Valve Clarkson Kga

Diunggah oleh

Flores CesarHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Valve Clarkson Kga

Diunggah oleh

Flores CesarHak Cipta:

Format Tersedia

CLARKSON KGA HEAVY DUTY SLURRY KNIFE GATE VALVE

The Clarkson KGA slurry knife gate valves feature heavy-duty, full port

elastomer sleeves offering the ultimate isolation against heavy slurries

FEATURES

Meets a wide range of abrasion, corrosion,

temperature, and pressure requirements.

May be used in wet or dry services easily

dealing with large, heavy particles and tramp

material.

100% isolation; bubble-tight shut-off results

in absolutely zero downstream leakage.

Heavy-duty, field replaceable elastomer

sleeves with internal stiffener

(U. S. patent 5,271,426).

Double-seated design provides bi-directional

flow and shut-off.

Unobstructed flow eliminates turbulence,

minimizes pressure drop across valve.

No seat cavity where solids can collect and

prevent full gate closure.

No metal parts in contact with the flowing

slurry.

No gate or stem packing is required,

eliminating packing leakage and

maintenance.

Adaptable frame (yoke) design featuring a

top-removal stem nut.

GENERAL APPLICATIONS

TECHNICAL DATA

Mining

Power

Pulp and paper

Alumina

Chemical

Cement

Size range:

Temperatures:

NPS 3 - 60 (DN 80 - 1500)

Standard sleeve rated

to 180F (80C), up to

400F (200C) with proper

elastomer selection.

Pressure rating: NPS 3 - 24 = 100 psi

(DN 80 - 600 = 6.9 bar)

NPS 26 - 42 = 75 psi

(DN 650 - 1050 = 5.2 bar)

NPS 48 - 54 = 50 psi

(DN 1200 - 1350 = 3.4 bar)

NPS 60 = 30 psi

(DN 1500 = 2 bar)

Sleeve:

Natural rubber (standard)

NOTE

Some optional gate materials allow higher pressure

ratings, contact Pentair for additional information.

www.pentair.com/valves

2012 Pentair Inc. All Rights Reserved.

CLKMC-0113-EN-1405

CLARKSON KGA HEAVY DUTY SLURRY KNIFE GATE VALVE

HOW THE KGA SLEEVES WORK

SLEEVE CONFIGURATIONS

When the gate is open, matching elastomer sleeves seal against each under a high compression

load, creating the valve pressure vessel and provide an unobstructed port, protecting metal parts

from the flowing slurry. As the gate strokes to close, the gate tip creates a gap between the facing

sleeves, allowing any media that could potentially clog or jam the valve to be purged out from

between the sleeves, and potentially expelled outside the valve housing to atmosphere. When

closed, the sleeves seal against the gate face, isolating upstream from downstream providing

positive sealing action.

Encapsulated internal stiffener ring

Maintains round configuration of sleeve

Resists shearing forces during actuation

Retains the internal line pressure

Open position:

Gate positioned above seals, out of flow

Matching elastomer sleeves seal against

each other under a high compression load

Sleeves act as pressure vessel

No metal parts in contact with slurry

Unobstructed port area eliminates

turbulence, minimizes pressure drop across

valve

No seat cavity where solids can collect and

prevent full gate closure

3 to 16

(DN 80-400)

18 (DN 450)

and larger

STANDARD CONFIGURATION

Gate Open

Closed position:

Gate travels through sleeves to provide blind

flange shut-off, allowing opportunity for

media to expel to atmosphere

100% Isolation-bubble tight shut-off results in

absolutely zero downstream leakage

When properly installed and maintained, the

KGA is designed to provide man-safe isolation

Double-seated design provides

bi-directionalflow and shut-off

Controlled stroke prevents gate from

penetrating too far, minimizing stress on

sleeve

Cast ductile iron or carbon steel housings.

