One-Way Joist Part 1

Diunggah oleh

Humberto EstevezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

One-Way Joist Part 1

Diunggah oleh

Humberto EstevezHak Cipta:

Format Tersedia

ONE-WAY CONCRETE JOIST

CONSTRUCTION: STEEL LAP PAN

FORMING SYSTEM

A SERVICE OF THE CONCRETE REINFORCING STEEL INSTITUTE

CRSI

ENGINEERING

DATA REPORT

NUMBER 43

933 N. Plum Grove Rd., Schaumburg, Illinois 60173-4758

INTRODUCTION

This type of construction has frequently utilized

ready-made steel pan forms of standard sizes.

Depths and spacings for one-way concrete joist

construction were standardized in 1932 by the U.S.

Department of Commerce on the basis of an industry

study by a committee of Architects/Engineers,

Contractors and Steel Form Suppliers. That early

standard has since been replaced by ANSI/CRSI

A48.11986 Forms for One-Way Joist Construction,

which establishes standard dimensions for one-way

joist forms. Standard form widths are 20, 30, 40*, 53*

and 66* inches, corresponding to structural modules

ranging from 2 to 6 feet. Standard depths are 8, 10,

12, 14, 16, 18, 20, 22* and 24* inches. Not all depths

are manufactured in each form width. Filler forms

and tapered endforms are usually available locally to

fit varying floor layouts and sizes. This type of

construction is well established with a long record of

successful use.

Joist construction was developed to reduce dead

weight and reinforcement. As desired spans

increase, the efficiency of solid slab construction is

rapidly offset by the increase in the dead load. Joist

construction enables the Architect/Engineer to

provide the depth required for adequate stiffness and

efficient utilization of the reinforcement without

excessively high dead load/live load ratios. Standard

size reusable forms make it possible to eliminate

unnecessary dead weight with overall economy.

Longer spans or relatively heavy loads can be

accommodated by using tapered end forms which

permit widening of the ribs in areas of high shear.

DESCRIPTION

One-way concrete joist construction provides a

monolithic combination of regularly-spaced joists

(ribs) and a thin slab of concrete cast in place to form

an integral unit with the supporting beams, columns

and walls. In one-way concrete joist construction, the

joists are arranged in one direction between parallel

supports. Joist rib widths vary from 4 to 6 inches.

Standard endforms consist of square endforms. A

tapered endform for a 2-foot module tapers from 20

to 16 inches wide in a distance of 36 inches. A

tapered endform for a 3-foot module tapers from 30

*

For wide-module joists only.

1 inch = 25.4 millimeters

Copyright 1998 by the Concrete Reinforcing Steel Institute

to 25 inches (in some systems 26 inches) wide in a

distance of 36 inches. See Figure 1.

Figure 1

Tapered Endforms

Wide-module joist systems (also referred to as

skip-joist systems) are defined as joist systems with

a clear spacing between the ribs of more than 30

inches. Since this module, for application of the ACI

Building Code, exceeds the rib spacing limit for

standard joist construction (Section 8.11.3), widemodule joists become repetitive T beams and are

subject to design requirements for such members.

Joist widths for wide-module joist systems vary

from 6 to 8 inches. Standard forms for void spaces

between ribs are 40, 53 or 66 inches wide and 12,

14, 16, 18, 20, 22 or 24 inches deep. Standard

endforms consist of square endforms. Use of square

end joist forms simplifies forming. Tapered endforms

are generally not available for wide-module systems.

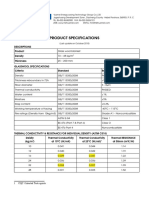

See Table 1.

FORMWORK SELECTION

CONSIDERATIONS

Maximum overall economy in concrete joist

construction, as in any cast-in-place reinforced

concrete design, is achieved by considering the

relatively high cost of formwork and construction

time versus material costs. Almost invariably overall

economy is achieved by the maximum reuse of the

same forms throughout the project, not only

throughout each floor but also the same layout and

size of forms for all levels of the structure.

