73M Bridge

Diunggah oleh

manoj_structureJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

73M Bridge

Diunggah oleh

manoj_structureHak Cipta:

Format Tersedia

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

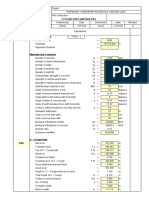

DESIGN DATA FOR SUPERSTRUCTURE(73 M BRIDGE)

Span of bridge

Nos. of panels

Length of intermediate panels

Length of end panels

Spacing of intermediate girders

Spacing of end girders

Width of slab

Panel length of slab

Panel width of slab

Thickness of deck slab

Width of carriageway

Av. Thickness of wearing coat

Density of concrete(slab)

Density of wearing coat

Height of truss

Height of kerb

Width of kerb

Impact factor (for steel members)

Length of cross girder

Width of member

Effective width of bridge

Width of footpath

Overall width

SATVIR GUPTA FABRICATOR

73

11

6.636

6.636

6.636

6.636

4.68

4.68

6.636

0.008

4.25

0

2.5

2.5

7.5

0.275

0.215

1.154

4.68

0.4

5.104

0

5.50

m

nos

m

m

m

m

m

m

m

m

m

m

t/m3

t/m3

m

m

m

m

m

m

m

m

3.318

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF DECK SLAB :

A)Dead load calculation :

Dead load intensity of deck :

dead loadintensity of wearing:

total

0.008

0

*

*

7.85

2.5

=

=

0.0628

0

0.0628

0.23

Say

Use M25 grade of concrete and spanning transversely between the cross girder . Influence

co-efficient are taken from "Steel Table" by Prof. Ramamrutham.

Deck slab is design like a continuous beam.

B.M. due to dead load :

a. + Ve B.M. at 0.5L in the end

=

0.078 x

0.23

=

0.790101322 t-m/m

b. -Ve B.M.at penultimate support

=

0.105 x

0.23

=

1.063597934 t-m/m

c. -Ve B.M. at inner support

=

0.079 x

0.23

=

0.800230826 t-m/m

d. +Ve B.M.at 0.5L in inner span

=

0.046

=

0.46595719 t-m/m

SATVIR GUPTA FABRICATOR

0.23

6.636 *

6.636

6.636

6.636

6.636

6.636

6.636

6.636

t/m2

t/m2

t/m2

t/m2

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Live load calculation :

CLASS A LOAD

Length of load

:

Total load

:

Width of track

:

Width overall track

:

Clearence

:

0.25

11.4

0.5

2.3

0.3

m

t

m

m

m

Dispersed width of load in longitudinal direction :

=

=

0.25 +

0.266 m

2 *(

Bw =

=

2.708 m

6.636 m

4.68

/

6.636

=

0.70520548

2.48 ( As per IRC-21 cl -305.16.2 for continuous slab)

0.5 +

0.5 m

Be =

2.48 *

=

3.9755

+

=

4.475 m >

So there is overlapping.

2.708 ( 1 0.5

1.8 m

1.8 m

4.475

SATVIR GUPTA FABRICATOR

0.008 )

11.4

1.22

Alpha * x ( 1 - x/l) + Bw

l =

6.636 m

x =

2.708 m

Length of slab / Width of slab

So Alpha

+

11.4

Dispersed width of load in transverse direction

Be =

0.4080822

) +

0.5

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

So Be

4.475 +

1.8 =

Intensity of load :

Impact factor

:

50 % as per IRC-6-2000

=

11.4 *

1.5 / (

=

2.724885869 t/m

Total intensity of load =

2.7248859 t/m

=

4.1 t/m

B.M. due to live load :

a. + Ve B.M. at 0.5L in the end

=

4.1 *

=

11.10354545 =

4.531159166 tm/m

b. -Ve B.M.at penultimate support

=

6.572386289

SATVIR GUPTA FABRICATOR

2.7081818 6.5723863

6.2754922 m

6.2754922 *

1 )

4.1 *

2.70818 *

3.9282 /

6.6364

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Total B.M.

1. Max . -Ve B.M. :

2. Max. + Ve B.M. :

1.063597934

0.790101322

+

+

6.57238629

4.53115917

=

=

7.635984 tm

5.32126 tm

Check for depth of deck slab :

Depth reqd. : SQRT(

M / R b)

Use M35 Grade Concrete

Here Permissible compressive stress of concrete:

Permissible tensile stress of steel

:

For bridge m

:

k =

=

=

11.5

115

0.323943662

*

/

j =

=

1

0.892018779

R =

=

0.5 *

1.661542022

11.5 N/mm2

240 N/mm2

10

10 /

355

11.5 *

10

240

0.3239437

11.5

0.3239437

0.89202

Check for depth of deckslab :

d reqd =

=

SQRT

76359842.23

214.3763372 mm

Provided depth of deck slab =

Provided clear cover

Dia. of reinforcement

=

Effective depth of deck slab =

=

SATVIR GUPTA FABRICATOR

1.66154202

1000

8 mm

40 mm

12 mm

8 -38 mm

40

>

O.K.

214.3763 mm

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Main reinforcement :

1. Top reinforcement :

Ast

=

=

76359842.23 / (

-9386.33795 mm2/m

Provided

240

16 dia bar @

0.8920188

-38 )

130 mm c/c. Area provided =

1547 mm2

Hence OK

2.Bottom reinforcement :

Ast

=

=

53212604.88

/

-6541.02311 mm2/m

Provided

240

12 dia bar @

Distribution reinforcement

Ast

=

=

OR Ast =

0.8920188

-38

150 mm c/c. Area provided =

754 mm2

Hence OK

0.12

*

9.6 mm2/m

1000

0.3 *

Provided

10 dia bar @

-9386.3379 =

100

-2815.9 mm2

200 mm c/c. Area provided =

392.7 mm2

Check for shear :

Shear force

at support

=

=

=

=

=

Depth (d)

Width (b)

Due to Dead Load

0.23

4.1

0.763181818

8.209455791

-38

1000

*

*

+

t

mm

mm

6.63636364

/

5.41636364 /

7.44627397

0.23 t/m

0.008 m

A

X

SATVIR GUPTA FABRICATOR

2 *

6.636364

6.6363636 m

4.1 +

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

X

Reaction on Support

:

=

=

0.23

4.1

0.7631818

8.2094558

Force at section X-X :

=

8.209455791 8.207615791 t

Shear stress

82076.15791 / (

-2.15989889 N/mm2

=

=

% of Tensile steel

:

;

Permissible shear stress :

100

-38

-4.07008

/

*6.63636364

*

5.4163636 /

+

4.1 +

ton

0.23 *

-38

*

*

-0.683118 N/mm2

Hence OK

As per Cl. 304.7.1.3.3 of IRC : 21 : 2000

The shear stress shall be increased by 15 %

SATVIR GUPTA FABRICATOR

2 +

6.63636

3.34627

4.1 +

0.008

1000 )

1546.6302

1000

-4.07008

0.75

1.00

-0.59402

0.37

0.42

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF INTERMEDIATE CROSS GIRDER:

Crossgirder is design as a composite section.Composite section is consist of deck slab

and steelsection.

Ec =

290000 kg/cm2

Es =

2110000 kg/cm2

Section Properties ( Permanent Loads)

m

15 ( For Bridge)

Effective flange width ( As per IRC 21 -2000-cl-305.15.2)

be =

bw + l/ 5

13.35

+

468

/

=

106.95 cm

beff =

=

106.95

15

Properties ISMB 400

Area

78.46 cm2

C.G.

20.00 cm

I

20458.4 cm4

Depth

40.00 cm

7.13 cm

Section properties for dead loads :

Item

size(cm)

B(cm)

t(cm)

Slab

7.13000

ISMB 400

14

Plate

33

0.8

0.89

Total

5.704

78.46

1634.2496

20458.70421

/

+

SATVIR GUPTA FABRICATOR

A * Yt(cm3) A*Yt2(cm4Ixo(cm4)

0.4

2.2816

20.8 1631.968

40

84.164

Ycg =

Ixx

Area (cm2) Yt(cm)

0.9 0.30421

33945 20458.4

61.2 1634.2496

33946 20458.7

84.164

19.417442 cm

33945.847

19.417442

*

*

19.4174

84.164

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

22671.60421 cm4

=

=

22671.60421 /

1167.589637 cm3

19.417442

Zbb =

=

22671.60421 /

1060.284946 cm3

21.382558

Ztt

400

ISMB 400

Section Properties ( Transient Loads)

m

7.5 ( For Bridge)

Effective flange width ( As per IRC 21 -2000-cl-305.15.2)

be =

bw + l/ 5

6.675

+

468

/

=

100.275 cm

beff =

=

100.275

7.5

Properties ISMB 400

Area

78.46 cm2

C.G.