316 stainless steel gate rated for:

100 psi (3 thru 24) [6.9 bar (DN 80-600)]

75 psi (26 thru 42) [5.2 bar (DN 650-1050)]

50 psi (48 thru 54) [3.4 bar (DN 1200-1350)]

30 psi (60) [2 bar (DN1500)]

Carbon steel actuator support frames.

Flat-faced body flanges to match ASMEB16.5

Class 150 (3 thru 24 (DN 80-600)) or

MSSSP44 (26 thru 60 (DN 650-1500))

companion flange dimensions

High tear strength natural rubber sleeves

with encapsulated stiffener ring

Sizes 10 thru 60 (DN 250-1500) include

natural rubber covered carbon steel sleeve

retainer flanges

Gate Closed

ACTUATION OPTIONS

OPTIONS

NOTE: Some optional gate materials allow higher

pressure ratings, contact Pentair for additional

information.

MH Manual handwheel

BG Manual bevel gear

AC Air cylinder

HC Hydraulic cylinder

NOTE: Not all actuators shown are available on all

valve sizes.

EM Electro-mechanical

Hydra-helper

316L S/S

317L S/S

17-4 PH

317L MN

317L S/S

Alloy 20

Alloy C-276

2205

OTHERS

Natural rubber-covered carbon steel sleeve retainer

flanges are (3 thru 8 (DN 80-200))

Sleeve elastomers (see page 3)

Stem covers

Splash guard devices (see page 4)

Actuators (see page 4)

Control accessories

CLARKSON KGA HEAVY DUTY SLURRY KNIFE GATE VALVE

AVAILABLE SLEEVE MATERIALS

FEATURES

Natural rubber (standard): This category

includes all natural gum elastomers, both filled

and unfilled and synthetic polyisoprene.

Has high tensile strength, superior resistance

to tear and abrasion and good resistance to

heat build-up.

Maximum continuous operating temperature

180F (82C).

Heavy-duty frame (yoke) designed to accept top

removal stem nut, bevel gear or cylinder actuator.

Optional open and closed lockout/tagout positions.

The stainless steel gate is completely withdrawn

from the process flow in the open position and can be

inspected or replaced without taking the valve out of

service.

EPDM-HTP: Advantages - excellent resistance

to heat, ozone and sunlight, very good

flexibility at low temperature, good resistance

to alkalis, acids, and oxygenated solvents

and superior resistance to water and steam.

Limitations - poor resistance to oil, gasoline,

and hydrocarbon based solvents. Maximum

continuous operating temperature 300F

(150C).

316 stainless steel gate is standard.

Packingless design.

Body housing to suit ASME B16.5/150 through

24 (DN 600), sizes 26 (DN 650) and larger suit

MSS-SP44.

Double sleeved configuration is designed provides a

blind flange shut-off when the gate is closed. Any

potential leakage should be to atmosphere and not

downstream.

Optional available sleeve materials:

Pentair Valves & Controls offers optional

elastomers. These may be available upon

request and review of application.

Contact Pentair for additional information.

Elastomer sleeve molded with an integral stiffener

ring to properly center the sleeve in the valve body

housing and resist the high shearing forces present

when the gate cycles.

NBR (Nitrile): Advantages - very good

resistance to petroleum based greases/

oils, silicone greases/oils and nonoxidizing

chemicals. Good resistance hydrocarbon based

fuels. Limitations - Inferior resistance to ozone

and oxygenated solvents.

Maximum continuous operating temperature

275F (135C).

Elastomer sleeves provide unobstructed flow area, no

metal-to-metal contact, no guides or wedges.

Elastomer covered retainer flanges eliminates need

for gaskets (optional on sizes 3 to 8 (DN 80-200),

standard on 10 (DN 250) and larger).

Discharge, clean-out area. Any discharge purged from

valve can be controlled with optional bottom splash

guard device.

HNBR (Nitrile-HTP): Same as above except

maximum continuous operating temperature

325F (163C).

Chlorobutyl: Advantages - Outstanding

impermeability to gases and vapor, very good

resistance to heat, oxygen, ozone and sunlight.

