P1064-00-M05-123-R1-Check Valve

Diunggah oleh

Narayana MugalurDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

P1064-00-M05-123-R1-Check Valve

Diunggah oleh

Narayana MugalurHak Cipta:

Format Tersedia

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 1 of 10

ORDER SPECIFICATION

OF

CHECK VALVE

Rev. No.

R0

R1

Rev. Date

09-05-2013

19-07-2013

Prepared by

Faisal Farooqui

Faisal Farooqui

Checked by

Nilesh Mahajan

Nilesh Mahajan

App. by (Consu.)

Jagdish Pathak

Jagdish Pathak

For Enquiry

For Order

Status

R2

R3

R4

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 2 of 10

INDEX

A.

PROJECT INFORMATION .................................................................................................................. 3

B.

TECHNICAL SPECIFICATION............................................................................................................... 4

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

SCOPE ................................................................................................................................................... 4

SPECIFICATION DATASHEET ......................................................................................................................... 4

SPECIAL REQUIREMENT .............................................................................................................................. 4

INSPECTION AND TESTING .......................................................................................................................... 4

ERECTION AND COMMISSIONING.................................................................................................................. 5

GUARANTEE ............................................................................................................................................ 5

POST ORDER SUPPORT .............................................................................................................................. 5

DOCUMENT SUBMITTAL ............................................................................................................................. 5

8.1

ALONG WITH OFFER ................................................................................................................ ERROR! BOOKMARK NOT DEFINED.

8.2

WITHIN 2 WEEKS OF ORDER FOR APPROVAL ............................................................................................................................. 5

8.3

BEFORE COMMISSIONING OF SYSTEM. ...................................................................................................................................... 5

C.

COMMERCIAL DETAILS ................................................................................................................... 6

D.

ANNEXURES ................................................................................................................................ 7

1.0

2.0

3.0

4.0

ANNEXURE I: ........................................................................................................................................ 7

ANNEXURE II: ....................................................................................................................................... 8

ANNEXURE III: ...................................................................................................................................... 9

ANNEXURE IV: .................................................................................................................................... 10

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

A.

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 3 of 10

Project Information

M/s. Carlsberg India Pvt. Ltd.

5th Floor, Paras Twin Towers, Tower B,

: Sector-54, Gurgaon,

Harayana-122 002

1.0

Client

2.0

Plant location

3.0

Project

: Greenfield Brewery Plant, Patna.

4.0

5.0

Site data

Access to Site

Ambient data

(As per ISHARE)

M/s. Carlsberg India Pvt. Ltd.

Patna , Bihar

DBT (0C)

WBT (0C)

RH (%)

Summer

42.2

25.6

26

Monsoon

32.2

28.3

78

Winter

10.0

6.7

60

By Road

: Patna

Railway Station

: Patna

Nearest Airport

: Patna

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

B.

1.0

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 4 of 10

Technical Specification

Scope

The scope of specification covers design, manufacturing, assembly, inspection and supply.

2.0

Specification Datasheet

Please refer the following Annexures:

Swing Type

2. 1

Carbon Steel, Check Valve - Swing Type, Flange End 150#

1SV3

Annexure-I

2. 2

Carbon Steel, Check Valve - Swing Type, Flange End 300# IBR

Approved.

2SV4

Annexure-II

1LV1

Annexure-III

1WV3

Annexure-IV

Lift Type

2. 3

Carbon Steel, Check Valve, Lift Type, Screwed End 600#

Wafer type

2. 4

3.0

Carbon Steel, Wafer Type Swing Check Valve ( Sandwich Type)

Special Requirement

3. 1 Valve code number shall be punched on the valve body.

4.0

Inspection and Testing

4.1

All valves and accessories shall be subjected to Inspection and inspection shall be carried out as per

approved QAP.

4.2

No Valves or its accessories / part shall be shipped without testing at shop up to full satisfaction of

inspection authority.

4.3

Performance test of equipment shall be carried out at site as per relevant acceptance standard.

