Yahya - Garba Et Al

Diunggah oleh

Kang LeeJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Yahya - Garba Et Al

Diunggah oleh

Kang LeeHak Cipta:

Format Tersedia

European Journal of Business and Management

ISSN 2222-1905 (Paper) ISSN 2222-2839 (Online)

Vol 4, No.17, 2012

www.iiste.org

Profit Maximization In A Product Mix Company Using Linear

Programming

Waheed Babatunde Yahya1*, Muhammed Kabir Garba1, Samuel Oluwasuyi Ige2

and Adekunle Ezekiel Adeyosoye1

1. Department of Statistics, University of Ilorin, P.M.B. 1515, Ilorin, Nigeria.

2. Department of Mathematics and Computer Studies, Federal Polytechnic, Ado-Ekiti, Nigeria.

* E-mail of corresponding author: wbyahya@unilorin.edu.ng

Abstract

This paper demonstrates the use of linear programming methods as applicable in the manufacturing industry. Data

were collected as extracts from the records of KASMO Industry Limited, Osogbo, Nigeria, on four types of sales

packages adopted for selling her medicated soap product which include 1 tablet per pack, 3 tablets per pack, 12

tablets per pack and 120 tablets per pack. Information on selling price per pack and on the cost of five basic raw

materials used as well as the quantity of each of the raw material held in stock per month for the production of soap

tablets were available in the records of the company. Based on the costs of raw materials, the maximum profit that

would accrue to the company given the product mix was determined. The results showed that the company would

attain optimal monthly profit level of about N271,296 if she concentrates mainly on the unit sales (one tablet per

pack) of her medicated soap product, ignoring other forms of sales packages. By this, her sales turn-over per month

would be about 18,900 soap tablets. The analysis was carried out with R statistical package (www.cran.org) using the

library lpSolve.

Key Words: Linear programming, Simplex Method, Objective function, Product mix, R software.

JEL Classification: C40, C44, C61

1. Introduction

Linear programming (LP) can be defined as a mathematical technique for determining the best allocation of a firms

limited resources to achieve optimum goal. It is also a mathematical technique used in Operation Research (OR) or

Management Sciences to solve specific types of problems such as allocation, transportation and assignment problems

that permits a choice or choices between alternative courses of action (Yahya, 2004). Linear programming is a term

that covers a whole range of mathematical techniques that is aimed at optimizing performance in terms of

combinations of resources (Lucey, 1996).

Linear Programming being the most prominent OR technique, it is designed for models with linear objective and

constraint functions. A LP model can be designed and solved to determine the best course of action as in a product

mix subject to the available constraints.

Generally, the objective function may be of maximization of profit (which is the focus of this paper) or minimization

of costs or labor hours. Moreover, the model also consists of certain structural constraints which are set of conditions

that the optimal solution should justify. Examples of the structural constraints include the raw material constraints,

production time constraint, and skilled labour constraints to mention a few. An optimum solution is a solution that

fulfills both the constraints of the problem and the set objective to be met.

The term linear, as stated by Akingbade (1996), implies proportionality, which means that the elements in a

situation are so connected that they appear as straight line when graphed. While the programming indicates the

solution method which can be carried out by an iterative process in which a researcher advances from one solution to

better solution until a final solution is reached which cannot be improved upon. This final solution is termed the

optimal solution of the LP problem.

This work demonstrates the pragmatic use of linear programming methods in a manufacturing company in Nigeria

126

European Journal of Business and Management

ISSN 2222-1905 (Paper) ISSN 2222-2839 (Online)

Vol 4, No.17, 2012

www.iiste.org

KASMO Industry Limited. The problem addressed here was to determine the product mix (combination of sales

package) to be adopted by the company for selling her medicated soap product at which the optimal profit level

would be attained.

2. Materials and Methods

The dataset used for this work was collected as extracts from the records of KASMO Industry Limited, Osogbo,

Osun State, Nigeria on her main product line (medicated soap) and four different types of sales packages adopted for

selling her soap product in 2010. These four types of sales packages include sales in 1 soap tablet (unit sales), sales

in 3 soap tablets (3 tablets per pack), sales in dozen soap tablets (12 tablets per pack), and sales in carton soap tablets

(120 tablets per pack). The marketing strategy of the company is to ensure a relative reduction in the selling price per

unit of soap tablet as the number of units in each pack increases. This was designed to encourage wholesales

purchase of the soap product by the users.

