Method Statement For Interlock Works

Diunggah oleh

qoci5koJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Method Statement For Interlock Works

Diunggah oleh

qoci5koHak Cipta:

Format Tersedia

Method Statement for Interlock Works

There are projects that sometimes can proceed for interlock or paving block

works while progressing the main project. This is sometime a technique of the

management to avoid workers to be idle if they have extra people while the

project is at starting stage.

So here are the method statement for interlock work that you might want to learn how it will be

done.

1. Title

Method Statement for Interlock Works

2. Purpose and scope

The purpose of this method statement is to describe the measures and ways

of proper installation of interlock or paving block within our project. The

workwill be as per the project specification and approved drawing.

3. Work procedure

1.

Preparation

o

Before interlock work starts, make sure that sub-grade is

compacted when the area is above natural ground.

The sub-base shall be compacted with vibratory roller, size of

roller shall be suitable for the area where it could maneuver and can

move back and fort.

Once compacted and met the specification requirement for

compaction and approvedby Engineer, base course shall then be

placed above compacted sub-base but make sure thickness of the

bases are as per approved drawing.

MEP rough-in or underground embedments (wherever applicable)

shall be in placed before interlock work commences.

In the areas where there are kerb stone, the blinding shall be

constructed first serve as the base but make sure it shall be as per

drawing.

The importance of pre-installation of kerb stone is to prevent the

migration or dis-alignment of interlock or block, and it will serve as

reference line or level.

After compaction of base-course, the black sand shall be laid on it

of 50 mm thick. There are cases that the bedding is mixed with

cement to adhere cohesiveness but it will be as

per specification requirements.

2.

Installation of Interlock or Paving block

The minimum thickness of interlock shall be 60mm with various

colors. Approvedinterlock or paving block shall be used in

the installation.

The dimension, thickness and design shall be as per approve

shop drawing.

Land surveying shall be made to mark the required levels,

alignments, setting out lines for interlock as per approved drawing.

Once the whole area is completed, fine sand can then laid on the

installed interlock or paving block. Sand shall be spread evenly on

the whole area.

Plate compactor shall be used to compact the installed interlock

or paving blocks.

Once compacted, cleaning shall be followed to remove all excess

sand and damaged pieces.

Inspection request will then be submitted to the Engineer for

approval.

4. Safety

1.

All works shall comply with safety procedure or instruction set out in

project safety plan andMunicipality rules and regulations.

2.

Basic PPE to be worn by all staff or laborers.

3.

All operatives involve in this work shall be inducted before entering the

site.

4.

Tool box talk shall be conducted regularly.

5. Equipments and tools

1.

Interlock cutter

2.

Plate compactor

3.

Wheel borrow

4.

Meter

6. Materials and references

1.

60mm thick Interlock Tile or paving block

2.

Approved Drawing

3.

Specification

Anda mungkin juga menyukai

- Method Statement of Interlocking BlockDokumen11 halamanMethod Statement of Interlocking BlockJulfikar Khan83% (6)

- Method Statement For Interlock PaversDokumen3 halamanMethod Statement For Interlock PaversSumit Gupta100% (2)

- Method Statement For Interlocking BlocksDokumen3 halamanMethod Statement For Interlocking BlocksJaime Manalili LandinginBelum ada peringkat

- Screed-Method StatementDokumen5 halamanScreed-Method StatementTATATAHER100% (2)

- Method of Statement For Interlocking Block and Curb StoneDokumen4 halamanMethod of Statement For Interlocking Block and Curb StoneTAHER AMMAR100% (2)

- Method Statement TileDokumen10 halamanMethod Statement Tilebeshnu garanaikBelum ada peringkat

- Method Statement For Columns2Dokumen5 halamanMethod Statement For Columns2Jasmine TsoBelum ada peringkat

- Roof Waterproofing-Method StatementDokumen5 halamanRoof Waterproofing-Method StatementTATATAHER100% (1)

- Anti Termite Method StatementDokumen5 halamanAnti Termite Method StatementTijjani BelloBelum ada peringkat