4.4

Authorized representative of Client / Consultant shall at all times have an access to vendors / vendors subcontractors workshop to witness fabrication / manufacturing stages of the equipment. All inspection

facilities shall be made available to the inspection engineer by vendor or sub vendor.

4.5

Vendor should maintain internal inspection records at all times, if any stages are found lacking by way of

proper records, inspection authority reserves the right to ask vendor to modify / amend the fabrication

stage.

4.6

Any such inspection at vendors work or inspection waiver however shall not relieve vendor from his

responsibility for supply of equipment / its accessories as per specifications and other obligations stipulated

in contract.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

5.0

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 5 of 10

Erection and Commissioning

Incase client require some assistance in setting the valves (Leak Setting, Hot Tightening etc.), vendor should

arrange required manpower (skilled and unskilled) with tools & tackles. The cost of the same shall be

included in the pricing.

6.0

Guarantee

6.1

Complete Equipment / system shall be guaranteed for trouble free operation for the period of 12 months

from the date of commissioning or 18 months from the date of receipt at site whichever is earlier.

6.2

All components shall be guaranteed against faulty design, defective or improper materials, poor

workmanship or failure from normal use during the guarantee period.

6.3

In case of nonfulfillment of guarantee, vendor shall repair / replace such defective part/ parts of the

equipment supplied. Vendor shall be liable for all expenses occurred for such repair / replacement.

7.0

Post Order Support

7.1

Maintenance and trouble shooting

7.2

By giving notification on regular basis about any improvements available.

8.0

Document Submittal

Vendor to submit documents (soft copies as well as hard copies.) as given in schedule below.

8.1

Within 4 Weeks Of Order For Approval

Vendor to submit 4 sets and soft copies of following documents within 2 weeks of order for approval.

a.

General arrangement drawing.

b.

Cross sectional drawing.

c.

Quality assurance plan.

8.2

Before Commissioning Of System.

Vendor to submit 4 sets of following documents before commissioning of system.

a.

As Built GA & Cross section drawing.

b.

Operation and maintenance manual.

c.

Material test certificates.

d.

Inspection and Test Reports.

e.

Guarantee / Warrantee Certificates.

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

C.

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 6 of 10

Commercial Details

1.0

Price basis

FOR Site, Patna

2.0

Packing and forwarding

Included

3.0

Excise Duty

Included

4.0

Sales Tax

2% CST against C-FORM

5.0

Transportation charges

Included

6.0

Transit insurance

Included

7.0

Inspection and testing charges

Included

8.0

Documentation charges

Included

9.0

Time lines

Submission of drawings / documents

Within 4 week from the date of LOI / PO

Delivery

As per PO terms

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

D.

1.0

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 7 of 10

Annexures

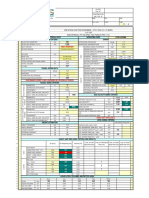

Annexure I:

Item

Tag No.

c

d

e

f

g

h

i

j

k

l

m

Type

Design & Manufacturing Standard

Dimension Standard ( End to End)

Rating

Make

Model No.

Service

Op. Temperature - Min/Max (C)

Op. Pressure - Min/Max (kg/cm(g))

Design pressure

Pressure testing (as per API 598 / BS 6755

Part 1)

Body -Hydraulic (kg/cm(g))

Seat -Hydraulic (kg/cm(g))

End Connection

Flange rating

Material of Construction

Body

Cover

Seat Ring

Disc

Hing

Hing Pin

Disc Nut

Split Pin

Body Gasket

Studs / Nuts

Finish

External Surfaces

Special requirement

Special note

Unit Rate

Size (NB)

Qty. (Nos.)

40

As per Annexure

50

As per Annexure

n

o

p

q

r

s

t

No.

1.

2.

