Flo-Tite Flanged Floating Ball Valves

Diunggah oleh

viller_lpHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Flo-Tite Flanged Floating Ball Valves

Diunggah oleh

viller_lpHak Cipta:

Format Tersedia

Tech Bulletin Page 58-11

Flanged End Floating Ball Valves

Ideal Design for Process and Petrochemical Applications

Size - 3 F300

Size - 6 SF150

FULL-FLO SERIES

UNI-FLO SERIES

Models

F150 Class 150 / F300 Class 300

Full Port:1/2" - 12"

Standard Steam Working Pressure:

150 SWP, optional 300 psig

Models

SF150 Class 150 / SF300 Class 300

Reduced Port: 1-12

Standard Steam Working Pressure:

150 SWP, optional 300 psig

Floating Ball Design

Protected Seat Design

O-Ring Backed Seat

Fire Safe Designed to API 607-5

Spiral Wound Body Gasket with

Secondary Metal to Metal Seal

Open and Close Locking Device

for Position Safety Lockout

O-Ring Reinforced Stem Packing

Cryogenic Design Option

Design Features

I-SO-Mount Type,

Actuator

Mounting Pad Standard

Super-Tek Seating

Live Loaded Stem Design

Anti-Static Grounding Device

Secondary Containment Option

Flatted Shaft - Positive Flow Direction

Ball Cavity Relief

V-Ball Control Option

Metal Seats Option, Class V & VI

Valves for other flanged standards, such as DIN, JIS, BS, NFE and GB are also available.

Website: www.flotite.com

Tech Bulletin Page 59-11

Design Specifications

Standards of Compliance

2.5-8 valve stems feature a

NAMUR stem slot for ease of

limit switch mounting

Parallel flat stem head for

positive ball position indication

2 pc design of diamond

shaped packing gland

preventing side loading due

to uneven adjustment

V-Ring Packing Rings

Form a Rigid, High

Cycle Stem Seal

Travel stop incorprates Locking

Device, can also be used as

actuator lock out device

Stop housing separates valve stop

from packing gland, eliminates stop

plate impacting on packing gland

I-SO Mount Actuator

Mounting, 4 Bolt

Design Eliminates

Torsional Stress,

Actuator can be

Removed while

Valve is under

Full Pressure

Recessed groove

enables top flange

to be be adapted

with a secondary

containment bonnet

for fugitive

emission, cryogenic

service and other

critical applications

O-Ring serves as

second barrier for

stem leakage

Grounding antistatic devices at

two locations

enable electricity

continuity

Tapered Thrust Bearing

Provides an Excellent

Long Life Bearing Support

Up to 6, Body Precision

Investment Casting, Shell/

Wall ANSI B16.34

Fully Encapsulated Graphite

Gaskets Isolates media

from atomsphere

Bolts and Nuts of High Quality and

High Strength Ensure Body Structural

Strength and Sealing Intergrity

Pocketed and recessed

seats with secondary

metal backup seal.

O-Ring encapsulated in the back of the

seat, a unique flex-load energized

seat design

Ball

Body

Ball

Metalto-Metal

Contact

Standards and Specifications

Valves covered in this bulletin are available to conform to the following

industry standards and specifications

All valves are manufactured to ISO 9001 quality standards.

WW-V-35C

ANSI/ASME B16.10

ANSI/ASME B16.5

ANSI/ASME B16.34

ANSI/ASME B31.1

ANSI/ASME B31.3

ANSI/FCI 70-2-1976

BS 6755, Part 2

ISO 5752:1982

ISA 75.02

ISA S75.19

ISO 5211

MSS-SP-25

MSS SP-55

Federal Specification: Valve, Ball

Face-to-Face / End-to-End Dimensions of Ferrous Valves

Steel Pipe Flanges and Flange Fittings

Steel Valves - Flanged and Buttwelded End

Power Piping

Chemical Plant & Petroleum Refinery Piping

For Control Valve Leakage

Testing of Valves - Specification for Fire Type Testing

Metal Valves for use in Flanged Piping Systems

Valve Sizing Coefficient Cv, Piping Geometry Factor Fp

and Pressure Drop Limitation XT

Hydrostatic Testing of Control Valves

Dimensions for Attachment of Actuators/Gear Boxes to

Valves (ISO Mounting)

Standard Marking Systems for Valves

Quality Standards for Steel Castings

www.flotite.com

Metalto-Metal

Contact

Burned Seat

Blow-Out Proof Stem

Fire Safe: API607-4 & 5 Certified

Spiral Wound Wire

Gasket

Flo-Tites Flanged series valves with graphite stem

packing meet the highest fire safety standards

under extreme conditions. In the event of a fire,

after heat destroys the primary resilient seat, the

ball makes contact with the secondary metal seat,

forming a secure seal. The body seal, composed

of stainless steel and graphite wound into a spiral,

prevents external leakage. The graphite stem

rings prevent stem leakage.