Excellent energy absorption and resistance

to alkalis and oxygenated solvents, superior

resistance to water & steam.

Limitations - Poor resistance to oil, gasoline

and hydrocarbon based solvents, poor

resilience. Maximum continuous operating

temperature, 230F (110C).

OEM replacement sleeves and parts:

To maintain the expected performance always

use genuine Clarkson OEM sleeves and other

replacement parts from Pentair Valves &

Controls. Genuine sleeves are easily recognized

by the laser etched identification marks;

allowing traceability.

The use of copycat parts may invalidate any

remaining warranty.

SPECIFICATIONS

Clarkson KGA slurry knife gate valve

Heavy duty, slurry knife gate valve shall be flat-face flanged, packingless, rubber-lined,

bi-directional valve suitable for a wide range of industrial applications. The full port design shall

have no internal obstructions and will provide a blind flange shut-off when the gate is closed.

The valves sealing surface is to be between two thick, rubber sleeves that are compressed into

the valve housings. The sleeve will be molded with an internal stiffener ring that locates the sleeve

in the valve housing and helps the sleeves resist the high shearing forces present when the gate

is driven between them. The stainless steel gate shall be completely withdrawn from the process

flow when in the open position, and can be inspected and replaced, if necessary, without taking

the valve out of service. The valve body housing to be full flanged, drilled and tapped or slotted to

suit ASME B16.5/150 through 24 (DN600) and MSS-SP44 above 24 (DN600). Valve is equipped

with a heavy steel fabricated frame (yoke) which can be converted to bevel gear or double acting

cylinder in the field, complete with a 304 stainless steel rising stem (except cylinder actuated

valves). All nonferrous exterior surfaces shall be painted to factory standard. Specify Clarkson

KGA slurry knife gate valve from Pentair Valves & Controls.

CLARKSON KGA HEAVY DUTY SLURRY KNIFE GATE VALVE

SPECIAL COATINGS TO ENHANCE SERVICE LIFE

Pentair Valves & Controls is a leader in coating technology with broad experience using special coatings in various industries and applications on a

worldwide basis. Each of the coatings below offer advantages in service life and operation, improving performance and adding value.

SSEC: Synergistic surface enhancement coating

Well suited for use in applications where corrosive media or abrasion

is a problem, SSEC is ideal for applications with sticky, viscous media,

scaling/plating or where galling is a problem. The low coefficient of

friction eliminates stick-slip problems, reduces drag and increases

sleeve life. Often improves micro finish of a gate or body. SSEC is a

synergistic coating that combines the advantages of anodizing, plating

orthermal spraying with the controlled infusion of polymers, dry

lubricants and other materials to provide an entirely new composite

with improved properties to the base metal. This coating will work on

most metal surfaces and creates a harder-than- steel surface, excellent

release (non-stick) properties, protects against wear, corrosion and

chemical attack and provides permanent lubricity and a superior

resistance to static buildup of material. SSEC has a hardness/wear and

abrasion rating of up to Rc 68 Equilibrium Wear Rate (EWR) using Taber

abrasion testing methods (CS-10 wheel): 2.0 - 4.0 mg per 1000 cycles.

SSEC is also very corrosion resistant and will survive 500 hours

in ASTMB-117 salt spray. (Coating thickness will affect corrosion

resistance.) Suitable for use on steel, stainless, copper, brass, bronze,

titanium, and aluminum.

metal surfaces and has excellent release (non-stick) properties, protects

against wear and chemical attack as well as it features excellent

abrasion and galling resistance, and provides permanent lubricity and

a superior resistance to static buildup of material. TBSEC has excellent

abrasion resistance as well as various chemical and acid resistances.

Used on steel, stainless, copper, brass, bronze, titanium, and aluminum.

SSEC+: Synergistic surface enhancement coating plus

Select SSEC+ for additional corrosion resistance, about 3 times better

than the base SSEC coating (based on ASTM B117 salt spray testing).