: Carbon Steel, Check Valve-Swing Type, Flange End

150#

: 1SV3

:

:

:

:

:

:

:

:

:

:

:

Check Valve (Swing Type)

BS 1868 / BS 5352

ANSI B16.11

150#

To be specified

To be specified

Utility

-25/150

-1/10.0

To be specified

:

:

:

:

30

22

Flange RF

ANSI B16.5, ASA 150#

:

:

:

:

:

:

:

:

:

:

A216 Gr. WCB

A216 Gr. WCB Bolted

13% Cr- Renewable

ASTM A 276 Gr.410

A216 Gr. WCB

SS 410

SS 304

SS 304

SPW 304 (graphite Filled)

A 193 Gr. B7/A 194 Gr.2H (galvanized)

: Epoxy Painted

: Valve Shall be tested for lower pressure also.

: All gaskets should be asbestos free

Unit Rate (Rs.)

Amount (Rs.)

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

2.0

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 8 of 10

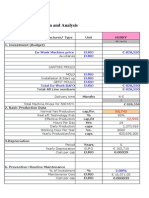

Annexure II:

Item

Tag No.

c

d

e

f

g

h

i

j

k

l

Type

Design & Manufacturing Standard

Dimension Standard

Make

Model No.

Service

Op. Temperature - Min/Max (C)

Op. Pressure - Min/Max (kg/cm(g))

Design pressure

Pressure testing (as per API 598 / BS 6755

Part 1)

Body -Hydraulic (kg/cm(g))

Seat -Hydraulic (kg/cm(g))

End Connection

Flange rating

Material of Construction

Body

Cover

Seat Ring

Disc

Hing

Hing Pin

Disc Nut

Split Pin

Body Gasket

Studs / Nuts

Finish

External Surfaces

:

:

:

:

:

:

:

:

:

:

Check Valve (Swing Type)

BS 1868 / BS 5352

ANSI B16.11

To be specified

To be specified

Utility

-25/200

-1/10.54

To be specified

:

:

:

:

96

64

Flange RF

ANSI B16.5, ASA 300#

:

:

:

:

:

:

:

:

:

:

A216 Gr. WCB

A 216 GR WCB Bolted

13 % Cr Renewable

ASTM A 276 Gr.410

A216 Gr. WCB

SS 410

SS 304

SS 304

SPW 304 (PTFE Filled)

A 193 Gr. B7/A 194 Gr.2H (galvanized)

Special requirement

Special note

Statutory Approval

Size (NB)

40

50

80

100

:

:

:

Painted with 2 Coats of Aluminium Paint suitable for

250C

Valve Shall be tested for lower pressure also.

All gaskets should be asbestos free

IBR Approval

Size (NB)

Qty. (Nos.)

150

As per Annexure

200

As per Annexure

250

As per Annexure

As per Annexure

m

n

o

q

r

s

No.

1.

2.

3.

4.

Qty. (Nos.)

As per Annexure

As per Annexure

As per Annexure

As per Annexure

Carbon Steel, Check Valve-Swing Type, Flange end

300# IBR Approved.

2SV4

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

3.0

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 9 of 10

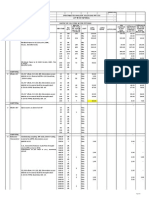

Annexure III:

a

b

Item

Tag No.

:

:

Carbon Steel, Check Valve, Lift Type, Screwed End 600#

1LV1

c

d

e

f

g

h

i

j

k

l

Type

Design Standard

Dimension Standard ( End to End)

Rating

Make

Model No.

Service

Op. Temperature - Min/Max (C)

Op. Pressure - Min/Max (kg/cm(g))

Pressure testing API598/ BS EN 12266 -1

Body -Hydraulic (kg/cm(g))

Seat -Hydraulic (kg/cm(g))

End Connection

Material of Construction

Body

Cover

Disc

Seat Ring

Spring

Stud/Nut

Gasket

Finish

External Surfaces

Special requirement

Unit Rate

Size (NB)

Qty. (Nos.)