Data on the five basic raw materials used for the manufacturing of KASMO medicated soaps were available in the

records of the company. These raw materials are Caustic soda, Palm Kernel Oil (PKO), Colourant, Perfume and

Disinfectant. Information on the quantity of each raw material held in stock per month, probably due to space or

financial constraint, was obtained. Also, information on the quantity mix of these basic five raw materials and their

costs for effective manufacturing of the soap product was equally available and obtained from the companys records.

Finally, data were collected on the quoted selling prices of the four sales packages of soap adopted by the company.

However, information regarding labour cost, sales and marketing expenses and other related overheads were not

obtainable, and as such, their effects were ignored in the analysis. Therefore, the only cost element considered for

soap manufacturing in this paper is the cost of raw materials.

In a nutshell, the main focus of this work is to determine the quantity of each of the four sales packages that will

maximize the profit of the company given the aforementioned raw materials constraints.

The analysis was carried out using linear programming techniques. The linear programming problem developed here

is a mathematical program in which the objective function is linear in the unknown variables and the constraints have

linear equation or linear inequality or both. The general form of a linear programming problem is stated in matrix

form as shown below:

Objective function: Maximize Z = CX

(1)

Linear Constraints: Subject to AX = b

(2)

Non-negativity condition:

X0

The C in (1) is a row vector of m-dimension representing the objective function coefficients, X is a m

vector of the decision variables of the LP model, A is an m

k matrix of coefficients, and b is an k

vector of values in the right hand side of the constraint equations in (2).

(3)

1 column

1 column

Based on the data analysed in this work, the number of decision variables is four setting m = 4 in (1). The four

decision variables X1, X2, X3 and X4 in vector X in the objective function represent the four types of sales packages

of soaps adopted by the company with X1 represents sales in 1 tablet (unit sales), X2 represents sales in 3 tablets per

pack, X3 represents sales in dozen (12 tablets per pack) while X4 represents sales of soaps in carton (120 tablets per

pack).

Also, since the company uses five different raw materials for the manufacturing of her medicated soaps, therefore,

there are five linear constraints for the LP model, setting k = 5 in (2). The whole analysis was performed using R

statistical package (www.cran.org). A self contributed library package in R, the lpSolve that implements the LP

was adapted in this study.

3. Data Analysis

The data collected from KASMO Industry Limited (KIL) Osogbo, Nigeria on her main product line medicated

soap were analysed to determine the best sales package that would yield maximum profit to the company.

Table 1 in Appendix A presents the five raw materials used for the production of soaps at KIL, Osogbo. The

maximum quantity of each raw material held in stock for monthly production is also reported in the table.

The combinations of the quantities of these five basic raw materials (raw material mix) for soap production per

127

European Journal of Business and Management

ISSN 2222-1905 (Paper) ISSN 2222-2839 (Online)

Vol 4, No.17, 2012

www.iiste.org

boiling (in litres) are presented in Table 2 in Appendix A. This information is used to determine the production cost

(in terms of raw materials) per tablet of medicated soap produced by the company.

Not only that, the companys quoted selling price per package of soap as indexed by the four decision variables X1,

X2, X3 and X4 are presented in Table 3 in Appendix A. This information was later used to determine the marginal

profit derived from each sales package by the company as presented in Table 4 in Appendix A.

All the information provided in Tables 1 through 4 was used to form the linear programming model of the

maximization type for the data as stated below.

Maximize the objective function (profits):

Z = 14.36X1 + 33.08X2 + 112.32X3 + 1023.20X4

Subject to (raw materials constraints):

Caustic Soda:

0.88995X1 + 2.66984X2 + 10.67937X3 + 106.793650X4 16820

Palm Kernel Oil:

2.14815X1 + 6.44444X2 + 25.77778X3 + 257.77778X4 40600

Colourant:

0.00153X1 + 0.00460X2 + 0.01841X3 + 0.18413X4 29

Perfume:

0.00614X1 + 0.01841X2 + 0.07365X3 + 0.73651X4 116

Disinfectant:

0.02762X1 + 0.08286X2 + 0.33143X3 + 3.31429X4 522

X 1, X 2, X 3, X 4 0

In order to represent the above LP model in canonical form, five slack variables Xi (i = 5, 6, 7, 8, 9) were introduced

into the model. This changed the inequalities signs in the constraint aspect of the model to equality signs. A slack

variable will account for the unused quantity of raw material (if any) it represents at end of the production. As a

result, the above LP model becomes that of

Maximize

Z = 14.36X1 + 33.08X2 + 112.32X3 + 1023.20X4

Subject to (raw materials constraints):