- 9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKDokumen15 halaman9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKShenbagaraja Pandian100% (2)

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Dokumen10 halamanWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainBelum ada peringkat

- Work Method Statement For Toilet PartitionDokumen3 halamanWork Method Statement For Toilet PartitionKhyle Laurenz Duro100% (2)

- Method Statement For PlasteringDokumen6 halamanMethod Statement For PlasteringSana NazirBelum ada peringkat

- MOS Temporary HoardingDokumen4 halamanMOS Temporary Hoardinganiesbaek88% (8)

- Ms - Carpet InstallationDokumen9 halamanMs - Carpet Installationlinga2014Belum ada peringkat

- Method Statement For The Erection of Pre Cast Concrete StairDokumen2 halamanMethod Statement For The Erection of Pre Cast Concrete StairBaguma Grace Gariyo100% (3)

- Method Statement of Waterproofing (Wet Area & Brick Bat Coba)Dokumen4 halamanMethod Statement of Waterproofing (Wet Area & Brick Bat Coba)Salman Shah100% (1)

- Method Statement For False Ceiling WorksDokumen2 halamanMethod Statement For False Ceiling WorksTAHER AMMAR33% (3)

- Method of Statement For WaterproofingDokumen10 halamanMethod of Statement For WaterproofingJoe PsBelum ada peringkat

- Work Method Statement For Toilet CubicleDokumen2 halamanWork Method Statement For Toilet CubiclePunk Gowthaman83% (6)

- Ceramic Tile Fixing StatementDokumen5 halamanCeramic Tile Fixing StatementAmit KhazanchiBelum ada peringkat

- Renovations Method StatementDokumen6 halamanRenovations Method StatementOfentse Ledwaba100% (2)

- TilingDokumen4 halamanTilingMalith De SilvaBelum ada peringkat

- Method Statement For Railing WorksDokumen6 halamanMethod Statement For Railing WorksMin LuoBelum ada peringkat

- Method Statement For Screeding WorksDokumen5 halamanMethod Statement For Screeding WorksArunKumar Chandrasekar100% (2)

- Method Statement For Epoxy Risen Floor Coating SystemDokumen7 halamanMethod Statement For Epoxy Risen Floor Coating SystemAnjo MolinaBelum ada peringkat

- Mos DrainageDokumen3 halamanMos DrainageaniesbaekBelum ada peringkat

- Method Statement For Chipping and Grouting For All EDI System in PH2Dokumen6 halamanMethod Statement For Chipping and Grouting For All EDI System in PH2vinodhyperBelum ada peringkat

- Method of Statement Road Drain RockDokumen6 halamanMethod of Statement Road Drain RockAlister PangBelum ada peringkat

- Method of Statement For Concrete WorksDokumen15 halamanMethod of Statement For Concrete WorksAhmed Ibrahim100% (1)

- Method Statements For Reinforcement BarsDokumen2 halamanMethod Statements For Reinforcement BarsSupun Sandaruwan0% (1)

- Work Method Statement For BrickDokumen3 halamanWork Method Statement For BrickBzy Bir Bikram Shrestha100% (6)

- Earthwork Excavation Method StatementDokumen4 halamanEarthwork Excavation Method StatementPageduesca RouelBelum ada peringkat

- Method Statement For Anti Termite TreatmentDokumen5 halamanMethod Statement For Anti Termite TreatmentrayBelum ada peringkat

- Method Statement For Kerb Stone InstallationDokumen16 halamanMethod Statement For Kerb Stone InstallationAnantha Padmanabhan100% (1)

- Work Method Statement ForTile FlooringDokumen3 halamanWork Method Statement ForTile FlooringPunk Gowthaman100% (2)

- Sunken FillingDokumen3 halamanSunken FillingASHOKKUMARBelum ada peringkat

- Method Statement For Substructural Waterproofing Works REV 00Dokumen40 halamanMethod Statement For Substructural Waterproofing Works REV 00Bleep News100% (1)