Standard Finishes for Contact Faces of Pipe Flanges and

Connecting-End Flanges of Valves and Fittings

Steel Pipe Line Flanges

MSS-SP-44

Pressure Testing of Steel Valves

MSS-SP-61

MSS-SP-72

Flanged or Butt and Weld End Ball Valves Having Full

or Reduced Bores for General Liquid and Gas Service

Terminology for Valves and Fittings

MSS-SP-96

NACE MR01-75 Sulfide Stress Cracking Resistant Materials for Oilfield

Equipment.

MSS-SP-6

Optional Standards & Specification

API 608

API 6D

API 598

MSS-SP-53

MSS-SP-93

Metal Ball valves Used in On-Off Service that have

Buttwelded or Flanged Ends for Size 1/2NPS - 12 NPS

Specifications for Pipeline Valves

Valve Inspection and Testing

Quality Standard for Steel Casting and Forging for

Valves, Flanges and Fittings and Other Piping Components-Magnetic Paticle Examination Method

Quality Standard for Steel Casting and Forging for

Valves, Flanges and Fittings and Other Piping Components-Liquid Penetrant Method

Tech Bulletin Page 60-11

Bill of Materials / Full Port Valves

Name

Body

Cap

Stem*

Packing Follower

Belleville Washer

Lock Washer

Ball

Seat

Gasket

Stem Packing

Packing Protector

Thrust Washer

Anti-Static

Valve Stop

Handle

Locking Device

Handle Sleeve

Thin Nut

Body Stud

Body Nut

Bolt

O-Ring

Seat O-Ring

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Stainless Steel

ASTM A351 CF8M

ASTM A351 CF8M

SS316

SS304

SS301

SS304

SS316

TFM

RPTFE / Graphite

TFM / Graphite

50%PTFE+SS316

25%Carbon+TFM

SS304

SS304

SS304

SS304

Plastic

SS304

ASTM A193 B8

ASTM A194 Gr.8

SS304

Viton

Viton

Carbon Steel

ASTM A216 WCB

ASTM A216 WCB

SS316 / SS304

SS304

SS301

SS304

SS316 / SS304

TFM

RPTFE / Graphite

TFM / Graphite

50%PTFE+SS316

25%Carbon+TFM

SS304

SS304

SS304

SS304

Plastic

SS304

ASTM A193 B7

ASTM A194 2H

SS304

Viton

Viton

1/2-2

F150/F300

Exploded View

18

6

5

4

11

10

21

14

22

12

Repair Kits

Soft Parts

Item # 8, 9, 10,

11, 12, 22, 23

3

13

1

23

8

7

8

23

9

18

16

15

Locking Device Standard

19

20

Bill of Materials

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Carbon Steel

ASTM A216 WCB

ASTM A216 WCB

SS316 / SS304

ASTM A351 CF8

SS304

SS316 / SS304

TFM

TFM / Graphite

50%PTFE+SS316

RPTFE / Graphite

25%Carbon+TFM

Viton

SS304

Steel

Plated Steel

Ductile Iron

Steel

SS304

SS304

ASTM A193 B7

ASTM A194 2H

Viton

Steel

Stainless Steel

ASTM A351 CF8M

ASTM A351 CF8M

SS316

ASTM A351 CF8

SS304

SS316

TFM

TFM / Graphite

50%PTFE+SS316

RPTFE / Graphite

25%Carbon+TFM

Viton

SS304

SS304

Plated Steel

Ductile Iron

SS304

SS304

SS304

ASTM A193 B8

ASTM A194 Gr.8

Viton

Steel

15

14

19

2-1/2-12

F150/F300

Exploded View

18

17

Repair Kits

Soft Parts

Item # 8, 9,

10, 11, 12, 22

4

5

9

8

12

11

3

13

1

22

7

6

7

22

16

15

10

23

2

20

21

Stem Optional Material 17-4PH

Pressure Temperature Rating

These ratings are conservative guide for general service. Previous experience in process or new development may permit applications at ratings

above those shown.

