TSB Ajuste Válvulas e Inyector

Diunggah oleh

MASTERTECH_01Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TSB Ajuste Válvulas e Inyector

Diunggah oleh

MASTERTECH_01Hak Cipta:

Format Tersedia

Mack Trucks, Inc.

Greensboro, NC USA

Service Bulletin

Trucks

This service bulletin replaces bulletin 214-93 dated 7.2013.

Date

Group

No.

Release

Page

11.2014

214

93

03

1(13)

Valves and Engine injectors, Adjustment

MP8

Valves and Engine Injectors, Adjustment

W2005941

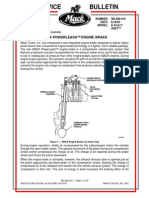

This information covers the correct procedure for adjusting the valves and engine injectors on

MACK MP8 engines.

Note: This information also applies to Mack Trucks Australia.

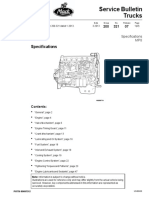

Contents

Special Tools, page 2

Valves and Engine Injectors, Adjustment, page 3

Note: Information is subject to change without notice.

Illustrations are used for reference only and may differ slightly from the actual engine

version. However, key components addressed in this information are represented as

accurately as possible.

PV776-89174548

USA67433

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Tools

Special Tools

For special tools ordering instructions, refer to Tool Information, Function Group 08.

T0012612

W0000416

88800014

Flywheel Turning Tool

85111377 or 88880053

Feeler Gauge Set

W2055377

88880052 (part of set 88880053)

Feeler Gauges

Page

2(13)

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

3(13)

Service Procedures

2140-05-03-01

Valves and Engine Injectors, Adjustment

Valve cover removed

You must read and understand the precautions and guidelines in Service Information, Function Group 20, "Engine

Safety Practices" before performing this procedure. If you

are not properly trained and certified in this procedure, ask

your supervisor for training before you perform it.

DANGER

Do not attempt to repair or service this vehicle without sufficient training, the correct service literature and the proper

tools. Failure to follow this could make the vehicle unsafe

and lead to serious personal injury or death.

DANGER

Before working on a vehicle, set the parking brake, place

the shift lever in Neutral, and block the wheels. Failure to

do so can result in unexpected vehicle movement and can

cause serious personal injury or death.

Special tools: 3949521, 85111377 or

88880053, 88800014, 88880052

1

Remove the plug from the lower right side of the flywheel

housing and install the flywheel turning tool.

88800014

W0002368

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

4(13)

2

Remove the fasteners retaining the leaf springs to release

spring tension on the engine brake rocker arms. Remove leaf

springs.

W2005753

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

5(13)

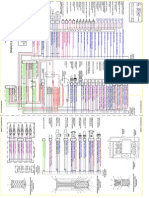

3

Camshaft Marks for Setting Valves and Engine Injectors

Without engine brake: Markings 16 apply to adjustment

of inlet valves, exhaust valves and engine injectors.

With engine brake: Markings 16 apply to adjustment of

inlet valves and engine injector. Markings E1E6 apply to

adjustment of exhaust valves.

Valve and Injector Settings with Engine Brake

Cam

Position

Injector

Intake/

Exhaust

Exhaust

Engine

Brake

Engine

Brake

Rocker

E6

W2006171

E2

6

E4

2

E1

4

E5

1

E3

Valve and Injector Settings without Engine Brake

Cam

Position

Injector

Intake

Exhaust

Note: The V markings on the camshaft are for cylinder TDC

reference only and are not used for valve adjustment.

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

6(13)

Intake Valves Adjustment (with or without engine brake)

4

Using the flywheel turning tool, rotate the engine to the next

camshaft marking for adjustment of the intake valve. Rotate

the engine until the valve and injector mark on the front end

of the camshaft aligns with the stamped mark on the camshaft front bearing cap.

Note: Engine must be rotated in the normal direction of operation when advancing to the next mark.

