Mack Erle 2002

Diunggah oleh

Carlos VegaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Mack Erle 2002

Diunggah oleh

Carlos VegaHak Cipta:

Format Tersedia

International Journal of Pressure Vessels and Piping 79 (2002) 126

www.elsevier.com/locate/ijpvp

Review

Finite elements in the analysis of pressure vessels and piping,

an addendum: a bibliography (19982001)

Jaroslav Mackerle*

Department of Mechanical Engineering, Linkoping Institute of Technology, S-581 83 Linkoping, Sweden

Received 28 September 2001; revised 8 October 2001; accepted 8 October 2001

Abstract

The paper gives a bibliographical review of nite element methods (FEMs) applied for the analysis of pressure vessel structures/

components and piping from the theoretical as well as practical points of view. This bibliography is an addendum to the Finite elements

in the analysis of pressure vessels and pipinga bibliography (19761996) published [Int J Press Vess Piping 69 (1996) 279] and Finite

elements in the analysis of pressure vessels and piping, an addendum (19961998) published [Int J Press Vess Piping 76 (1999) 461]. The

new bibliography at the end of the paper contains approximately 670 references to papers and conference proceedings on the subject that

were published in 19982001. These are classied in the following categories: linear and nonlinear, static and dynamic, stress and deection

analyses; stability problems; thermal problems; fracture mechanics problems; contact problems; uidstructure interaction problems;

manufacturing of pipes and tubes; welded pipes and pressure vessel components; development of special nite elements for pressure vessels

and pipes; nite element software; and other topics. q 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Finite element; Bibliography; Pressure vessels; Pipes; Linear and nonlinear static and dynamic analysis; Fracture mechanics; Contact problems;

Thermal problems; Fluidstructure interaction; Welding

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Finite elements in the analysis of pressure vessels and piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1. Linear and nonlinear, static and dynamic, stress and deection analyses (STR) . . . . . . . . . . . . . . . . . . . . . . .

2.2. Stability problems (STA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3. Thermal problems (THE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4. Fracture mechanics problems (FRA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5. Contact problems (CON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6. Fluidstructure interaction problems (FLU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7. Manufacturing of pipes and tubes (MAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8. Welded pipes and pressure vessel components (WEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9. Development of special nite elements for pressure vessels and pipes (ELE) . . . . . . . . . . . . . . . . . . . . . . . .

2.10. Finite element software (SOF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11. Other topics (OTH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acknowledgements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A. A bibliography (19982001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1. Linear and nonlinear, static and dynamic, stress and deection analyses (STR) . . . . . . . . . . . . . . . . . . . . . . .

A.2. Stability problems (STA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3. Thermal problems (THE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4. Fracture mechanics problems (FRA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5. Contact problems (CON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.6. Fluidstructure interaction problems (FLU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.7. Manufacturing of pipes and tubes (MAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

* Tel.: 146-13-28-1111; fax: 146-13-28-2717.

E-mail address: jarma@ikp.liu.se (J. Mackerle).

0308-0161/02/$ - see front matter q 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0308-016 1(01) 00128-4

1

2

2

3

3

3

3

3

3

4

4

4

4

4

4

4

9

10

11

19

21

21

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

A.8. Welded pipes and pressure vessel components (WEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.9. Development of special nite elements for pressure vessels and pipes (ELE) . . . . . . . . . . . . . . . . . . . . . . . .

A.10. Finite element software (SOF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.11. Other topics (OTH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Introduction

Pressure vessels and piping are widely used in reactor

technology, the chemical industry, marine and space engineering. They often operate under extremes of high and

low temperatures and high pressures, are becoming highly

sophisticated and therefore also need advanced methods

for their analyses. Advances are also made with materials

applied for their fabrication. Concrete and composite

materials are used in pressure vessels and their components

more frequently to replace, in some cases, conventional

steels.

During the last three decades considerable advances have

been made in the applications of numerical techniques to

analyze pressure vessels and piping problems. Among the

numerical procedures, nite element methods are the most

frequently used.

Pressure vessel and piping analyses may have a variety of

phases such as: elastic stress and deformation analysis

where both mechanical and thermal loads may be applied;

heat transfer analysis; dynamic analysis; plastic and creep

analysis; etc. There is in existence a large number of general

purpose and special purpose nite element programs available to cope with each phase of the analysis.

This review on the subject is divided into the following

parts and it concerns:

linear and nonlinear, static and dynamic, stress and

deection analyses (STR);

stability problems (STA);

thermal problems (THE);

fracture mechanics problems (FRA);

contact problems (CON);

uidstructure interaction problems (FLU);

manufacturing of pipes and tubes (MAN);

welded pipes and pressure vessel components (WEL);

development of special nite elements for pressure

vessels and pipes (ELE);

nite element software (SOF);

other topics (OTH).

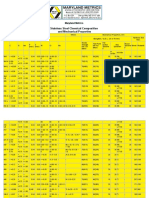

The status of nite element literature published between

1976 and 2001, and divided into the categories described

earlier, is illustrated in Fig. 1. Data presented in this gure

include published technical papers in the primary literature;

this means papers appearing in the various general and

specialized journals, conference proceedings as well as

theses and dissertations. If we take the number of published

22

24

24

24

26

papers as a measure of research activity in these various

subjects, we can see the priority trend in research in the past.

This paper is organized into two parts. In the rst, each

subject listed above is briey described by keywords where

current trends in application of nite element techniques

are mentioned. The second part, Appendix A, is a listing

of references on papers published in the open literature for

the period 19982001, retrieved from the author's database MAKEBASE [1,2]. Readers interested in the nite

element literature in general are referred to Ref. [3] or to

the author's Internet Finite Element Book Bibliography

(http://www.solid.ikp.liu.se/fe/index.html). The presented

bibliography is an addendum to the author's earlier bibliographies [4,5] where approximately 1900 and 630 references, respectively, have been listed.

2. Finite elements in the analysis of pressure vessels and

piping

2.1. Linear and nonlinear, static and dynamic, stress and

deection analyses (STR)

The main topics included deal with the static and dynamic

nite element analyses of pressure vessels, their components and piping, namely: stress and deformation analysis;

2D and 3D linear elastic static and dynamic analysis;

material and geometrical nonlinear static and dynamic

analysis; shakedown analysis; stress concentration factor

studies; local stresses and deformations; free vibration

analysis; response to shock loading; cyclic loading; seismic

response analysis; random excitation; vibro-impact dynamics; estimation of residual stresses; study of mechanical

properties; creep relaxation; whipping analysis; constraint

effects; prestressing effects; boundary conditions identication; stiffness properties identication; structural integrity.

Applications to: pipes; tubes; pipelines; pressure vessels;

Fig. 1. Finite elements and various topics in pressure vessels and piping

(19762001).

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

reactor pressure vessels; curved pipes; cantilevered pipes;

dented pipelines; multi-supported pipelines; saddlesupported pipelines and pressure vessels; sling-supported

pressure vessels; pressure vessel heads; pressure vessel

components; anges; piping elbows; pipe bends; nozzles;

bellows; perforated tubesheets; framed-tube systems; vertical pumps; conical reducers; burst discs; PWR cores;

boilers; corroded pipes; submarine pipelines; pipeline crossings; inatable tubes; coaxial exible tubes; tubes with

coating; shell intersections.

Materials under consideration: steels; stainless steels;

aluminium; composites; polymers; lament wound composites; bre-reinforced composites; concrete-lled steel

tubes.

2.2. Stability problems (STA)

Stability problems are the main subject of this section.

Other topics included are: stability and instability; buckling;

postbuckling; local buckling; lateral buckling; torsional

buckling; lateral thermal buckling; high-temperature buckling; buckle propagation; collapse; plastic collapse.

Applications to: pipes; tubes; pipelines; pressure vessels;

ellipsoids and toroids; corroded pipes; braced tubes; elbows;

liners; bellows; conecylinder intersections; buckle arrestors.

Materials: steels; low-alloy steels.

2.3. Thermal problems (THE)

Heat transfer problems and thermomechanical nite

element analyses are the main subjects of this section. The

following topics are included: heat transfer analysis

natural convection, forced convection, mixed convection,

radiation, turbulent problems; thermomechanical 2D and

3D analysis; thermoviscoplastic analysis; thermal deformation analysis; thermal shock; thermal ratchetting; transient

and residual thermal stresses.

Applications to: pipes; tubes; pressure vessels; reactor

pressure vessels; PWR vessels; tube bundles; tubesheets;

ns; pipe-cooling systems; liquid metal target container;

boiler drums.

Materials: steels; zircaloy; composites; glass reinforced

plastics.