15

As per Annexure

20

As per Annexure

25

As per Annexure

:

:

:

:

:

:

:

:

:

:

:

:

:

Check Valve (Lift Type), Full Bore

BS 5352

ANSI B16.11

600#

To be specified

To be specified

Utility

-15/100

1/8.0

207

152

Screwed BSPT(F) BS21

:

:

:

:

:

:

:

A 105

A 105

A276 TP.410

A276 TP.410

SS316

A 193 Gr. B7/A 194 Gr. 2H(Galv.)

SPW 304 (graphite Filled)

:

:

Epoxy Paint

Valve Shall be tested for lower pressure also.

m

n

o

p

q

No.

1.

2.

3.

Unit Rate (Rs.)

Amount (Rs.)

Knexir Consultants Pvt. Ltd.

Consulting Engineers

Tel.: 022 61547800. Fax.: 022 25111092

Website: www.knexir.in Email : Knexir@knexir.in

Doc. No.

Revision No.

4.0

KCPL:P1064:00:M05:123

R1

SPECIFICATION OF CHECK VALVES

Date

19-07-2013

Page No.

Page 10 of 10

Annexure IV:

Name

Tag No.

c

d

e

f

g

h

i

j

k

Type

Design & Manufacturing Standard

Dimension Standard

Make

Model No.

Service

Op. Temperature - Min/Max (C)

Op. Pressure - Min/Max (kg/cm(g))

Testing Std. API 6D / API 598

Body -Hydraulic (kg/cm(g))

Seat -Hydraulic (kg/cm(g))

End Connection

:

:

:

:

:

:

:

:

:

:

:

:

l

m

n

o

p

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Material of Construction

Body

Disc

Spring

O ring(Disc)

Finish

External surfaces

Special Requirement

Unit Rate

Size (NB)

Qty. (Nos.)

80

As per Annexure

100

As per Annexure

150

As per Annexure

200

As per Annexure

250

As per Annexure

300

As per Annexure

350

As per Annexure

400

As per Annexure

450

As per Annexure

Carbon Steel, Wafer Type Swing Check Valve

( Sandwich Type)

1WV3

Wafer Type Swing Check Valve

API 6D /

ANSI B16.5

To be specified

To be specified

Utility

-15/100

1/8.0

30

22

Wafer type to mount between Flanges as per ANSI

B16.5 RF,ASA 150#

:

:

:

:

A216 Gr. WCB

A351 Gr. CF8

SS304

EPDM

:

:

Epoxy Painted

Valve shall be tested for lower pressures also

Unit Rate (Rs.)

Amount (Rs.)

Anda mungkin juga menyukai

- P1064 00 M05 116 R1 Mechanical SupplyDokumen8 halamanP1064 00 M05 116 R1 Mechanical SupplyNarayana MugalurBelum ada peringkat

- P1064-00-M05-130-R1-Auto Drain TrapDokumen7 halamanP1064-00-M05-130-R1-Auto Drain TrapNarayana MugalurBelum ada peringkat

- KCPL p1064 00 m08 101 (Piping Legend)Dokumen1 halamanKCPL p1064 00 m08 101 (Piping Legend)Narayana MugalurBelum ada peringkat

- Iso-Propanol Production Report: Student Name: Course Name: Submission DateDokumen18 halamanIso-Propanol Production Report: Student Name: Course Name: Submission DateAmir Javed official100% (1)

- PHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow DiagramsDokumen54 halamanPHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow Diagramsmashari budiBelum ada peringkat

- De MisterDokumen2 halamanDe MisterLaxman G GalipelliBelum ada peringkat

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Dokumen10 halamanDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182Belum ada peringkat

- Sick Tanker Unloading PumpDokumen3 halamanSick Tanker Unloading PumpSumantrra ChattopadhyayBelum ada peringkat

- RideDokumen8 halamanRidewahyuBelum ada peringkat

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDokumen12 halamanSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoBelum ada peringkat

- FN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeDokumen1 halamanFN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeAjay ChodankarBelum ada peringkat