Abrasion resistance, lubricity, corrosion resistance are similar to the

base SSEC. SSEC+ is not recommended for strong acids.

PBSEC-80: Polymer-based surface enhancement coating

PBSEC-80 takes all the great qualities of the PBSEC coating and

amplifies them. Those qualities include; release (non-stick) properties,

protection against wear, chemical attack, corrosion, galling and abrasion

resistance. PBSEC-80 also provides permanent lubricity and a superior

resistance to static buildup of material. PBSEC-80 is a proprietary blend

of engineered polymers that exhibit a very low coefficient of friction.

This is placed on top of an inert ceramic base coating that becomes

infused with the PBSEC coating. Used on steel, stainless, brass, copper,

titanium, bronze and aluminum.

TBSEC: Tungsten-based surface enhancement coating

For applications where maximum wear resistance on ferrous and

nonferrous metals is needed over a broad temperature range, Pentair

Valves & Controls offers TBSEC - Tungsten-based surface enhancement

coating. TBSEC is a specific combination of ceramics, metals and

proprietary polymers that produces a moisture proof and nonporous

structural integrity matrix. Adding TBSEC improves the base metal

surface properties and is ideal for applications where galling or sticky

media and scaling/plating is a problem.

Applied by a thermal spray process, this coating will work on most all

COATING SELECTIONS

SSEC

SSEC+

TBSEC

PBSEC

PBSEC-80

Coefficient of friction

As low as 0.09

Static as low as 0.10

Dynamic as low as 0.09

As low as 0.06

Static as low as 0.4

Dynamic as low as 0.3

0.19

Temperatures a)

-250F to 550F b)

(-157C to 288C)

-250F to 500F

(-157C to 260C)

-200F to 550F

(-129C to 288C)

Cryogenic to 275F c)

(135C)

Cryogenic to 300F

(149C)

PBSEC: Polymer-based surface enhancement coating

PBSEC is a polymer-based impregnated surface enhancement coating

ideal for applications where maximum corrosion resistance on ferrous

and nonferrous metals is needed over a broad temperature range.

Like SSEC, PBSEC exhibits a very low coefficient of friction, providing

improved lubricity and reducing friction as the gate slides through the

sleeves thus increasing the sleeve life. It is ideal for applications where

galling or sticky media and scaling/ plating is a problem. It will work on

most all metal surfaces and has excellent release (non-stick) properties.

PBSEC features excellent abrasion and galling resistance and a superior

resistance to static buildup of material. It has excellent chemical and

abrasion resistance as well as high oxidative stability. Can be applied to

steel, stainless, copper, brass, bronze, titanium, and aluminum.

NOTE

Pentair Valves & Controls does not recommend coatings be used as an attempt to

reduce metallurgy of the base material required for the application.

Coatings from Pentair Valves & Controls are used on all our knife gate and slurry

valve products.

Thickness (Mils)

0.2 to 3

(5 to 76)

0.5 to 2.0

(12.7 to 51)

2 to 10

(51 to 254)

3 to 5

(76 to 127)

10 to 20

(254 to 508)

pH range

5 to 8.5

Abrasion

Good

Anti-stick (lubricity)

Excellent

Chemical resistance

Fair

5 to 8.5

Good

Excellent

Good

4 to 10

Excellent

Fair

Fair

Below 0 to 14

Fair

Not recommended

Excellent

0 to 14

Excellent

Fair

Excellent

a. Stated temperatures are above normal operating temperature of the valve and are not to be considered as

the rated temperature of the valve.

b. SSEC will survive temperatures of 1400F (760C), but all lubricant will dissipate above +800F (427C).

c. Short term exposure up to 350F (177C).