Higher Temperature Requirements

800 Class 300 WCB

700 Class 300 CF8M

UHM

Te

kI

Class 150 CF8M

II

400

EK

200 250 300 350

Temperature (oF)

Class 150 WCB

PE

150

EK

100

300

100

RT

Satu

400

r

pe

Su

PE

eam

d St

rate

100

500

200

SU

200

50

Class 300 CF8M

&

ek

Class 150 CF8M

0

-20 0

Class 300 WCB

700

T

S-

TF

RP

Class 150 WCB

FE

300

PT

400

LON

& NY

WPE

IN

DERR

500

800

600

Pressure (Psig)

600

Pressure (Psig)

Name

Body

Cap

Stem*

Packing Gland

Packing Follower

Ball

Seat

Stem Packing

Packing Protector

Gasket

Thrust Washer

O-Ring

Anti-Static

Travel Stopper

Snap Ring

Handle

Gland Bolt

Stop Housing

Housing Bolt

Body Stud

Body Nut

Seat O-Ring

Set Screw

450

500 550

600

0

-20 0

rate

Satu

50

100

150

eam

d St

200 250 300 350

Temperature (oF)

400

450

500 550

600

Saturated steam services above 150 psi use either Super Tek III or S-Tek. Saturated steam services above 250 psig use metal seats.

Metal Seated Ball Valve will take full ANSI body metal material ratings.

www.flotite.com

Tech Bulletin Page 61-11

Dimensions - Full Bore

Technical Submittal

F150/F300

SERIES

Size 1/2-2

Size 21/2- 12

Model F150 - ANSI Class 150

Torque Est.

Cv

All Valves are hydrostatically Pressure

Tested (Shell) & Air Pressure Tested

(seat) to the following:

Class 300:

Class 150:

Shell Test:

Shell Test:

1125 psi for CS

450 psi for CS

1100 psi for SS

425 psi for SS

Seat Test: 80 psi

Seat Test: 80 psi

4.25 0.59 2.60 1.54 6.50 1.79 3.50 4

2.38

0.62 17

62

3/4

4.62 0.79 2.91 1.70 6.50 2.01 3.88 4

2.75

0.62 43

90

5.00 0.98 3.43 2.06 7.87 2.05 4.25 4

3.12

0.62 74

100

7.5

11/4

5.50 1.26 3.62 2.35 7.87 2.45 4.62 4

3.50

0.62 192

240

13.5

11/2

6.50 1.50 4.13 2.65 9.84 2.76 5.00 4

3.88

0.62 290

270

14.5

Mounting Dimensions (F150/F300)

7.00 1.97 4.53 2.90 10.4 3.07 6.00 4

4.75

0.62 410

360

21

21/2

7.50 2.56 6.22 3.39 15.4 3.08 7.00 4

5.50

0.75 780

620

33.5

8.00 3.00 6.54 3.67 15.4 3.74 7.50 4

6.00

0.75 1120

800

42.5

9.00 4.00 7.20 4.40 15.4 4.47 9.00 8

7.50

0.75 1825

1700

62

15.5 5.98 11.2 7.20 25.6 7.62 11.0 8

9.50

0.88 4700

4600

165

Size

1/2~3/4

1~11/4

11/2~2

21/2~4

18.0 7.87 11.6 7.60 37.4 8.35 13.5 8

11.75 0.88 10100 9900

262

10

21.0 9.84 14.4 9.88 38.0 10.5 16.0 12 14.25 1.00 17500 17000

468

1.00 22400 23000

714

Size

1/2

C1

in-lb

Weight

Lbs

12 24.0 11.8 16.1 11.5 38.0 12.0 19.0 12 17.0

Large sizes available in our trunnion series

d

1.65

1.97

2.76

4.02

K

0.31

0.43

0.55

1.75

L

0.55

0.75

0.97

3.07

M

0.250

0.315

0.374

0.669

P

0.37

0.43

0.62

1.10

W

#10-24UNC

1/4-20UNC

5/16-18UNC

1/2-13UNC

ISO

F04

F05

F07

F10

Size 1/2-2

Model F300 - ANSI Class 300

Torque Est.

Size

1/2

5.5

3/4

1

C1

Weight

0.59 2.60 1.54 6.50 1.79 3.75 4

2.62

0.62 15

65

6.00

0.79 2.91 1.70 6.50 2.01 4.62 4

3.25

0.75 40

95

6.50

0.98 3.43 2.06 7.87 2.13 4.88 4

3.50

0.75 70

105

10

11/4

7.00

1.26 3.62 2.35 7.87 2.45 5.25 4

3.88

0.75 189

252

C/F

11/2

7.50

1.50 4.13 2.65 9.84 2.76 6.12 4

4.50

0.88 300

284

19

8.50

1.97 4.53 2.90 10.4 3.07 6.50 8

5.00

0.75 430

378

25

21/2

9.50

2.56 6.22 3.39 15.4 3.08 7.50 8

5.88

0.88 768

651

42

11.12 3.00 6.54 3.67 15.4 3.74 8.25 8

6.62

0.88 1090

840

60

12.0

7.88

0.88 1900

1785

93

15.88 5.98 11.2 7.20 25.6 7.62 12.5 12 10.62 0.88 4800

4830

221

19.75 7.87 11.6 7.60 37.4 8.35 15.0 12 13.0

10

22.38 9.84 14.4 9.88 38.0 10.5 17.5 16 15.25 1.12 17350 17850 576

12

25.50 11.8 16.1 11.5 38.0 12.0 20.5 16 17.75 1.25 21700 24150 C/F

Cv

in-lb

Lbs

4.00 7.20 4.40 15.4 4.47 10.0 8

1.00 10000 10395 371

Size 21/2- 4

* Verify mounting dimensions before

manufacturing mounting hardware

* For 6 and larger size mounting

dimensions, consult factory

Due to continuous development & improvement of our product range, we reserve the right to alter the dimensions & technical data included in this brochure.