- Sov - 1Dokumen1 halamanSov - 1biswasdipankar05Belum ada peringkat

- Standard Procedure For Vacuum Decay Test (Advisory Procedure)Dokumen7 halamanStandard Procedure For Vacuum Decay Test (Advisory Procedure)Jonathan MoralesBelum ada peringkat

- Vessel Process Data Sheet1Dokumen3 halamanVessel Process Data Sheet1AJAY1381Belum ada peringkat

- Design Basis - Package - B224-999-80-43 EDB-1002Dokumen12 halamanDesign Basis - Package - B224-999-80-43 EDB-1002Esakki muthu100% (1)

- DcrerweDokumen1 halamanDcrerwesri9987Belum ada peringkat

- 12 MGDP I 1150 0 (Instr Utility Air Calculation)Dokumen2 halaman12 MGDP I 1150 0 (Instr Utility Air Calculation)cytech6619Belum ada peringkat

- Indra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043Dokumen62 halamanIndra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043AnhTuấnPhanBelum ada peringkat

- Pid Engtech Pilot Plants v04pdfDokumen20 halamanPid Engtech Pilot Plants v04pdfFaizan SarangBelum ada peringkat

- Desalter DrumDokumen4 halamanDesalter DrumHsein WangBelum ada peringkat

- LPG Blending Facilities Tender Documents ListDokumen235 halamanLPG Blending Facilities Tender Documents ListManish MehtaBelum ada peringkat

- TRVDokumen3 halamanTRVbadelitamariusBelum ada peringkat

- Engineering DocumentDokumen56 halamanEngineering DocumentVishal100% (1)

- FlowmeterDokumen22 halamanFlowmeterAnandBelum ada peringkat

- Ethanol Plant Commissioning Startup and ShutdownDokumen5 halamanEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083Belum ada peringkat

- HRSG Equipment ListDokumen20 halamanHRSG Equipment ListManuel Jesus Perez MelgarBelum ada peringkat

- Pts 0800 - A (Process Description)Dokumen6 halamanPts 0800 - A (Process Description)ingegnere1234Belum ada peringkat

- Student Unit Op Lab Manual - Thin Film Evaporator PDFDokumen5 halamanStudent Unit Op Lab Manual - Thin Film Evaporator PDFMuiz MoktarBelum ada peringkat

- Line List: Bandar Abbas Gas Condensate Refinery ProjectDokumen31 halamanLine List: Bandar Abbas Gas Condensate Refinery Projectmb_sirousBelum ada peringkat

- TDS Futura AS Euk GB PDFDokumen4 halamanTDS Futura AS Euk GB PDFFu AdBelum ada peringkat

- Safet Valve Data SheetDokumen3 halamanSafet Valve Data SheetMathivanan AnbazhaganBelum ada peringkat

- Ione VP 14 P 102ab 001 - 1Dokumen8 halamanIone VP 14 P 102ab 001 - 1ضياء محمدBelum ada peringkat

- Manual On Ambient Water Quality MonitoringDokumen231 halamanManual On Ambient Water Quality MonitoringberiBelum ada peringkat

- WHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsDokumen17 halamanWHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsYasin ElaswadBelum ada peringkat

- Nioec230 02 Eb Me P0207 A0Dokumen9 halamanNioec230 02 Eb Me P0207 A0amini_mohiBelum ada peringkat

- 110-Ee-390 110-Ee-392 110-Ee-395 110-VV-391 110-VV-390 110-VV-350 A/b 110-VV-360 A/bDokumen1 halaman110-Ee-390 110-Ee-392 110-Ee-395 110-VV-391 110-VV-390 110-VV-350 A/b 110-VV-360 A/bDIPANKAR LALABelum ada peringkat

- File 1428726206Dokumen8 halamanFile 1428726206Rizwanahmad Khan Rizwanahmad KhanBelum ada peringkat

- R2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Dokumen21 halamanR2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Diana Paula Echartea MolinaBelum ada peringkat