4

CLARKSON KGA HEAVY DUTY SLURRY KNIFE GATE VALVE

MH

BG

AC

HC

D

A

C

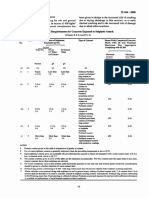

DIMENSIONS (inches) AND WEIGHTS (lbs)

Valve size

NPS

3

4

6

8

10

12

14

16

18

20

24

26

28

30

32

36

42

48

54

60

A*

B**

MH

D

7.50

9.00

11.00

13.50

16.00

19.00

21.00

23.50

25.00

27.50

32.00

34.25

36.50

38.75

41.75

46.25

53.00

59.50

66.19

73.00

6.88

6.88

7.00

7.25

8.88

10.13

10.13

11.00

12.25

14.13

14.63

14.38

14.88

15.57

16.19

18.50

21.13

21.13

21.13

21.13

8.88

11.00

13.00

15.25

16.56

21.00

22.75

24.25

26.50

28.38

33.80

36.75

36.75

41.50

41.50

48.25

56.50

60.35

67.25

77.00

18.93

22.00

28.00

32.90

38.75

DIMENSIONS (mm) AND WEIGHTS (kg)

Valve size

DN

80

100

150

200

250

300

350

400

450

500

600

650

700

750

800

900

1050

1200

1350

1500

A*

190.50

228.60

279.40

342.90

406.40

482.60

533.40

596.90

635.00

698.50

812.80

869.95

927.10

984.25

1060.45

1174.75

1346.20

1511.30

1681.23

1854.20

H Port

B**

174.75

174.75

177.80

184.15

225.55

257.30

257.30

279.40

311.15

358.90

371.60

365.25

378.00

395.48

411.23

469.90

536.60

536.60

536.60

536.60

C

225.55

279.40

330.20

387.35

420.62

533.40

577.85

615.95

673.10

720.85

858.52

933.45

933.45

1054.10

1054.10

1225.55

1435.10

1532.89

1708.15

1955.80

MH

D

480.82

558.80

711.20

835.66

984.25

4019.55

Centerline to top

BG

AC

E

F

21.38

23.33

31.82

34.00

42.63

47.45

53.31

57.20

66.75

71.94

86.19

21.38

23.94

30.18

35.00

40.50

45.50

53.43

60.19

67.62

73.50

88.00

Centerline to top

BG

AC

E

F

543.05 543.05

592.58 608.08

864.00 766.57

378.21 889.00

1082.80 1028.70

1205.23 1155.70

1354.07 1357.12

1452.88 1528.83

1695.45 1717.55

1827.28 1866.90

2189.23 2235.20

1117.09

J Inlet

Handwheel

MH

BG

M

M

MH

BG

AC

HC

15.81

16.88

17.88

19.00

23.40

25.50

26.38

27.62

30.35

31.29

34.75

12

12

16

20

20

50

64

98

135

198

127

141

175

212

275

427

448

573

875

1054

85

130

180

210

310

669

720

1125

1330

1680

2200

50

70

98

135

175

360

414

550

950

1200

1400

1700

1800

2400

2900

3800

5700

6970

8275

9500

K

401.57

428.75

454.15

482.60

594.36

647.70

670.05

701.55

770.89

794.77

882.65

Handwheel

MH

BG

M

M

305

305

305

305

406

305

610

305

610

610

610

610

610

610

610

610

HC

G

24.56

27.63

34.00

38.31

44.25

53.13

57.80

64.06

68.75

74.44

89.63

93.63

93.63

106.19

106.19

119.25

145.68

158.25

172.88

188.25

2.41

3.33

5.38

6.88

9.06

10.75

12.50

14.00

14.88

16.56

21.19

23.50

23.50

26.75

26.75

31.88

38.25

43.98

48.98

57.13

2.81

3.88

5.81

7.75

9.81

11.50

13.25

14.75

16.75

18.50

23.00

25.00

25.00

29.00

29.00

35.00

41.00

46.75

51.75

59.50

HC

G

H

J

623.82

61.21

71.37

701.80

84.58

98.55

863.60 136.65 147.57

973.07 174.75 196.85

1123.95 230.12 249.17

1349.50 273.05 292.10

1468.12 317.50 336.55

1627.12 355.60 374.65

1746.25 377.95 425.45

1890.78 420.62 469.90

2276.60 538.23 584.20

2378.20 596.90 635.00

2378.20 596.90 635.00

2697.23 679.45 736.60

2697.23 679.45 736.60

3028.95 809.75 889.00

3700.27 971.55 1041.40

1187.45

4391.15 1244.09 1314.45

4781.55 1451.10 1511.30

12

12

12

12

24

24

24

24

24

24

24

Weight (lbs)