Caustic Soda:

0.88995X1 + 2.66984X2 + 10.67937X3 + 106.793650X4 + X5 = 16820

Palm Kernel Oil:

2.14815X1 + 6.44444X2 + 25.77778X3 + 257.77778X4 + X6 = 40600

Colourant:

0.00153X1 + 0.00460X2 + 0.01841X3 + 0.18413X4 + X7 = 29

Perfume:

Disinfectant:

0.00614X1 + 0.01841X2 + 0.07365X3 + 0.73651X4 + X8 = 116

0.02762X1 + 0.08286X2 + 0.33143X3 + 3.31429X4 + X9 = 522

with non-negativity constraint that X1, X2, X3, X4,X5, X6, X7, X8, X9 0.

For analysis proper, the Simplex method proposed by George B. Dantzig in 1947 as published in Dantzig(1963) was

adopted to solve the above LP problem. The Simplex method has been found to be more efficient and convenient for

computer software implementation in many instances (Yahya, 2004). The initial tableau of the above LP model as

used by Simplex algorithm is given by Table 5 in Appendix A. The R statistical package was employed to fit the LP

model using the lpSolve library. The R codes used to fit the model are given in Appendix B. The results obtained

from this analysis are presented in the next section.

4. Results

Results from the analysis carried out on the LP model in the previous section using Simplex method estimated the

value of the objective function to be 271,296.4. The contributions of the four decision variables X1, X2, X3 and X4

into the objective function are 18893, 0, 0 and 0 respectively. This simply shows that only X1 variable contributed

meaningfully to improve the value of the objective function of the LP model.

It is observed from the results output in the appendix that the optimal solution to the linear programming model

fitted here was attained at the first iteration. This simply shows the goodness of the structure of the data collected for

analysis.

5. Discussions and Conclusion

The appropriateness of the linear programming methods for optimal resource allocation in industry has been

128

European Journal of Business and Management

ISSN 2222-1905 (Paper) ISSN 2222-2839 (Online)

Vol 4, No.17, 2012

www.iiste.org

demonstrated in this work. This is evident from the results obtained from the profit maximization type of the LP

model fitted to the data collected on soap manufacturing from KASMO Industry Limited Osogbo, Nigeria.

From the results of the LP model in Section 3 as reported in Section 4, it is desirable for the KIL company to

concentrate on the unit sales (1 soap tablet per pack) of her soap products. By this, total sales of about 18,893 tablets

would be sold by the company per month. This would fetch the company an optimal profit of about N271,296.4 per

month based on the costs of raw materials only. A simple division of the value of the objective function, N271,296.4

by 18,893 soap tablets sold based on 1 tablet per pack strategy (as shown in Table 3) yields a profit of N14.36 per

soap tablet. This value agreed perfectly with the profit expected by the company on the sales of a soap tablet as

contained in Table 4.

The results of the LP model fitted to the data collected from KIL are only based on the cost of raw materials used for

soap production. Therefore, it is quite instructive to remark that if information on other elements of cost of

production such as labour and overhead costs is available and incorporated into the LP model formulation and

analysis, the results reported here might be remarkably different. Nonetheless, findings from this work could still

serve as useful guides to the management of KIL in the formulation of production and marketing strategies for their

soap product.

References

Akingbade, F. (1996); Basic Operational Research Techniques, Panaf Inc. Lagos, Nigeria.

Dantzig, G. B. (1963); Linear Programming and Extensions, Princeton University Press, New York.

Hamdy, A. T. (2007); Operations Research: An Introduction, 8th edition, Pearson Education Inc. USA

Hillier, F. S. and Lieberman, G. J. (2001); Introduction to Operations Research, 7th edition, McGrwa-Hill Higher

Education, New York.

Lucey, T. (1996); Quantitative Techniques, DP Publications, London.

R Development Core Team, R: A language and environment for statistical computing. R foundation for Statistical

computing, Vienna, Austria, (2007), ISBN 3-900051-07-0, URL http://www.R-project.org.

Yahya, W. B. (2004); Determination of Optimum Product Mix at Minimum Raw Material Cost, Using Linear

programming. Nigerian Journal of Pure and Applied Sciences, Vol.19:1712-1721.