4

www.flotite.com

Tech Bulletin Page 62-11

Bill of Materials / Standard Bore Valves

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Name

Body

Cap

Stem*

Packing Follower

Belleville Washer

lock Washer

Ball

Seat

Gasket

Stem Packing

Packing Protector

Thrust Washer

Anti-Static

Valve Stop

Handle

Locking Device

Handle Sleeve

Thin Nut

Bolt

O-Ring

Carbon Steel

ASTM A216 WCB

ASTM A216 WCB

SS316 / SS304

SS304

SS301

SS304

SS316 / SS304

TFM

RPTFE / Graphite

TFM / Graphite

50%PTFE+SS316

25%Carbon+TFM

SS304

SS304

SS304

SS304

Plastic

SS304

Carbon Steel

Viton

Stainless Steel

ASTM A351 CF8M

ASTM A351 CF8M

SS316

SS304

SS301

SS304

SS316

TFM

RPTFE / Graphite

TFM / Graphite

50%PTFE+SS316

25%Carbon+TFM

SS304

SS304

SS304

SS304

Plastic

SS304

SS304

Viton

1/2-2

SF150/SF300

Exploded View

Repair Kits

Soft Parts

Item # 8, 9,

10, 11, 12, 20

18

6

5

4

11

19

14

10

20

11

3

13

13

1

8

9

7

18

15

17

16

Locking Device Standard

Bill of Materials

Name

Body

Cap

Stem*

Packing Gland

Belleville Follower

Ball

Seat

Stem Packing

Packing Protector

Gasket

Thrust Washer

O-Ring

Anti-Static

Travel Stopper

Snap Ring

Handle

Gland Bolt

Stop Housing

Housing Bolt

Set Screw

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Stainless Steel

ASTM A351 CF8M

ASTM A351 CF8M

SS316

ASTM A351 CF8

SS304

SS316

TFM

TFM / Graphite

50%PTFE+SS316

RPTFE/ Graphite

25%Carbon+TFM

Viton

SS304

SS304

Plated Steel

Ductile lron

SS304

SS304

SS304

Steel

Carbon Steel

ASTM A216 WCB

ASTM A216 WCB

SS316 / SS304

ASTM A351 CF8

SS304

SS316 / SS304

TFM

TFM / Graphite

50%PTFE+SS316

RPTFE / Graphite

25%Carbon+TFM

Viton

SS304

Steel

Plated Steel

Ductile lron

Steel

SS304

SS304

Steel

Repair Kits

3-12

SF150/SF300 Soft Parts

Exploded View Item # 7, 8,

9, 10, 11, 12

15

14

12

11

17

18

19

4

5

9

8

13

13

2

10

7

16

6

7

20

1

* Stem Optional Material 17-4PH

Pressure Temperature Rating

These ratings are conservative guide for general service. Previous experience in process or new development may permit applications at ratings

above those shown.

Higher Temperature Requirements

800 Class 300 WCB

700 Class 300 CF8M

Pressure (Psig)

Pressure (Psig)

400

II

200 250 300 350

Temperature (oF)

kI

150

Te

100

EK

50

100

EK

0

-20 0

Class 150 WCB

Class 150 CF8M

200

RT

rat

Satu

300

PE

team

ed S

PE

100

SU

200

400

r

pe

Su

Class 150 CF8M

500

&

ek

TF

RP

Class 150 WCB

FE

300

Class 300 CF8M

600

PT

400

Class 300 WCB

700

T

S-

500

LON

& NY

WPE

UHM

IN

DERR

600

800

450

500 550

600

0

-20 0

rate

Satu

50

100

150

eam

d St

200 250 300 350

Temperature (oF)

400

450

500 550

600

Saturated steam services above 150 psi use either Super Tek III or S-Tek. Saturated steam services above 250 psig use metal seats.