2.4. Fracture mechanics problems (FRA)

In this section fracture mechanics and fatigue problems

are handled. The listing of references in Section A.4

includes: linear and nonlinear 2D and 3D static and dynamic

fracture mechanics problems; mechanical and thermal

loading; macromechanical and micromechanical studies;

cracks; multiple cracks; crack growth; crack opening;

crack path bifurcation; crack arrest; crack shape development; circumferential cracks; longitudinal cracks; transverse cracks; axial cracks; surface cracks; through-wall

cracks; part-through cracks; tight cracks; ductile fracture;

brittle fracture; residual strength; ultimate strength; fracture

toughness; fatigue studies; thermal fatigue; multi-axial

fatigue; damage; local damage; damage identication;

creep-damage analysis; creep failure; failure behaviour;

cleavage failure; damage tolerance; creep crack growth;

aws; aw detection; cladding effects; leak-before-break;

load bearing capacity; limit load analysis; wave scattering;

ring test; squash test; wide-plate test; failure probability;

stochastic analysis; autofrettage; parametric studies.

Applications to: pipes; tubes; pipelines; pressure vessels;

reactor pressure vessels; bellows; elbows; nozzles; pump

casing; threaded pressure vessels; pressure vessel closures;

ring joint groove; tube-gusset plate connections; adhesively

bonded connections; reinforced branch connections; ange

joints; welded pipes; pipe couplers; pipe piers; crushed tubes;

corroded pipes; shell intersections; concrete containments.

Materials: steels; stainless steels; low-alloy steels; aluminium; zircaloy; zirconium; concrete; composites; brereinforced composites; polymers; PVC; graphiteepoxy;

refractory; functionally graded materials.

2.5. Contact problems (CON)

2D and 3D nite element studies of static and dynamic

contact problems dealing with pipes and pressure vessels are

included in this section. Other subjects under consideration

are: mechanical behaviour of joints; structures under impact

loading; blast loading effects; stress concentration factors;

expansion and residual contact pressure.

Applications to: pipes; tubes; pressure vessels; reactor

pressure vessels; tube-to-tubesheet joints; reinforced nozzle

connections; gasket seal rings; cylindrical shell connections;

casing-tubing connections; threaded connections; bolted

joints; bonded connections; adhesive butt joints; pipe ange

connections; press t joining; piping branch junctions;

multi-connected systems.

Materials: steels; stainless steels; aluminium; composites.

2.6. Fluidstructure interaction problems (FLU)

The main topics include: coupled uidstructure

response analyses; pipe/tube conveying uids; cross-owinduced vibrations; modal analysis and damping; active

modal control; dynamic analysis of uid-lled pipes;

uidstructure interaction under cavitation; large displacement uidstructure interaction; Stokes ow problems;

internal unsteady ow; gassolid ow; instability analysis.

Applications to: pipes; tubes; pressure vessels; tube

bundles; submerged perforated tubes; cylindrical shells.

Materials: steels; composites; elastomers; uids; hot

liquid sodium; high temperature uids.

2.7. Manufacturing of pipes and tubes (MAN)

The nite element simulation of manufacturing processes

is the subject of this section. The main topics listed are:

material characteristics and formability; spring-back analysis;

drawing; bulge forming; hot extrusion process; isostatic

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

pressing; hydro-bulge forming; roll bending; rolling;

extrudingbulging process; cold upsettingextruding; dieless forming; hydroforming; backward tube spinning; local

induction heating; pressure ltrating process; hydraulic

bulge testing.

Applications to manufacturing of: pipes; tubes; pressure

vessels and closures; non-circular tubes; tube anges; pipe

bends; toroidal shells; elbows.

Materials: steels; stainless steels; metals; copper; tungsten; composites; silicon carbide; ferromagnetic materials.

2.8. Welded pipes and pressure vessel components (WEL)

The subjects in the simulation of welding processes

included here are: 2D and 3D thermomechanical analysis;

heat transfer analysis; shrinkage analysis; assessment of

creep behaviour; residual stresses; effect of welding conditions on residual stresses; measurement of residual stresses;

burn-through prediction; effects of repair; friction welding;

seam welds; butt welds; multi-pass butt welds; multi-pass

girth welds; circular patch welds; spiral weld cladding;

bimetallic welds; wet repair welding.

Welding of: pipes; tubes; pressure vessels; reactor pressure

vessels; pipe-to-pipe; nozzles on spheres; pipeange.

Materials: steels; stainless steels; austenitic steels;

bimetallic materials.

2.9. Development of special nite elements for pressure

vessels and pipes (ELE)

In this section, references dealing with development as

well as applications of special nite elements used for

analyses of pressure vessels and piping systems are given.

The element types included are: experiences with various

types of elements; 3D special shell element; axisymmetric

thin shell element; axisymmetric hybrid-stressdisplacement element; enhanced pipe elbow element; interface

beam element.

2.10. Finite element software (SOF)

At present, thousands of nite element software packages

exist and new programs are under development. The existing software can vary from large, sophisticated, general

purpose, integrated systems to small, special purpose

programs for PCs. Most of these programs have been

mentioned and described in Ref. [4]. In Section A.10

some new references dealing with development/applications of FE software are listed. They are concerned with:

code developments for pressure vessels and piping, code

evaluations, users' experiences, etc.

2.11. Other topics (OTH)

In this section, subjects not treated earlier are included.

They deal with: static and dynamic geomechanical analyses

of pressure vessels and pipes in 2D and 3D; buried structures; soilstructure interaction; seismic studies; inspection

and maintenance; nondestructive testingeddy current,

neutron diffraction; health monitoring; design sensitivity

analysis; structural integrity assessment; pipeline bundles

on seabed; reliability analysis; optimization problems.

Applications to: crossbores; high-curvature well bores;

steam generator tubes; evacuation pipes; offshore pipelines;

pile-supported buried pipelines; metal beverage containers;

pressure vessels with embedded sensors.

Materials: steels; composites; braided composites; lament

wound composites.

Acknowledgements

The bibliography presented in Appendix A is by no means

complete, but it gives a comprehensive representation of

different nite element applications on the subject. The author

wishes to apologize for the unintentional exclusions of missing references and would appreciate receiving comments

and pointers to other relevant literature for a future update.

Appendix A. A bibliography (19982001)

This bibliography provides a list of literature references

on nite element analysis of pressure vessel structures/

components and pipes/tubes. The listings presented contain

papers published in scientic journals and conference

proceedings retrospectively to 1998. References have been

retrieved from the author's database, MAKEBASE. They

are grouped into the same sections described in the rst

part of this paper, and are sorted alphabetically according

to the rst author's name. In some cases, if a specic paper

is relevant to several subject categories, the same reference

is listed under the respective section headings.

A.1. Linear and nonlinear, static and dynamic, stress and

deection analyses (STR)

1. STR Abdel-Hamid AN, Farahat WA. Evaluation of

stresses in piping systems subjected to unspecied

random excitation. 17th Int Modal Anal Conf. Kissimmee: IMAC, 1999. p. 4639.

2. STR Abdel-Haq M, et al. Constraint effects on energy

absorption in unidirectional PMC tubes. J Compos

Mater 1999;33(9):77493.

3. STR Abhary K, et al. Exact analytical method for

stress analysis of pipelines. Int J Press Vess Piping

1999; 76(8):5615.

4. STR Afshari P, Widera GEO. Free vibration analysis

of composite plates. J Press Vess Technol, ASME

2000; 122(3):3908.

5. STR Al-Hassani STS, Vartdal B. Investigation into the

effect of circumferential through-wall slits on a cantilevered pipe subjected to a transverse end load. Proc

Inst Mech Engng, Part E 1998;212(3):16370.

6. STR Alexander CR. Analysis of dented pipelines

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

considering constrained and unconstrained dent

congurations. 1999 ASME Energy Sources Technology Conference, Houston. New York: ASME, 1999.

p. 113.

STR Alleyne DN, et al. The reection of guided waves

from circumferential notches in pipes. J Appl Mech,

ASME 1998;65(3):63541.

STR Averbuch D, et al. Implementation of elastoplastic material laws in dynamic riser analysis with applications to reeled pipes. 9th International Offshore

Polar Engineering Conference, ISOPE, vol. 2. 1999.

p. 2727.

STR Babu S, Iyer PK. Inelastic analysis of components

using a modulus adjustment scheme. J Press Vess

Technol, ASME 1998;120(1):15.

STR Babu S, Iyer PK. A robust method for inelastic

analysis of components made of anisotropic material.

J Press Vess Technol, ASME 1999;121(2):1549.

STR Badr EA, et al. An analytical procedure for estimating residual stresses in blocks containing crossbores. Int J Press Vess Piping 2000;77(12):73749.

STR Baniotopoulos CC, Preftitsi F. Inuence of the

design parameters on the stress state of saddlesupported pipelines: an articial neural network

approach. Int J Press Vess Piping 1999;76(7):4019.

STR Beltman WM, et al. The structural response of

cylindrical shells to internal shock loading. J Press

Vess Technol, ASME 1999;121(3):31522.

STR Betten J, Krieger J. Bestimmung des Aushartungseinusses bei FVK-Bauteilen mittels FEA. ZAMM

1999;79(S3):8556.

STR Binienda WK, Wang Y. Residual stress reduction

in lament wound composite tubes. J Reinf Plast

Compos 1999;18(8):684701.

STR Blachut J, Jaiswal OR. On the choice of initial

geometric imperfections in externally pressurized

shells.