20.00 cm

I

20458.4 cm4

Depth

40.00 cm

13.37 cm

Section properties :

Item

size(cm)

B(cm)

t(cm)

Slab

13.37

ISMB 400

14

Plate

33

Total

SATVIR GUPTA FABRICATOR

Area (cm2) Yt(cm)

0.8

0.89

10.696

78.46

0

89.156

A * Yt(cm3) A*Yt2(cm4Ixo(cm4)

0.4

4.2784

20.8 1631.968

40

1.7 0.57045

33945 20458.4

61.2 1636.2464

33947

20459

400

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ycg =

Ixx

1636.2464

18.352622 cm

33946.646

18.352622

20458.97045

24376.20393 cm4

=

=

24376.20393 /

1328.213671 cm3

18.352622

Zbb =

=

24376.20393 /

1085.926576 cm3

22.447378

Ztt

89.156

SATVIR GUPTA FABRICATOR

400

*

*

18.3526

89.156

ISMB 400

400

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

LOAD CALCULATION :

1) Dead load :

Load due to deck slab :

0.23

Load due to crossgirder :

Total UDL :

6.6363636

1.53 t/m

0.06 t/m

1.59 t/m

1.59

5.104 m

A

4.05

B

4.05

Max. SF at end =

=

1.59 *

4.05 t

Max. B.M. at mid =

4.05

*

=

5.104

2.552

t

2

1.59

5.104

5.7

1.48

5.17 t-m

Live load analysis for Crossgirder :

Load of each wheel with impact:

SATVIR GUPTA FABRICATOR

8.436 t

5.104

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

6.636

Max. reaction at central support

8.436 t

8.436

1.22 m

6.636

8.436 +

:

8.436

8.436 +

15.321163 ton

5.41636

6.6364

6.8851627

Max. B.M. :

1.652

15.32 t

15.32 t

1.652

1.8

1.035

A

B.M.

:

=

=

Max. S.F. :

5.104 m

15.32

15.32

15.32 *

25.31

25.31 tm

0.212 0.325

2.552

15.32 t

0.40

SATVIR GUPTA FABRICATOR

15.32

0.9

15.32 t

1.8

2.455

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

5.104

A

S.F. : (

B

15.32

4.255

15.32

2.455 )

5.104

/

+

=

=

=

102.805002 /

20.14204584

20.14204584 t

Total B.M. :

Total S.F. :

5.104

5.17

4.05

+

+

25.31

20.14

=

=

30.48 t-m

24.19 t

Check for compressive and tensile stress :

Max. compressive stress in concrete :

due to dead load

517093.958 /

29.5248686 kg/cm2

1167.59

<

15

116.7 kg/cm2

Hence OK

Max . Tensile stress in steel

due to dead load

:

=

517093.958

/

487.693389 kg/cm2

1060.285

<

1550 kg/cm2

Hence OK

Max. compressive stress in concrete :

due to live load

2531056.08 /

254.081216 kg/cm2

1328.214

>

7.5

116.7 kg/cm2

Revise

Max . Tensile stress in steel

due to dead load

:

=

2531056.08

/

2330.78013 kg/cm2

1085.927

>

1550 kg/cm2

Revise

Total compressive stress in concrete

283.606085 Kg/cm2

Total tensile stress in steel

2818.47352 Kg/cm2

SATVIR GUPTA FABRICATOR

<

<

116.7 Kg/cm2

1550 Kg/cm2

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Shear stress

SATVIR GUPTA FABRICATOR

24194.5063 / (

776.709674 Kg/cm2

0.89 *

<

35 )

950 Kg/cm2

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Connection of Plate and angle :

Maximum shear

24.19450633 t

Horizental shear per 1 cm length

Ay

I

=

24194.50633

12.46 *

18.972442

#REF!

16.387

22671.60421

=

1.067172226

* (

236.39663

#REF! )

#REF! kg

Provide staggere pitch

Dia of rivet

Shear strength of rivet

1.6 cm

3.14*

=

Bearing strenght

7.5

16875 kg

#REF!

#REF! cm

#REF!

Provided

10.68 cm spacing c/c

Connection of Web Plate and angle :

Maximum shear

24.19450633 t

SATVIR GUPTA FABRICATOR

1.75

*

/

#REF!

4

#REF! kg

Spacing =

1.75

( Not exceed 12t)

2250

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Horizental shear per 1 cm length

Ay

I

=

24194.50633

6.675 *

14.777442

#REF!

16.387

22671.60421

=

1.067172226

* (

98.639426

#REF! )

#REF! kg

Provide staggere pitch

Dia of rivet

Shear strength of rivet

1.6 cm

3.14*

=

Bearing strenght

7.5

16875 kg

#REF!

#REF! cm

#REF!

Provided

9.6 cm spacing c/c

SATVIR GUPTA FABRICATOR

1.75

*

/

#REF!

4

#REF! kg

=

Spacing =

1.75

( Not exceed 12t)

2250

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF END CROSS GIRDER:

Properties ISA 100 100 8

Area

15.39 cm2

C.G.

2.76

cm

I

145.1 cm4

Depth

cm

Section properties :

Item

size(cm)

B(cm)

PL

PL

ISA 100 100

Web PL

Web PL

ISA 100 100

PL

PL

Total

Ycg =

Ixx

Design as a symmetical section

Area (cm2) Yt(cm)

A * Yt(cm3) A*Yt2(cm4Ixo(cm4) Nos

t(cm)

45

35

10

33.6

31.6

10

35

45

9861.392

1.8

1.6

0.8

1.6

1.2

0.8

1.6

1.8

12016.67333

131447.7438 cm4

81

56

30.78

53.76

75.84

30.78

56

81

465.16

0.9

72.9

65.6

2.6

145.6

378.6

6.16 189.6048

1168.0

21.20 1139.712 24161.9

21.20 1607.808 34085.5

36.24 1115.4672 40424.5

39.8

2228.8 88706.2

41.5

3361.5 139502.3

9861.392 328492.6

465.16

21.2 cm

328492.58

21.2

*

*

21.87

11.9467

290.2

5057.74

6310.9

290.2

11.9467

21.87

12016.7

1

1

2 nos

1

2

2

1

1

21.2

465.16

350 *

16

ISA 100 100 8

Web PL

316

Web PL

336.0

356.0 mm

Ztt

=

=

131447.7438 /

6200.365275 cm3

SATVIR GUPTA FABRICATOR

21.2

12

424

16 mm

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Zbb =

=

131447.7438 /

6200.365275 cm3

SATVIR GUPTA FABRICATOR

21.2

450 *

18 mm

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Stress check for Jackup Condition :

47.5

47.5 t

-1.198 m

-1.198

7.5 m

Reaction on each support A

B.M. at Support A :

47.5

47.45

Bending stress

:

=

-56.8451

*

-916.802438 kg/cm2

:

=

47.45 *

279.7759434 kg/cm2

Combined Stress

2.552

47.5

3.8

42.4

-56.8451 t-m

S.F. at centre

Shear stress

-1.198

47.5

47.5 t

-56.8451 t-m

S.F. at support A :

=

B.M. at centre

47.45 t

SQRT

SATVIR GUPTA FABRICATOR

-916.8024

100000

<

1000

<

*

/

6200.365

1650kg/cm2

4

950 kg/cm2

-916.8024

3 *

279.78

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

*

=

1036.991054 kg/cm2

<

2300kg/cm2

OK

SATVIR GUPTA FABRICATOR

279.78

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CONNECTION BETWEEN CROSSGIRDER AND BOTTOM CHORD :(Intermediate Girder)

Max. S.F.