Weight (kg)

MH

22.7

29.0

44.5

61.2

89.8

BG

57.6

64.0

79.4

96.2

124.7

193.7

203.2

259.9

396.9

478.1

AC

38.6

59.0

81.6

95.3

140.6

303.5

326.6

510.3

603.3

762.0

997.9

HC

22.7

31.8

44.5

61.2

79.4

163.3

187.8

249.5

430.9

544.3

635.0

771.1

816.5

975.2

1089.0

1724.0

2585.5

3161.5

3754.8

4309.1

* Flange diameter: Designed to match ASME B16.5/150 thru 24 (DN 600), MSS-SP44 above 24 (DN 600)

** Face-to-face includes the retainer flanges, all sizes. Retainer flanges are standard sizes 10 (DN 250) and larger, optional on 8 (DN 200) and smaller.

Add (8 mm) to (15 mm) for ease of installation.

5

CLARKSON KGA HEAVY DUTY SLURRY KNIFE GATE VALVE

GLOBAL LEADER IN SLURRY VALVE TECHNOLOGY

Field proven, heavy duty, trouble-free slurry valves for abrasive, corrosive and coarse slurries. The Clarkson slurry valves from

PentairValves&Controls feature elastomer sleeves offering the ultimate in protection against heavy slurries. They provide both high performance

and long life in the toughest of environments.

KGF and HGF-HP HIGH PRESSURE slurry valve

For high pressure slurry application, the only choice is the KGF slurry knife gate valve. It offers

the same features and performance of the KGA or KGD but in a 300, 450, 740 psi (21, 31, 51 bar)

design.

KGF: 300 and 450 psi (21 and 31 bar)

- Sizes NPS 3 to 36 (DN 80-900)

KGF-HP: up to 740 psi (51 bar) CWP

- Sizes NPS 3 to 36 (DN 80-900)

KGD wafer slurry knife gate valve

MSS face-to-face dimension

100% full port

Double-seated, bi-directional shutoff design

Exclusive, dynamic self-adjusting sleeve design

Standard operating pressures up to 150 psi (10 bar); higher pressures available

Sizes NPS 2 to 24 (DN 50-600)

KLB and KGL linear line blinds

The KLB is based on the KGD and the KGL is derived from the KGA. Both provide man-safe

isolation in a blanking application.

Man-safe line blind

No downstream leakage even with sleeve failure

KLB: Sizes NPS 2 to 24 (DN 50-600)

KGL: Sizes NPS 3 to 60 (DN 80-1500)

C-Valve slurry throttling valve

Unique and unsurpassed in the industry, the Clarkson C-Valve is a true slurry throttling valve that

provides both high performance and long life in the toughest of environments.

Sizes NPS 1 to 8 (DN 25-200)

Operating pressure 100 psi (7 bar)

Gum rubber sleeve standard

Temperatures to 400F (204C)

PENTAIR VALVES & CONTROLS

www.pentair.com/valves

All Pentair trademarks and logos are owned by Pentair Ltd. All other brand or product names are trademarks or registered marks of their respective owners.

Because we are continuously improving our products and services, Pentair reserves the right to change product designs and specifications without notice.

Pentair is an equal opportunity employer. 2012 Pentair Ltd. All rights reserved.