The use of the lap-type steel one-way pan system

is probably one of the most efficient methods of

Anda mungkin juga menyukai

- Design of Steel-Concrete Composite Structures Using High-Strength MaterialsDari EverandDesign of Steel-Concrete Composite Structures Using High-Strength MaterialsBelum ada peringkat

- CORUS Composite Steel Highway BridgesDokumen28 halamanCORUS Composite Steel Highway BridgessuvraBelum ada peringkat

- How to Build a Global Model Earthship Operation II: Concrete WorkDari EverandHow to Build a Global Model Earthship Operation II: Concrete WorkBelum ada peringkat

- Reinforced Concrete Buildings: Behavior and DesignDari EverandReinforced Concrete Buildings: Behavior and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDari EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyBelum ada peringkat

- ASME B 31.3 2016 Process PipingDokumen30 halamanASME B 31.3 2016 Process Pipingr.devendran25% (4)

- One-Way Concrete Joist Construction: Steel Lap Pan Forming SystemDokumen4 halamanOne-Way Concrete Joist Construction: Steel Lap Pan Forming SystemEric NolascoBelum ada peringkat

- Prednapete Ploce PDFDokumen6 halamanPrednapete Ploce PDFIvan KelamBelum ada peringkat

- PCA - CI-Economical-Concrete-Formwork PDFDokumen4 halamanPCA - CI-Economical-Concrete-Formwork PDFMIKHA2014Belum ada peringkat

- Chapter 10-2 Analysis and Design of One-Way SlabsDokumen10 halamanChapter 10-2 Analysis and Design of One-Way Slabssajjad.ghazai2001Belum ada peringkat

- Structure Term Paper (17122057)Dokumen12 halamanStructure Term Paper (17122057)YELAGONDA SNEHABelum ada peringkat

- Parametric Studies of Voided R.C.C. Slab For Different Forms of CutoutsDokumen6 halamanParametric Studies of Voided R.C.C. Slab For Different Forms of CutoutsTJPRC PublicationsBelum ada peringkat

- Composite Steel Bridges - CorusDokumen28 halamanComposite Steel Bridges - CorusRui OliveiraBelum ada peringkat

- Pranay Kumar Tode Pktode@yahoo - Co.inDokumen44 halamanPranay Kumar Tode Pktode@yahoo - Co.inKhabib IbragimovBelum ada peringkat

- Different Floor SystemsDokumen25 halamanDifferent Floor Systemsfoush bashaBelum ada peringkat

- Brick Force Engineers Guide 2008Dokumen28 halamanBrick Force Engineers Guide 2008prashmb6084Belum ada peringkat

- Bridge Chapter 03Dokumen23 halamanBridge Chapter 03Cynthiya MargaretBelum ada peringkat

- Economic Long Span Concrete Floors, Bca, Uk, 1995. 50p.Dokumen50 halamanEconomic Long Span Concrete Floors, Bca, Uk, 1995. 50p.MANUEL ARTURO FIGUEROA LEONBelum ada peringkat

- Trusses English PDFDokumen12 halamanTrusses English PDFPrakash SharmaBelum ada peringkat

- 2009 ACIStructJ LubellBentzCollins SpacingDokumen10 halaman2009 ACIStructJ LubellBentzCollins SpacingrohitBelum ada peringkat

- Pranay Kumar Tode Pktode@yahoo - Co.i NDokumen44 halamanPranay Kumar Tode Pktode@yahoo - Co.i NToyeeb ArowonaBelum ada peringkat

- Precast, Prestressed Concrete Structural ElementsDokumen3 halamanPrecast, Prestressed Concrete Structural ElementsManuel Alberto PeñarandaBelum ada peringkat

- 265 Reinforced Concrete Box and Three-Sided Culverts: 265.1 GeneralDokumen14 halaman265 Reinforced Concrete Box and Three-Sided Culverts: 265.1 GeneralNatiBelum ada peringkat

- Practical Shear Reinforcement For Concrete Flat Slabs - tcm45-341902Dokumen2 halamanPractical Shear Reinforcement For Concrete Flat Slabs - tcm45-341902Deana WhiteBelum ada peringkat