5

With the engine cold (140F or less), check the intake valve

clearance. Push down on the back of the rocker and insert a

feeler gauge of the proper specification, 0.20 0.05 mm

(0.008 0.002 inch), between the bridge and the adjustment

screw. If the inlet rocker requires adjustment, loosen the lock

nut on the rocker and adjust the plunger.

T2023322

6

Hold the adjusting screw to prevent it from turning and tighten

the adjusting screw lock nut to 38 4 Nm (28 3 ft-lb).

7

Check the valve clearance again after the nut is tightened.

Note: Mark the rocker arm when the valve has been

adjusted.

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

7(13)

Engine Injector Adjustment

8

To adjust the injector on the same cylinder location, loosen

the lock nut and back off the adjusting screw until it no longer

makes contact.

9

Adjust the engine injector's rocker arm to zero clearance.

Note: The spring must not be compressed. There should not

be any movement of the spring.

10

Tighten the adjusting screw an additional four flats or 240 degrees of clockwise rotation.

T2023323

11

Tighten the adjusting screw lock nut to

52 4 Nm (38 3 ft-lb).

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

8(13)

Exhaust Valves Adjustment (without engine

brake)

12

Continue adjustment on the same cylinder location by checking the exhaust rocker valve clearance. Push down on the

back of the exhaust rocker and insert a 0.80 0.05 mm

(0.031 0.002 inch) feeler gauge between the bridge and the

adjustment screw. If the exhaust rocker requires adjustment,

loosen the lock nut on the rocker and adjust the plunger.

T2022277

13

Hold the adjusting screw to prevent it from turning and tighten

the adjusting screw lock nut to 38 4 Nm (28 3 ft-lb).

14

Check valve clearance again after the lock nut is tightened.

Note: Mark the rocker arm when the valve has been

adjusted.

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

9(13)

Exhaust Valves Adjustment (with engine brake,

with or without shims)

15

Using the flywheel turning tool, rotate the engine to the next

camshaft marking (number plus E) for the adjustment of the

exhaust valves. Adjust the exhaust and brake rocker on the

cylinder number following the "E".

W2006171

16

Push down on the back of the exhaust rocker and insert a

1.00 0.05 mm (0.039 0.002 inch) feeler gauge between

the bridge and the brake plunger.

T2023324

17

If clearance is not within specification, adjust the clearance

as required, using shims placed on top of the valve bridge.

For engines without shims, loosen the lock nut on the rocker

and adjust the plunger. Hold the adjusting screw to prevent it

from turning and tighten the adjusting screw lock nut to

38 4 Nm (28 3 ft-lb).

Note: For engines without shims, go to Step 22.

18

Remove the shim retaining screw and remove the shim.

Note: When loosening or tightening the shim retaining screw

to change the shim, the yoke must be kept fixed with a tool to

avoid bending the valve stem.

19

Make sure that the valve bridge and shim(s) are clean.

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

10(13)

20

Determine the thickness of the shim(s) required to match the

measured clearance.

Note: DO NOT use more than two shims. Shims are available in 0.05 mm (0.002 inch) increments with the thickness

marked on the surface. If two shims are required to take up

the clearance, the shims should be of nearly equal thickness.

3949521 (Shim Kit)

T2009008

21

Place the shim(s) in position on the valve yoke, install the retaining screw and tighten to 38 4 Nm (28 3 ft-lb).

Note: When loosening or tightening the shim retaining screw

to change the shim, the yoke must be kept fixed with a tool to

avoid bending the valve stem.

22

Check valve clearance again after lock nut is tightened or

shim is fastened. Allow feeler gauge to remain in place between the exhaust rocker arm and the valve bridge during

the following engine brake rocker check.

Engine Brake Rocker Adjustment (with or without shims)

23

Using a 2.5 mm feeler gauge, check the exhaust brake rocker arm clearance by placing the feeler gauge between the

brake rocker arm roller and the cam lobe. The clearance

should be 2.5 0.07 mm (0.1 0.003 inch).

Note: 1.00 0.05 mm feeler gauge should still be between

exhaust rocker arm and valve bridge.