6

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Shell Gadus Product Family BrochureDokumen6 halamanShell Gadus Product Family BrochurefahreezBelum ada peringkat

- Casting Defect in Slab PDFDokumen55 halamanCasting Defect in Slab PDFBhoomaiah SunkenapalliBelum ada peringkat

- Lecture5 AllDokumen43 halamanLecture5 Alladeelyj100% (1)

- Aluminium Boat BuildingDokumen6 halamanAluminium Boat Buildingjohnknight000Belum ada peringkat

- Tsurumi 3013 CatalogDokumen32 halamanTsurumi 3013 CatalogFlores Cesar0% (1)

- Catalogo Industrial SKFDokumen209 halamanCatalogo Industrial SKFOfelia DiazBelum ada peringkat

- Sculpting With LightDokumen15 halamanSculpting With LightMizuho IeiriBelum ada peringkat

- Reduct orDokumen20 halamanReduct orFlores CesarBelum ada peringkat

- Ingles Vi: Lic. Elva Cirilo ChapiDokumen15 halamanIngles Vi: Lic. Elva Cirilo ChapiFlores CesarBelum ada peringkat

- F-Modelo de Examen Final Inglés VDokumen3 halamanF-Modelo de Examen Final Inglés VFlores CesarBelum ada peringkat

- Manual de Instalacion Se, CompletoDokumen16 halamanManual de Instalacion Se, CompletoFlores CesarBelum ada peringkat

- SAGSim RecycleDokumen162 halamanSAGSim RecycleFlores CesarBelum ada peringkat

- Ingles Vi: Lic. Elva Cirilo ChapiDokumen11 halamanIngles Vi: Lic. Elva Cirilo ChapiFlores CesarBelum ada peringkat

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMDokumen8 halamanBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMJhon Arias FloresBelum ada peringkat

- 15 07 2014.pdfeDokumen29 halaman15 07 2014.pdfeFlores CesarBelum ada peringkat

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 05-Ago-2014 19:56:46Dokumen8 halamanBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 05-Ago-2014 19:56:46Flores CesarBelum ada peringkat

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Dokumen10 halamanBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Flores CesarBelum ada peringkat

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 01-Jul-2014 19:52:22Dokumen72 halamanBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 01-Jul-2014 19:52:22Flores CesarBelum ada peringkat

- FLENDER Supplies: Oil-Supply SystemsDokumen34 halamanFLENDER Supplies: Oil-Supply SystemsFlores CesarBelum ada peringkat

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 10-Jul-2014 20:53:58Dokumen31 halamanBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 10-Jul-2014 20:53:58Flores CesarBelum ada peringkat

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Dokumen10 halamanBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Flores CesarBelum ada peringkat

- 001 Rotex en PDFDokumen34 halaman001 Rotex en PDFFlores CesarBelum ada peringkat

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMDokumen8 halamanBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMJhon Arias FloresBelum ada peringkat

- 03 07 2014ba - PDFNDokumen8 halaman03 07 2014ba - PDFNFlores CesarBelum ada peringkat

- pl1021 UsDokumen7 halamanpl1021 UsFlores CesarBelum ada peringkat

- SLM SeriesDokumen4 halamanSLM SeriesFlores CesarBelum ada peringkat

- Rodamientos ToleranciaDokumen32 halamanRodamientos ToleranciaFlores CesarBelum ada peringkat

- Teco MaxDokumen40 halamanTeco MaxFlores CesarBelum ada peringkat

- Speedmaster: Than Just A Motor CompanyDokumen8 halamanSpeedmaster: Than Just A Motor CompanyFlores CesarBelum ada peringkat

- Turbine Mixers 4Dokumen27 halamanTurbine Mixers 4Flores CesarBelum ada peringkat

- 301-100 - Falk Ram Mixer Drives - BrochureDokumen4 halaman301-100 - Falk Ram Mixer Drives - BrochureFlores CesarBelum ada peringkat

- Eta SeriesDokumen4 halamanEta SeriesFlores CesarBelum ada peringkat

- Eta SeriesDokumen4 halamanEta SeriesFlores CesarBelum ada peringkat

- Fsd166eng SLMDokumen4 halamanFsd166eng SLMFlores CesarBelum ada peringkat

- BS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDFDokumen28 halamanBS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDF梁山伯Belum ada peringkat