Appendix A

Table 1: Types and quantity of raw materials used for the production of medicated soaps tablets per month

Raw Materials

Quantity held for production per month (in kg)

Caustic Soda

16,820

Palm Kernel Oil

40,600

Colourant

29

Perfume

116

Disinfectant

522

Table 2: Quantities of the five raw materials (raw material mix) used for soap production per boiling

Raw Materials

Quantity used (raw material mix) per boiling (in liters)

Caustic Soda

290

Palm Kernel Oil (PKO)

700

Colourant

0.5

Perfume

Disinfectant

129

European Journal of Business and Management

ISSN 2222-1905 (Paper) ISSN 2222-2839 (Online)

Vol 4, No.17, 2012

Table 3:

www.iiste.org

The selling price per pack of soap tablet(s) and the unit selling price in each pack of soaps

Soap Package

Selling Price per pack (N)

Unit selling price per soap tablet (N)

X1 (1 tablet per pack)

30.00

30.00

X2 (3 tablets per pack)

80.00

26.67

X3 (12 tablets per pack)

300.00

25.00

X4 (24 tablets per pack)

2900.00

24.17

Table 4:

Soap Package

The production cost, selling price and profit earned per pack of soap tablets

Production Cost per

pack of soap (N)

Profit (N)

X1

15.64

30.00

14.36

X2

46.92

80.00

33.08

X3

187.68

300.00

112.32

X4

1876.80

2900.00

1023.20

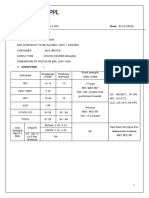

Table 5:

Slack

Selling Price per pack (N)

Initial tableau of the linear programming model for soap data

X1

X2

X3

X4

X5

X6

X7

X8

X9

X5

0.88995

2.66984

10.79365

106.79365

X6

2.14815

6.44444

25.77778

257.77778

X7

0.00153

0.00460

0.01841

0.18413

X8

0.00614

0.01841

0.07365

0.73651

X9

0.02762

0.08286

0.33143

3.31429

-14.36

-33.08

-112.32

-1023.20

Variable

130

Quantity

16820

40600

29

116

522

0

European Journal of Business and Management

ISSN 2222-1905 (Paper) ISSN 2222-2839 (Online)

Vol 4, No.17, 2012

www.iiste.org

Appendix B

R codes employed to fit the linear programming model for soap data.

## Linear Programming Implementation in R for soap data ##

########################################################################

## Load the required library ##

library(lpSolve)

KASMO <- lp(objective.in = c(14.36, 33.08, 112.32, 1023.20),

const.mat = matrix(c(0.88995, 2.66984, 10.67937,

106.79365, 2.14815, 6.44444, 25.77778, 257.77778,

0.00153, 0.00460, 0.01841, 0.18413, 0.00614, 0.01841,

0.07365, 0.73651, 0.02762, 0.08286,0.33143, 3.31429),

nrow= 5, byrow = T), const.rhs = c(16820, 40600,

29, 116, 522), const.dir = rep("<=", 5), direction =

"max")

KASMO

## Print the quantity of each of the decision variables that

##

## contributed to the value of the objective function (profit) ##

KASMO$solution

[1] 18892.51

0.00

0.00

0.00

## Print the value of the objective function ##

KASMO$objval

[1] 271296.4

## Determine the profit per soap tablet ##

KASMO$objval/KASMO$solution

[1] 14.36

Inf

Inf

Inf

########################################################################

131

Anda mungkin juga menyukai

- Profit Maximization in A Product Mix Company Using Linear ProgrammingDokumen6 halamanProfit Maximization in A Product Mix Company Using Linear Programmingdereje assefaBelum ada peringkat

- Yahya GarbaetalDokumen7 halamanYahya Garbaetaloverhear sbyBelum ada peringkat

- Nigerian Company Model - Product Mix PDFDokumen7 halamanNigerian Company Model - Product Mix PDFHarsh SaxenaBelum ada peringkat

- Maximizing profits and resource utilization in Ethiopia's apparel industryDokumen12 halamanMaximizing profits and resource utilization in Ethiopia's apparel industryjanella100% (1)

- Linear Programming Techniques for Optimizing Paint Product Mix in NigeriaDokumen10 halamanLinear Programming Techniques for Optimizing Paint Product Mix in NigeriaHarsh SaxenaBelum ada peringkat