88880053

W2005815

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

11(13)

24

If the clearance is not within specification, loosen the brake

rocker arm lock nut (A) and turn the adjuster screw (B) 1/2 to

1 turn counter-clockwise. With the 2.5 mm feeler gauge in position between the rocker arm roller and cam lobe, tighten the

adjuster screw (B) until it makes contact and then a further

1/2 turn until the valve yoke clearly moves down and the exhaust valve opens slightly. The engine brake mechanism is

now preloaded.

T2027091

25

Loosen the adjusting screw slowly until the 2.5 mm gauge

can be pushed in and out with some effort. Hold the adjusting

screw to prevent it from turning and tighten the lock nut to

52 4 Nm (38 3 ft-lb).

Engine Brake Check

26

Allow 1.00 0.05 mm (0.039 0.002 inch) feeler gauge to remain in place between the exhaust rocker arm and the valve

bridge during the following brake rocker check.

27

Check the engine brake rocker arm clearance between the

rocker arm roller and the camshaft with the 2.5 mm feeler

gauge between the camshaft lobe and the rocker arm roller.

88880053

W2005815

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

12(13)

28

Clearance between the camshaft and rocker roller should

meet a specification of 2.5 0.07 mm (0.1 0.003 inch).

29

If the clearance is not within the specification, the adjustment

must be repeated per the previous adjustment.

30

Check valve clearance again after the lock nut is tightened.

Note: Mark the rocker arm when the valve has been

adjusted.

31

Remove the feeler gauge from between the exhaust rocker

arm and valve bridge. Check the clearance between the

camshaft and the brake rocker roller using a 3.20 mm shim this shim should pass with no resistance. If there is resistance then the adjustment is incorrect. Repeat the adjustment

procedure.

32

Repeat the above procedure to adjust all other engine injectors and valve locations by rotating the engine to the next

nearest camshaft mark.

W0002368

33

After all engine injectors and valves have been checked and

adjusted if necessary, clean the valve cover contact surface

on the cylinder head.

34

For engines with engine brake, install brake rocker leaf

springs and tighten the retaining screws on the exhaust rocker arms to 25 3 Nm (18 2 ft-lb). Ensure that the brake

rocker arm push rod is centered and properly seated into leaf

spring socket before tightening retaining screws.

T2022951

Mack Trucks, Inc.

Service Bulletin

Date

11.2014

Group

No.

Release

214

93

03

Page

13(13)

35

Install the valve cover. Refer to Function Group 211, Valve

Cover, Replacement, for this procedure.

36

Bring the engine to normal operating temperature. Let the engine idle for approximately 5 minutes; the system performs

its own cylinder balancing in order to attain even idling.

Note: During cylinder balancing, do not use any form of

power-consuming equipment, such as power take-off or air

conditioning.

Anda mungkin juga menyukai

- 2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132Dokumen13 halaman2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132Ricardo75% (4)

- Calibracion Valvulas Motor c12 CaterpillarDokumen5 halamanCalibracion Valvulas Motor c12 CaterpillarOmar Diaz Segura100% (1)

- Motor Mp8 Mack 2Dokumen144 halamanMotor Mp8 Mack 2Padilla Ramos92% (24)

- Ajustes de Valvulas Motor Mack E-TechDokumen40 halamanAjustes de Valvulas Motor Mack E-TechJohn MkCito KI100% (3)

- Overhall Diferencial Mack PDFDokumen150 halamanOverhall Diferencial Mack PDFmanuel fernandezBelum ada peringkat

- Service Bulletin: Air-Operated Clutch Assist System - Adjustment, Troubleshooting and Retrofit InstructionsDokumen21 halamanService Bulletin: Air-Operated Clutch Assist System - Adjustment, Troubleshooting and Retrofit Instructionshamilton miranda100% (2)

- Motor D12D - Motor - Valvulas, AjustarDokumen6 halamanMotor D12D - Motor - Valvulas, AjustarAparecidaMarquesBelum ada peringkat