J

Press

Vess

Technol,

ASME

1999;121(1):716.

STR Burdekin FM, Lidbury DPG. Views of TAGSI on

the current position with regard to benets of warm

prestressing. Int J Press Vess Piping 1999;76(13):885

90.

STR Carter P. Stress analysis and design for cyclic

loading. J Press Vess Technol, ASME 2000;122(4);

42730.

STR Chan WS, Demirhan KC. A simple closed-form

solution of bending stiffness for laminated composite

tubes. J Reinf Plast Compos 2000;19(4):27891.

STR Chawla DS, et al. Assessment of operability and

structural integrity of a vertical pump for extreme

loads. Int J Press Vess Piping 1998;75(4):297306.

STR Cohn MJ, Yee RK. Creep relaxation behavior of

high energy piping. ASME/JSME Joint Pressure

Vessel Piping Conference PVP 380, New York:

ASME, 1998. p. 13550.

STR Cunha J, Piranda J. Identication of stiffness pro-

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

perties of composite tubes from dynamic tests. Exp

Mech 2000;40(2):2118.

STR Da Dilveira JLL, et al. Shakedown and limit

analysis in a pressure vessel. Fourth World Cong

Comput Mech, Buenos Aires, 1998. p. 198.

STR Datta TK. Seismic response of buried pipelines:

a state-of-the-art review. Nucl Engng Des 1999;

192(2/3):27184.

STR Desikan V, Sethuraman R. Analysis of material

nonlinear problems using pseudo-elastic nite element

method.

J

Press

Vess

Technol,

ASME

2000;122(4):45761.

STR El-Abbasi N, et al. Three-dimensional nite

element analysis of saddle supported pressure vessels.

Int J Mech Sci 2001;43(5):122942.

STR Filippov SB, et al. Free vibrations of square elastic tubes with a free end. Mech Res Commun 2000;

27(4):45764.

STR Franco JRQ, Barros FB. Advances in nite

element modelling of plastic behaviour of pressure

vessels. 4th World Cong Comput Mech, Buenos Aires.

1998. p. 185.

STR Frikha S, et al. Boundary condition identication

using condensation and inversionapplication to

operating

piping

network. J

Sound

Vib

2000;233(3):495514.

STR Fyrileiv O, et al. Free span assessment of the

Zeepipe IIA pipeline. 17th Int Conf Offshore Mech

Arctic Engng. Lisbon: OMAE, 1998. p. 18.

STR Goncalves JPM, De Castro PMST. Application of

the line spring model to some complex geometries,

and comparison with three-dimensional results. Int J

Press Vess Piping 1999;76(8):55160.

STR Hajjar JF, et al. Distributed plasticity model for

concrete-lled steel tube beam-columns with interlayer slip. Engng Struct 1998;20(8):66376.

STR Halldorsson B. On modeling of earthquake wave

motion and its effects on multi-support pipelines. Acta

Polytech Scand, Civ Engng Build Cons 1999;(115):1

29.

STR Hamilton R, et al. A simple upper-bound method

for calculating approximate shakedown loads. J Press

Vess Technol, ASME 1998;120(2):1959.

STR Hari Y, Williams DK. Analysis of transition radii in

conical reducers. ASME/JSME Joint Press Vess Piping

Conf PVP 360. New York: ASME, 1998. p. 33542.

STR Hauch S, Bai Y. Bending moment capacity of

groove corroded pipes. 10th Int Offshore Polar Engng

Conf, Seattle. 2000. p. 25362.

STR Hersh CL, Herakovich CT. Local effects in

stiffened composite tubes under generalized plane deformation. J Compos Mater 1999;33(5):42042.

STR Hsieh CS, et al. Investigation of anges subjected

to operating conditions of pressure, temperature and

bending moments. ASME/JSME Joint Press Vess Piping

Conf PVP 368. New York: ASME, 1998. p. 24557.

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

39. STR Hsu PW. Stresses in a uniformly paralelepiped solid

with a pressurized cylindrical cavity. 42nd Str, Str Dyn

Mater Conf, Seattle. 2001. p. 294750.

40. STR Hu G, et al. Mechanical behaviour of lamentwound glass-bre/epoxy-resin tubes. III. Macromechanical model of the macroscopic behaviour of

tubular structures. Compos Sci Technol 1998;58(1):

1929.

41. STR Hyer MW, Riddick JC. Internal pressure loading of

segmented-stiffness composite cylinders. Compos Struct

1999;45(4):31120.

42. STR Jacquelin E, et al. Modelling the behaviour of a

PWR core by a homogenization technique. Comp

Meth Appl Mech Engng 1999;155(1/2):113.

43. STR Jones DP, Holliday JE. Elasticplastic analysis of

the PVRC burst disk tests with comparison to the ASME

code primary stress limits. J Press Vess Technol, ASME

2000;122(2):14651.

44. STR Jones DP, et al. Application of equivalent elastic

methods in three-dimensional nite element structural

analysis. J Press Vess Technol, ASME 1999;121(3):

28390.

45. STR Kabir MZ. Computer analysis of lament overwrapped metallic pressure vessels with an optimum

head shape. 6th Int Conf Comput Meth Compos Mater,

Montreal. Southampton: CMP, 1998. p. 48392.

46. STR Kabir MZ. Finite element analysis of composite

pressure vessels with a load sharing metallic liner.

Compos Struct 2000;49(3):24755.

47. STR Kalliontzis C. Non-linear nite element simulations

of highly curved submarine pipelines. Commun Numer

Meth Engng 1998;14(11):106788.

48. STR Kalliontzis C. Geometric nonlinear modelling of

submarine pipeline crossings. Int J Offshore Polar

Engng 1998;8(4):292302.

49. STR Kardaras C, Lu G. Finite element analysis of thin

walled tubes under point loads subjected to large

plastic deformation. Key Engng Mater 2000;177180:

7338.

50. STR Knudsen J, Massih AR. Vibro-impact dynamics of a

periodically forced beam. J Press Vess Technol, ASME

2000;122(2):21021.

51. STR Koerner JP, Hiller W. Elasticplastic nite element

analysis of high pressure components in low density

polyethylene plants. ASME/JSME Joint Press Vess

Piping Conf PVP 371. New York: ASME, 1998. p.

1722.

52. STR Koh BK, Park GJ. Analysis and optimization of

bellows with general shape. J Press Vess Technol,

ASME 1998;120(4):32533.

53. STR Konno K, et al. Study on mechanical property of

prestressed concrete encased by double steel tubes

subjected to axial forces. Proc Jpn Soc Civil Engng

1999;613(V):118.

54. STR Kosasayama H, et al. New stress analysis procedure

for piping with refractory lining. ASME/JSME Joint

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

67.

68.

69.

70.

Press Vess Piping Conf PVP 368. New York: ASME,

1998. p. 20110.

STR Kristiansen NO, et al. Structural modelling of multispan pipe congurations subjected to vortex induced

vibrations. 8th Int Offshore Polar Engng Conf, Montreal,

vol. 2. 1998. p. 12733.

STR Kumar R, Saleem MA. Bend angle effect on B2 and

C2 stress indices for piping elbows. J Press Vess Technol, ASME 2001;123(2):22631.

STR Kussmaul K, Mayinger W. Numerical and experimental analyses of the behaviour of a nozzle with thermal sleeve under stratied ow. Nuclear Engng Des

1999; 190(1/2):12740.

STR Lengsfeld M, et al. Spring rates for low type tank

nozzles. ASME/JSME Joint Press Vess Piping Conf PVP

368. New York: ASME, 1998. p. 27580.

STR Lengsfeld M, et al. Alternate method to determine

xed tube sheet thickness. ASME/JSME Joint Press

Vess Piping Conf PVP 368. New York: ASME, 1998.

p. 416.

STR Liang CC, et al. Study of the nonlinear responses of

a submersible pressure hull. Int J Press Vess Piping

1998;75(2):13149.

STR Liang CC, et al. Curvature effect on stress concentrations around circular hole in opened shallow cylindrical shell under external pressure. Int J Press Vess Piping

1998;75(10):74963.

STR Lidbury DPG, et al. Key features arising from structural analysis of the NESC-1 PTS benchmark experiment. Int J Press Vess Piping 2001;78(2/3):22536.

STR Lin CY, Chan WS. Stiffness evaluation of elliptical

laminated composite tube under bending. 42nd Str, Str

Dyn Mater Conf, Seattle. 2001. p. 117580.

STR Liu J, Hirano T. Design and analysis of FRP pressure vessels with load-carrying metallic liners. ASME/

JSME Joint Press Vess Piping Conf PVP 368. New York:

ASME, 1998. p. 95101.

STR Lo YL, et al. Pressure vessel wall thinning

detection using multiple pairs of ber Bragg

gratings for unbalanced strain measurements.

J Nondestr Eval 2000;19(3):10513.

STR Loktionov VD, et al. Numerical investigation of

the reactor pressure vessel behaviour under severe

accident conditions taking into account the combined

processes. Nuclear Engng Des 1999;191(1):3152.