- Oisd Gen 235 PDFDokumen110 halamanOisd Gen 235 PDFPankaj GoelBelum ada peringkat

- Skikda Training CDU (Basis - Process.EQ Modi. Interlock)Dokumen48 halamanSkikda Training CDU (Basis - Process.EQ Modi. Interlock)Mohamed OuichaouiBelum ada peringkat

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Dokumen5 halaman18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaBelum ada peringkat

- Pumps Final TeDokumen48 halamanPumps Final Tegharsallah mounaBelum ada peringkat

- Stationary Equipment List From SAPDokumen132 halamanStationary Equipment List From SAPVajid MadathilBelum ada peringkat

- Tendernotice 5 PDFDokumen148 halamanTendernotice 5 PDFAbhijit BhandarkarBelum ada peringkat

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectDokumen10 halamanClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarBelum ada peringkat

- Phase1 Hassi Bir Rekaiz Field DevelopmentDokumen4 halamanPhase1 Hassi Bir Rekaiz Field Developmentahmed.njahBelum ada peringkat

- Chemical Plant Utility - Nitrogen System DesignDokumen10 halamanChemical Plant Utility - Nitrogen System DesignIJRASETPublicationsBelum ada peringkat

- 3181xxx - PDS For FilterDokumen1 halaman3181xxx - PDS For FiltersafaldBelum ada peringkat

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDokumen6 halamanR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Tata Consulting Engineers Limited Dew Point Analyzer: GeneralDokumen2 halamanTata Consulting Engineers Limited Dew Point Analyzer: GeneralcvkgrpdBelum ada peringkat

- Vertical Pyrolysis Plant OfferDokumen5 halamanVertical Pyrolysis Plant OfferGaurav BihaniBelum ada peringkat

- Condensate Stabilization Design BasisDokumen22 halamanCondensate Stabilization Design BasisMuhammad.SaimBelum ada peringkat

- P&ID Process Gas System PDFDokumen2 halamanP&ID Process Gas System PDFmuieed siddiquiBelum ada peringkat

- LP ValveDokumen72 halamanLP ValvetataircBelum ada peringkat

- 528 - Tank Weighing System - 0Dokumen4 halaman528 - Tank Weighing System - 0Nikhil KarkeraBelum ada peringkat

- KPD-TAY Integrated Development Project Phase-II DatasheetDokumen2 halamanKPD-TAY Integrated Development Project Phase-II Datasheetm.shehreyar.khanBelum ada peringkat

- SMP For Silica Hach 5500scDokumen7 halamanSMP For Silica Hach 5500scPrince MaheshBelum ada peringkat

- MetoxidoDokumen8 halamanMetoxidocessavelinoBelum ada peringkat

- Statistics for Process Control Engineers: A Practical ApproachDari EverandStatistics for Process Control Engineers: A Practical ApproachBelum ada peringkat

- P1064-00-M05-122-R1 - Butterfly ValveDokumen9 halamanP1064-00-M05-122-R1 - Butterfly ValveNarayana MugalurBelum ada peringkat

- Emergency Acupressure TreatmentDokumen39 halamanEmergency Acupressure TreatmentNarayana Mugalur100% (1)

- DocumentsDokumen3 halamanDocumentsNarayana MugalurBelum ada peringkat

- Name of Employee Employee PF NoDokumen2 halamanName of Employee Employee PF NoNarayana MugalurBelum ada peringkat

- Wage CalculationDokumen60 halamanWage CalculationNarayana MugalurBelum ada peringkat

- Visakhapatnam Steel Plant: Rashtriya Ispat Nigam Limited (A Government of India Enterprise) Visakhapatnam - 530031Dokumen2 halamanVisakhapatnam Steel Plant: Rashtriya Ispat Nigam Limited (A Government of India Enterprise) Visakhapatnam - 530031Narayana MugalurBelum ada peringkat