24.194506 t

Use 2 nos ISA 150* 150* 12 as a cleat angle

Depth :

Thick :

35.00 cm

1.2 cm

Shear stress

:

=

24194.506 / (

776.70967 kg/cm2

<

O.K.

35 *

0.89 )

950 kg/cm2

( 0.38fy)

Design of nos. bolt :

1.Connection between crossgirder and cleat angle :(Intermediate Girder)

Force : 24194.506 kg

Min thick

0.89 cm

HSFG Bolt :

Provide 22 dia 8 G Bolts

As per table 1 of SP:6(4)-1989

Proof Load =

18180 Kg

Shear per Bolt

=

0.45 *

18180 *

=

5843.57 N

Kg

N=2

Nos. of effective interfaces

Shear per Bolt =

5843.5714 * 2

=

11687.143 Kg

Nos. of Bolts reqd. = 24194.506 /

11687.14 *

= 2.1736905

Provided 6 Nos Bolt

SATVIR GUPTA FABRICATOR

N / 1.4

1.05

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

2.Connection between bottomchord and cleat angle :(Intermediate Girder)

Force : 24194.506

Min thick

0.76

Dia of Bolt:

Gross dia :

Bolt value

Nos. of bolts reqd :

=

Provided

kg

cm

2.2

2.35

5843.5714

24194.506

4.347381

cm

cm

Kg

*

nos

3 nos bolt on each side

SATVIR GUPTA FABRICATOR

1.05

5843.57

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CONNECTION BETWEEN CROSSGIRDER AND BOTTOM CHORD :(End Girder)

Max. S.F.

47.5 t

Use 2 nos ISA 200* 200* 16 as a cleat angle and 10mm plate both side

Depth :

Thick :

33.6 cm

2.6 cm

Shear stress

:

=

47450 / 2 *

271.57738 kg/cm2

<

O.K.

33.6 *

950 kg/cm2

2.6

Design of nos. of rivet :

1.Connection between crossgirder and cleat angle :(End Girder)

Force :

47450 kg

Min thick

2.6 cm

Dia of rivet:

2.4 cm

Gross dia :

2.55 cm

Permissible shear strss :

950 kg/cm2

Permissible bearing strss :

2250 kg/cm2

We provided the cleat angle on both side of web of cross girder. So double shear will be

acted.

Use 22 mm dia power driven rivet.

Shear strength of rivet

=

=

SATVIR GUPTA FABRICATOR

2 * 3.14*

9698.48 kg

2.55

2.55

*

/

950

4

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Bearing strength

Rivet value

Nos. of rivets reqd

=

Provided

=

=

:

4 *

22950 kg

2.55

2250

9698.4788 kg

47450 *

5.8710238 nos

20 nos of rivet

SATVIR GUPTA FABRICATOR

1.2

9698.48

b

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

2.Connection between bottomchord and cleat angle :(End Girder)

Force :

47450 kg

Min thick

1.6 cm

Dia of rivet:

2.4 cm

Gross dia :

2.55

Permissible shear strss :

950 kg/cm2

Permissible bearing strss :

2250 kg/cm2

Use 24 mm dia power driven rivet.

Shear strength of rivet

Bearing strength

Rivet value

Nos. of rivets reqd

=

Provided

3.14*

4849.24 kg

=

=

1.6 *

9180 kg

2.55

2.55

2.55

4849.2394 kg

47450 *

11.742048 nos

20 nos of rivet on each side

SATVIR GUPTA FABRICATOR

1.2

4849.24

*

/

2250

950

4

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF SHEAR CONNECTORS :

The longitudinal shear per unit length at the interface of prefebricated section and castin-situ shall be evaluated from the following expression.

VL =

VL =

V =

Ac =

Ycg =

VL =

=

=

V *

Ac *

Ycg /

Longitudinal shear per unit length.

Vertical shear due to SIDL and live load with impact =

20870.8

Area of transform section on one side of interface

=

0

Distance of the centriod of the area under consideration from the neutral axis

of the composite section. (

23.0136867 0.4 )

=

22.6137

Moment of inertia of the composite section

=

22671.6

20870.80415 *

0 kg/cm

0 N/mm

0 *

22.613687

Use ISA 75*75*8 as a shear connectors with 10 dia bar and grade of concrete is M35

For the angle connector made with mild steel (As per IRC-21-cl-611-4-1-3-1)

Q

=

3.32 * (

h + 0.5 t) L * SQRT fck

10mm dia bar

100mm

ISA75*75*8

150mm

40mm

crossgirder

SATVIR GUPTA FABRICATOR

22671.6

kg

cm2

cm

cm4

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Q =

h

=

t

=

L

=

SQRTfck :

The safe shear resistance in Newton's of one shear connector

Mimimum thickness of flange

=

8 mm

Mimimum thickness of web

=

8 mm

Length of shear connector

=

140

SQRT

35

=

5.9160798

3.32 * (

3.32 *

155166.9406 N

=

=

=

75

79

+ 0.5 *

*

8 ) *

100 *

2 *

100

5.91608

20

Spacing of shear connectors :

P

=

=

=

Q

/

155166.9406 /

#DIV/0! mm

VL

But P <

600 mm

OR

4 *

So We provided ISA 75*75*8 @ 200 mm C/C

SATVIR GUPTA FABRICATOR

Height of connector

600mm

5.91607978

100

mm

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

0.9955 t

1.6 m

Design of Footpath Beam :

1.7 m

Intensity of live load

( P' :

400.00-

260

260

4800 ) (

73

65.753425 ) (

16.5

15

16.5

- W )

-

0 )

15

205.75

226.32877 kg/m2

Dead load due to deck slab :

Load duee to live load

1.1

0.15 *

0.226 *

6.6363636 *

2.5 =

2.4886 t/m

=

=

1.502 t/m

3.9906 t/m

0.9955 t

6.6363636

Total

Point load due to railing and railing post :

B.M. :

=

=

3.990636364 *

5.766469545

+

7.359196818 t-m

SATVIR GUPTA FABRICATOR

0.15 *

1.7 *

1.5927273

6.636

1.7

/

0.995455 *

+

1.6

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

S.F. :

3.990636364 *

1.7

0.9954545

7.77954 t

Provided ISMB 200 as a footpath beam

A

:

Ixx :

Zxx :

Zyy :

Depth :

Thickness

32.33

2235.4

223.5

30

20

0.57

cm2

cm4

cm3

cm3

cm

cm

Bending stress

:

=

7.359196818

*

3292.705511 kg/cm2

:

=

7.779536364 *

682.4154705 kg/cm2

Shear stress

Combined Stress

SQRT

3292.7055

3498.425676 kg/cm2

100000

<

1000

/

1550kg/cm2

223.5

20

3292.7055

<

2300kg/cm2

0.57

3 *

*

682.42

682.42

OK

DESIGN OF FOOTPATH SLAB

Dead load of footpath Slab

:

:

0.15

2.5

Use M35 grade of concrete and spanning transversely between the cross girder . Influence

SATVIR GUPTA FABRICATOR

0.375 t/m2

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

co-efficient are taken from "Steel Table" by Prof. Ramamrutham.

Deck slab is design like a continuous beam.

B.M. due to dead load :

a. + Ve B.M. at 0.5L in the end

=

0.078 *

0.375

=

1.288208678 t-m/m

b. -Ve B.M.at penultimate support

SATVIR GUPTA FABRICATOR

6.63636364 *

6.636364

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

=

0.105 *

0.375

=

1.734127066 t-m/m

c. -Ve B.M. at inner support

=

0.079 *

0.375

=

1.304724174 t-m/m

d. +Ve B.M.at 0.5L in inner span

=

0.046 *

0.375

=

0.75971281 t-m/m

B.M. Due to live load :

1. +Ve B.M. at 0.5L in the end span :

=

0.1 *

=

0.996781818 t- m/m

6.63636364

6.636364

6.63636364

6.636364

6.63636364

6.636364

0.2263288 *

6.6363636

6.63636

2. -Ve B.M. atpenultimate support :

=

0.116 *

=

1.156266909 t- m/m

0.2263288 *

6.6363636

6.63636

3. -Ve B.M. at inner support :

=

0.107 *

=

1.066556545 t- m/m

0.2263288 *

6.6363636

6.63636

4. +Ve B.M. at 0.5L in inner support :

=

0.086 *

=

0.857232364 t- m/m

0.2263288 *

6.6363636

6.63636

Total B.M.