- M1 MP-7 and MP-8 OverhaulDokumen116 halamanM1 MP-7 and MP-8 OverhaulHEY86% (7)

- Eaton Fuller Rtx-14715Dokumen43 halamanEaton Fuller Rtx-14715davidbeju100% (1)

- Adjust The Valves and N3 Fuel Injector Settings As Follows:: Series 60 Service ManualDokumen4 halamanAdjust The Valves and N3 Fuel Injector Settings As Follows:: Series 60 Service ManualJavier Leyva Yuco100% (1)

- Eaton 10 Speed Service ManualDokumen186 halamanEaton 10 Speed Service ManualKeith McCann100% (1)

- Calibración de InyectoresDokumen3 halamanCalibración de InyectoresAbdel Alvarez67% (3)

- Eaton Fro 15210c TransDokumen194 halamanEaton Fro 15210c Transsonicbluel83% (6)

- Procedimiento de Ajuste de Freno de Motor C-15, C-16 and C-18 EnginesDokumen10 halamanProcedimiento de Ajuste de Freno de Motor C-15, C-16 and C-18 EnginesJose MontoyaBelum ada peringkat

- Valve Lash Ddec Vi.Dokumen2 halamanValve Lash Ddec Vi.Gerardo PonceBelum ada peringkat

- Manual de Motor Mack Mp8Dokumen20 halamanManual de Motor Mack Mp8Alex ChampiBelum ada peringkat

- TRTS0980EN-US 0317wDokumen600 halamanTRTS0980EN-US 0317wHipac Tapicu100% (2)

- Mack MP8 Cabeza de Cilindros CambioDokumen15 halamanMack MP8 Cabeza de Cilindros Cambiohamilton mirandaBelum ada peringkat

- Caja de Super 10Dokumen178 halamanCaja de Super 10AnGel Amaya100% (1)

- MP7, MP8, and MP10 Engines For MACK VehiclesDokumen39 halamanMP7, MP8, and MP10 Engines For MACK VehiclesRichard Ochoa100% (5)

- No.: 04 TS-43Rev3: Detroit Diesel 13400 Outer Drive, West / Detroit, Michigan 48239-4001Dokumen9 halamanNo.: 04 TS-43Rev3: Detroit Diesel 13400 Outer Drive, West / Detroit, Michigan 48239-4001Gutierrez EfrainBelum ada peringkat

- Mack ESPECIF-MP8Dokumen47 halamanMack ESPECIF-MP8Samuel Yogui Lara100% (6)

- Meritor 14x Driveaxle Parts CatalogDokumen39 halamanMeritor 14x Driveaxle Parts CatalogeduardoBelum ada peringkat

- Series 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelDokumen14 halamanSeries 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelJuan RiveraBelum ada peringkat

- Serie 60 Informacion AdicionalDokumen51 halamanSerie 60 Informacion AdicionalMauricio Campos QuirosBelum ada peringkat

- Mack Motor Volvo, Códigos FalloDokumen82 halamanMack Motor Volvo, Códigos FalloRicardo Diaz94% (18)

- Rockwell 9 and 10 Speed Manual Transmission Parts Manual PDFDokumen35 halamanRockwell 9 and 10 Speed Manual Transmission Parts Manual PDFDenia Isalia Santana Anguiano100% (1)

- n14 Cylinder Head InstallationDokumen3 halamann14 Cylinder Head InstallationOumarba KamandaBelum ada peringkat

- Service Manual Fuller Heavy Duty Frfro Transmissions Trsm2400 Eaton FullerDokumen196 halamanService Manual Fuller Heavy Duty Frfro Transmissions Trsm2400 Eaton FullerCristian Muñoz100% (10)

- Overhall Diferencial MackDokumen150 halamanOverhall Diferencial MackMiguel Cordero91% (11)

- Compresor Bendix Ba-921 P Detroit PDFDokumen36 halamanCompresor Bendix Ba-921 P Detroit PDFDenis HernandezBelum ada peringkat

