Exh DG 1826

Diunggah oleh

liamo8888Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Exh DG 1826

Diunggah oleh

liamo8888Hak Cipta:

Format Tersedia

Chevron

Data Sheet Guide EXH-DG-1826

INSTRUCTIONS FOR EXTENDED SURFACE AIR COOLED HEAT EXCHANGER

DESIGN DATA SHEET EXH-DS-1826

INSTRUCTIONS FOR EXTENDED SURFACE

AIR COOLED HEAT EXCHANGER

DESIGN DATA SHEET EXH-DS-1826

December 1989

Page 1 of 5

Chevron

Data Sheet Guide EXH-DG-1826

INSTRUCTIONS FOR EXTENDED SURFACE AIR COOLED HEAT EXCHANGER

DESIGN DATA SHEET EXH-DS-1826

CONTENTS

1.0

PURPOSE ............................................................................................................................3

2.0

SCOPE .................................................................................................................................3

3.0

RESPONSIBILITY FOR THE DATA SHEET ....................................................................3

4.0

DESCRIPTION OF ITEMS.................................................................................................3

4.1

4.2

4.3

4.4

4.5

Performance Data ...................................................................................................................3

Construction Data...................................................................................................................4

Materials of Construction ........................................................................................................5

Notes.....................................................................................................................................5

Order Data .............................................................................................................................5

Page 2 of 5

December 1989

Chevron

Data Sheet Guide EXH-DG-1826

INSTRUCTIONS FOR EXTENDED SURFACE AIR COOLED HEAT EXCHANGER

DESIGN DATA SHEET EXH-DS-1826

1.0

PURPOSE

This guide provides instruction on how to complete the Extended Surface Air Cooled Heat

Exchanger Data Sheet EXH-DS-1826. It does not provide rules for the design of air coolers.

Section 600, Model Specification EXH-MS-1826 and API STANDARD 661 have more detailed

information and illustrations of air coolers. Unless otherwise specified, the sections referred to in

this guide refer to sections in the Heat Exchanger and Cooling Tower Manual.

2.0

SCOPE

Data Sheet EXH-DS-1826 summarizes important parameters of performance, construction and

materials. This guide explains terms on the Data Sheet. The section headings in Section 4.0 of this

guide correspond to the section headings on the Data Sheet. This guide does not define every term

on the Data Sheet, only those which need some interpretation.

3.0

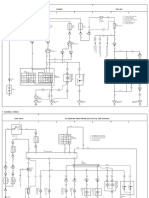

RESPONSIBILITY FOR THE DATA SHEET

A Data Sheet should be completely filled out for each air cooler purchased. Air coolers are

usually vendor designed items. Consequently, the engineer normally only completes the parts of

the Data Sheet needed to define the design basis. Items normally filled out by the engineer are

indicated by an asterisk in Figure DG-1826-1. The Vendor completes the rest of the Data Sheet.

4.0

DESCRIPTION OF ITEMS

4.1 Performance Data

4.1.1

Duty is the rate of energy transfer between the process fluid and the ambient air.

4.1.2

Effective mean temperature difference is the area weighted temperature difference

between the cooling process fluid and the heating air.

4.1.3

Overall Transfer Coefficient (Service and Clean) - The value for clean includes

resistances for film coefficients of the process fluid and air, the tube wall, the fin

bond, and the effect of fin efficiency (variable fin temperature). The value for

service includes the expected fouling resistance and/or an allowance to provide

operating flexibility.

4.1.4

Not all fluid property information applies in every case.

For example,

condensation/vaporization curve number, latent heat of vaporization and "L/V"

(L=liquid & V=vapor) are not needed for single phase service. The engineer should

cross out or indicate N/A (not applicable) for such items.

December 1989

Page 3 of 5

Chevron

Data Sheet Guide EXH-DG-1826

INSTRUCTIONS FOR EXTENDED SURFACE AIR COOLED HEAT EXCHANGER

DESIGN DATA SHEET EXH-DS-1826

4.1.5

Enter tube side fouling allowance where experience indicates the need and the value.

Where tube side fouling is not expected (the usual situation), indicate the desired

degree of excess surface area in a note (i.e., "provide 125% of calculated clean

surface area.").

4.1.6

Design dry bulb air temperature is the highest ambient air temperature at which the

design duty can be achieved. Section 610 gives the normal basis for picking this

temperature.

4.2 Construction Data

Page 4 of 5

4.2.1

Number of bays - A bay is one or more tube bundles serviced by one or two fans

with a common plenum chamber. See API STANDARD 661 for illustrations.