1. Max . -Ve B.M. :

2. Max. + Ve B.M. :

1.734127066

1.288208678

Check for depth of deck slab :

Depth reqd. : SQRT(

M / R b)

SATVIR GUPTA FABRICATOR

+

+

1.15626691

0.99678182

=

=

2.890394 t- m/m

2.28499 t- m/m

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Here Permissible compressive stress of concrete:

Permissible tensile stress of steel

:

For bridge m

:

11.5 N/mm2

200 N/mm2

10

k =

=

=

11.5

115

0.365079365

*

/

11.5 *

j =

=

1

0.878306878

R =

=

0.5 *

1.843747375

10 /

315

10

200

0.3650794

11.5

0.3650794

0.87831

Check for depth of deckslab :

d reqd =

=

SQRT

28903939.75

125.2067706 mm

1.84374738

Provided depth of footpath slab =

Provided clear cover

=

Dia. Of reinforcement

=

Width of footpath beam

=

150

40

16

125

Effective depth of deck slab =

150 102 mm

1000

mm

mm

mm

mm

40

>

O.K.

125.2068 mm

Main reinforcement :

1. Top reinforcement :

Ast

=

=

Provided

28903939.75 /

1613.171691 mm2

10 dia bar @

2.Bottom reinforcement :

SATVIR GUPTA FABRICATOR

200

0.8783069

220 mm c/c. Area provided =

102

357 mm2

Revise

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ast

=

=

Provided

22849905

/

1275.287041 mm2

10 dia bar @

Distribution reinforcement

Ast

=

=

Provided

200

0.8783069

250 mm c/c. Area provided =

102

314.16 mm2

Revise

0.12

*

180 mm2

8 dia bar @

SATVIR GUPTA FABRICATOR

1000

150

250 mm c/c. Area provided =

100

201.06 mm2

Hence OK

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Check for shear :

Shear force

= (

=

Depth (d)

Width (b)

=

=

0.375

+

1.995318182 t/m

0.22632877 ) *

6.636364

102 mm

1000 mm

1.99531818 t/m

0.2125 m

6.6363636 m

A

X

Reaction on each Support

:

=

1.9953182 *6.63636364

6.6208285 t

Force at section X-X :

=

6.620828512 6.196823399 t

Shear stress

61968.23399 /

0.607531706 N/mm2

=

=

% of Tensile steel

:

;

Permissible shear stress :

100

102

0.3499992

1.99531818 *

102

*

*

0.2399998 N/mm2

Revise

SATVIR GUPTA FABRICATOR

0.2125

1000

356.99917

1000

0.35

0.75

1.00

0.24

0.32

0.37

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CONNECTION BETWEEN FOOTPATH BEAM AND BOTTOM CHORD :

Check for shear stress :

Moment :

7.36 t-m

Max. S.F.: 7.779536364 t

Moment resisted by equal forces in angles , forming a couple of magnitude equal to end moment.

Pull on angles

Moment

Depth section

735.919682

20

36.796 t

This pull will cause shear in both connecting angles to the section.

Use 2 ISA 150 150 12 as cleat angles

Thickness of web :

0.57 cm

Depth :

15 cm

Shear stress

:

=

36795.98409 /

2151.811935 kg/cm2<

O.K.

0.57

*

1075 kg/cm2

15

Design of nos. of rivet :

1.Connection between beam and cleat angle :

Force :

36795.98409

Min thick :

0.57

Dia of rivet:

Gross dia :

Permissible shear strss

Permissible bearing strss

kg

cm

2.2 cm

2.35 cm

:

:

950 kg/cm2

2250 kg/cm2

We provided the cleat angle on both side of web of cross girder. So double shear will be

acted.

Use 20mm dia power driven rivet.

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Shear strength of rivet

Bearing strength

Rivet value

2 * 3.14*

=

8236.8088 kg

=

=

0.57 *

3013.875 kg

2.35

2.35

*

/

950

4

2250

3013.875 kg

Nos. of rivets reqd :

=

Provided

2.35

36795.98409 *

14.65063445 nos

1.2

3013.875

2.35

2.35

6 nos of rivet .

2.Connection between bottomchord and cleat angle :

Force :

36795.98409

Min thick :

1.2

Dia of rivet:

Gross dia :

Permissible shear strss

Permissible bearing strss

kg

cm

2.2 cm

2.35 cm

:

:

950 kg/cm2

2250 kg/cm2

Use 20mm dia power driven rivet.

Shear strength of rivet

Bearing strength

Rivet value

3.14*

=

4118.4044 kg

=

=

1.2 *

6345 kg

4118.404375 kg

SATVIR GUPTA FABRICATOR

2.35

*

/

950

4

2250

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Nos. of rivets reqd :

=

Provided

36795.98409 *

10.7214292 nos

6 nos rivet on each side.

SATVIR GUPTA FABRICATOR

1.2

4118.404

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CALCULATION OF MULTIPLYING FACTORS :

1. Class A Loading (single lane)

Half width of member

:

Width of kerb

:

Clearence

:

Half Width of overall width of load

0.2

0.227

0.2

0.227

0.15

0.9

m

m

m

m

P(unit load)

0.9

3.377 m

0.40

5.104 m

Multiplying factor with impact :

=

=

Axle Load

Axle Load

Axle Load

3.377

0.763530172

1.154

2.7 t with multipication factor =

11.4 t with multipication factor =

6.8 with multiplication factor =

SATVIR GUPTA FABRICATOR

5.104

2.0615315 ton

8.704244 ton

5.1920052 ton

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

2. Class 24 R Track Loading ( Singla Lane ) :

Half width of member

:

Width of kerb

:

Clearence

:

Half Width of overall width of load

0.2

0.337

0.2

0.227

0.3

1.22

m

m

m

m

P(unit load)

1.22

3.157 m

1.937

0.30

5.104 m

Multiplying factor with impact :

=

=

Track Load

3.157

0.680387931

1.1

5.104

25 t with multipication factor =

=

SATVIR GUPTA FABRICATOR

17.009698 ton

17 ton ( Say )

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Total Wt. of Structral Steel =

Dead load of deck slab :

=

73

0 t

4.68

2.5

Dead load of W.C :

=

73

0 t

4.25

2.4

0.275

73

2.5 *

Wt of kerb

150 ton

0.215 *

21.580625 t

=

Railing

0.1

Total Dead load

186.180625 t

Load per truss

93.0903125 t

93.0903125

/

1.27520976 t/m

UDL on Truss

=

Say :

Snow load =

Total load of snow on the bridge

Load on each truss

SATVIR GUPTA FABRICATOR

73

14.6 t

73

1.3 t/m

25 cm

=

=

=

=

=

=

189.8 t

0.25

76.869

76.869

38.4345

38.4345

0.5265

*

ton

/2

ton

/

ton/m

4.68 *

73

73 *

0.9

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Bearing Load Calculations

Braking force is considered 20 % of live load coming on the span for the first train and 10% for the succeeding train as per

cl. 214.2 of IRC :6.

0

Non Seismic Case

Horizontal force at bearing level :

I

Normal Case Live Load Max.

Total braking force

82.6 kN

Horizontal force at free end

R

=

0.03

LL rc. at free end

x (

474.50

300.00 +

0.03

952.70

28.5811 kN

28.581111

82.6

69.8811 kN

=

Horizontal force =

DL

SATVIR GUPTA FABRICATOR

wind load

178.20 +

0)

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

at fixed end

Max. Vertical load

=

952.70 KN

Governing Longitudnal force at Fixed End

=

Governing Longitudinal force at Free End

2

69.8811 kn

28.5811 KN

Non Seismic Case

Horizontal force at bearing level :

II

Normal Case Live Load Min.

Total braking force

82.6 kN

Horizontal force at free end

R

=

0.03

=

0.03

DL

LL rc. at free end

x (

474.50

296.30

0.00 8.88889 kN

Horizontal force =

at fixed end

8.8888891

+

82.6

=

50.1889 kN

=

2

82.6 =

73.7111 KN

Max. Vertical Load =

296.30 KN

Governing Longitudnal force at Fixed End

=

73.7111 kN

Governing Longitudinal force at Free End

ii

Seismic Case Live Load Max.