- Tek 02-01BDokumen7 halamanTek 02-01BRaquelBelum ada peringkat

- Long Span Beams 2Dokumen14 halamanLong Span Beams 2ashBelum ada peringkat

- The Design Process Encompasses The Architectural Design PDFDokumen11 halamanThe Design Process Encompasses The Architectural Design PDFAlbert LuckyBelum ada peringkat

- Centering and FormworkDokumen50 halamanCentering and FormworkSakshi RawatBelum ada peringkat

- One Way Wide Module Joist SlabDokumen17 halamanOne Way Wide Module Joist SlabMa.Rinelle Pante100% (1)

- 22) Composite Beams - IIDokumen47 halaman22) Composite Beams - IIPrabhumk07100% (2)

- CRSI Notes PDFDokumen8 halamanCRSI Notes PDFRajha RajeswaranBelum ada peringkat

- Plate Dowels: An Innovation Driven by Industrial Concrete PavingDokumen6 halamanPlate Dowels: An Innovation Driven by Industrial Concrete PavingRizaam Nafiz100% (1)

- Technical Aid 1 Shelf Angle and Brick Ledge Design Rev 4Dokumen18 halamanTechnical Aid 1 Shelf Angle and Brick Ledge Design Rev 4cd dBelum ada peringkat

- Long Span StructuresDokumen27 halamanLong Span Structuressurya kiranBelum ada peringkat

- Construction Joints: 1:3 SlopeDokumen13 halamanConstruction Joints: 1:3 Slopecharles_hutabarat_2007Belum ada peringkat

- Design For Economic Reinforced Concrete StructureDokumen5 halamanDesign For Economic Reinforced Concrete StructureCarlos AquinoBelum ada peringkat

- Construction JointsDokumen4 halamanConstruction JointsAvelino De Leon Jr100% (1)

- Let It Crack - tcm45-343570Dokumen2 halamanLet It Crack - tcm45-343570Anonymous K7JMmMwBelum ada peringkat

- 98 Tips: For DesigningDokumen6 halaman98 Tips: For DesigningKarthikeyan KrishBelum ada peringkat

- Mini ProjectDokumen14 halamanMini ProjectMr. Himanshu111100% (1)

- Design and Construction FailuresDokumen23 halamanDesign and Construction Failuresgokulnath.asoorBelum ada peringkat

- Flat SlabDokumen38 halamanFlat SlabRicky Gunawan100% (1)

- Stud RailsDokumen3 halamanStud RailsBruno PilieciBelum ada peringkat

- Form Scaffolding and StagingDokumen27 halamanForm Scaffolding and Stagingincrediblesmile1234Belum ada peringkat

- Bce413d (1644) - Activity Week - VenusDokumen25 halamanBce413d (1644) - Activity Week - VenusDIOSAN DAVE VENUSBelum ada peringkat

- Sarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresDokumen17 halamanSarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresMais Maher AldwaikBelum ada peringkat

- AASHTO Section 5 ManualDokumen136 halamanAASHTO Section 5 ManualChristine HermawanBelum ada peringkat

- Long-Span, Open-Web TrussesDokumen8 halamanLong-Span, Open-Web Trussesmina saadatBelum ada peringkat

- Steel MembersDokumen6 halamanSteel Membersalinaitwe shalifuBelum ada peringkat

- Effect of Column Spacing On Economy of G+5 R.C Moment Resisting Frame - A Typical Computer Aided Case StudyDokumen18 halamanEffect of Column Spacing On Economy of G+5 R.C Moment Resisting Frame - A Typical Computer Aided Case StudyHarsh ShahBelum ada peringkat

- The Filigree Method Chapter 4Dokumen13 halamanThe Filigree Method Chapter 4lidetechristoszinabuBelum ada peringkat

- ConstructionDokumen2 halamanConstructionJohn MatzBelum ada peringkat

- Manual ViewerDokumen4 halamanManual ViewerLeonardo CruzBelum ada peringkat

- Project Training Report: Name of The ProjectDokumen15 halamanProject Training Report: Name of The ProjectShoubhik SahaBelum ada peringkat

- Scaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaDokumen7 halamanScaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaJoanna YengBelum ada peringkat

- One-Way Joist Part 2Dokumen1 halamanOne-Way Joist Part 2Humberto EstevezBelum ada peringkat

- Framing Schematics - SteelConstruction - InfoDokumen13 halamanFraming Schematics - SteelConstruction - InfoNouman MohsinBelum ada peringkat

- Construction Methods in Industrialized BuildingsDokumen37 halamanConstruction Methods in Industrialized BuildingsJoseph EzekielBelum ada peringkat

- Hollow Sections For Multi Storey ColumnsDokumen37 halamanHollow Sections For Multi Storey ColumnsVimut SuttipongBelum ada peringkat

- 2.6.2 Minimum Spacing Between Reinforcement Bars: The Art of Construction and The DesignDokumen6 halaman2.6.2 Minimum Spacing Between Reinforcement Bars: The Art of Construction and The DesignSamuel AntobamBelum ada peringkat

- 08+Updates+to+the+Seismic+Provisions+in+ASCE+7 16+Dokumen20 halaman08+Updates+to+the+Seismic+Provisions+in+ASCE+7 16+Humberto EstevezBelum ada peringkat

- Hilti-Hy 200-RDokumen74 halamanHilti-Hy 200-RHumberto EstevezBelum ada peringkat

- SDVI 2019 Gs FR Tutorial and Exercise 1552485157Dokumen81 halamanSDVI 2019 Gs FR Tutorial and Exercise 1552485157Humberto EstevezBelum ada peringkat

- Canam Steel Deck PDFDokumen168 halamanCanam Steel Deck PDFAnonymous 8hx6hKN3Belum ada peringkat

- Gaps in Bearing and SC ConexDokumen1 halamanGaps in Bearing and SC ConexHumberto EstevezBelum ada peringkat

- Footings Limit StatesDokumen1 halamanFootings Limit StatesHumberto EstevezBelum ada peringkat

- ARCH 614 Note Set 26.1 S2012abn: Foundation DesignDokumen1 halamanARCH 614 Note Set 26.1 S2012abn: Foundation DesignHumberto EstevezBelum ada peringkat

- Tolerances: Table 2 Surface Finish ClassDokumen1 halamanTolerances: Table 2 Surface Finish ClassHumberto EstevezBelum ada peringkat

- Proportionate and Nonproportionate Shear WallsDokumen5 halamanProportionate and Nonproportionate Shear WallsHumberto Estevez100% (1)

- Prestressed Compression MembersDokumen1 halamanPrestressed Compression MembersHumberto EstevezBelum ada peringkat

- Prestressed Compression MembersDokumen1 halamanPrestressed Compression MembersHumberto EstevezBelum ada peringkat

- Pages From R.C.hibbbending in Composite Eler-Mechanics of Materials 8th EditionDokumen2 halamanPages From R.C.hibbbending in Composite Eler-Mechanics of Materials 8th EditionHumberto EstevezBelum ada peringkat

- Spread Footing CalcsDokumen1 halamanSpread Footing CalcsHumberto EstevezBelum ada peringkat

- Lower Bound Theory High RiseDokumen1 halamanLower Bound Theory High RiseHumberto EstevezBelum ada peringkat

- One-Way Joist Part 2Dokumen1 halamanOne-Way Joist Part 2Humberto EstevezBelum ada peringkat

- B. Singh, S.K. Kaushik, K.F. Naveen and S. Sharma 470: 5. Design of TiesDokumen1 halamanB. Singh, S.K. Kaushik, K.F. Naveen and S. Sharma 470: 5. Design of TiesHumberto EstevezBelum ada peringkat

- Cable Stays Lecture-PatscenterDokumen1 halamanCable Stays Lecture-PatscenterHumberto EstevezBelum ada peringkat

- Stayed RoofDokumen1 halamanStayed RoofHumberto EstevezBelum ada peringkat

- Cantilever Wall Tall BuildingDokumen1 halamanCantilever Wall Tall BuildingHumberto EstevezBelum ada peringkat