Metal Seated Ball Valve will take full ANSI body metal material ratings.

www.flotite.com

Tech Bulletin Page 63-11

Dimensions - Reduced Bore

Technical Submittal

SF150/SF300

Series

Size 21/2- 12

Size 1-2

Model SF150 - ANSI Class 150

Mounting Dimensions (SF150/SF300)

Size

C1

Cv

1

11/2

2

3

4

6

8

10

12

5.00

6.50

7.00

8.00

9.00

10.5

11.5

13.0

14.0

0.79

1.26

1.50

2.56

3.00

4.00

5.98

7.87

9.84

2.91

3.62

4.20

6.22

6.38

.52

10.1

11.6

12.8

1.67

2.20

2.61

3.78

4.69

4.33

6.85

7.62

8.92

6.50

7.87

10.4

15.4

15.4

15.4

25.6

37.4

38.0

2.0

2.17

2.56

3.0

3.35

4.61

5.85

6.85

7.00

4.25

5.00

6.00

7.50

9.00

11.0

13.5

16.0

19.0

4

4

4

4

8

8

8

12

12

3.13

3.88

4.75

6.00

7.50

9.50

11.75

14.25

17.0

0.63

0.63

0.75

0.75

0.75

0.87

0.87

1.00

1.00

33

85

160

340

800

1090

2300

4000

7700

Torque Est.

in-lb

Weight

Lbs

95

7

252

12

17

284

38

651

55

840

80

1785

191

4830

10395 315

17850 518

Model SF300 - ANSI Class 300

Size

1

11/2

2

3

4

6

8

10

12

6.50 0.79

7.50 1.26

8.50 1.50

11.14 2.24

12.0 3.15

15.87 3.94

16.5 5.91

18.0 7.87

19.75 9.53

C1

Cv

2.91

3.62

4.13

6.77

7.68

7.52

10.1

11.6

13.7

1.67

2.20

2.61

3.78

4.69

4.33

6.85

7.62

8.92

6.50

7.87

10.4

15.4

15.4

15.4

25.6

37.4

38.0

2.18

2.60

2.92

3.75

3.86

4.61

5.85

6.85

7.00

4.88

6.14

6.50

8.27

10.0

12.5

15.0

17.5

20.5

4

4

8

8

8

12

12

16

16

3.50

4.50

5.00

6.62

7.87

10.63

13.0

15.25

17.75

0.75

0.87

0.75

0.87

0.87

0.87

1.00

1.14

1.25

33

85

160

340

800

1090

2300

4000

7700

Torque Est.

in-lb

Weight

Lbs

100

9

265

18

298

25

684

56

882

75

1874

133

5072

303

10915 464

18743 818

ISO

Size

1.65 0.43 0.59 0.250 0.37 #10-24UNC F04

11/2

1.97 0.43 0.75 0.315 0.43 1/4-20UNC

2.76 0.55 0.91 0.374 0.62 5/16-18UNC F07

4.02 1.31 2.59 0.669 1.10 1/2-13UNC

F10

4,6

4.02 1.75 3.07 0.669 1.10 1/2-13UNC

F10

8,10 4.92 1.65 3.58 1.024 1.71 1/2-13UNC

F12

5.51 2.13 3.86 1.378 1.97 5/8-11UNC

F14

12

F05

Size

1-2

Size

21/2- 12

* Verify mounting dimensions before

manufacturing mounting hardware

Unique Design Feature

Tamper Proof Locking Device Standard

Valve topworks

incorporates a tamper

proof locking device,

locks in open or

closed positions.

When valve stop

housing is removed,

four bolts remain to

mount actuator bracket.

Size: 21/2~8

Pressure Relieving &

Equalizing Seat Design

Specially

designed seats

allow equalization of pressure

in the ball cavity

which reduces

operating torque

and increases

seat life.

Ball Design Added

Safety Feature

All balls are provided

with a 1/8 hole drilled

into the stem slot of each

ball to prevent excessive

pressure build up in the

cavity from trapped liquid when the valve is in

the open position.

Due to continuous development & improvement of our product range, we reserve the right to alter the dimensions & technical data included in this brochure.

6

www.flotite.com

Tech Bulletin Page 64-11

High-Tech Design Features

Flo-Tites Van Guard Stem Sealing System, designed to minimize fugitive

emissions. Increases safety and provide an immediate ball valve solution to the

newer EPA performance requirements, for valves meeting with a leak rate of

500ppm.

Flo-Tites Van Guard Seal, state of the art stem sealing system. Incorporating a

Size 1/2-2

AntiExtrusion

Stem

Packing

Tab Washer

Belleville

Washer

Follower

triple set of valve stem seals. This unique system eliminates the possibility of valve

stem leaks in most all media applications.

Stem

O-Ring

STAGE I - FRONT LINE

Stage I provides a front line defense against leakage. The blow-out proof stem

shoulder has a 45 degree bell shaped slope. The bell shaped design offers more

sealing surface, effectively blocking all leak paths during rotation. The wedging

action of the portion of the stem is far superior to the common small flat stem

shoulder design.