SATVIR GUPTA FABRICATOR

178.20 )

8.88889 KN

8.8888891

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Seismic Coefficient

=

Braking force due to live load =

Total braking force in normal case

Fh due to seismic

0.150

0.15

41.3 kN

=

KN

984.5875

) =

147.688 kN

147.6881

41.3

188.988

33.0044

156

kN

188.988

2

Total Vertical load

=

474.50

=

660.09

Governing Longitudnal force at Fixed End

33.0044

127.5

kN

+

KN

=

0.075

475

155.984

kN

33.004

KN

Total Fh in Seismic Case

Fh

Fh/2

x (

41.3

Governing Horizontal force at Free End

ii

188.98813 kN

150.0

Seismic Case Live Load Min.

Seismic Coefficient

=

Braking force due to live load =

Total braking force in normal case

Fh due to seismic

Total Fh in Seismic Case

SATVIR GUPTA FABRICATOR

0.150

=

0.15

41.3 kN

=

x (

41.3

684.59

102.6881

KN

) =

102.688 kN

41.3

143.98813 kN

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

h

Fh

143.988

21.9456

122

kN

143.988

2

Total Vertical load

=

474.50

=

438.91

Governing Longitudnal force at Fixed End

21.9456

93.94

kN

KN

=

0.075

475

122.043

kN

21.946

KN

Fh/2

Governing Horizontal force at Free End

BEARING LOADS FOR 73 M SPAN STEEL BRIDGE OVER INDUS RIVER

Type of superstructure

=

Distribution plate

=

Grade of concrete for pedestal

Steel truss ( Through type)

Reqd.

=

M35

Fixed Bearing

Non Seismic Case

Max. Vertical Load

Min. Vertical load

Hor. Force ( Max. load)

Hor. Force ( Min. Load)

Movement Long.

Movement Trans

Rotation

=

=

=

=

=

=

=

952.7037

296.2963

69.881111

73.711111

0

0

0.01

KN

KN

KN

KN

mm

mm

radians

Seismic Case

Max. Vertical Load

Min. Vertical load

=

=

SATVIR GUPTA FABRICATOR

660.0875 KN

438.9125 KN

0.00

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Hor. Force ( Max. load)

Hor. Force (Min. Load)

Movement Long.

Movement Trans

Rotation

=

=

=

=

=

155.98375

122.0425

0

0

0.01

KN

KN

mm

mm

radians

952.7037

296.2963

28.581111

8.8888891

+/- 40

+/- 4.0

0.01

KN

KN

KN

KN

mm

mm

radians

=

=

=

=

=

=

=

660.0875

438.9125

33.004375

21.945625

+/- 40

+/- 2.5

0.01

KN

KN

KN

KN

mm

mm

radians

=

=

=

=

=

=

=

952.7037

296.2963

69.881111

73.711111

+/- 4.0

+/-12.5

0.01

KN

KN

KN

KN

mm

mm

radians

Guide L Bearing

Non Seismic Case

Max. Vertical Load

=

Min. Vertical Load

=

Horizontal force ( Max. load ) =

Horizontal force ( Min. Load ) =

Movement Long.

=

Movement trans.

=

Rotation

=

Seismic Case

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Horizontal force

Movement Long.

Movement trans.

Rotation

Guide T Bearing

Non Seismic Case

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Horizontal force

Movement Long.

Movement trans.

Rotation

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Seismic Case

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Horizontal force

Movement Long.

Movement trans.

Rotation

=

=

=

=

=

=

=

660.0875

438.9125

155.98375

122.0425

+/-4.0

+/- 12.5

0.01

KN

KN

KN

KN

mm

mm

radians

Max. Vertical Load

=

Min. Vertical Load

=

Horizontal force ( Max. Lo =

Horizontal force ( Min. Lo =

Movement Long.

=

Movement trans.

=

Rotation

=

952.7037

296.2963

28.581111

8.8888891

+/- 40

+/-12.5

0.01

KN

KN

KN

KN

mm

mm

radians

660.0875

438.9125

33.004375

21.945625

+/- 40

+/- 12.5

0.01

KN

KN

KN

KN

mm

mm

radians

Free Float Bearing

Non Seismic Case

Seismic Case

Max. Vertical Load

=

Min. Vertical Load

=

Horizontal force ( Max. Lo =

Horizontal force ( Min. Lo =

Movement Long.

=

Movement trans.

=

Rotation

=

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

BEARING LOADS FOR 73 M SPAN STEEL BRIDGE OVER INDUS RIVER

Type of superstructure

=

Distribution plate

=

Grade of concrete for pedestal

Steel truss ( Through type)

Reqd.

=

M35

Fixed Bearing

No. of bearing

Non Seismic Case

Max. Vertical Load

Min. Vertical load

Hor. Force ( Max Load )

Hor. Force (Min. load )

Movement Long.

Movement Trans

Rotation

=

=

=

=

=

=

=

970

290

70

75

0

0

0.01

KN

KN

KN

KN

mm

mm

radians

Max. Vertical Load

Min. Vertical load

Hor. Force ( Max. Load )

Hor. Force ( Min. Load )

Movement Long.

Movement Trans

Rotation

=

=

=

=

=

=

=

670

430

160

125

0

0

0.01

KN

KN

KN

KN

mm

mm

radians

Guide L Bearing

No. of bearing

Non Seismic Case

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

=

=

=

Seismic Case

SATVIR GUPTA FABRICATOR

970 KN

290 KN

30 KN

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Min. Horizontal force

Movement Long.

Movement trans.

Rotation

=

=

=

=

10

+/- 40

+/- 2.5

0.01

KN

mm

mm

radians

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Horizontal forcee

Movement Long.

Movement trans.

Rotation

=

=

=

=

=

=

=

670

430

35

25

KN

KN

KN

KN

+/- 40

mm

+/- 2.5

mm

0.01 radians

Guide T Bearing

No. of bearing

Non Seismic Case

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Vertical force

Movement Long.

Movement trans.

Rotation

=

=

=

=

=

=

=

970

290

70

75

Seismic Case

KN

KN

KN

KN

+/- 2.5

mm

+/-15.0

mm

0.01 radians

Seismic Case

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Vertical force

Movement Long.

Movement trans.

Rotation

=

=

=

=

=

=

=

670

430

160

125

KN

KN

KN

KN

+/-2.5

mm

+/- 15.0

mm

0.01 radians

Free Float Bearing

No. of bearing

Non Seismic Case

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Vertical force

Movement Long.

Movement trans.

Rotation

=

=

=

=

=

=

=

970

290

170

114

KN

KN

KN

KN

+/- 40

mm

+/-15.0

mm

0.01 radians

Seismic Case

Max. Vertical Load

Min. Vertical Load

Max. Horizontal force

Min. Vertical force

Movement Long.

Movement trans.

Rotation

=

=

=

=

=

=

=

SATVIR GUPTA FABRICATOR

670

430

35

25

KN

KN

KN

KN

+/- 40

mm

+/-15.0

mm

0.01 radians

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

WIND LOAD ANALYSIS ( IRC-6-2000)

Member

Ttop chord member :

Bottom member

:

Vertical member :

Secondary vertical member :

diogonal member :

Length

6.636364

6.636364

7.5

3.75

8.20124

Depth

0.4

0.45

0.25

0.16

0.25

m

m

m

m

m

m

m

m

m

m

Case 1. For Unloaded Bridge :

Intensity of wind pressure :

2.4 KN/m2

I.Exposed area per panel ( for top chord)

Member

Top Chord

Vertical member

Diagonal member

Windward Truss

1 Gusset

1*1.5

Total

Average Ht. Of Ground Level =

P

=

82 Kg/m2 =

Total Exposed area =

SATVIR GUPTA FABRICATOR

2.654545

1.875

2.05031

1.5

8.079855

8m

0.8 KN/m2

8.08

+

Leeward Truss

1.33

0.94

1.03

0.75

4.04

(As per Table 4 of IRC : 6:2000)

4.04 =

12.12 m2

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Wind force on top chord

P1 :