4.2.2

Effective surface all bays (finned and bare tube) - Finned surface is the actual

external surface area including the fins. Bare tube surface is the outside surface area

of the tubes without fins.

4.2.3

Louvers, air recirculation and steam coils are used for winterization. See API

Recommended Practice 632 for guidance.

4.2.4

Mounting refers to where the air cooler will be installed. Specify pipe-rack and it's

width and elevation for air coolers to be mounted over pipe ways. The vendor

usually decides overall length and width for grade mounted units.

4.2.5

Header type is almost always the plug type.

illustrations.

4.2.6

Minimum design pressure is the highest pressure the unit will see in service and is

specified by the engineer. The as-built design pressure is determined by the vendor

and should be equal to or greater than the specified minimum.

4.2.7

Nozzle size, facing and rating should match the piping classification and is specified

by the engineer.

4.2.8

Standard air cooler tubes are 1" OD. Tube wall thickness, or Birmingham Wire Gage

(BWG), is usually minimum wall (min) for carbon steel and average wall (ave) for

alloys. The difference between average and minimum wall is approximately one

BWG point. Specified tube thickness is based on design pressure and corrosion

considerations.

4.2.9

Tube layout should be specified as triangular in all cases. In-line layouts result in

channelling and poor heat transfer.

See API STANDARD 661 for

December 1989

Chevron

Data Sheet Guide EXH-DG-1826

INSTRUCTIONS FOR EXTENDED SURFACE AIR COOLED HEAT EXCHANGER

DESIGN DATA SHEET EXH-DS-1826

4.2.10 Fin type is selected by the vendor subject to limitations in Specification EXH-MS1826.

4.2.11 The engineer should specify forced draft if the process inlet temperature or steam

out temperature is high enough to damage the fan or automatic fan pitch control hub.

When in doubt, let the vendor select draft.

4.2.12 50 % auto-variable pitch fans is usually justified to save fan power consumption

and/or control process temperature. The remaining fans have manually adjustable

pitch.

4.2.13 Specify the steam out temperature if the unit will be steamed out during shut downs.

This may affect selection of fan material or type of draft.

4.2.14 Electric motors are used for most air coolers.

4.2.15 High torque drive (HTD) belts are used for most air coolers.

4.3 Materials of Construction

Materials of construction and minimum pressurizing temperature are usually specified by

a materials specialist or project engineer. Material for the tube sheet, plug sheet, pass

partitions, stiffeners, end plates and top/bottom plates should be the same.

4.4 Notes

4.4.1

The blanks in Note 2 should be filled in to tell the vendor how to balance fan power

cost against the cost of heat transfer surface, and how we intend to evaluate the

vendor's bid.

4.4.2

Additional notes should be added to the Data Sheet to describe any design features

not addressed by the pre-printed items on the Data Sheet.

4.5 Order Data

The manufacturer, manufacturer's shop order number and the Company order number

should be listed here. This reference information may be needed to get additional information

from the vendor in the future.

December 1989

Page 5 of 5

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Property Management SystemDokumen48 halamanProperty Management SystemAkshay P50% (2)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Civ 500Dokumen106 halamanCiv 500liamo8888Belum ada peringkat

- Appendix F. Secondary Containment For New Construction and Existing FacilitiesDokumen30 halamanAppendix F. Secondary Containment For New Construction and Existing Facilitiesliamo8888Belum ada peringkat

- CivappaDokumen22 halamanCivappaliamo8888Belum ada peringkat

- 800 Cranes, Rigging and LiftingDokumen43 halaman800 Cranes, Rigging and LiftingLm Imran100% (5)

- Appendix D. Theoretical Tanker Berthing Impact Analysis: Chevron Corporation D-1 April 1989Dokumen5 halamanAppendix D. Theoretical Tanker Berthing Impact Analysis: Chevron Corporation D-1 April 1989liamo8888Belum ada peringkat

- Appendix C. Rating Procedure For Existing BridgesDokumen4 halamanAppendix C. Rating Procedure For Existing Bridgesliamo8888Belum ada peringkat

- Civ 900Dokumen74 halamanCiv 900liamo8888Belum ada peringkat

- Societal Risk of N 1 (Or More) - V - Individual RiskDokumen1 halamanSocietal Risk of N 1 (Or More) - V - Individual Riskliamo8888Belum ada peringkat

- Civ 300Dokumen70 halamanCiv 300liamo8888Belum ada peringkat

- 400 Small Buildings: 410 Background and Basic Data 400-2Dokumen31 halaman400 Small Buildings: 410 Background and Basic Data 400-2liamo8888Belum ada peringkat