Conical

Front

Seal

STAGE II - GUIDE-SEAL

The O-ring originated early in valve design and has been a proven performer in

high cycle applications. Its basic function reduces the potential of machining

inperfections and provides a low torque flexible seal. This center guide also helps

to maintain a perfect stem alignment, by eliminating side loading stress which can

cause stem leaks.

Size

21/2- 12

STAGE III - LIVE-SEAL

Live-seal is considered the intellectual component and the workhorse of Flo-Tites

Van Guard stem sealing system. Working in unison with stages I and II, stage III

calls upon the use of V-Ring packing sets which expands sideways as it is

compressed and pressurized blocking all air pockets. The Van-Guard stem system

is energized by disk or coil springs which continueouly adjusts packing compression to componsate for wear, pressure or temperature changes.

Whether your service involves volatile organic compounds, volatile hazardous

chemicals, or air pollutants, Flo-Tites ball valves are by design dependable,

long lasting and fully maintainable. Flo-Tite has various valve solutions and

designs that provides end-users freedom of choice for the toughest requirements

imposed by the industry and by international standards.

Packing

Gland

Coil

Spring

AntiExtrusion

Energized

Follower

Stem

Packing

Stem

O-Ring

Conical

Front Seal

Flex-Load Energized Seat Design

Seat

O Ring

Body

Ball

Upstream

Pressure

Seat

Viton O Rings are inserted behind valve seats. The O Ring exerts only a

minimum amount of pressure on the seats that in turn helps seal on both

upstream and downstream sides of the ball. Also, helps provide additional

seat memory.

Ideal for high cycle, very low pressure & vacuum service applications.

Flanged Valves with Media Containment Units

The I-SO-Mount platform is ideal for the addition of our secondary containment units. Flo-Tites media containment unit offers in-line maintenance for

stem repair, protection for high temperature service, fugitive emission

monitoring for early leak detection, positive displacement. It also can be used

as a high-tech stem extension. See Tech Bulletin Page 140.

Fugitive Emission

Top Bonnet Design

www.flotite.com

Tech Bulletin Page 65-11

Product Identification Code for Complete Valve Model Numbers

Model

Body

Material

Seat

316SS SS TFM

WCB CS CTFM

RTFM

Full Port:

PTFE

F150

RPTFE

F300

50/50

UHMWPE

PEEK

Cavity Filled

Red. Port:

SF150

METAL

SF300

Stem Seal Body Seal

F

Y

X

T

R

S

U

P

C

M

TFM

CTFM

RTFM

PTFE

RPTFE

50/50

UHMWPE

GRAPHITE

TFM

RTFM

PTFE

RPTFE

50/50

UHMWPE

PEEK

GRAPHITE

F

Y

X

T

R

S

U

G

F

X

T

R

S

U

P

G

Operator

Size

1/2

3/4

1

Oval

O

Locking

11/4

G 11/2

GEAR

Deadman S 2

Actuator A 21/2

Bare Stem N 3

4

6

8

10

12

Lever

Locking

15

20

25

32

40

50

65

80

100

150

200

250

300

Ordering Information

when placing an order or requesting a quotation, please

provide as many details on the application as possible such

as media type, temperature, pressure, pipe size and etc.

Material Identification

Flo-Tites marking system

follows MSS SP-25-1998

guidelines. In addition to the

casted body information, we

have decided to add metal

name plates that identify all

valve soft parts.

Valve users worldwide will be able to contact Flo-Tite

quickly for any installation or service requirements as the

company website address will be on all valves.

Ordering Examples by Part Numbers

Model

Body

Seat

Material

Stem

Seal

Body

Operator Size

Seal

Reduced Port Stainless

TFM GRAPHITE TFM

316

Class 150

SF150 Stainless F

G

F

316

LEVER

L

Special

Feature

Media

2 Containment

50

H3

Optional - Special Design Valves

Flanged Valves with

Cryogenic Extension

Vacuum Service Suitable to 20 Micron

Flo-Tite offers cryogenic

Flanged Valve with Fusible Link

Specially cleaned and lubricated valves can handle services

of 10-3 mm of Hg (1 micron)

flanged valves. See tech

Flo-Tite offers flanged valve

with fusible link. See tech

bulletin page 126.

bulletin page 138.

Flanged Valve in Control Valve Service

Flo-Tite offers modulating V-port control valves. The V-ball is characterized

to meet all custom flow requirements. See tech bulletin page 120.

V-ports 15, 30, 60, 90 deg V & slotted balls.

Flo-Tite Ball Valves, serving multi-national end users in a wide range of applications

in many industries including:

Chemical & petrochemical

Power generation plants

Ship building industries

Fiber industries

Food industries

LNG, HRSG industries

Oil refinery industries

Desalination industries

Steel & iron industries

Pulp & paper plants

Coal & mining industries

Higher Presure HVAC Applications

Specific descriptions, dimensions and construction details illustrated may vary slighly from this bulletin. They arefor general use only.