12.12 *

2.4 /

Governing wind force on top chord top chord P1 =

minimum as per cl- 212-6-IRC-6

6.63636

4.38304 KN/m

4.3830448 KN/m

being greater than 2.25 KN/m as

II.Exposed area per panel ( for bottom chord)

Member

Bottom chord

+ ST + Deck +

WC + Kerb

Vertical

Diagonal

Short vertical

Short diogonal

1 Gusset

Total

Windward Truss

6.636 *

0.683

4.53

1.88

2.05

0.00

0.00

1.50

9.96

Total Exposed area =

Wind force on bpttom chord

Leeward Truss

2.27

9.96

P2 :

+

14.94 *

Governing wind force on bottom chord P2 =

minimum as per cl- 212-6-IRC-6

Total wind force on the two truss :

=

SATVIR GUPTA FABRICATOR

4.38304 *

656.122 KN

0.94

1.03

0.00

0.00

0.75

4.98

4.98

14.94 m2

2.4 /

6.63636

5.4018448 KN/m

5.40184 KN/m

being greater than 4.5 KN/m as

59.7273

5.40184 *

73

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

For loaded Bridge :

Length of live load

Height of live load

:

:

18.84 m

3m

Wind load per panel on top chord /m :

=

Live load area per panel :

=

( total length of train )

0.8 *

1.80061 KN/m

18.84 *

5.138182 m2

14.94 /

< 2.25 KN/m

3

6.63636

6.636

73

18.84m length of load train

3m height of load train

Total exposed area bottom chord :

14.94

wind load on bottom chord /m

20.08 *

5.13818

0.8

=

/

20.08 m2

6.63636

=

2.4200122 KN/m

< 4.5 KN/m

Governing wind pressure on bridge at loaded condition as follows

1. Wind force on unloaded at top chord :

2. Wind force on loaded bottomchord :

3. Wind force on moving load

:

Total wind load :

2.25 KN/m

4.5 KN/m

3 KN/m

2.25 *

59.727 +

4.5 *

73

3*

SATVIR GUPTA FABRICATOR

+

18.84

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

519.4064 KN

III. Overturning Effect :

Taking the worst case in loaded condition .

wind force on top chord P1:

Wind load on moving load :

2.25 KN/m

3 KN/m

acting at a height of 1.5 m above deck

Overturning moment about the CG of the loaded truss

Moment :

=

2.25

18.22

*

KN-m/m

7.5

1.733

18.84

6.6364

5.104

top

Overturning Effect on worst loaded case :

18.217

=

=

=

=

=

=

Overturning moment on in unloaded condition :

Overturning effect on panel point :

=

=

=

=

=

SATVIR GUPTA FABRICATOR

23.686 KN on each panel point

23.686

/

6.6364

3.5691 KN/m

3.5691

/

13

0.2745

*

100

27.455

% of dead load

4.383

*

7.5

=

32.873

*

6.6364

/

42.742 KN on each panel point

42.742

/

6.6364

6.4406 KN/m

6.4406

/

13

0.4954

*

100

32.8728

5.104

KN-m/m

73

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

SATVIR GUPTA FABRICATOR

49.543 %

of dead load

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

LOAD ON MEMBER DUE TO SEISMIC :

For design of superstructure as per IS-1893 and IRC-6 . Seismic force shall be considered

only on 25% 0f LL + DL in transverse direction and only 50 % LL shall be considered for load analysis

during earthquake.

As per Ramchandra

Dead load of the bridge :

1898 KN

In critical condition for one train of Class B loading :

=

Dead load on top chord / panel :

18.98 KN/panel

( Assuming Dead load of top chord be about 10 % of total weight of bridge )

DL + 0.25 LL on the bottom chord :

1898 -

1 *

332 KN

332

18.98 *

10 +

0.25

332

1791.2 KN

Seismic force in Unloaded case :

On top chord :

0.12

On bottom chord :

Load on bottom chord/panel :

*

0.12

Load on top chord per metre :

Load on bottom chord per metre :

Overturning moment about cg of bottom

Moment :

=

=

2.2776

17.082

50.9454502

SATVIR GUPTA FABRICATOR

18.98 =

*

1791.2

214.944 /

2.2776 /

19.5404 /

2.2776 KN/panel

=

214.94 KN

11 =

19.5404 KN/panel

6.64

6.64

=

=

19.5404

0.3432 KN/m

2.94444 KN/m

chord member

*

+

KN/panel

7.5

33.8635

1.733

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Overturning effect on panel point :

=

=

=

=

=

=

55.4 ton

Load of 1 Train of Loading =

Braking force =

=

SATVIR GUPTA FABRICATOR

0.2 *

16.62 ton

50.9455

9.98148

9.98148

1.50406

1.50406

0.1157

11.5697

55.4 +

/

KN

/

KN/m

/

*

%

5.104

6.64

13.00

100.00

of dead load

0.1 *

55.4

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

SUMMARY OF FORCES

Member

L0L1

L1L2

L2L3

L3L4

L4L5

L5L5

U1U2

U2U3

U3U4

U4U5

U5U6

Normal case

Dead load

Class A

in tonne

Load

20.04 21.93

54.39 57.32

81.11 80.75

100.19 96.57

111.64 101.52

115.46 97.49

38.57 40.98

68.7 70.65

91.61 89.58

106.87 100.67

114.51 100.07

Wind load case Seismic case

Pedestrian Snow

Braking Total

wind loa Total

seismic Total

Load

Load

in ton in ton

1.15 % alload

1.25%

7.71

14.14

8.31

72.13 10.22

52.09

2.40

65.79

20.92

14.14

8.31 155.08 27.74 139.45

6.53

146.02

31.20

24.56

8.31 225.93 41.37 203.85

9.73

213.48

38.53

32.00

8.31 275.60 51.10 249.04 12.02

260.93

42.94

36.46

8.31 300.87 56.94 272.20 13.40

285.76

44.41

36.46

8.31 302.13 58.88 274.99 13.86

288.31

14.83

26.42

35.23

41.10

44.04

23.81

31.25

35.72

37.21

37.21

118.19

197.02

252.14

285.85

295.83

19.67

35.04

46.72

54.50

58.40

99.18

174.62

228.82

263.61

275.67

4.63

8.24

10.99

12.82

13.74

L0U1

U1L1

L1U2

U2L2

L2U3

U3L3

L3U4

U4L4

L4U5

U5L5

L5U6

49.53

49.53

40.09

35.38

30.66

25.94

21.23

16.51

11.79

7.08

2.36

52.4

48.04

43.32

40.01

35.28

31.93

27.54

24.77

21.1

19.06

16.66

19.05

19.05

15.42

13.61

11.79

9.98

8.17

6.35

4.53

2.72

0.91

20.66

15.22

10.87

6.52

2.17

2.17

2.17

2.17

2.17

2.17

2.17

141.64

131.84

109.70

95.52

79.90

70.02

59.11

49.80

39.59

31.03

22.10

25.26

25.26

20.45

18.04

15.64

13.23

10.83

8.42

6.01

3.61

1.20

127.17

123.37

103.72

93.08

81.19

70.50

58.92

48.74

37.77

28.24

18.38

5.94

5.94

4.81

4.25

3.68

3.11

2.55

1.98

1.41

0.85

0.28

U1M1

U2M2

4.31

4.31

14.9

13.82

1.66

1.66

3.17

7.93

24.04

27.72

2.20

2.20

20.06

19.12

0.52

0.52

SATVIR GUPTA FABRICATOR

110.13

185.35

238.70

271.83

282.89

Nature

Governing

72.13

155.08

225.93

275.60

300.87

302.13

Tensile

Tensile

Tensile

Tensile

Tensile

Tensile

118.19

197.02

252.14

285.85

295.83

Comp

Comp

Comp

Comp

Comp

133.31 141.64 Comp

125.47 131.84 Tensile

103.94 109.70 Comp

90.70 95.52 Tensile

76.30 81.19 Comp.

66.49 70.50 Tensile

55.85 59.11 Comp

46.50 49.80 Tensile

36.44 39.59 Comp.

27.68 31.03 Tensile

18.63 22.10 Comp.