STR Madureira L, Melo FQ. A hybrid formulation in

the stress analysis of curved pipes. Engng Comput

2000; 17(8):97080.

STR Maher A, Hamada AA. On the modelling of tubes

with composite coat. IMAC-XIX, Kissimmee, FL.

2001. p. 7829.

STR Mamalis AG, et al. The bending of bre-reinforced composite thin-walled tubular components:

numerical modelling. Int J Crashworth 2000;5(2):

193205.

STR Masu LM. Numerical analysis of cylinders con-

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

taining circular offset cross-bores. Int J Press Vess

Piping 1998;75(3):1916.

STR Matzen VC, Yu L. Elbow stress indices using

nite element analysis. Nucl Engng Des 1998;181

(1/3):25765.

STR McGrath TJ. Replacing E prime with the constrained modulus in exible pipe design. Proc Pipe

Div Conf Pipelines Constr Env, San Diego. New

York: ASCE, 1998. p. 2840.

STR Miki C, et al. Study on seismic resistance of steel

pipe pier made of two different sections. Proc Jpn Soc

Civil Engng 1998;605(I-45):11727.

STR Mirza S, et al. Fiber-reinforced composite cylindrical vessel with lugs. Compos Struct 2001;53(2):143

51.

STR Mohamed AI, et al. Applications of iterative elastic techniques for elasticplastic analysis of pressure

vessels. J Press Vess Technol, ASME 1999;121(1):

249.

STR Mohan R, et al. A study of effects of pipe geometry on FAD curves for austenitic stainless steel and

ferritic steel piping materials. J Press Vess Technol,

ASME 1998;120(1):8692.

STR Mourad HM, Younan MYA. The effect of modeling parameters on the predicted limit loads for pipe

bends subjected to out-of-plane moment loading and

internal pressure. J Press Vess Technol, ASME 2000;

122(4):4506.

STR Mourad HM, Younan MYA. Nonlinear analysis

of pipe bends subjected to out-of-plane moment loading and internal pressure. J Press Vess Technol, ASME

2001;123(2):2538.

STR Moussa WA, Abdel Hamid AN. On the evaluation of dynamic stresses in pipelines using limited

vibration measurements and FEA in the frequency

domain. 1998 Int Pipeline Conf, Calgary. New York:

ASME, 1998. p. 70510.

STR Moussa WA, Abdel Hamid AN. On the evaluation of dynamics stresses in pipelines using limited

vibration measurements and FEA in the time domain.

ASME/JSME Joint Press Vess Piping Conf PVP 368.

New York: ASME, 1998. p. 2934.

STR Moussa WA, Abdel Hamid AN. On the evaluation of dynamic stresses in pipelines using limited

vibration measurements and FEA in the time domain.

J Press Vess Technol, ASME 1999;121(1):3741.

STR Moussa WA, Abdel Hamid AN. On the

evaluation of dynamic stresses in pipelines using

limited vibration measurements and FEA in the

frequency domain. J Press Vess Technol, ASME

1999;121(3): 2415.

STR Mullarkey TP, et al. Assessment of alternative

approaches for the representation of torque and twist

in pipeline and riser analysis. 10th Int Offshore Polar

Engng Conf, Seattle, vol. 2. 2000. p. 3741.

STR Muller C, Bohmann A. Numerical simulation of

85.

86.

87.

88.

89.

90.

91.

92.

93.

94.

95.

96.

97.

98.

99.

100.

mechanical effects in composite structures by the

nite element method. J Press Vess Technol, ASME

2001;123(2):24852.

STR Nadarajah C, Foo LT. Finite element study of

keyed backing ring design for oating head. Int J

Press Vess Piping 1998;75(6):5216.

STR Nash DH, et al. A parametric study of metal-tometal full face taper-hub anges. Int J Press Vess

Piping 2000;77(13):7917.

STR Nash DH, et al. Finite element modelling of slingsupported pressure vessels. Thin-Wall Struct 1998;

30(1/4):95110.

STR Pantelelis NG, Kanarachos AE. FEM stress

analysis and design of a PVC reinforced pipe. 56th

Ann Tech Conf, ANTEC, Atlanta. 1998. p. 351721.

STR Porter MA, Martens DH. Stress evaluation of a

typical vessel nozzle using PVRC 3D stress criteria:

guidelines for application. ASME/JSME Joint Press

Vess Piping Conf PVP 368. New York: ASME,

1998. p. 297301.

STR Preiss R. On the shakedown analysis of nozzles

using elasto-plastic FEA. Int J Press Vess Piping 1999;

76(7):42134.

STR Price NM, et al. Vibrations of cylindrical pipes

and open shells. J Sound Vib 1998;218(3):36187.

STR Ramos A, et al. Delayed coke drum assessment

using eld measurements and FEA. ASME/JSME

Joint Press Vess Piping Conf PVP 368. New York:

ASME, 1998. p. 2317.

STR Ramos R, et al. Comparative analysis between

analytical and FE-based models for exible pipes

subjected to axisymmetric loads. 10th Int Offshore

Polar Engng Conf, Seattle, vol. 2. 2000. p. 808.

STR Reid SR, Kim TH. Softening effects in the bending of tubular structures and components. Key Engng

Mater 2000;177180:67990.

STR Reid SR, Yang JL. Non-linear dynamic analysis

of cantilever whipping pipes. Proc Inst Mech Engng,

Part E 1998;212(3):13349.

STR Roberts KA, Pick RJ. Correction for longitudinal

stress in the assessment of corroded line pipe. 1998

Int Pipeline Conf, Calgary. New York: ASME, 1998.

p. 55361.

STR Ross CTF, Etheridge J. The vibration and instability

of tube-stiffened axisymmetric shells under external

hydrostatic pressure. Adv Civil Str Engng Comput

Pract. Edinburgh: Civil-Comp, 1998. p. 33542.

STR Sakamoto H, et al. Deection of multi-cellular

inatable tubes for redundant space structures. 42nd

Str, Str Dyn Mater Conf, Seattle. 2001. p. 320411.

STR Sanal Z. Geometrically and physically nonlinear

analysis of pressure vessels. Stahlbau 1998;67(6):

47882.

STR Sanal Z. Nonlinear analysis of pressure vessels:

some examples. Int J Press Vess Piping 2000; 77(12):

7059.

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

101. STR Sarma GB, et al. Modeling studies to predict

stresses in composite oor tubes of black liquor

recovery boilers. J Engng Mater Technol, ASME

2001;123(3):34954.

102. STR Sattari-Far I, Dahlberg L. Sensitivity study of the

pretest analysis of the NESC-1 spinning cylinder

experiment. ASME/JSME Joint Press Vess Piping

Conf PVP 365. New York: ASME, 1998. p. 5966.

103. STR Schneider SP. Flexural capacity of pressurized

steel pipe. J Struct Engng, ASCE 1998;124(3):330

40.

104. STR Schneider SP. Axially loaded concrete-lled steel

tubes. J Struct Engng, ASCE 1998;124(10):112538.

105. STR Seay PA, Plaut RH. Three-dimensional behavior

of geosynthetic tubes. Thin-Wall Struct 1998; 32(4):

26374.

106. STR Seibi AC, Al-Shabibi AM. Pipe bending and

running forces in medium to high-curvature wells

using FE analysis. J Energy Resource Technol,

ASME 1998;120(4):2637.

107. STR Seshadri R, Babu S. Extended GLOSS method

for determining inelastic effects in mechanical components and structures: isotropic materials. J Press Vess

Technol, ASME 2000;122(4):41320.

108. STR Shalaby MA, Younan MYA. Nonlinear analysis

and plastic deformation of pipe elbows subjected

to in-plane bending. Int J Press Vess Piping 1998;

75(8):60311.

109. STR Shalaby MA, Younan MYA. Effect of internal

pressure on elasticplastic behavior of pipe elbows

under in-plane bending moments. J Press Vess Technol, ASME 1999;121(4):4005.

110. STR Shen ZY, et al. Synthetic discrete method for

analyzing the elastoplastic seismic response of tall

steel framed-tube systems. Adv Struct Engng 1998;

1(3):17783.

111. STR Sherry AH, et al. Application of local approach to

predict the outcome of the NESC experiment. ASME/

JSME Joint Press Vess Piping Conf PVP 365. New

York: ASME, 1998. p. 7584.

112. STR Sherry AH, et al. Developments in local approach

methodology with application to the analysis reanalysis of the NESC-1 PTS benchmark experiment.

Int J Press Vess Piping 2001;78(2/3):23749.

113. STR Shoji Y, Nagata S. On the modeling of pressure

vessel shell portion affecting local deformation at

nozzles and other structural discontinuities. ASME/

JSME Joint Press Vess Piping Conf PVP 368. New

York: ASME, 1998. p. 4753.

114. STR Shu D, et al. Investigation of pressure in pipe

subjected to axial-symmetric pulse loading. Int J

Impact Engng 2001;25(6):52336.

115. STR Sinha JK, et al. Parameter identication technique for detection of spacer locations in an assembly of

two coaxial exible tubes. Nuclear Engng Des 2000;

196(2):13951.