- A Linear Programming Method To Enhance Resource Utilization Case of Ethiopian Apparel SectorDokumen14 halamanA Linear Programming Method To Enhance Resource Utilization Case of Ethiopian Apparel SectorHruday ChandBelum ada peringkat

- A Linear Programming Approach To Maximize Profit and Minimize Wastage in A Hospital Products Manufacturing Firm-Global Services LTDDokumen7 halamanA Linear Programming Approach To Maximize Profit and Minimize Wastage in A Hospital Products Manufacturing Firm-Global Services LTDSHASHANK ROHITBelum ada peringkat

- LinearProgrammingModel1 PDFDokumen14 halamanLinearProgrammingModel1 PDFOntime BestwritersBelum ada peringkat

- Application of Linear Programming For Optimal Use of Raw Materials in BakeryDokumen11 halamanApplication of Linear Programming For Optimal Use of Raw Materials in BakeryMann KumarBelum ada peringkat

- Linear Programing Nodelo de Fabrica TextilDokumen18 halamanLinear Programing Nodelo de Fabrica TextilPaola OrtizBelum ada peringkat

- Volume5Issue12Paper13 PDFDokumen9 halamanVolume5Issue12Paper13 PDFNasir QayyumBelum ada peringkat

- Factors Shaping Target Costing in Japanese FirmsDokumen30 halamanFactors Shaping Target Costing in Japanese FirmsAnonymous fE2l3DzlBelum ada peringkat

- Key Words To KnowDokumen5 halamanKey Words To KnowZech PackBelum ada peringkat

- Application of Linear Programming For Optimal Use of Raw Materials in Bakery (Kelompok 6) - DikonversiDokumen10 halamanApplication of Linear Programming For Optimal Use of Raw Materials in Bakery (Kelompok 6) - DikonversimasturalfiBelum ada peringkat

- Critique MeDokumen2 halamanCritique Mekeith tambaBelum ada peringkat

- Profit Maximization in A Product Mix Bakery Using Linear Programming TechniqueDokumen4 halamanProfit Maximization in A Product Mix Bakery Using Linear Programming TechniqueShamim MahmudBelum ada peringkat

- 24 PDFDokumen8 halaman24 PDFAutomotiveEngineerBelum ada peringkat

- Profit Maximization in A Product Mix Company Using Linear Programming Approach To Resource AllocationDokumen7 halamanProfit Maximization in A Product Mix Company Using Linear Programming Approach To Resource AllocationRaka Kirana PratamaBelum ada peringkat

- Paper Information: Optimizing Profit in Lace Baking Industry Lafia With Linear Programming ModelDokumen9 halamanPaper Information: Optimizing Profit in Lace Baking Industry Lafia With Linear Programming ModelFebriBelum ada peringkat

- Use of Linear Programming For Optimal Production in A Production Line in Coca - Cola Bottling Company, IlorinDokumen43 halamanUse of Linear Programming For Optimal Production in A Production Line in Coca - Cola Bottling Company, IlorinTejas GosaviBelum ada peringkat

- Unilever Un-Chained Case Study: Format Surf Excel Liquids White Magic Liquid PowderDokumen7 halamanUnilever Un-Chained Case Study: Format Surf Excel Liquids White Magic Liquid PowderSwathi PatibandlaBelum ada peringkat

- Simplex Optimization of Production Mix A Case of Custard Producing Industries in NigeriaDokumen10 halamanSimplex Optimization of Production Mix A Case of Custard Producing Industries in NigeriaAqueel Amir AliBelum ada peringkat

- British Journal of Management and Marketing Studies ISSN: 2689-5072 Volume 3, Issue 4, 2020 (Pp. 94-105)Dokumen12 halamanBritish Journal of Management and Marketing Studies ISSN: 2689-5072 Volume 3, Issue 4, 2020 (Pp. 94-105)reehammostafa77Belum ada peringkat

- Dire Dawa University College of Business and Economics Department of ManagementDokumen13 halamanDire Dawa University College of Business and Economics Department of Managementzimitaw yibekalBelum ada peringkat

- Literature Review of Optimization Technique Business: Based On CaseDokumen6 halamanLiterature Review of Optimization Technique Business: Based On CaseIAEME PublicationBelum ada peringkat

- Last One FileDokumen45 halamanLast One FilekirubelBelum ada peringkat

- Application of Linear Programming For Optimal Use of Raw Materials in BakeryDokumen8 halamanApplication of Linear Programming For Optimal Use of Raw Materials in BakeryKelly ArrietaBelum ada peringkat