- 8 372Dokumen268 halaman8 372Hamilton Miranda80% (5)

- Sheppard M100 - MP8 - 163Dokumen70 halamanSheppard M100 - MP8 - 163orlandolanchipaBelum ada peringkat

- RTLO-18918B Manual PartsDokumen40 halamanRTLO-18918B Manual PartszaidsantoyoBelum ada peringkat

- TR Navistar International DT466E DT530 TSIDokumen2 halamanTR Navistar International DT466E DT530 TSIDavid Fuentes100% (2)

- Dt466-Dt570-Torque de Cabaza ValvuasDokumen22 halamanDt466-Dt570-Torque de Cabaza ValvuasWero vences Alpargatas80% (5)

- Dd15 FaultDokumen19 halamanDd15 FaultSsBelum ada peringkat

- Ajuste de Tren de EngranesDokumen9 halamanAjuste de Tren de Engranessinger50100% (1)

- Mack Truck Fault Codes ListDokumen2 halamanMack Truck Fault Codes ListAlexanderRomero100% (3)

- Ddec IiDokumen1 halamanDdec IiEduardo PerezBelum ada peringkat

- Valves and Unit Injectors, AdjustmentDokumen17 halamanValves and Unit Injectors, AdjustmentRolando Mancilla Flores91% (58)

- 2 Valves and Injectors Adjustment VEBDokumen21 halaman2 Valves and Injectors Adjustment VEBRuju RujuBelum ada peringkat

- Calibracion Valvulas Motor C12 CaterpillarDokumen5 halamanCalibracion Valvulas Motor C12 CaterpillarRamón José Aponte Franco100% (9)

- PV776-20 006218Dokumen9 halamanPV776-20 006218Benjamin Miranda FloresBelum ada peringkat

- Qdoc - Tips Calibracion Valvulas Motor c12 CaterpillarDokumen5 halamanQdoc - Tips Calibracion Valvulas Motor c12 CaterpillarJoel MendezBelum ada peringkat

- Engine Valve Lash - Inspect/Adjust: Shutdown SISDokumen5 halamanEngine Valve Lash - Inspect/Adjust: Shutdown SISChakrouneBelum ada peringkat

- Actuator Variable Geometry Turbocharger ReplacementDokumen11 halamanActuator Variable Geometry Turbocharger ReplacementZoltán Szecsődi100% (1)

- Special Features of The f5r 740 EngineDokumen146 halamanSpecial Features of The f5r 740 EngineBen Van Der MerweBelum ada peringkat

- Calibre Valvulas MP8 s34-5116Dokumen20 halamanCalibre Valvulas MP8 s34-5116Jose AGBelum ada peringkat

- Brake Pedal AdjustmentDokumen5 halamanBrake Pedal AdjustmentWilson BuenoBelum ada peringkat

- Volvo D13H Shop Armed Vol2Dokumen34 halamanVolvo D13H Shop Armed Vol2Juan José AldanaBelum ada peringkat

- 3007a Je0m f9q Special FeaturesDokumen101 halaman3007a Je0m f9q Special FeaturesAdam JohnsonBelum ada peringkat

- 3116 Cat Valvuklas Calibre PDFDokumen4 halaman3116 Cat Valvuklas Calibre PDFsergio blandon lBelum ada peringkat

- Adjust valves and unit injectors on Volvo D16F engineDokumen20 halamanAdjust valves and unit injectors on Volvo D16F engineMabelRinaldi86% (7)

- Installation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)Dokumen23 halamanInstallation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)aliBelum ada peringkat

- Fuel Injection Timing: Engine Setup and AdjustmentsDokumen28 halamanFuel Injection Timing: Engine Setup and AdjustmentsDaniel PaisBelum ada peringkat

- Procedimiento de Ajuste de Freno de Motor C-15 Engines NXS (SENR9692)Dokumen6 halamanProcedimiento de Ajuste de Freno de Motor C-15 Engines NXS (SENR9692)Carlos U. CallirgosBelum ada peringkat