116. STR Skopinsky VN. Stress analysis of shell intersections

with torus transition under internal pressure loading.

J Press Vess Technol, ASME 1998; 119(3): 28892.

117. STR Skopinsky VN. Stresses in ellipsoidal pressure

vessel heads with noncentral nozzle. Nuclear Engng

Des 2000;198(3):31723.

118. STR Skopinsky VN. Stress concentration in cone

cylinder intersection. Int J Press Vess Piping 2001;

78(1):3541.

119. STR Takahashi H, et al. Multiple-slip work-hardening

model in crystals with application to torsiontension

behaviors of aluminium tubes. Int J Plasticity 1998;

14(6):489509.

120. STR Taljat B, et al. Mechanical design of steel tubing

for use in black liquor recovery boilers. Int Symp

Corros Pulp Paper Ind. Ottawa: CPPA, 1998. p. 1937.

121. STR Taware A, Brown RH. Dynamic linear nite

element model for pressure prediction in a gas pipeline. 38th IEEE Conf Decision Contr. Piscataway:

IEEE, 1999. p. 324852.

122. STR Touboul F, et al. Experimental, analytical, and

regulatory evaluation of seismic behavior of piping

systems. J Press Vess Technol, ASME 1999; 121(4):

38892.

123. STR Tripa VM, et al. On the transfer-matrix method

(TMM) for the cylindrical vessels with an intermediate

edge under uniformly distributed pressure. ASME/

JSME Joint Press Vess Piping Conf PVP 375. New

York: ASME, 1998. p. 638.

124. STR Truong KT. Improved FCCU refractory-lined

piping design. Hydrocarbon Process 1998;77(7):14.

125. STR Tsukimori K. Theoretical modeling of creep

behavior of bellows and some applications. J Press

Vess Technol, ASME 2001;123(2):17990.

126. STR Ukadgaonker VG, Kale PA. Finite element stress

analysis of tubesheets perforated by circular holes in

square pitch pattern. J Press Vess Technol, ASME

1998;120(1):126.

127. STR Varga L. Design of pressure vessels taking plastic

reserve into account. Int J Press Vess Piping 1998;

75(4):33141.

128. STR Vitali L, et al. Hotpipe project: capacity of pipes

subject to internal pressure, axial force and bending

moment. 9th Int Offshore Polar Engng Conf. ISOPE,

vol. 2. 1999. p. 223.

129. STR Vrbka J, et al. On stress and strain computational

modelling at compound vessel. 4th World Cong

Comput Mech, Buenos Aires. 1998. p. 204.

130. STR Wada H, Oguchi N. Interaction between double

dressed zones on the outer surface of a pressure vessel.

ASME/JSME Joint Press Vess Piping Conf PVP 375.

New York: ASME, 1998. p. 5561.

131. STR Williams DK. Finite element analysis of composite pressure vessels in a microwave environment.

ASME/JSME Joint Press Vess Piping Conf PVP 368.

New York: ASME, 1998. p. 7985.

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

132. STR Xu JJ, et al. Local pressure stresses on lateral

pipe-nozzle with various angles of intersection. Nucl

Engng Des 2000;199(3):33540.

133. STR Xue M, et al. Analytical solution for cylindrical

thin shells with normally intersecting nozzles due to

external moments on the ends of shells. Sci China Ser

A 1999;42(3):293304.

134. STR Xue MD, et al. Stress analysis of cylindrical

shells with nozzles due to external run pipe moments.

J Strain Anal Engng Des 2000;35(3):15970.

135. STR Yee RK, Cohn MJ. Creep relaxation behavior of

high-energy piping. J Press Vess Technol, ASME

2000;122(4):48893.

136. STR Yokoyama T. Finite element computation of

torsional plastic waves in a thin-walled tube. Arch

Appl Mech 2001;71(6/7):35970.

137. STR Yoshizaki K, et al. Large deformation behavior of

pipe bends subjected to in-plane bending. 1998 Int

Pipeline Conf, Calgary. New York: ASME, 1998.

p. 73340.

138. STR Yu L, Matzen VC. B2 stress index for elbow

analysis. Nuclear Engng Des 1999;192(2/3):261

70.

139. STR Yu TX, et al. Dynamic behavior of double

cantilever beams subjected to impact. Int J Press

Vess Piping 2001;78(1):4957.

140. STR Zouain N, Silveira JL. Bounds to shakedown

loads. Int J Solids Struct 2001;38(10):224966.

A.2. Stability problems (STA)

1. STA Assanelli AP, et al. Analysis of the collapse of

steel tubes under external pressure. 4th World Cong

Comput Mech, Buenos Aires. 1998. p. 172.

2. STA Assanelli AP, et al. Experimental/numerical analysis of the collapse behavior of steel pipes. Engng

Comput 2000;17(4):45986.

3. STA Bai Y, Hauch S. Analytical collapse capacity of

corroded pipes. 8th Int Offshore Polar Engng Conf,

Montreal, vol. 2. 1998. p. 1828.

4. STA Bai Y, Song R. Reliability-based limit-state design

and re-qualication of pipelines. 17th Int Conf Offshore

Mech Arctic Eng. Lisbon: OMAE, 1998. p. 18.

5. STA Bai Y, et al. Local buckling and plastic

collapse of corroded pipes with yield anisotropy.

9th Int Offshore Polar Engng Conf, ISOPE, vol. 2,

1999. p. 7481.

6. STA Bastard AH. New buckle arrestor for reeled pipein-pipe. 10th Int Offshore Polar Engng Conf, Seattle,

vol. 2. 2000. p. 20511.

7. STA Blachut J, Jaiswal OR. Buckling of imperfect

ellipsoids and closed toroids subjected to external

pressure. ASME/JSME Joint Press Vess Piping Conf

PVP 368. New York: ASME, 1998. p. 1218.

8. STA Chattopadhyay J, et al. Closed-form collapse

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

moment equations of elbows under combined internal

pressure and in-plane bending moment. J Press Vess

Technol, ASME 2000;122(4):4316.

STA El-Sawy K, Moore ID. Stability of loosely tted

liners used to rehabilitate rigid pipes. J Struct Engng,

ASCE 1998;124(11):13507.

STA Frederiksen PS, et al. Controlled lateral buckling

of submarine pipelines in snaked conguration. 17th Int

Conf Offshore Mech Arctic Engng. Lisbon: OMAE,

1998. p. 110.

STA Gresnigt AM, Steenbergen, HMGM. Plastic deformation and local buckling of pipelines loaded by

bending and torsion. 8th Int Offshore Polar Engng

Conf, Montreal, vol. 2. 1998. p. 14352.

STA Gresnigt AM, et al. Collapse of UOE manufactured steel pipes. 10th Int Offshore Polar Engng

Conf, Seattle, vol. 2. 2000. p. 17081.

STA Hoo Fatt MS, et al. Steady-state buckle propagation

in corroded pipelines. 10th Int Offshore Polar Engng

Conf, Seattle, vol. 2. 2000. p. 197204.

STA Koundy V, Thiebaut C. High-temperature buckling analysis of titanium cans under external pressure.

J Press Vess Technol, ASME 1999;121(4):3648.

STA Koundy V, et al. Effects of torsional buckling

on the cleavage failure of low-alloy steel tension

pipe specimens. J Press Vess Technol, ASME 1998;

120(3):25661.

STA Kyriakides S, Netto TA. On the dynamics of

propagating buckles in pipelines. Int J Solids Struct

2000;37(46/47):684367.

STA Li JZ, et al. Finite element analysis for buckling of

pressure vessels with ellipsoidal head. Int J Press Vess

Piping 1998;75(2):11520.

STA Magnucki K, Szyc W. Stability problems of pressure vessel ellipsoidal heads. Arch Budowy Maszyn

1999;46(1):4355.

STA Mikkelsen LP, Tvergaard V. A nonlocal twodimensional analysis of instabilities in tubes under

internal pressure. J Mech Phys Solids 1999; 47(4):

95369.

STA Miles DJ, Calladine CR. Lateral thermal buckling

of pipelines on the sea bed. J Appl Mech, ASME

1999;66(4):8917.

STA Mou Y, et al. Plastic instability in pressure vessels

and their role in design. ASME/JSME Joint Press

Vess Piping Conf PVP 370. New York: ASME, 1998.

p. 13541.

STA Netto TA, Kyriakides S. Dynamic performance of

integral buckle arrestors for offshore pipelines. Part II.

Analysis. Int J Mech Sci 2000;42(7):142552.

STA Palmer-Jones R, Turner TE. Pipeline buckling,

corrosion and low cycle fatigue. 17th Int Conf Offshore

Mech Arctic Engng. Lisbon: OMAE, 1998. p. 18.

STA Payten W, Law M. Estimating the plastic collapse

of pressure vessels using plasticity contours. Int J Press

Vess Piping 1998;75(7):52936.

10

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

25. STA Razakamiadana A, Zidi M. Buckling and postbuckling of concentric cylindrical tubes under external

pressure. Mech Res Commun 1999;26(3):35362.