- Labour WagesDokumen145 halamanLabour WagesNarayana MugalurBelum ada peringkat

- GPI cap production Technology Comparison and AnalysisDokumen54 halamanGPI cap production Technology Comparison and AnalysisNarayana MugalurBelum ada peringkat

- Precious MetalDokumen3 halamanPrecious MetalNarayana MugalurBelum ada peringkat

- No More ExcusesDokumen19 halamanNo More ExcusesNarayana MugalurBelum ada peringkat

- Hathway Internet billDokumen1 halamanHathway Internet billNarayana MugalurBelum ada peringkat

- Payment and IssuesDokumen27 halamanPayment and IssuesNarayana Mugalur100% (1)

- Ree Microbrewery Business PlanDokumen19 halamanRee Microbrewery Business PlanNarayana Mugalur100% (1)

- Payment ModesDokumen24 halamanPayment ModesNarayana MugalurBelum ada peringkat

- Comparis I OnDokumen8 halamanComparis I OnNarayana MugalurBelum ada peringkat

- Materials Despatched List From Om Industrial Supplier To Carlsberg Patna - STL-13024Dokumen8 halamanMaterials Despatched List From Om Industrial Supplier To Carlsberg Patna - STL-13024Narayana MugalurBelum ada peringkat

- Instrumentation Supply StatusDokumen3 halamanInstrumentation Supply StatusNarayana MugalurBelum ada peringkat

- Mat Supply - As On 13112013Dokumen41 halamanMat Supply - As On 13112013Narayana MugalurBelum ada peringkat

- Final Mat Requiement CompDokumen20 halamanFinal Mat Requiement CompNarayana MugalurBelum ada peringkat

- Space Pipe Stacking and Stores Container Stores PlacingDokumen1 halamanSpace Pipe Stacking and Stores Container Stores PlacingNarayana MugalurBelum ada peringkat

- 7 Avenue de La Paix 1202 Geneva Switzerland Wa License n1Dokumen2 halaman7 Avenue de La Paix 1202 Geneva Switzerland Wa License n1Narayana MugalurBelum ada peringkat

- Senior Analyst Profile - Ashoka B VDokumen1 halamanSenior Analyst Profile - Ashoka B VNarayana MugalurBelum ada peringkat

- Erection CostingDokumen1 halamanErection CostingNarayana MugalurBelum ada peringkat

- Required Details FormDokumen9 halamanRequired Details FormNarayana MugalurBelum ada peringkat

- Ree Microbrewery Business PlanDokumen19 halamanRee Microbrewery Business PlanNarayana Mugalur100% (1)

- Details To Be Printed On First Page Details To Be Printed On Last PageDokumen1 halamanDetails To Be Printed On First Page Details To Be Printed On Last PageNarayana MugalurBelum ada peringkat

- Invoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaDokumen5 halamanInvoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaNarayana MugalurBelum ada peringkat

- Pipe FittingsDokumen8 halamanPipe FittingsNarayana MugalurBelum ada peringkat

- 7th Mile, Mysore Road, Nayandahalli, Bangaluru - 560 039Dokumen8 halaman7th Mile, Mysore Road, Nayandahalli, Bangaluru - 560 039Narayana MugalurBelum ada peringkat

- Invoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaDokumen5 halamanInvoice A/ctd by Carlsber G Total Invoices Billed As Per SpectraaNarayana MugalurBelum ada peringkat

- Learning Resource Management Made SimpleDokumen12 halamanLearning Resource Management Made SimpleJosenia ConstantinoBelum ada peringkat

- Gsxp07er Opera1tion Manual PDFDokumen94 halamanGsxp07er Opera1tion Manual PDFMohamed SaadAllahBelum ada peringkat

- Engine Service Tool ReferenceDokumen4 halamanEngine Service Tool ReferenceandrzejBelum ada peringkat

- Pink Fun Doodles and Blobs Math Online Class Creative Presentation SlidesCarnivalDokumen28 halamanPink Fun Doodles and Blobs Math Online Class Creative Presentation SlidesCarnivalraine castorBelum ada peringkat