- Efficient Consumer Response PDFDokumen5 halamanEfficient Consumer Response PDFSafijo AlphonsBelum ada peringkat

- Organization & Strategy Paper Analyzes Apple's I-Products CostsDokumen26 halamanOrganization & Strategy Paper Analyzes Apple's I-Products Costsshefali srivastavaBelum ada peringkat

- Optimal Management of Production Stocks With The Neutrosophic Fuzzy NumbersDokumen20 halamanOptimal Management of Production Stocks With The Neutrosophic Fuzzy NumbersScience DirectBelum ada peringkat

- Application of The Analytic Hierarchy Process in Determining The Marketing Mix Strategy of Rice Elevator MachinesDokumen8 halamanApplication of The Analytic Hierarchy Process in Determining The Marketing Mix Strategy of Rice Elevator MachinesAJHSSR JournalBelum ada peringkat

- Sip More Imp ProjectDokumen75 halamanSip More Imp ProjectSarthak padwalkarBelum ada peringkat

- Impact of ERP On Supply Chain Optimization in Malls of Nagpur Region.Dokumen10 halamanImpact of ERP On Supply Chain Optimization in Malls of Nagpur Region.Deepak SinghBelum ada peringkat

- Genetic Programming for Bankruptcy Prediction Using Unbalanced DataDokumen10 halamanGenetic Programming for Bankruptcy Prediction Using Unbalanced DatahardikmahetaBelum ada peringkat

- Full Download Solution Manual For Operations and Supply Management The Core Jacobs Chase 3rd Edition PDF Full ChapterDokumen36 halamanFull Download Solution Manual For Operations and Supply Management The Core Jacobs Chase 3rd Edition PDF Full Chapterdewdrop.threat.7ia4yn100% (16)

- Ensure Optimum Profit Using Linear Programming a ProductDokumen16 halamanEnsure Optimum Profit Using Linear Programming a ProductSulogna SikidarBelum ada peringkat

- Operations Research Case Study Using Global Supply Chain ManagementDokumen10 halamanOperations Research Case Study Using Global Supply Chain ManagementJV MallariBelum ada peringkat

- Application of Linear Programming For Optimal Use of Raw Materials in BakeryDokumen7 halamanApplication of Linear Programming For Optimal Use of Raw Materials in Bakerytheijes67% (3)

- Application of Linear Programming To Analyze Profit of FoodDokumen7 halamanApplication of Linear Programming To Analyze Profit of FoodNalla vedavathiBelum ada peringkat

- RMG Supply Chain OptimizationDokumen8 halamanRMG Supply Chain Optimizationraish alamBelum ada peringkat

- Resumo Alargado Sofia CarvalhoDokumen10 halamanResumo Alargado Sofia CarvalhoPatricio Arancibia OrellanaBelum ada peringkat

- Resumo Alargado - RicardoSimoesDokumen10 halamanResumo Alargado - RicardoSimoesAmhara AammhhaarraaBelum ada peringkat

- Supply Chain and Design - HOANG TRUNG DUNG-S3697071-1Dokumen13 halamanSupply Chain and Design - HOANG TRUNG DUNG-S3697071-1Dũng HoàngBelum ada peringkat

- Executive Summary:: Page 1 of 33Dokumen33 halamanExecutive Summary:: Page 1 of 33Raja RashidBelum ada peringkat

- 10 5923 J Statistics 20180801 03 PDFDokumen5 halaman10 5923 J Statistics 20180801 03 PDFjamal effendiBelum ada peringkat

- CMA Research PaperDokumen2 halamanCMA Research PaperDhrubajyoti SaikiaBelum ada peringkat

- Nestlé's ERP Journey to Integration and EfficiencyDokumen36 halamanNestlé's ERP Journey to Integration and EfficiencySatish J. Makwana50% (2)

- JPNR - S08 - 368Dokumen6 halamanJPNR - S08 - 368Dimas SultoniBelum ada peringkat

- Market Basket AnalysisDokumen5 halamanMarket Basket AnalysisManisha MukherjeeBelum ada peringkat

- Linear Programming for Furniture Company Cost ControlDokumen9 halamanLinear Programming for Furniture Company Cost ControlHindun ZawawiBelum ada peringkat

- Ration Management in Sun PharmaDokumen47 halamanRation Management in Sun PharmaNilesh VadherBelum ada peringkat