- Exercise Book (FI109) - (Joint Venture) v1.1Dokumen9 halamanExercise Book (FI109) - (Joint Venture) v1.1Shyam JaganathBelum ada peringkat

- 1.outllok Manual Archive SettingsDokumen5 halaman1.outllok Manual Archive SettingsVedadrisrinivasnBelum ada peringkat

- 3161 Governor: For Control of Engines and Steam TurbinesDokumen4 halaman3161 Governor: For Control of Engines and Steam TurbinesWilliam's SalgadoBelum ada peringkat

- Avanza Xenia Wiring DiagramDokumen5 halamanAvanza Xenia Wiring DiagramFazri Putugerah100% (2)

- ST Vid10523-St444Dokumen65 halamanST Vid10523-St444Sistel HuanucoBelum ada peringkat

- ControllersDokumen16 halamanControllersMONIRAJ MONDALBelum ada peringkat

- Automation TestingDokumen104 halamanAutomation TestingAnant ChavanBelum ada peringkat

- 2 PagesDokumen3 halaman2 PagesJohn Manuel BautistaBelum ada peringkat

- Narada 12ndt190sDokumen2 halamanNarada 12ndt190sYANdalfBelum ada peringkat

- Education Course Catalog enDokumen8 halamanEducation Course Catalog enlipasot781Belum ada peringkat

- 5G Mobile Technology: BY M.Hemalatha HT - NO: 106T1A0453Dokumen26 halaman5G Mobile Technology: BY M.Hemalatha HT - NO: 106T1A0453munnaBelum ada peringkat

- International ISBN Agency Agence Internationale ISBN Agencia Internacional ISBNDokumen2 halamanInternational ISBN Agency Agence Internationale ISBN Agencia Internacional ISBNapi-26751250Belum ada peringkat

- Process Models: Dr. Hameedur RahmanDokumen15 halamanProcess Models: Dr. Hameedur RahmanOrhan rumiBelum ada peringkat

- The Effect of Heavy Equipment Management On The PeDokumen8 halamanThe Effect of Heavy Equipment Management On The PeGary NashBelum ada peringkat

- Owner's ManualDokumen208 halamanOwner's ManualChantal LilouBelum ada peringkat

- Sounder Beacons Specification - 240Dokumen4 halamanSounder Beacons Specification - 240ABDUL GHAFOORBelum ada peringkat

- Quality Part 1-Subcontractor Quality Management Requirements AIRTELDokumen26 halamanQuality Part 1-Subcontractor Quality Management Requirements AIRTELAnonymous KKtWOIKMA6100% (1)

- Bsbpmg512 - Manage Project Time Gustavo Lima Quirino Summative 2Dokumen5 halamanBsbpmg512 - Manage Project Time Gustavo Lima Quirino Summative 2EjBelum ada peringkat

- SLC Twin Rt2 0,7.. 10 kVA: User ManualDokumen48 halamanSLC Twin Rt2 0,7.. 10 kVA: User Manualsomae AbbasBelum ada peringkat

- Chapter Five RVU MT&PDokumen39 halamanChapter Five RVU MT&PSisay DeresaBelum ada peringkat

- Airport Qualification and Familiarization ChartsDokumen3 halamanAirport Qualification and Familiarization Chartsjackygdp645Belum ada peringkat

- From The President's Desk: in This IssueDokumen6 halamanFrom The President's Desk: in This IssueJayant ShaligramBelum ada peringkat

- As 4607-1999 Personal Response SystemsDokumen8 halamanAs 4607-1999 Personal Response SystemsSAI Global - APACBelum ada peringkat

- AnthropometricsDokumen5 halamanAnthropometricsNoel Dela CruzBelum ada peringkat

- File Upload XSS - Hack 2 LearnDokumen12 halamanFile Upload XSS - Hack 2 LearnTech HelpBelum ada peringkat

- TJP 4.x - 1VLC000524 Rev.5, enDokumen6 halamanTJP 4.x - 1VLC000524 Rev.5, enTetianaBelum ada peringkat

- GeofencingDokumen3 halamanGeofencinggirishtiwaskarBelum ada peringkat

- Resistron: Operating InstructionsDokumen51 halamanResistron: Operating Instructions16_45_2013_gabri0% (1)

- Nha Balut Tondo Manila - Less 1tDokumen20 halamanNha Balut Tondo Manila - Less 1tTechnical Unit SjmdoBelum ada peringkat