26. STA Skoczen B. Effect of shear deformation and

relaxation of support conditions on elastic buckling

of pressurized expansion bellows. J Press Vess Technol,

ASME 1999;121(2):12732.

27. STA Spinazze M, et al. Hotpipe project: use of analytical models/formulas in prediction of lateral buckling

and interacting buckles. 9th Int Offshore Polar Engng

Conf. ISOPE, vol. 2. 1999. p. 921.

28. STA Sriskandarajah T, et al. Effect of initial imperfections on the lateral buckling of subsea pipelines. 9th Int

Offshore Polar Engng Conf, ISOPE, vol. 2. 1999. p.

16875.

29. STA Teng JG, Ma HW. Elastic buckling of ringstiffened conecylinder intersections under internal

pressure. Int J Mech Sci 1999;41(11):135783.

30. STA Teng JG, Zhao Y. On the buckling failure of a

pressure vessel with a conical end. Engng Failure

Anal 2000;7(4):26180.

31. STA Wang A. Stresses and stability for the cone

cylinder shells with toroidal transition. Int J Press

Vess Piping 1998;75(1):4956.

32. STA Wu L, Carney JF. Experimental analyses of

collapse behaviors of braced elliptical tubes under

lateral compression. Int J Mech Sci 1998;40(8):76177.

33. STA Xu B, et al. Practical computation of the plastic

collapse limit of defective pipelines under complex

loadings. Key Engng Mater 2000;177180:691702.

34. STA Yan AM, et al. Practical estimation of the plastic

collapse limit of curved pipes subjected to complex

loading. Struct Engng Mech 1999;8(4):42138.

A.3. Thermal problems (THE)

1. THE Amin MR. Conjugate forced convection heat

transfer in tubes with obstruction. J Thermophys Heat

Transf 1998;12(1):1146.

2. THE Aswendt P, et al. Thermal deformation behaviour

of CFRP pipes: verication of nite element simulation

by interferometric measurements. Materialpruefung/

Mater Test 1999;41(7):3149.

3. THE Bass BR, et al. Overview of the international

comparative assessment study of pressurized thermal

shock in reactor pressure vessels (RPV PTS ICAS).

Int J Press Vess Piping 2001;78(2/3):197211.

4. THE Cannarozzi AA, et al. A hybrid ux axisymmetric

model for thermal analysis. Comput Struct 2001;

79(12):1187201.

5. THE Chellapandi P, et al. Theoretical and experimental

investigations of thermal ratchetting in PFBR main

vessel. Trans Indian Inst Met 2000;53(3):3919.

6. THE Diaz V, et al. Simplied thermo-visco-plastic

model for PWR vessel behaviour during a severe

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

accident. ASME/JSME Joint Press Vess Piping Conf

PVP 362. New York: ASME, 1998. p. 918.

THE Fabbri G. Optimum proles for asymmetrical

longitudinal ns in cylindrical ducts. Int J Heat Mass

Transf 1999;42(3):51123.

THE Gowda YTK, et al. Finite element analysis of

mixed convection over in-line tube bundles. Int J Heat

Mass Transf 1998;41(11):16139.

THE Guijt W. Design considerations of high-temperature pipelines. 9th Int Offshore Polar Engng Conf,

ISOPE, vol. 2. 1999. p. 6839.

THE Han LH. Fire performance of concrete lled

steel tubular beam-columns. J Constr Steel Res 2001;

57(6):697711.

THE Holstein D, et al. Simulation and experiment on

the thermal deformation of composite tubes. Proc SPIE

1998;3479:26473.

THE Igari T, et al. Mechanism-based evaluation of

thermal ratchetting due to travelling temperature

distribution. J Press Vess Technol, ASME 2000;

122(2):1308.

THE Keim E, et al. Life management of reactor pressure vessels under pressurized thermal shock loading:

deterministic procedure and application to western type

of reactor. Int J Press Vess Piping 2001;78(2/3):8598.

THE Kim JK, et al. Thermal analysis of hydration

heat in concrete structures with pipe-cooling system.

Comput Struct 2001;79(2):16371.

THE Kim JS, Jin TE. Structural integrity assessment of

the reactor pressure vessel under the external reactor

vessel cooling condition. Nucl Engng Des 1999;

191(2):11733.

THE Konka WT. Natural convection heat transfer

around horizontal tube in vertical slot. Int J Heat Mass

Transf 2000;43(3):44755.

THE Kostylev VI, Margolin BZ. Determination of residual stress and strain elds caused by cladding and

tempering of reactor pressure vessels. Int J Press Vess

Piping 2000;77(12):72335.

THE Li LJ, et al. Turbulent heat transfer to near-critical

water in a heated curved pipe under the conditions of

mixed convection. 1998 ASME Int Mech Engng Cong

Expo HTD 361-1. New York: ASME, 1998. p. 1018.

THE Lin CL, et al. Thermal performance of embedded

heat pipe composite sandwich panels. 1999 Str, Str Dyn

Mater Conf Exhib, St Louis, AIAA, 1999. p. 112534.

THE Lin CX, Ebadian MA. Combined laminar forced

convection and thermal radiation in a curved pipe. 7th

Joint Thermophys Heat Trans Conf, Albuquerque,

AIAA. 1998. p. 7380.

THE Looyeh MRE. Thermomechanical modelling of

glass reinforced plastic pipes. 10th Int Offshore Polar

Engng Conf, Seattle, vol. 4. 2000. p. 839.

THE Mehta RC, et al. Thermal stress analysis of a solid

rocket motor nozzle throat insert using FEM. Ind J

Engng Mater Sci 1998;5(5):2717.

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

23. THE Mensah PF, et al. Thermal stress analysis of heat

activated coupling of composite-to-composite pipe.

1999 ASME Energy Sources Tech Conf, Houston.

New York: ASME, 1999. p. 19.

24. THE Miles DJ, Calladine CR. Lateral thermal buckling

of pipelines on the sea bed. J Appl Mech, ASME

1999;66(4):8917.

25. THE Miroshnik R, et al. Probabilistic life assessment of

chest valve under thermal stresses. Int J Press Vess

Piping 1998;75(1):15.

26. THE Moinereau D, et al. Methodology for the pressurized thermal shock evaluation: recent improvements in

French RPV PTS assessment. Int J Press Vess Piping

2001;78(2/3):6983.

27. THE Mukhopadhyay NK, et al. Deterministic assessment of reactor pressure vessel integrity under

pressurised thermal shock. Int J Press Vess Piping

1998;75(15):105564.

28. THE Ni L, Bauer GS. Dynamic stress of a liquid metal

target container under pulsed heating. J Press Vess

Technol, ASME 1998;120(4):35964.

29. THE Ong LS, et al. Parametric equations for maximum

stresses in cylindrical vessels subjected to thermal

expansion loading. Int J Press Vess Piping 1998;

75(3):25562.

30. THE Perl M, Greenberg Y. Three-dimensional analysis

of thermal shock effect on inner semi-elliptical surface

cracks in a cylindrical pressure vessel. Int J Fracture

1999;99(3):16170.

31. THE Reinhardt W, et al. Design and analysis of a tubesheet for extreme transient thermal loading. ASME/

JSME Joint Press Vess Piping Conf PVP 370. New

York: ASME, 1998. p. 14350.

32. THE Reinhardt W, et al. Analysis of a tubesheet undergoing rapid transient thermal loading. J Press Vess

Technol, ASME 2000;122(4):47681.

33. THE Reinhardt WD. Yield criteria for the elastic

plastic design of tubesheets with triangular penetration

patterns. ASME/JSME Joint Press Vess Piping Conf

PVP 370. New York: ASME, 1998. p. 1139.

34. THE Reinhardt WD. Yield criteria for the elastic

plastic design of tubesheet with triangular penetration

pattern. J Press Vess Technol, ASME 2001; 123(1):

11823.

35. THE Schafer I, et al. Thermomechanical behavior and

modeling between 350 Degree C and 400 C of Zircaloy4 cladding tubes from an unirradiated state to high

uence. J Engng Mater Technol, ASME 2000;

122(2):16876.

36. THE Sen S, et al. Transient and residual thermal stresses

in quenched cylindrical bodies. Int J Mech Sci 2001;

42(10):201329.

37. THE Schimpfke T, et al. Simulation of the structuremechanical behaviour of a PWR coolant loop under

extreme loads. Nucl Engng Des 1999;190(1/2):11726.

38. THE Seibi AC, Amateau MF. Finite element modelling

11

and optimization for controlling the residual thermal

stresses of laminated composite tubes. Compos Struct

1998;41(2):1517.

39. THE Taler J, et al. Analysis of thermal stresses in a

boiler drum during start-up. J Press Vess Technol,

ASME 1999;121(1):8493.

40. THE Tsai SF, Sheu TWH. Some physical insights into a

two-row nned-tube heat transfer. Comput Fluids

1998;27(1):2946.

41. THE Tzou DY, et al. Thermomechanical fracture on

pressurized cylindrical vessels. Proc SPIE 1998;3343:

60817.