20.97

23.91

24.04 Tensile

27.72 Tensile

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

U3M3

U4M4

U5M5

U6M6

4.31

4.31

4.31

4.31

SATVIR GUPTA FABRICATOR

13.77

13.77

13.76

13.77

1.66

1.66

1.66

1.66

4.76

1.58

2.16

2.16

24.50

21.32

21.88

21.89

2.20

2.20

2.20

2.20

19.07

19.07

19.07

19.07

0.52

0.52

0.52

0.52

21.34

18.79

19.25

19.25

24.50

21.32

21.88

21.89

Tensile

Tensile

Tensile

Tensile

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF MEMBERS :

Design of Tensile members :

Member :

L0L1

Force

A net reqd

72.13 t

72.1276923

( tension )

1000

1500

48.0851 cm2

400

Provided area

Plate

2 Plate

Width(cm)

43

Thk

Area

0.8

Nos

2

Total(cm2)

68.8

450

ISA 100 *100*8

Total

0.8

15.39

ISA 100 *100*8

61.56

130.36

Plate

Dia of bolt

Nos. of bolt in one rows

Deduction for hole :

=

2.2 cm

Net Area provided

SATVIR GUPTA FABRICATOR

5 nos

p

2

*

=

1.6

92.76 cm2 >

48.0851 cm2

2.35

=

OK

37.6 cm2

430 * 8

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Design of Connection :

Total area of web

=

43 *

0.8 *

=

100.8 cm2

Area of gusset and splice plate required

=

100.8 *

=

105.84 cm2

Provide 12 mm gusset plate on each side

Area of gusset plate provided

=

45 *

1.2 *

=

108 cm2

Area of flange

=

10 *

0.8 *

=

32 cm2

Area of cover plates required

=

32 *

1.05

=

33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided

=

40 *

0.8 *

=

64 cm2

Nos. of 22 dia HSFG Bolts required

In Web

=

105.84 *

1500 /

5843

=

27.171

Provide

13.59 Nos. bolt on each face

( In Single Shear)

6.79 Nos bolt on each face ( In double shear)

In flange

=

33.6 *

1500 /

5843

=

8.6257

Provide

4.313 on each face

SATVIR GUPTA FABRICATOR

2+

10 *

1.05

2

4

0.8 *

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member :

L1L2

Force

A net reqd

=

=

Provided area

Plate

2 Plate

155.1

155.1 ton

*

1000

1500

103.386 cm2

400

Width(cm)

43

Thk

Area

0.8

Nos

Total(cm2)

2

68.8

61.56

130.36

450

ISA 100 * 100*8

Total

0.8

15.39

ISA 100 * 100*8

Plate

=

Dia of bolt

2.2 cm

Nos. of bolt in one rows

5 nos

Deduction for hole :

=

2

*

1.6 *

+

3*

0.8 *

=

26.32 cm2

Area provided

: 104.04 cm2

Hence OK

SATVIR GUPTA FABRICATOR

2.35

2*

2.35

430 * 8

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Design of Connection :

Total area of web

=

43 *

0.8 *

=

100.8 cm2

Area of gusset and splice plate required

=

100.8 *

=

105.84 cm2

Provide 12 mm gusset plate on each side

Area of gusset plate provided

=

45 *

1.2 *

=

108 cm2

Area of flange

=

10 *

0.8 *

=

32 cm2

Area of cover plates required

=

32 *

1.05

=

33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided

=

40 *

0.8 *

=

64 cm2

Nos. of 22 dia HSFG Bolts required

In Web

=

105.84 *

1500 /

5843

=

27.171

Provide

13.5854869 Nos. bolt on each face

( In Single Shear)

6.79274345 Nos bolt on each face ( In double shear)

In flange

=

33.6 *

1500 /

5843

=

8.6257

Provide

4.31285299 on each face

SATVIR GUPTA FABRICATOR

2+

10 *

1.05

2

4

0.8 *

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member :

Force

L2L3

A net reqd

225.93 t

225.926154

( tension )

1000

1500

150.617 cm2

400

Provided area

Plate

PL

Width(cm)

43

Thk

Area

1.2

Nos

Total(cm2)

2

103.2

450

ISA 100*100*8

Total

Dia of bolt

2.2

Nos. of bolt in one rows

Deduction for hole :

=

2

+

=

35.72

Provide 2 No.extra plate

Area of extra plate provided

Area provided

:

at joint

Design of Connection :

Total area of web

0.8

15.39

61.56

164.76

Plate

430 * 12

cm

5 nos

*

2*

1.2 *

cm2

230 *

8 mm

=

36.8 cm2

165.84 cm2

Hence OK

=

43 *

=

135.2 cm2

Area of gusset and splice plate required

=

SATVIR GUPTA FABRICATOR

ISA 100*100*8

2.35

3*

2.35

on inner face at joint location

1.2 *

135.2 *

2+

1.05

10 *

0.8 *

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

=

141.96 cm2

Provide 16 mm gusset plate on each side

Area of gusset plate provided

=

45 *

1.6 *

=

144 cm2

Area of flange

=

10 *

0.8 *

=

32 cm2

Area of cover plates required

=

32 *

1.05

=

33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided

=

40 *

0.8 *

=

64 cm2

Nos. of 22 dia HSFG Bolts required

In Web

=

141.96 *

1500 /

5843

=

36.444

Provide

18.22 Nos. bolt on each face

( In Single Shear)

9.11 Nos bolt on each face ( In double shear)

In flange

=

33.6 *

1500 /

5843

=

8.6257

Provide

4.313 on each face

SATVIR GUPTA FABRICATOR

2

4

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member :

Force

L3L4

A net reqd

275.60 t

275.604615

( tension )

1000

1500

183.736 cm2

400

Provided area

Plate

PL

Width(cm)

43

Thk

1.6

Nos

2

Total(cm2)

137.6

450

ISA 100*100*8

Total

0.8

15.39

ISA 100*100*8

61.56

199.16

Plate

430*16

=

Dia of bolt

2.2

Nos. of bolt in one rows

Deduction for hole :

=

2

+

=

45.12

Provide 2 No.extra plate

Area of extra plate provided

Area provided

:

at joint

Design of Connection :

Total area of web

cm

5 nos

*

2.4

2*

1.6 *

cm2

230 *

8 mm

=

36.8 cm2

190.84 cm2

Hence OK

=

43 *

=

169.6 cm2

Area of gusset and splice plate required

=

SATVIR GUPTA FABRICATOR

2.35

3*

2.35

on inner face at joint location

1.6 *

169.6 *

2+

1.05

10 *

0.8 *

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

=

178.08 cm2

Provide 12 mm gusset plate on each side and 10 mm splice plate on inner face.

Area of gusset plate provided

=

45 *

1.2 *

=

192 cm2

Area of flange

=

10 *

0.8 *

=

32 cm2

Area of cover plates required

=

32 *

1.05

=

33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided

=

40 *

0.8 *

=

64 cm2

Nos. of 22 dia HSFG Bolts required

In Web

=

178.08 *

1500 /

5843

=

45.716

Provide

22.86 Nos. bolt on each face

( In Single Shear)

11.43 Nos bolt on each face ( In double shear)

In flange

=

33.6 *

1500 /

5843

=

8.63

Provide

4.31 on each face

SATVIR GUPTA FABRICATOR

2+

4

42 *

1*2

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member :

Force

L4L5, L5L5

A net reqd

302.13 t

302.127692

( tension )

1000

1500

201.418 cm2

400

Provided area

Plate

PL

Width(cm)

43

Thk

Area

1.6

Nos

2

Total(cm2)

137.6

450

ISA 100*100*10

Total

19.03

ISA 100*100*10

76.12

213.72

Plate

=

Dia of bolt

2.2 cm

Nos. of bolt in one rows

5 nos

Deduction for hole :

=

2

*

2.6 *

+

2*

=

39.8 cm2

Provide 2 No.extra plate

230 *

Area of extra plate provided =

46 cm2

Area provided

at joint

SATVIR GUPTA FABRICATOR

: 219.92 cm2

2

1.6 *

10 mm

Hence OK

2.35

3*

1.6

on inner face at joint location

430*16

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Design of Connection :

Total area of web

=

43 *

1.6 *

2+

=

177.6 cm2

Area of gusset and splice plate required

=

177.6 *

1.05

=

186.48 cm2

Provide 12 mm gusset plate on each side and 420 * 10 mm splice plates on inner face.