- STP 538-1973Dokumen239 halamanSTP 538-1973Tim SchouwBelum ada peringkat

- Nano SensorsDokumen16 halamanNano SensorsAnkusjBelum ada peringkat

- Plastic Raw Material MIS: Date 18-Apr-2022Dokumen3 halamanPlastic Raw Material MIS: Date 18-Apr-2022Office atozBelum ada peringkat

- JKM550 570N 72HL4 BDV F1 enDokumen2 halamanJKM550 570N 72HL4 BDV F1 enSai LaoBelum ada peringkat

- Monoestearato de Glicerilo 95% - China - Wellgo - FT Gms90Dokumen2 halamanMonoestearato de Glicerilo 95% - China - Wellgo - FT Gms90Diego GuzmánBelum ada peringkat

- Pub 83 Al Bronze Alloys For Industry PDFDokumen24 halamanPub 83 Al Bronze Alloys For Industry PDFpbanerjeeBelum ada peringkat

- Sigma Marine Coatings Manual - Part45Dokumen2 halamanSigma Marine Coatings Manual - Part45EngTamerBelum ada peringkat

- IS 456: 2000 8.2.4.2 Maximum Cement Content: Chss TypeDokumen1 halamanIS 456: 2000 8.2.4.2 Maximum Cement Content: Chss Typesharath1199Belum ada peringkat

- JAMB Chemistry Past Question 1983 2004Dokumen119 halamanJAMB Chemistry Past Question 1983 2004iamprecious2allBelum ada peringkat

- BOYSEN QDE For Metal and WoodDokumen1 halamanBOYSEN QDE For Metal and WoodSTEEBelum ada peringkat

- Bostik Boscoprime 1 Rev1Dokumen2 halamanBostik Boscoprime 1 Rev1Loyd EncinaBelum ada peringkat

- Pressure For Different Temperatures For Dimensions of Stainless Steel Welded Pipe and Seamless PipesDokumen7 halamanPressure For Different Temperatures For Dimensions of Stainless Steel Welded Pipe and Seamless PipeswenigmaBelum ada peringkat

- Mil I 46058CDokumen15 halamanMil I 46058Cyamuna yamuBelum ada peringkat

- Xfs Sub Surface Dripline Performance ChartsDokumen2 halamanXfs Sub Surface Dripline Performance ChartsYASSER SHAALANBelum ada peringkat

- Acid Rain Explanation TextDokumen2 halamanAcid Rain Explanation TextIndah Dwi Cahayany100% (2)

- Chem Unit 5 Quantitative QuestionsDokumen27 halamanChem Unit 5 Quantitative QuestionsRizam UmerBelum ada peringkat

- Brosure Gridswitch MK 1.1Dokumen1 halamanBrosure Gridswitch MK 1.1Anwar regarBelum ada peringkat

- 18.05.2020 SR Bipc, SR Aiims & Longterm Re-Revision Schedule PDFDokumen5 halaman18.05.2020 SR Bipc, SR Aiims & Longterm Re-Revision Schedule PDFGuru charan ReddyBelum ada peringkat

- Silicon Run 1 QuestionsDokumen1 halamanSilicon Run 1 QuestionsedWVMBelum ada peringkat

- Estabilidad de Emulsiones PDFDokumen94 halamanEstabilidad de Emulsiones PDFfraniq2007Belum ada peringkat

- Types of Impurities in WaterDokumen7 halamanTypes of Impurities in WaterAhmed BatunBelum ada peringkat

- Thawing 1 RACUDokumen66 halamanThawing 1 RACURfsdjr AceBelum ada peringkat

- Reodata41 PDFDokumen68 halamanReodata41 PDFMunzuara AktherBelum ada peringkat

- Comprehension Passage - Paper Bag DayDokumen2 halamanComprehension Passage - Paper Bag DayJagmeet DhillonBelum ada peringkat