A.4. Fracture mechanics problems (FRA)

1. FRA Abah L, Limam A. Upon the effects of cutouts on

the behaviour of axially crushed tubes. ASME/JSME

Joint Press Vess Piping Conf PVP 361. New York:

ASME, 1998. p. 18794.

2. FRA Andersen A, et al. Protection against high-energy

line breaks in WWER power plants. Nucl Engng Des

2001;206(2/3):11928.

3. FRA Andrade-Lima E, Bruno AC. Improving the

detection of aws in steel pipes using SQUID planar

gradiometers. IEEE Trans Appl Supercond 2001;

11(1):1299302.

4. FRA Arsene S, Bai J. New approach to measuring

transverse properties of structural tubing by a ring

testexperimental investigation. J Test Eval 1998;

26(1):2630.

5. FRA Bai H, et al. Scattering of guided waves by

circumferential cracks in steel pipes. J Appl Mech,

ASME 2001;68(4):61931.

6. FRA Bass BR, et al. An investigation of cladding

effects on shallow-aw fracture toughness of reactor

pressure vessel steel under prototypic biaxial loading.

J Press Vess Technol, ASME 1999;121(3):25768.

7. FRA Becht C. Fatigue of bellows, a new design

approach. Int J Press Vess Piping 2000;77(13):843

50.

8. FRA Bhandari S, et al. Mechanical behaviour of RPV

materials in case of complete core melt. ASME/JSME

Joint Press Vess Piping Conf PVP 362. New York:

ASME, 1998. p. 16774.

9. FRA Bhandari S, et al. Creep-damage analysis:

comparison between coupled and uncoupled models.

J Press Vess Technol, ASME 2000;122(4):40812.

10. FRA Bhuyan GS, et al. Prediction of failure behavior

of a welded pressure vessel containing aws during a

hydrogen-charged burst test. J Press Vess Technol,

ASME 1999;121(3):24651.

11. FRA Bouchard PJ, et al. J-integral and local damage

fracture analyses for a pump casing containing large

weld repairs. Int J Press Vess Piping 2001;78(4):295

305.

12

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

12. FRA Bouyne E, et al. Mechanical and microstructural

investigations into the crack arrest behaviour of a

modern 2 1/4 Cr1 Mo pressure vessel steel. Fatigue

Fract Engng Mater Struct 2001;24(2):10516.

13. FRA Brickstad B, Sattari-Far I. Crack shape developments for LBB applications. Engng Fract Mech 2000;

67(6):62546.

14. FRA Brighenti R. Surface cracks in shells under different hoop stress distributions. Int J Press Vess Piping

2000; 77(9):5039.

15. FRA Brighenti R. Axially-cracked pipes under pulsating internal pressure. Int J Fatigue 2000;22(7):55967.

16. FRA Brighenti R. External longitudinal aws in pipes

under complex loading. J Press Vess Technol, ASME

2001;123(1):13945.

17. FRA Brocca M, Bazant ZP. Evaluation of tube-squash

test of concrete at very large strains using microplane

nite element analysis. 5th US Nat Cong Comput

Mech, Boulder. 1999. p. 320.

18. FRA Brown RG, et al. Fitness for service evaluation of

ring joint groove cracking. J Press Vess Technol,

ASME 2000;122(1):725.

19. FRA Burande S, Sethuraman R. Computational simulation of fatigue crack growth and demonstration of

leak before break criterion. Int J Press Vess Piping

1999;76(5):3318.

20. FRA Cai W, et al. Nonlinear analysis on residual

strength of corroded pipeline. J Univ Petrol China

1999;23(1): 668.

21. FRA Carpinteri A, Brighenti R. Circumferential

surface aws in pipes under cyclic axial loading.

Engng Fract Mech 1998;60(4):38396.

22. FRA Carpinteri A, Brighenti R. A three-parameter

model for fatigue behaviour of circumferential surface

aws in pipes. Int J Mech Sci 2000;42(7):125569.

23. FRA Carpinteri A, et al. Part-through cracks in pipes

under cyclic bending. Nucl Engng Des 1998;185(1):

110.

24. FRA Carpinteri A, et al. External longitudinal partthrough aw in an internally pressurized pipe. Fatigue

'99, Higher Educat Press China, 1999. p. 2397402.

25. FRA Carpinteri A, et al. Fatigue behavior of cracked

pipes under rotary bending. Fatigue '99, Higher

Educat Press China, 1999. p. 243135.

26. FRA Carpinteri A, et al. Fatigue growth simulation of

part-through aws in thick-walled pipes under rotary

bending. Int J Fatigue 2000;22(1):19.

27. FRA Casey GA, et al. Stress intensity factors for

circumferential cracks in pressure vessel door

closures. Int J Press Vess Piping 1999;76(1):112.

28. FRA Cavak M, et al. Initial bending fatigue of PVC

pipe joints. ASME/JSME Joint Press Vess Piping Conf

PVP 365. New York: ASME, 1998. p. 40936.

29. FRA Chamis CC, Minnetyan L. Defect/damage tolerance of pressurized ber composite shells. Compos

Struct 2001;51(2):15968.

30. FRA Chang YS, et al. A parametric study on the fracture mechanics analysis of elbow with surface crack.

Key Engng Mater 2000;183187:50510.

31. FRA Chapuliot S, et al. Stress intensity factors for

internal circumferential cracks in tubes over a wide

range of radius over thickness ratios. ASME/JSME

Joint Press Vess Piping Conf PVP 365. New York:

ASME, 1998. p. 95106.

32. FRA Chattopadhyay J, et al. Leak-before-break qualication of primary heat transport piping of 500 MWE

Tarapur atomic power plant. Int J Press Vess Piping

1999;76(4):22143.

33. FRA Chen HF, Shu D. Simplied limit analysis of

pipelines with multi-defects. Engng Struct 2001;

23(2):20713.

34. FRA Chen HF, Shu DW. Lower and upper bound limit

analyses for pipeline with multi-slots of various congurations. Int J Press Vess Piping 2000;77(1):1725.

35. FRA Chen HF, Shu DW. The effects of the distance

between two defects on the load-carrying capacity of a

pressure vessel. J Press Vess Technol, ASME 2000;

122(2):198203.

36. FRA Chen HF, Shu DW. The load carrying capacity of

the pressure vessel with two defects along axial direction. Key Engng Mater 2000;177180:75762.

37. FRA Chen HF, Shu DW. Numerical method for lower

bound limit analysis of 3-D structures with multi-loading systems. Int J Press Vess Piping 1999;76(2):105

12.

38. FRA Chiesa M, et al. Efcient fracture assessment

of pipelines. A constraint-corrected SENT specimen

approach. Engng Fract Mech 2001;68(5):52747.

39. FRA Choi JB, et al. Effect of cladding on stress intensity factors in the pressure vessel. ASME/JSME Joint

Press Vess Piping Conf PVP 374. New York: ASME,

1998. p. 2933.

40. FRA Choi SN, et al. Effect of cladding on the stress

intensity factors in the reactor pressure vessel. Nucl

Engng Des 2000;199(1/2):10111.

41. FRA Chung M, et al. 3-D analysis and validation of a

crack in a pressurized pipe under creep conditions

using submodelling techniques. 4th World Cong

Comput Mech, Buenos Aires. 1998. p. 561.

42. FRA Cowan AL, et al. Crack path bifurcation at a tear

strap in a pressured shell. 41st Str, Str Dyn Mater Conf

Exhib, AIAA, 2000. p. 1090101.

43. FRA Cui X, et al. Analysis on the elastic load bearing

capacity of tubes inside slips. J Univ Petrol China

1999;23(1):625.

44. FRA Das J, Sivakumar SM. An evaluation of multiaxial fatigue life assessment methods for engineering

components. Int J Press Vess Piping 1999;76(10):741

6.

45. FRA Dhar S, et al. A continuum damage mechanics

model for ductile fracture. Int J Press Vess Piping

2000;77(6):33544.

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

46. FRA Dinovitzer AS, et al. Strain-based failure criteria for

sharp part-wall defects in pipelines. 1998 Int Pipeline

Conf, Calgary. New York: ASME, 1998. p. 25561.

47. FRA Dixon RD, Perez EH. Effects of cross-bores on

the limit load of high pressure cylindrical vessels.

ASME/JSME Joint Press Vess Piping Conf PVP 371.

New York: ASME, 1998. p. 11923.

48. FRA Eisinger FL, Francis JT. Acoustically induced

structural fatigue of piping systems. J Press Vess Technol, ASME 1999;121(4):43843.

49. FRA Endicott JS, Leventry SC. Ultimate strength of

reduced girth seams on cylindrical vessels. ASME/

JSME Joint Press Vess Piping Conf PVP 360. New

York: ASME, 1998. p. 3619.

50. FRA Estrada H, Parsons ID. Strength and leakage

nite element analysis of a GFRP ange joint. Int J

Press Vess Piping 1999;76(8):54350.