- Direct Product ProfitDokumen5 halamanDirect Product Profitahmed_23zulfiqarBelum ada peringkat

- Cost Modeling Analysis in Sand Casting Foundry: Coatanéa Eric Makkonen Petri Saarelainen Tanja María O. Castillón-SolanoDokumen10 halamanCost Modeling Analysis in Sand Casting Foundry: Coatanéa Eric Makkonen Petri Saarelainen Tanja María O. Castillón-SolanofsdtBelum ada peringkat

- Introduction To Management Science: Applications and Solutions of Linear ProgrammingDokumen43 halamanIntroduction To Management Science: Applications and Solutions of Linear ProgrammingsalsabilaBelum ada peringkat

- Optimization Principle and Its Applicati PDFDokumen8 halamanOptimization Principle and Its Applicati PDFdian permanaBelum ada peringkat

- Optimization Principle and Its ApplicatiDokumen8 halamanOptimization Principle and Its Applicatiadedejipraize1Belum ada peringkat

- Operations Research AssignmentDokumen14 halamanOperations Research AssignmentGodfred AbleduBelum ada peringkat

- Marketing Management Worked Assignment: Model Answer SeriesDari EverandMarketing Management Worked Assignment: Model Answer SeriesBelum ada peringkat

- Management Science using Excel: Harnessing Excel's advanced features for business optimization (English Edition)Dari EverandManagement Science using Excel: Harnessing Excel's advanced features for business optimization (English Edition)Belum ada peringkat

- The Goal: A Process of Ongoing Improvement by Eliyahu M. Goldratt and Jeff Cox | Key Takeaways, Analysis & ReviewDari EverandThe Goal: A Process of Ongoing Improvement by Eliyahu M. Goldratt and Jeff Cox | Key Takeaways, Analysis & ReviewBelum ada peringkat

- Individual INB Mobile FormDokumen12 halamanIndividual INB Mobile Formsauryan123Belum ada peringkat

- Test Number: RDT 1612-1103 Date: 8/12/2016Dokumen1 halamanTest Number: RDT 1612-1103 Date: 8/12/2016dawncpainBelum ada peringkat

- Tcodes MMDokumen2 halamanTcodes MMdawncpainBelum ada peringkat

- JargonDokumen2 halamanJargondawncpainBelum ada peringkat

- Summary Notes Excel PDFDokumen4 halamanSummary Notes Excel PDFdawncpainBelum ada peringkat

- Vba In-Built FunctionDokumen3 halamanVba In-Built FunctiondawncpainBelum ada peringkat

- Advantage of Mulund PDFDokumen10 halamanAdvantage of Mulund PDFdawncpainBelum ada peringkat

- Time Value of MoneyDokumen14 halamanTime Value of MoneydawncpainBelum ada peringkat

- JitDokumen6 halamanJitDharmesh MistryBelum ada peringkat

- Seven Eleven Case StudyDokumen3 halamanSeven Eleven Case StudyAshish Shadija100% (2)

- Capital BudgetingDokumen45 halamanCapital BudgetingdawncpainBelum ada peringkat

- E2 EM Chapter 7Dokumen50 halamanE2 EM Chapter 7Str Engr Mohammad AliBelum ada peringkat

- Ahp Vendor Selection5Dokumen1 halamanAhp Vendor Selection5dawncpainBelum ada peringkat

- Pay Out DecisionDokumen19 halamanPay Out DecisiondawncpainBelum ada peringkat

- LingoDokumen1 halamanLingodawncpainBelum ada peringkat

- Organisation Srtructure OB & HRDokumen29 halamanOrganisation Srtructure OB & HRdawncpainBelum ada peringkat

- Time StudyDokumen25 halamanTime StudydawncpainBelum ada peringkat

- Operations Research Hiller Solutions CH 4Dokumen81 halamanOperations Research Hiller Solutions CH 4dawncpainBelum ada peringkat

- Bond ValuationDokumen17 halamanBond ValuationdawncpainBelum ada peringkat

- Risk & ReturnDokumen27 halamanRisk & ReturnSadia Farhan KhanBelum ada peringkat

- Report On Indian Bath Soap IndustryDokumen69 halamanReport On Indian Bath Soap IndustrydawncpainBelum ada peringkat

- Time StudyDokumen25 halamanTime StudydawncpainBelum ada peringkat

- LeverageDokumen10 halamanLeveragedawncpainBelum ada peringkat