeamA.k.MandalBelum ada peringkat

- Interest Calculation On Fixed DepositDokumen2 halamanInterest Calculation On Fixed DepositA.k.MandalBelum ada peringkat

- ExpNo 5 - Grain Size Distribution by SievingDokumen2 halamanExpNo 5 - Grain Size Distribution by SievingA.k.MandalBelum ada peringkat

- ExpNo 6 - Insitu Density by Sand ReplacementrDokumen3 halamanExpNo 6 - Insitu Density by Sand ReplacementrA.k.MandalBelum ada peringkat

- Prescolite Akt4 WH Specsheet 13Dokumen2 halamanPrescolite Akt4 WH Specsheet 13James HohensteinBelum ada peringkat

- Mine Design and SchedulingDokumen10 halamanMine Design and SchedulingLeandro FagundesBelum ada peringkat

- Database transactions, recovery, and concurrencyDokumen30 halamanDatabase transactions, recovery, and concurrencyIvan Jan AvigueteroBelum ada peringkat

- A Review of Heat Transfer Enhancement Using Twisted Tape With and Without PerforationDokumen9 halamanA Review of Heat Transfer Enhancement Using Twisted Tape With and Without PerforationIJIERT-International Journal of Innovations in Engineering Research and TechnologyBelum ada peringkat

- INNOVATIVE TRENDS - FLYER-converted-mergedDokumen6 halamanINNOVATIVE TRENDS - FLYER-converted-mergedPandimadevi MBelum ada peringkat

- BCE-Practical SyllabusDokumen2 halamanBCE-Practical SyllabusGovind TivadiBelum ada peringkat

- Robotics Answer KeyDokumen4 halamanRobotics Answer KeyChad ValenciaBelum ada peringkat

- NCP1117, NCV1117Dokumen17 halamanNCP1117, NCV1117kalimbaloBelum ada peringkat

- 9.1 LoLog LL VistaDokumen2 halaman9.1 LoLog LL VistaMais OmarBelum ada peringkat

- Heat Exchangers: T T T TDokumen11 halamanHeat Exchangers: T T T Tcjc0706Belum ada peringkat

- 11 Iso 10110Dokumen28 halaman11 Iso 10110fmeylanBelum ada peringkat

- Sangshad BhabanDokumen21 halamanSangshad Bhabanuniqueboy6050% (2)

- Hydraulic: Centrifugal Pump Application Performance CurvesDokumen1 halamanHydraulic: Centrifugal Pump Application Performance CurvesEdwin ChavezBelum ada peringkat

- Commsys 2 2012 4Dokumen47 halamanCommsys 2 2012 4AnuBelum ada peringkat

- Customer service records for auto repairsDokumen30 halamanCustomer service records for auto repairsAsad LaghariBelum ada peringkat

- Net Positive Suction HeadDokumen4 halamanNet Positive Suction Headjorge alarconBelum ada peringkat

- Cutting Guide: Integrated Seat Post (ISP)Dokumen4 halamanCutting Guide: Integrated Seat Post (ISP)Anand sBelum ada peringkat

- 7216Dokumen8 halaman7216siicmorelosBelum ada peringkat

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutDokumen7 halaman9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- PMOS RunsheetDokumen3 halamanPMOS Runsheetkrishna_singhalBelum ada peringkat

- Nylatron GSM Technical Data SheetDokumen1 halamanNylatron GSM Technical Data SheetgovindsrBelum ada peringkat

- Supports For Pipelines 1758uk 7-03-15 PDFDokumen46 halamanSupports For Pipelines 1758uk 7-03-15 PDFAndor MolitoriszBelum ada peringkat

- Consolidation: Photocopiable © University of Dayton Publishing, 2012Dokumen3 halamanConsolidation: Photocopiable © University of Dayton Publishing, 2012borboleta_sBelum ada peringkat

- List of FEM Documents 2012Dokumen5 halamanList of FEM Documents 2012Gustavo AquinoBelum ada peringkat

- Tsi 20040109 PDFDokumen2 halamanTsi 20040109 PDFenache_marian0% (1)

- Farris 2700 ManualDokumen12 halamanFarris 2700 ManualNelson AlvarezBelum ada peringkat