51. FRA Feng H, et al. Finite element modelling of lowtemperature autofrettage of thick-walled tubes of the

austenitic stainless steel AISI 304 L. Part I. Model

Simul Mater Sci Engng 1998;6(1):5169.

52. FRA Feng H, et al. Finite element modelling of lowtemperature autofrettage of thick-walled tubes of the

austenitic stainless steel AISI 304 L. Part II. Model

Simul Mater Sci Engng 1998;6(1):7185.

53. FRA Folias ES, Perry LJ. Failure of a threaded

pressurized vessel. Int J Press Vess Piping

1999;76(10):68592.

54. FRA Foxen J, Rahman S. Elasticplastic analysis of

small cracks in tubes under internal pressure and bending. Nucl Engng Des 2000;197(1):7587.

55. FRA Goldthorpe MR, Wiesner CS. Micromechanical

prediction of fracture toughness for pressure vessel

steel using a coupled model. ASTM Spec Publ

1999;1332:34163.

56. FRA Goncalves R, Casanova EL. Stress intensication

factors for encirclement sleeve reinforced branch

connections. ASME/JSME Joint Press Vess Piping

Conf PVP 360. New York: ASME, 1998. p. 47782.

57. FRA Gong JM, et al. Damage assessment and maintenance strategy of hydrogen reformer furnace tubes.

Engng Failure Anal 1999;6(3):14353.

58. FRA Grant RJ, Smart J. Crack growth in pin-loaded

tubes. II. Comparison of experimental data with

numerical results. J Strain Anal Engng Des

1999;34(4):27184.

59. FRA Han J, Yamazaki K. A study on maximization of

dynamic crushing energy absorption of square tubes

with and without stiffener. JSME Int J, A

2000;43(2):13845.

60. FRA Han LH, et al. Limit moment of local wall thinning in pipe under bending. Int J Press Vess Piping

1999; 76(8):53942.

61. FRA Harris DO, Woytowitz PJ. Fully plastic J-integrals for through-wall axial cracks in pipes. ASTM

Spec Publ 1999;1332:21532.

13

62. FRA Hassan T, Liu Z. On the difference of fatigue

strengths from rotating bending, four-point bending,

and cantilever bending tests. Int J Press Vess Piping

2001;78(1):1930.

63. FRA Hassan T, et al. Improved ratchetting analysis of

piping components. Int J Press Vess Piping 1998;

75(8):64352.

64. FRA Hayhurst DR, Perrin IJ. Continuum damage

mechanics analyses of Type IV creep failure in ferritic

steel crossweld specimens. Int J Press Vess Piping

1999;76(9):599617.

65. FRA Hong SJ, et al. A study on crushing characteristics of thick-walled aluminum tubes under axial loading. Int J Crashworth 1998;3(3):22536.

66. FRA Hoogkamer D, et al. Damage tolerance of

cracked cylindrical shells under internal pressure.

42nd Str, Str Dyn Mater Conf, Seattle. 2001. p.

226576.

67. FRA Hornet P, Comparison of experimental results,

FE calculations and analytical approach on the fracture

behavior of circumferential through wall cracked

pipes. ASME/JSME Joint Press Vess Piping Conf

PVP 373. New York: ASME, 1998. p. 1638.

68. FRA Hornet P, Eripret C. Fracture behaviour of

circumferential through wall cracked welded pipes in

four point bending. Engng Fract Mech 1999;

64(4):45972.

69. FRA Hornet P, et al. Failure probability calculation of

an axisymmetrically cracked pipe under pressure and

tension using a nite element code. ASME/JSME Joint

Press Vess Piping Conf PVP 373. New York: ASME,

1998. p. 37.

70. FRA Hou YC, et al. Fracture analysis of welded pipes

with consideration of residual stresses. ASME/JSME

Joint Press Vess Piping Conf PVP 373. New York:

ASME, 1998. p. 4337.

71. FRA Hsieh MF, et al. Nozzles in the knuckle region of

a torispherical head: limit load interaction under

combined pressure and piping loads. Int J Press Vess

Piping 2000;77(13):80715.

72. FRA Hu HT, Liang JI. Ultimate analysis of BWR

Mark III reinforced concrete containment subjected

to internal pressure. Nucl Engng Des 2000;195(1):1

11.

73. FRA Huang X, et al. Collapse strength analysis of

casing design using nite element method. Int J

Press Vess Piping 2000;77(7):35967.

74. FRA Huh NS, et al. Prediction of piping failure behavior using wide-plate test. Key Engng Mater

2000;183187:65560.

75. FRA Huo L, et al. Effect of mismatching on J-integral

for pipe-welded joints with circumferential throughwall crack. Int J Press Vess Piping 1999;76(12):857

62.

76. FRA Huo L, et al. Reliability calculation for

piping containing circumferential crack based on

14

77.

78.

79.

80.

81.

82.

83.

84.

85.

86.

87.

88.

89.

90.

91.

J. Mackerle / International Journal of Pressure Vessels and Piping 79 (2002) 126

3-D elasticplastic SFEM. Key Engng Mater

2000;183187:6138.

FRA Huo LX, et al. Effect of the mismatching of

J-integral for pipe welded joint with circumferential

surface crack. Key Engng Mater 2000;183

187:132732.

FRA Huysmans G, et al. Structural analysis of GRP

pipe couplers by using a fracture mechanical approach.

Compos, Part B 1998;29(4):47787.

FRA Hyde TH, et al. Assessment of the use of nite

element creep steady state stresses for predicting the

creep life of welded pipes. Adv FE Proced Technol.

Edinburgh: Civil-Comp, 1998. p. 24751.

FRA Hyde TH, et al. Experimental and nite element

investigations on the static collapse of a plane tubular

framework structure. 9th Int Offshore Polar Engng

Conf. 4. ISOPE. 1999. p. 6370.

FRA Hyde TH, et al. Prediction of creep failure life of

internally pressurised thick walled CrMoV pipes. Int J

Press Vess Piping 1999;76(14):92533.

FRA Hyde TH, et al. Failure prediction for multimaterial creep test specimens using a steady-state

creep rupture test. Int J Mech Sci 2000;42(3):40123.

FRA Hyde TH, et al. Effect of weld angle and axial

load on the creep failure behaviour of an internally

pressurised thick walled CrMoV pipe weld. Int J

Press Vess Piping 2001;78(5):36572.

FRA Jing JP, et al. A continuum damage mechanics

model on low cycle fatigue life assessment of steam

turbine rotor. Int J Press Vess Piping 2001;78(1):59

64.

FRA Jones DP, Holliday JE. Elasticplastic analysis

of the PVRC burst disk tests with comparison to the

ASME code primary stress limits. J Press Vess Technol, ASME 2000;122(2):14651.

FRA Jones DP, et al. Elasticplastic failure analysis of

pressure burst tests of thin toroidal shells. J Press Vess

Technol, ASME 1999;121(2):14953.

FRA Jun HK, et al. Plastic collapse solutions based on

nite element analyses for axial surface cracks in pipelines under internal pressure. ASME/JSME Joint Press

Vess Piping Conf PVP 373. New York: ASME, 1998.

p. 5238.

FRA Keeney JA, Williams PT. Fracture analysis of

ductile crack growth in weld material from a fullthickness clad RPV shell segment. ASTM Spec Publ

1999; 1332:85161.

FRA Kim CH, et al. Welding residual stress analysis

and fatigue crack growth characteristics of multi-pass

welded pipe weldment. Key Engng Mater 2000;183

187:134550.

FRA Kim JH, Hwang IS. Elastic plastic fracture

mechanics behavior of a part-through crack in nuclear

piping. ASME/JSME Joint Press Vess Piping Conf

PVP 365. New York: ASME, 1998. p. 32531.

FRA Kim WB. Ultimate strength of tube-gusset plate

92.

93.

94.

95.

96.

97.

98.

99.

100.

101.

102.

103.

104.

105.

106.

107.

108.

connections considering eccentricity. Engng Struct

2001;23(11):141826.

FRA Kim YJ, et al. Development of modied piping

evaluation diagram for leak-before-break application

to Korean next generation reactor. Nucl Engng Des

1999;191(2):13545.

FRA Kisioglu Y, et al. Determination of burst pressure

and location of the DOT-39 refrigerant cylinders.

J Press Vess Technol, ASME 2001;123(2):2407.

FRA Knox EM, et al. Fatigue performance of adhesively bonded connections in GRE pipes. Int J Fatigue

2000; 22(6):5139.

FRA Kobidze G, Lord W. Tight crack modeling for the

nite element simulation of inspection tools in pipelines. Mater Eval 1998;56(10):12236.

FRA Koh BH, et al. Crack stability evaluation of

nuclear main steam pipe considering load reduction

effect. Nucl Engng Des 2001;203(2/3):17584.

FRA Koh SK. Fatigue analysis of autofrettaged pressure vessels with radial holes. Int J Fatigue

2000;22(8):71726.

FRA Kosai M, et al. Axial crack propagation and arrest

in a pressurized cylinder: an experimentalnumerical

analysis. Exp Mech 1999;39(4):25664.