We reserve the right to revise or modify product design without prior notice.

Flo-Tite, Inc.

305 East 21st Street

Lumberton, NC 28358

P.O. Box 1293

Lumberton, NC 28359

Website:www.flotite.com

Tel: (910) 738-8904

Fax: (910) 738-9112

E-mail: flotite@nc.rr.com

This brochure is general in nature and manufacturer reserves the right to alter dimensions, materials or to make design improvements

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Peterson - Magazines 20th CenturyDokumen480 halamanPeterson - Magazines 20th CenturyhehrlicherBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- CD KEY Untuk PerusahaanDokumen30 halamanCD KEY Untuk PerusahaanAriagus BjoBelum ada peringkat

- Ironmaking and Steelmaking Theory and PracticeDokumen9 halamanIronmaking and Steelmaking Theory and PracticeRasul BzBelum ada peringkat

- Ironmaking and Steelmaking Theory and PracticeDokumen9 halamanIronmaking and Steelmaking Theory and PracticeRasul BzBelum ada peringkat

- Nikon D7000 User's Manual (English) PrintableDokumen348 halamanNikon D7000 User's Manual (English) PrintablegoldfiresBelum ada peringkat

- Fitness For Service Data Form (Draft)Dokumen3 halamanFitness For Service Data Form (Draft)viller_lpBelum ada peringkat

- API 571 Study GuideDokumen11 halamanAPI 571 Study Guideviller_lp100% (4)

- API 510 Final Exam ReviewDokumen138 halamanAPI 510 Final Exam ReviewJeganeswaranBelum ada peringkat

- Teach Yourself Logic 2020 - Peter SmithDokumen99 halamanTeach Yourself Logic 2020 - Peter SmithPaolo Pagliaro100% (1)

- Industry Program Changes and EnhancementsDokumen3 halamanIndustry Program Changes and Enhancementsviller_lpBelum ada peringkat

- ISO 27001-2022 Transition BookDokumen20 halamanISO 27001-2022 Transition BookzghibBelum ada peringkat

- HEI 10th CondenserDokumen100 halamanHEI 10th CondenserHimanshu Chaturvedi100% (6)

- Battle of The Giants - Comparing Kimball and InmonDokumen15 halamanBattle of The Giants - Comparing Kimball and InmonFelipe Oliveira GutierrezBelum ada peringkat

- SQL Introduction and Practical ExamplesDokumen97 halamanSQL Introduction and Practical ExamplesRajiv Kumar100% (1)

- Refining Standards & Specifications Communication SP-42-18.2 Accessories For Atmospheric Storage TanksDokumen3 halamanRefining Standards & Specifications Communication SP-42-18.2 Accessories For Atmospheric Storage Tanksviller_lpBelum ada peringkat

- Surface Eddy Current Scan TemplateDokumen11 halamanSurface Eddy Current Scan Templateviller_lpBelum ada peringkat

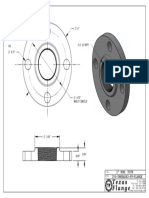

- 2" 150# Threaded FF FlangeDokumen1 halaman2" 150# Threaded FF Flangeviller_lpBelum ada peringkat

- Believers Adopted as HeirsDokumen4 halamanBelievers Adopted as Heirsviller_lpBelum ada peringkat

- Refining Standards & Specifications Communication SP-42-18 Atmospheric Storage TanksDokumen9 halamanRefining Standards & Specifications Communication SP-42-18 Atmospheric Storage Tanksviller_lpBelum ada peringkat

- Steel Tube and PipeDokumen63 halamanSteel Tube and PipeHasan AhmedBelum ada peringkat

- Overview of Data Required For Flaw and Damage AssessmentDokumen1 halamanOverview of Data Required For Flaw and Damage Assessmentviller_lpBelum ada peringkat

- BloodHorseDaily 20161124Dokumen32 halamanBloodHorseDaily 20161124viller_lpBelum ada peringkat

- Dog Training Book Rex in The CityDokumen56 halamanDog Training Book Rex in The CitybebekbuluhBelum ada peringkat

- 800 1500lb GateValveDokumen1 halaman800 1500lb GateValvePham AnhBelum ada peringkat

- Map of United States District Court CircuitsDokumen1 halamanMap of United States District Court Circuitscartographica100% (2)

- Ultra Sonic Flow Meter ManualDokumen97 halamanUltra Sonic Flow Meter ManualYashwanth MnBelum ada peringkat

- Installation Procedures for Inspection PortsDokumen2 halamanInstallation Procedures for Inspection Portsviller_lpBelum ada peringkat