- Standard Description Standard Description View Image View ImageDokumen27 halamanStandard Description Standard Description View Image View ImagejiyadBelum ada peringkat

- Ra DewateringGGDokumen8 halamanRa DewateringGGloveson709100% (1)

- Primary SchoolDokumen57 halamanPrimary SchoolMUUTHUKRISHNAN100% (1)

- Sun Temple, GujratDokumen11 halamanSun Temple, GujratSejal MengajiBelum ada peringkat

- Service Manual: Air ConditionerDokumen70 halamanService Manual: Air Conditionerboroda2410Belum ada peringkat

- Hollow SectionsDokumen199 halamanHollow SectionsmandregomesBelum ada peringkat

- Modular Stand Alone Covid Testing Laboratory RT-PCR BSL2+ PDFDokumen11 halamanModular Stand Alone Covid Testing Laboratory RT-PCR BSL2+ PDFAllen Rivera BuenaventuraBelum ada peringkat

- MS Basement Slab Casting (Completed)Dokumen72 halamanMS Basement Slab Casting (Completed)Hafiz Kamarudin100% (2)

- Applications of Bismaleimides ConfirmDokumen2 halamanApplications of Bismaleimides ConfirmsggdgdBelum ada peringkat

- Katalog Vers 2 ReprintDokumen52 halamanKatalog Vers 2 ReprintfernandoBelum ada peringkat

- Hammerhead Pier On Spread Footing PDFDokumen83 halamanHammerhead Pier On Spread Footing PDFRammiris ManBelum ada peringkat

- Jojo Septic Tank Design DoneDokumen7 halamanJojo Septic Tank Design DoneLenard SantiagoBelum ada peringkat

- Huamei Spec Sheets - 2018Dokumen1 halamanHuamei Spec Sheets - 2018Phan LongBelum ada peringkat

- Workplace Inspection Checklist TemplateDokumen5 halamanWorkplace Inspection Checklist Templatemyo lwinBelum ada peringkat

- Mesc Decoder CableDokumen38 halamanMesc Decoder CableashwinBelum ada peringkat

- Types of DamsDokumen8 halamanTypes of DamsNoeBonga100% (1)

- ELECTRICAL WIRING PLAN DemoDokumen24 halamanELECTRICAL WIRING PLAN DemoTommy Dela CruzBelum ada peringkat

- Lift Maintenance Outcome GuidebookDokumen44 halamanLift Maintenance Outcome GuidebookKayeyera LawrenceBelum ada peringkat

- LAteral BucklingDokumen12 halamanLAteral Bucklingabhi1648665Belum ada peringkat

- A23b - Chalenges For Underwater Concrete Repair in Deep WaterDokumen12 halamanA23b - Chalenges For Underwater Concrete Repair in Deep WaterJoão Carlos Protz ProtzBelum ada peringkat

- The Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDokumen6 halamanThe Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDavid TolentinoBelum ada peringkat

- Storage Tank Design Calculation - Api 650Dokumen21 halamanStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- 7 Medival ArchitectureDokumen50 halaman7 Medival ArchitectureRachana Muppala100% (3)

- Final Bill (Submitted)Dokumen16 halamanFinal Bill (Submitted)Tariq MahmoodBelum ada peringkat

- 54450b13e6c55 Dutypoint Dosing Pots DetailsDokumen2 halaman54450b13e6c55 Dutypoint Dosing Pots DetailsMohammed KhaledBelum ada peringkat

- PreviewpdfDokumen214 halamanPreviewpdfViviana MoraBelum ada peringkat

- Design: Rigid Solutions - Final CoachingDokumen11 halamanDesign: Rigid Solutions - Final CoachingEugene Ralph TimoteoBelum ada peringkat

- Sisteme Fixare EurofoxDokumen52 halamanSisteme Fixare EurofoxCosmin Ionut CristeaBelum ada peringkat

- 2016 KB Spec Book 2 Wall CabinetsDokumen20 halaman2016 KB Spec Book 2 Wall CabinetsMarium ZahidBelum ada peringkat