- Work Method Statement For Coring Works (A)Dokumen3 halamanWork Method Statement For Coring Works (A)Ben Lim50% (6)

- Method of Statement For R.C Piling WorkDokumen10 halamanMethod of Statement For R.C Piling WorkMacgjoyner SaLauBelum ada peringkat

- Installation of Marble and Granite Tiles On FloorDokumen7 halamanInstallation of Marble and Granite Tiles On FloorAleen Gamal Al-Dinji100% (2)

- 5 Method Statement For BRICK WORKSDokumen4 halaman5 Method Statement For BRICK WORKSSana Nazir50% (2)

- Method StatementDokumen102 halamanMethod StatementSagar AliasjackeyBelum ada peringkat

- Method Statement For GunitingDokumen2 halamanMethod Statement For GunitingAlsonChin100% (1)

- Method Statement For EarthworksDokumen3 halamanMethod Statement For EarthworksNorendro KangjamBelum ada peringkat

- Method Statement For Excavation and Backfilling WorksDokumen2 halamanMethod Statement For Excavation and Backfilling WorksAnonymous wTTx1L86% (22)

- Method Statement For Asphalt Paving WorksDokumen5 halamanMethod Statement For Asphalt Paving WorksGokulakrishnan Govindarajan100% (1)

- Method Statement HoldingDokumen4 halamanMethod Statement Holdingqoci5koBelum ada peringkat

- Tiling Method StatementDokumen2 halamanTiling Method StatementVarun60% (10)

- Method Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامDokumen20 halamanMethod Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامM.ZEKEBA0% (1)

- Method Statement Roadworks Acdc Lane-DraftDokumen8 halamanMethod Statement Roadworks Acdc Lane-DraftDeqBelum ada peringkat

- Method Statement For Roof, Wall and Floor WorkDokumen27 halamanMethod Statement For Roof, Wall and Floor WorkĐặng Quang HuyBelum ada peringkat

- METHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesDokumen10 halamanMETHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesHARISH ROHANBelum ada peringkat

- AAC Block Masonary - Method StatementDokumen2 halamanAAC Block Masonary - Method StatementdawoodnagnurBelum ada peringkat

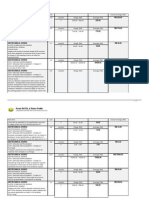

- Inspection and Test Plan For Internal Gypsum Plaster: Oberoi Maxima ProjectDokumen5 halamanInspection and Test Plan For Internal Gypsum Plaster: Oberoi Maxima Projectlokesh.kukadiya100% (1)

- Method Statements InterLock WorksDokumen3 halamanMethod Statements InterLock WorksNino Celso AstilleroBelum ada peringkat

- MsDokumen2 halamanMsVarsha PrakashBelum ada peringkat

- Fencin Method StatementDokumen7 halamanFencin Method StatementNdaba Zams100% (2)

- Interlocking Method StatementDokumen4 halamanInterlocking Method StatementToyEn MEgat100% (1)

- 12 Steps of ConstructionDokumen2 halaman12 Steps of ConstructionBienvenida Ycoy MontenegroBelum ada peringkat

- Faça o Que Tem de Ser FeitoDokumen1 halamanFaça o Que Tem de Ser Feitowagnerjohny100% (2)

- Method Statement SurveyDokumen3 halamanMethod Statement Surveyqoci5koBelum ada peringkat

- Material Take-Off PDFDokumen4 halamanMaterial Take-Off PDFRanilo SumalinogBelum ada peringkat

- Survey Using A TheodoliteDokumen40 halamanSurvey Using A TheodoliteshinobiBelum ada peringkat

- Method Statement - Site ClearanceDokumen6 halamanMethod Statement - Site Clearanceqoci5ko100% (1)

- 02 SurveysDokumen27 halaman02 Surveysqoci5koBelum ada peringkat

- Set Calculation For Hammer Driven Piles Using Modofoed HILLEY's FormulaDokumen2 halamanSet Calculation For Hammer Driven Piles Using Modofoed HILLEY's Formulaqoci5ko89% (9)