- Ajuste Freno de MotorDokumen8 halamanAjuste Freno de MotorAlvaro Escalona GtzBelum ada peringkat

- C-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDokumen4 halamanC-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDamien LEGRANDBelum ada peringkat

- Esquemas Eléctricos BMWDokumen3 halamanEsquemas Eléctricos BMWMASTERTECH_01Belum ada peringkat

- Eurocargo Tector 6-26t Electronic System PDFDokumen192 halamanEurocargo Tector 6-26t Electronic System PDFRogério Moreno80% (15)

- JOHN DEERE Manual Tecnico 644H ,,,,,1Dokumen392 halamanJOHN DEERE Manual Tecnico 644H ,,,,,1MASTERTECH_01Belum ada peringkat

- Manual V-Mall IDokumen9 halamanManual V-Mall IMASTERTECH_01Belum ada peringkat

- 5-113 FinalDokumen386 halaman5-113 FinalMASTERTECH_0198% (45)

- ECM DTC Guide ManualDokumen98 halamanECM DTC Guide Manualfam5964Belum ada peringkat

- MP Series ManualDokumen167 halamanMP Series ManualOrji Okoro60% (5)

- JOHN DEERE Manual Tecnico 644H ,,,,2Dokumen486 halamanJOHN DEERE Manual Tecnico 644H ,,,,2MASTERTECH_01Belum ada peringkat

- Mack Motor Volvo, Códigos FalloDokumen82 halamanMack Motor Volvo, Códigos FalloRicardo Diaz94% (18)

- Especificaciones Sensores Motor Mack TodosDokumen6 halamanEspecificaciones Sensores Motor Mack TodosMASTERTECH_01100% (1)

- CUMMINS-IsBe ISB (4 Cylinder) - Diagrama ElectricoDokumen1 halamanCUMMINS-IsBe ISB (4 Cylinder) - Diagrama ElectricoMASTERTECH_0167% (3)

- T - 180-360L - MAINT Rev - 1105 TSGDokumen299 halamanT - 180-360L - MAINT Rev - 1105 TSGMASTERTECH_01Belum ada peringkat

- 5-113 FinalDokumen386 halaman5-113 FinalMASTERTECH_0198% (45)

- Manual Motor CONTROL ELECTRON PDFDokumen368 halamanManual Motor CONTROL ELECTRON PDFMASTERTECH_01100% (9)

- Tractores d9r D10r-HeuiDokumen49 halamanTractores d9r D10r-HeuiRodrigo Chacca100% (1)

- ITec - Hyundai Codigos OBD EspecificosDokumen10 halamanITec - Hyundai Codigos OBD EspecificosMASTERTECH_01100% (1)

- Manual de Servicio Jac j2Dokumen243 halamanManual de Servicio Jac j2MASTERTECH_0162% (13)

- Manual de Servicio Jac j2Dokumen243 halamanManual de Servicio Jac j2MASTERTECH_0162% (13)

- Pico ScopeDokumen0 halamanPico ScopeMASTERTECH_01Belum ada peringkat

- ITec - Hyundai Codigos OBD EspecificosDokumen10 halamanITec - Hyundai Codigos OBD EspecificosMASTERTECH_01100% (1)

- CUMMINS-IsBe ISB (4 Cylinder) - Diagrama ElectricoDokumen1 halamanCUMMINS-IsBe ISB (4 Cylinder) - Diagrama ElectricoMASTERTECH_0167% (3)

- Tractores d9r D10r-HeuiDokumen49 halamanTractores d9r D10r-HeuiRodrigo Chacca100% (1)

- MAXTER 125 Service ManualDokumen278 halamanMAXTER 125 Service ManualRobert Byrd90% (21)

- Power Screw Rod DesignDokumen52 halamanPower Screw Rod Designramkumar121Belum ada peringkat

- EMDGDokumen112 halamanEMDGbasantsriBelum ada peringkat

- SAF HOLLAND Suspension Parts ManualDokumen60 halamanSAF HOLLAND Suspension Parts Manualjinxy5779100% (1)