Area of gusset plate provided

=

45 *

1.2 *

=

192 cm2

Area of flange

=

10 *

0.8 *

=

32 cm2

Area of cover plates required

=

32 *

1.05

=

33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided

=

40 *

0.8 *

=

64 cm2

Nos. of 22 dia HSFG Bolts required

In Web

=

186.48 *

1500 /

5843

=

47.873

Provide

23.94 Nos. bolt on each face

( In Single Shear)

11.97 Nos bolt on each face ( In double shear)

In flange

=

33.6 *

1500 /

5843

=

8.63

Provide

4.31 on each face

SATVIR GUPTA FABRICATOR

10 *

2+

4

1*

42 *

1*2

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member :

Force

L5L6

A net reqd

#REF! t

Provided area

Plate

PL

#REF!

( tension )

1000

1500

#REF! cm2

400

Width(cm)

43

Thk

Area

2.8

ISA 100*100*10

Total

Dia of bolt

Nos. of bolt in one rows

Deduction for hole :

=

Nos

2

19.03

Total(cm2)

240.8

76.12

316.92

2.2 cm

SATVIR GUPTA FABRICATOR

ISA 100*100*10

Plate

430*28

=

3 nos

Provide 2 No.extra plate

230 *

Area of extra plate provided =

Area provided

at joint

450

3.8

3

12 mm

55.2 cm2

: 318.54 cm2

Hence OK

2.35

on inner face at joint location

53.58 cm2

p\

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

TOP CHORD MEMBER

Member

U1U2

Plate 340*8

Force

118.19 t

( compression )

400

400

Properties

Area

C.G.

Ixx

Iyy

ISMC 400

62.93

2.83

15082.8

504.8

ISMC 400

cm2

cm

cm4

cm4

Moment of inertia considered in X-X direction

Item

B(cm)

Top PL

ISMC 400

Size

t(cm) Area

Nos

34

0.8

62.93

Total

Ycg =

Ixx

2628.768

30168.4333

SATVIR GUPTA FABRICATOR

Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

1

2

27.2

125.86

0.400

10.88

20.8 2617.89

153.06

2628.77

153.06

54456.4

=

-

4.352 2.83333

54452 30165.6

54456

30168

17.1748 cm

153.06

17.1748

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

SATVIR GUPTA FABRICATOR

17.1748

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

39476.4094

r min =

=

SQRT

SQRT

16.0597199

cm4

39476.41

257.9146

cm

153.06

Moment of inertia considered in Y-Y direction

Item

Size

t(cm) Area

Nos

34

0.8

62.93

62.93

B(cm)

Top PL

ISMC 400

ISMC 400

Total

Ycg =

Ixx

3061.2

27.2 20.000

544

62.93

2.83 178.092

62.93 37.17 2339.11

153.06

3061.2

153.06

98328.6

3629.86667

40734.5148

cm4

r min =

=

SQRT

SQRT

16.3136229

S.R =

=

0.85

35.1245795

SATVIR GUPTA FABRICATOR

1

1

1

Permissible stress :

Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

40734.51

266.1343

cm

*

663.636

1419.253 kg/cm2

=

-

10880 2620.27

504

504.8

86945

504.8

98329 3629.87

20 cm

153.06

*

*

20

20

153.06

16.0597

35.1246

1419.25

30

1450

40

1390

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Axial Stress

118.1946

=

772.211 kg/cm2

1000

<

153.06

1419.25 kg/cm2

Hence OK

Design of connection :

Total area of web

=

40 *

0.84 *

2+

=

67.2 cm2

Area of gusset and splice plate required

=

67.2 *

1.05

=

70.56 cm2

Provide 12 mm gusset plate on each side and 420 * 0 mm splice plate on each face

Area of gusset plate provided

=

40 *

1.2 *

=

96 cm2

Area of flange at top

=

10 *

1.53 *

=

57.8 cm2

Area of cover plates required

=

57.8 *

1.05

=

60.69 cm2

Provide 400 * 12 mm thick cover plate at top

Area of cover plate provided

=

40 *

1.2 *

=

48 cm2

Area of flange at bottom

=

=

Area of cover plates required

=

=

Provide 400 * 8 mm thick cover plate bottom

Area of cover plate provided

=

=

SATVIR GUPTA FABRICATOR

10

30.6

30.6

32.13

*

cm2

*

cm2

1.53 *

40 *

32 cm2

0.8 *

10 *

0.8 *

2+

42 *

0* 2

2+

34 *

0.8 * 1

1.05

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Nos. of 22 dia HSFG Bolts required

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

In Web

=

=

Provide

9.05699127

4.52849564

In flange at top =

=

Provide

7.79

In flange at bottom =

=

Provide

4.12

SATVIR GUPTA FABRICATOR

70.56 *

1500 /

5843

18.114

Nos. bolt on each face

( In Single Shear)

Nos bolt on each face ( In double shear)

60.69 *

1500 /

5843

15.58

on each face

32.13 *

1500 /

5843

8.25

on each face

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

TOP CHORD MEMBER

MEMBER U1U2, U2U3

Force

197.02 t

( compression )

Plate

340 * 8

400

Properties

Area

C.G.

I

ISA 100*100*8

15.39

cm2

2.76

cm

145.1

cm4

400

ISA 100*100*8

Plate

380 * 8

=

Moment of inertia considered in X-X direction

Item

Size

t(cm) Area

Nos

34

0.8

15.39

15.39

38

0.8

B(cm)

Top PL

ISA 100*100*8

ISA 100*100*8

2 Plate

Total

Ycg =

Ixx

2555.968

7899.5

SATVIR GUPTA FABRICATOR

Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

1

2

2

2

27.2

30.78

30.78

60.8

149.56

149.56

71238.9

0.400

10.88 4.352 2.83333

3.56 109.577 390.09

290.2

38.04 1170.87 44540

290.2

20.8 1264.64 26305 7316.27

2556 71239 7899.5

=

-

17.0899 cm

149.56

*

*

17.0899

17.0899

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

35457.1167

r min =

=

SQRT

SQRT

15.397279

S.R =

=

0.85

36.6357529

cm4

35457.12

237.0762

cm

*

663.636

Permissible stress :

1410.185 kg/cm2

Axial Stress

197.0231

:

=

149.56

1317.351 kg/cm2

1000

<

15.3973

36.6358

1410.19

40

1390

149.56

1410.19 kg/cm2

Hence OK

Design of connection :

Total area of web

=

38 *

0.8 *

2+

=

92.8 cm2

Area of gusset and splice plate required

=

92.8 *

1.05

=

97.44 cm2

Provide 12 mm gusset plate on each side and 420 * 0 mm splice plate on each face

Area of gusset plate provided

=

40 *

1.2 *

=

96 cm2

Area of flange at top

=

10 *

0.8 *

=

43.2 cm2

Area of cover plates required

=

43.2 *

1.05

=

45.36 cm2

Provide 400 * 12 mm thick cover plate at top

Area of cover plate provided

=

40 *

1.2 *

=

48 cm2

SATVIR GUPTA FABRICATOR

30

1450

10 *

0.8 *

2+

42 *

0* 2

2+

34 *

0.8 * 1

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Area of flange at bottom

=

=

Area of cover plates required

=

=

Provide 400 * 8 mm thick cover plate bottom

Area of cover plate provided

=

=

10

16

16

16.8

*

cm2

*

cm2

40 *

32 cm2

0.8 *

1.05

0.8 *

Nos. of 22 dia HSFG Bolts required

In Web

=

97.44 *

1500 /

5843

=

25.015

Provide

12.51 Nos. bolt on each face

( In Single Shear)

6.25 Nos bolt on each face ( In double shear)

In flange at top =

45.36 *

1500 /

5843

=

11.645

In flange at bottom =

=

SATVIR GUPTA FABRICATOR

16.8 *

4.31

1500 /

5843

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

MEMBER

U3U4

Force

252.14 t

( compression )

Plate

340 * 8

400

Properties

Area

C.G.

I

ISA 100*100*8

15.39

cm2

2.76

cm

145.1

cm4

400

ISA 100*100*8

Plate

Moment of inertia considered in X-X direction

Item

B(cm)

Top PL

ISA 100*100*8