- Method Statement HoldingDokumen4 halamanMethod Statement Holdingqoci5koBelum ada peringkat

- Concrete Pumping Risk AssessmentDokumen1 halamanConcrete Pumping Risk Assessmentqoci5ko50% (2)

- RCC Rate AnalsysisDokumen2 halamanRCC Rate AnalsysisjowarBelum ada peringkat

- Concrete Pumping With Boom PumpDokumen11 halamanConcrete Pumping With Boom PumpAnshuman GBelum ada peringkat

- Civil ReportsDokumen68 halamanCivil Reportsqoci5koBelum ada peringkat

- Rates 02032015Dokumen7 halamanRates 02032015qoci5koBelum ada peringkat

- Rates 02032015Dokumen5 halamanRates 02032015qoci5koBelum ada peringkat

- Rates 02032015Dokumen5 halamanRates 02032015qoci5koBelum ada peringkat

- Rates 02032015Dokumen3 halamanRates 02032015qoci5koBelum ada peringkat

- Rates 02032015Dokumen9 halamanRates 02032015qoci5koBelum ada peringkat

- Rates 02032015Dokumen7 halamanRates 02032015qoci5koBelum ada peringkat

- Rates 02032015Dokumen13 halamanRates 02032015qoci5koBelum ada peringkat

- FreameDokumen5 halamanFreameqoci5koBelum ada peringkat

- Method Statement HoldingDokumen3 halamanMethod Statement Holdingqoci5koBelum ada peringkat

- Pile Set CalculationDokumen2 halamanPile Set Calculationqoci5ko100% (1)

- JKR Spec 2005Dokumen188 halamanJKR Spec 2005rex79x98% (60)

- Method Statement ClearingDokumen5 halamanMethod Statement Clearingqoci5koBelum ada peringkat

- TryDokumen1 halamanTryqoci5koBelum ada peringkat

- Hansen Aise Im Ch12Dokumen66 halamanHansen Aise Im Ch12Rizki19maretBelum ada peringkat

- Presentation No. 3 - Songs and ChantsDokumen44 halamanPresentation No. 3 - Songs and Chantsandie hinchBelum ada peringkat

- Errata V0.1 For IT8212F V0.4.2Dokumen2 halamanErrata V0.1 For IT8212F V0.4.2tryujiBelum ada peringkat

- Genie PDFDokumen264 halamanGenie PDFjohanaBelum ada peringkat

- Final Matatag Epp Tle CG 2023 Grades 4 10Dokumen184 halamanFinal Matatag Epp Tle CG 2023 Grades 4 10DIVINE GRACE CABAHUGBelum ada peringkat

- ResearchDokumen10 halamanResearchhridoy tripuraBelum ada peringkat

- Bofa Turkish Banks-Back On The RadarDokumen15 halamanBofa Turkish Banks-Back On The RadarexperhtmBelum ada peringkat

- Appendix 3 COT RPMS For T I III SY 2020 2021 in The Time of COVID 19Dokumen12 halamanAppendix 3 COT RPMS For T I III SY 2020 2021 in The Time of COVID 19Marjun PachecoBelum ada peringkat

- Qcfi Durgapur Chapter: Question & Answers BankDokumen13 halamanQcfi Durgapur Chapter: Question & Answers Bankdeepakhishikar24Belum ada peringkat

- Microbial Diseases of The Different Organ System and Epidem.Dokumen36 halamanMicrobial Diseases of The Different Organ System and Epidem.Ysabelle GutierrezBelum ada peringkat

- Mehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Dokumen294 halamanMehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Alexandra KoehlerBelum ada peringkat

- ERBS UPDATE John Doe ProceedingDokumen3 halamanERBS UPDATE John Doe ProceedingtpeppermanBelum ada peringkat