- T603 Tractor Service ManualDokumen260 halamanT603 Tractor Service ManualsteveBelum ada peringkat

- Design of Joints: Equation Chapter 1 Section 1Dokumen131 halamanDesign of Joints: Equation Chapter 1 Section 1kartikijag100% (1)

- Ek 25 Boru Fabrikasyon Ve Montaj İşleri Uygulama Planı (Method Statement For Fabrication and Installation of Pipework) ÖrneğiDokumen8 halamanEk 25 Boru Fabrikasyon Ve Montaj İşleri Uygulama Planı (Method Statement For Fabrication and Installation of Pipework) ÖrneğiAniekanBelum ada peringkat

- BPWDokumen90 halamanBPWIlijaBelum ada peringkat

- Flowserve Digital PositionerDokumen54 halamanFlowserve Digital PositionerEdwin MercadoBelum ada peringkat

- FastenersDokumen46 halamanFastenerser_lalitgargBelum ada peringkat

- Technical Manual Adjustable Choke MANUAL006-1 PDFDokumen51 halamanTechnical Manual Adjustable Choke MANUAL006-1 PDFanwarhas05Belum ada peringkat

- Let Us Install Jyoti VT PumpsDokumen55 halamanLet Us Install Jyoti VT Pumpsraghavakl100% (3)

- T21 Thread Dimensions Tightening Torque Values and Dimensions For Cable GlandsDokumen2 halamanT21 Thread Dimensions Tightening Torque Values and Dimensions For Cable GlandsYBelum ada peringkat

- Installation, Operation and Maintenance ManualDokumen83 halamanInstallation, Operation and Maintenance ManualAlex LopezBelum ada peringkat

- Model T-60 Tubing Spider Installation, Operation, Service and Parts Book ManualDokumen14 halamanModel T-60 Tubing Spider Installation, Operation, Service and Parts Book ManualDean ReinBelum ada peringkat

- MM Standard ConfigurationDokumen156 halamanMM Standard ConfigurationSUBHOJIT BANERJEEBelum ada peringkat

- Man D0826le20Dokumen16 halamanMan D0826le20jetdede100% (1)

- NH - TM - Pumpa PDFDokumen34 halamanNH - TM - Pumpa PDFBoštjan Šumenjak100% (1)

- Type: FD25 T-14 Se. No.: M151A-566236 Mast: V025Y44?? 37B-7T7-30?Dokumen10 halamanType: FD25 T-14 Se. No.: M151A-566236 Mast: V025Y44?? 37B-7T7-30?Darshana ChathurangaBelum ada peringkat

- GMW16215Dokumen7 halamanGMW16215JOECOOL67100% (1)

- Mcqs Preparation For Engineering Competitive ExamsDokumen14 halamanMcqs Preparation For Engineering Competitive ExamsMukul TiwariBelum ada peringkat

- RT 650 TP - 214 - ADokumen24 halamanRT 650 TP - 214 - ARamón José Aponte FrancoBelum ada peringkat

- SB 1197BDokumen9 halamanSB 1197B80proofBelum ada peringkat

- Caterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)Dokumen28 halamanCaterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)rpoy9396615Belum ada peringkat

- Manual Motor 3ADokumen325 halamanManual Motor 3ATorque100% (1)

- FB250-Hatz Spare PartsDokumen56 halamanFB250-Hatz Spare PartsKlaudia BienioszekBelum ada peringkat

- 2008 Outlander Can Am ATVDokumen437 halaman2008 Outlander Can Am ATVHugo Andres Idarraga GallegoBelum ada peringkat

- Small Vertical Engine Parts ListDokumen49 halamanSmall Vertical Engine Parts ListsasaBelum ada peringkat

- Catalogo So-04m - Jan2011 - InglesDokumen53 halamanCatalogo So-04m - Jan2011 - InglesAndré Maria100% (1)

- Installation RecommendationsDokumen22 halamanInstallation RecommendationsAsif ShahBelum ada peringkat