- CV Ali EzzeddineDokumen3 halamanCV Ali EzzeddineOmar RajadBelum ada peringkat

- Recovering Valuable Metals From Recycled Photovoltaic ModulesDokumen12 halamanRecovering Valuable Metals From Recycled Photovoltaic ModulesNguyễn TriếtBelum ada peringkat

- Analytic DeviceDokumen4 halamanAnalytic DeviceuiuiuiuBelum ada peringkat

- DPWH Standard Specifications for ShotcreteDokumen12 halamanDPWH Standard Specifications for ShotcreteDino Garzon OcinoBelum ada peringkat

- Tutorial Ip 2 Win EnglishDokumen25 halamanTutorial Ip 2 Win EnglishGarry Zein0% (1)

- Educational Technology & Education Conferences - January To June 2016 - Clayton R WrightDokumen93 halamanEducational Technology & Education Conferences - January To June 2016 - Clayton R WrightEsperanza Román MendozaBelum ada peringkat

- Android Car Navigation User ManualDokumen74 halamanAndroid Car Navigation User ManualРисте ПановBelum ada peringkat

- UFED Solutions Brochure WebDokumen4 halamanUFED Solutions Brochure Webwilly irawanBelum ada peringkat

- MyPower S3220&S3320-INSTALLATIONDokumen83 halamanMyPower S3220&S3320-INSTALLATIONJorge GonzalesBelum ada peringkat

- PrintedElectronics ProductOverview PDFDokumen2 halamanPrintedElectronics ProductOverview PDFanon_551622158Belum ada peringkat

- Managing ImapDokumen408 halamanManaging ImapPriya RaoBelum ada peringkat

- Value-Instruments Cat2012 enDokumen58 halamanValue-Instruments Cat2012 enAnonymous C6Vaod9Belum ada peringkat

- IEC Certificate 1000V Single Glass 202304Dokumen35 halamanIEC Certificate 1000V Single Glass 202304Marian ProzorianuBelum ada peringkat

- Newsletter Template NewDokumen4 halamanNewsletter Template Newapi-458544253Belum ada peringkat

- Questionnaire For Future BLICZerDokumen1 halamanQuestionnaire For Future BLICZerAlejandra GheorghiuBelum ada peringkat

- BQ Mechanical (Sirim)Dokumen7 halamanBQ Mechanical (Sirim)mohd farhan ariff zaitonBelum ada peringkat

- Results Part III - Part III-March 2017 - ElectricalDokumen3 halamanResults Part III - Part III-March 2017 - ElectricalTharaka MunasingheBelum ada peringkat

- Touch Panel Debug Info Register ValuesDokumen17 halamanTouch Panel Debug Info Register ValuesAlghazyBelum ada peringkat

- RELAY SEEDER PROTECTION GUIDE (P40 Agile CompactDokumen23 halamanRELAY SEEDER PROTECTION GUIDE (P40 Agile CompactvinodlifeBelum ada peringkat

- Needle System Guide For Old Industrial Singer Sewing MachinesDokumen4 halamanNeedle System Guide For Old Industrial Singer Sewing MachinesWilberth FrancoBelum ada peringkat

- Microstructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic DeformationDokumen10 halamanMicrostructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic Deformationsoni180Belum ada peringkat

- 6303A HP Flare Drain DrumDokumen16 halaman6303A HP Flare Drain DrumMohammad MohseniBelum ada peringkat

- DS450 Shop Manual (Prelim)Dokumen94 halamanDS450 Shop Manual (Prelim)GuruRacerBelum ada peringkat

- Data Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewDokumen14 halamanData Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewSara GuimarãesBelum ada peringkat

- Virginia Transformer - Developments in Traction TransformersDokumen10 halamanVirginia Transformer - Developments in Traction TransformersTshepo Sharky SebeBelum ada peringkat

- Ite 001aDokumen6 halamanIte 001ajoshuaBelum ada peringkat