- ABS Electrical System Tiba 2Dokumen8 halamanABS Electrical System Tiba 2ﺍﻟﻄﺎﺋﺮ ﺍﻟﺤﺰﻳﻦBelum ada peringkat

- Game ApiDokumen16 halamanGame ApiIsidora Núñez PavezBelum ada peringkat

- Andromeda: Druid 3 Warborn06Dokumen5 halamanAndromeda: Druid 3 Warborn06AlanBelum ada peringkat

- 8. Nguyễn Tất Thành- Kon TumDokumen17 halaman8. Nguyễn Tất Thành- Kon TumK60 TRẦN MINH QUANGBelum ada peringkat

- Journal Articles: Types of JournalsDokumen4 halamanJournal Articles: Types of JournalsOtieno SteveBelum ada peringkat

- Demand Determinants EEMDokumen22 halamanDemand Determinants EEMPrabha KaranBelum ada peringkat

- Industry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineDokumen14 halamanIndustry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineCalebBelum ada peringkat

- Lit 30Dokumen2 halamanLit 30ReemAlashhab81Belum ada peringkat

- Lab Report 2Dokumen5 halamanLab Report 2Md jubayer SiddiqueBelum ada peringkat

- Sungbo's Eredo, Southern Nigeria: Nyame Akuma NoDokumen7 halamanSungbo's Eredo, Southern Nigeria: Nyame Akuma NosalatudeBelum ada peringkat

- Drawbot 1Dokumen4 halamanDrawbot 1SayanSanyalBelum ada peringkat

- Manuscript PDFDokumen50 halamanManuscript PDFMartina Mae Benig GinoBelum ada peringkat

- CCTV Guidelines - Commission Letter Dated 27.08.2022Dokumen2 halamanCCTV Guidelines - Commission Letter Dated 27.08.2022Sumeet TripathiBelum ada peringkat

- Ezpdf Reader 1 9 8 1Dokumen1 halamanEzpdf Reader 1 9 8 1AnthonyBelum ada peringkat

- Bankers ChoiceDokumen18 halamanBankers ChoiceArchana ThirunagariBelum ada peringkat

- Intergard 475HS - Part B - EVA046 - GBR - ENG PDFDokumen10 halamanIntergard 475HS - Part B - EVA046 - GBR - ENG PDFMohamed NouzerBelum ada peringkat

- Operation of A CRT MonitorDokumen8 halamanOperation of A CRT MonitorHarry W. HadelichBelum ada peringkat

- Story 1Dokumen3 halamanStory 1api-296631749Belum ada peringkat

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (242)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDari EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedPenilaian: 5 dari 5 bintang5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDari EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDari EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialBelum ada peringkat

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDari EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HousePenilaian: 5 dari 5 bintang5/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDari EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesBelum ada peringkat

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDari Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuidePenilaian: 3.5 dari 5 bintang3.5/5 (7)

- Building Construction Technology: A Useful Guide - Part 1Dari EverandBuilding Construction Technology: A Useful Guide - Part 1Penilaian: 4 dari 5 bintang4/5 (3)

- Civil Engineer's Handbook of Professional PracticeDari EverandCivil Engineer's Handbook of Professional PracticePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADari EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ABelum ada peringkat

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDari EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyPenilaian: 4 dari 5 bintang4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDari EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyPenilaian: 4 dari 5 bintang4/5 (1)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDari EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishPenilaian: 4 dari 5 bintang4/5 (3)

- Field Guide for Construction Management: Management by Walking AroundDari EverandField Guide for Construction Management: Management by Walking AroundPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressDari EverandNuclear Energy in the 21st Century: World Nuclear University PressPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Real Life: Construction Management Guide from A-ZDari EverandReal Life: Construction Management Guide from A-ZPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDari EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEPenilaian: 4 dari 5 bintang4/5 (1)

- Construction Project Management 101: For Beginners & New GraduatesDari EverandConstruction Project Management 101: For Beginners & New GraduatesBelum ada peringkat

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDari EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDari EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsBelum ada peringkat