- Carbon MonoxideDokumen1 halamanCarbon MonoxideAhmedAmer1Belum ada peringkat

- API 571 Practice TestsDokumen75 halamanAPI 571 Practice Testsviller_lp100% (3)

- Access Plug Flange CatalogDokumen16 halamanAccess Plug Flange CatalogEcruz Cruz LBelum ada peringkat

- ASNT Exam Hellier Payment Form HoustonDokumen1 halamanASNT Exam Hellier Payment Form Houstonviller_lpBelum ada peringkat

- ANSI RatingsDokumen2 halamanANSI Ratingsviller_lpBelum ada peringkat

- Map To Texas OperationsDokumen1 halamanMap To Texas Operationsviller_lpBelum ada peringkat

- DP 300 Portable Hardness TesterDokumen2 halamanDP 300 Portable Hardness Testerviller_lpBelum ada peringkat

- Karl Kraft's 2014 Level III BrochureDokumen2 halamanKarl Kraft's 2014 Level III Brochureviller_lpBelum ada peringkat

- Sandip University: End Semester Examinations-June 2021Dokumen1 halamanSandip University: End Semester Examinations-June 2021Industrial Training Institute ITI,SilvassaBelum ada peringkat

- Jedec Publication: TNHH Loc Ha VPDokumen58 halamanJedec Publication: TNHH Loc Ha VPxuanquyvtBelum ada peringkat

- Pervasive Healthcare Computing: EMR/EHR, Wireless and Health MonitoringDokumen3 halamanPervasive Healthcare Computing: EMR/EHR, Wireless and Health MonitoringPajak RedikonBelum ada peringkat

- Performance: Lenovo Legion 5 Pro 16ACH6HDokumen5 halamanPerformance: Lenovo Legion 5 Pro 16ACH6HsonyBelum ada peringkat

- Gaussian Filtering FpgaDokumen7 halamanGaussian Filtering Fpgaakkala vikasBelum ada peringkat

- AWUS036EW User Guide PDFDokumen29 halamanAWUS036EW User Guide PDFFelipe GabrielBelum ada peringkat

- Sunnxt AppDokumen8 halamanSunnxt ApppsiphoniphoneBelum ada peringkat

- Saurabh CV FormatDokumen3 halamanSaurabh CV FormatJane MooreBelum ada peringkat

- SPDIF WhitepaperDokumen14 halamanSPDIF Whitepaperapi-3760834100% (1)

- LG CM8440 PDFDokumen79 halamanLG CM8440 PDFALEJANDROBelum ada peringkat

- LogDokumen57 halamanLogEva AriantiBelum ada peringkat

- Assignment 4Dokumen2 halamanAssignment 4Priya RadhakrishnanBelum ada peringkat

- Ii. Literature Review: 2.1. Reclamation Bond ProvisionDokumen45 halamanIi. Literature Review: 2.1. Reclamation Bond ProvisionRandy SyamBelum ada peringkat

- Mock - 3sDokumen20 halamanMock - 3sPichuRangerBelum ada peringkat

- Epayroll System: User ManualDokumen66 halamanEpayroll System: User Manualvivek anandanBelum ada peringkat

- IT 111 Chapter1Dokumen72 halamanIT 111 Chapter1Maria Jonalene Dela MercedBelum ada peringkat

- G120X Op Instr 0319 en-USDokumen966 halamanG120X Op Instr 0319 en-USABI RAJESH GANESHA RAJABelum ada peringkat

- Tieng Anh 10 Friends Global - Unit 8 - Test 2Dokumen8 halamanTieng Anh 10 Friends Global - Unit 8 - Test 2haminhpham1708Belum ada peringkat

- Conectividad para Sistemas Industriales Jun 2018Dokumen49 halamanConectividad para Sistemas Industriales Jun 2018Cristian TorresBelum ada peringkat

- Harsh Environment UPS Features for Critical Industrial ApplicationsDokumen2 halamanHarsh Environment UPS Features for Critical Industrial Applicationsandy175Belum ada peringkat

- Presentation of Dairy Management SystemDokumen35 halamanPresentation of Dairy Management SystemEnola Syawla100% (1)

- Power Point Chapter - 15Dokumen6 halamanPower Point Chapter - 15Shahwaiz Bin Imran BajwaBelum ada peringkat

- Fertilizer Information System For Banana PlantatioDokumen5 halamanFertilizer Information System For Banana PlantatioHazem EmadBelum ada peringkat

- Rajant VHDC-24V-50W and VHDC-24V-50W-LC Data Sheet PDFDokumen2 halamanRajant VHDC-24V-50W and VHDC-24V-50W-LC Data Sheet PDFMaxtreme0070% (1)

- Face RecogDokumen26 halamanFace RecogFavasBelum ada peringkat