032-Itp For Painting and Coating PDF

Diunggah oleh

Köksal PatanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

032-Itp For Painting and Coating PDF

Diunggah oleh

Köksal PatanHak Cipta:

Format Tersedia

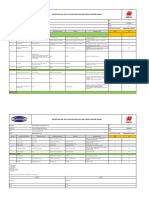

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.250.919

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: C

Page 2 of 13

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

05.01.09

As per Site Condition, Issued for Review

SK

EO

AG

IFR

18.12.08

As per Site Condition, Issued for Review

SK

EO

AG

IFR

08.10.08

Ready For Construction

SK

EO

AG

RFC

08.03.08

Ready For Construction

BR

UA

ZG

RFC

26.11.07

Issued for Company comments

BR

AU/MC

ZG

ICC

23.11.07

Issued for Review

BR

AU/MC

ZG

IFR

20.11.07

Issued for Internal Review

BR

AU/MC

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

ITP FOR PAINTING AND COATING

LINDEGINEERING AG

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

ITP

QAC

GTL

032

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.250.919

Vendor Code

Rev No: C

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-032

C2 ASU Construction Works

ITP FOR PAINTING AND COATING

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 05.01.2009 REV. G

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

Test Frequency

1.0

METHOD STATEMENTS/PROCEDURES

1.1

Method Statements /

Procedures Preparation

2.0

2.1

2.2

2.3

Prior to start of

activity

Reference Document

Acceptance Criteria

Responsible Party

Verifying Documents

Subcontractor Method

Statements / Procedure

Project

Requirements

QA/QC

T.4.305.119

T.4.250.916

Painting inspector

Calibration Test certificate

QA/QC

Calibration Test

Certificates

Ability to blast and

paint in accordance

with manufacturers

technical data sheets

Painting inspector

Qualification

Certificates

DEP 30.48.00.31;

T.13.376.799,MSD

S Manufacturers

Technical data

sheet, certificates

Painting inspector

T.13.376.799

DEP 30.48.00.31

Manufacturers

recommendation.

Painting inspector

CONTROL OF INSPECTION, MEASURING AND TESTING EQUIPMENT

Blasting and Painting

Standard practice and

Once per shift

Equipment Inspection

safety

Calibration of test

instruments

Coating personnel

qualification.

Blaster

Paint Applicator

3.0

MATERIALS CERTIFICATES

3.1

Verification of Paints,

Thinners, colors and

Abrasives

3.2

Storage and handling of

Paints & Abrasives

T-4.250.919 Rev. C

Each Inspection

100%

100%

Daily

User Manual of test Equipment

manufacturer

Standard Practice and

Safety

T-4.250.900,

T- 4.250.916

T-4.250.900,

T- 4.250.916

DEP 30.48.00.31;

T.13.376.799

DEP 30.48.00.31;

T.13.376.799

Page 4

MAR,MSDS

GAM-QCR-QAC-GTL-051

Visual confirmation

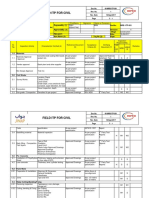

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-032

C2 ASU Construction Works

ITP FOR PAINTING AND COATING

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 05.01.2009 REV. G

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

4.0

1.1.1.1 INSPECTIONS

Test Frequency

Reference Document

Every 4hrs or

weather change

T-4.250.900,

T- 4.250.916

Acceptance Criteria

Responsible Party

Verifying Documents

Painting inspector

GAM-QCR-QAC-GTL-055

Painting inspector

GAM-QCR-QAC-GTL-055

Environmental Conditions

Dry Bulb

Temperature

4.1

Wet Bulb

Temperature

Relative Humidity

Substrate

Temperature

DEP30.48.00.31,

T.13.376.799

Manufacturers

recommendation.

Air temperature of

Compressed air

Surface preparation prior

to application of coating

systems

4.2

Surface Profile

and cleanliness

Max. Time

between end of

blasting and

application of

primer (4 hrs.)

T-4.250.919 Rev. C

100%

T-4.250.900,

T-4.250.916

T.13.376.799

DEP30.48.00.31

ISO 8501:SA 21/2

ISO 8501-1:SA 3

ISO 8504-2

Page 5

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-032

C2 ASU Construction Works

ITP FOR PAINTING AND COATING

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 05.01.2009 REV. G

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

In process inspection of

primer coat/first coat

a ) Paint system

verification

4.3

b ) Wet film thickness

c) Dry Film Thickness

d) Adhesion check (if

applicable)

Test Frequency

Reference Document

T.13.376.799

a)100%

b)100%

T-4.250.916,

T-4.250.900

c) Para 3.5.1

d) Para 3.5.3

Acceptance Criteria

T.13.376.799Para 3.5

DEP30.48.00.31Para 6

Manufacturers

recommendation &

ISO 2409, ASTM

D4541

Responsible Party

4.4

In process inspection of

intermediate coats & min.

Time b/w the application

of different coats

GAM-QCR-QAC-GTL-055

GAM-QCR-QAC-GTL-167

Painting inspector

GAM-QCR-QAC-GTL-167

T-4.250.900

T-4.250.916

Manufacturers

recommendation &

ISO 2409, ASTM

D4541

Painting Inspector

d) Adhesion check

Para 3.5.3

T-4.250.919 Rev. C

DEP30.48.00.31

T.13.376.799

b) wet Film

Thickness 100%

c)Dry film

Thickness Para

3.5.1

GAM-QCR-QAC-GTL-055

T.13.376.799

a) Visual Inspection

Verifying Documents

Page 6

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-032

C2 ASU Construction Works

ITP FOR PAINTING AND COATING

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 05.01.2009 REV. G

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

Test Frequency

Reference Document

Acceptance Criteria

Responsible Party

Verifying Documents

GAM-QCR-QAC-GTL-055

GAM-QCR-QAC-GTL-167

Painting Inspector

GAM-QCR-QAC-GTL-053

H H

Painting Inspector

GAM-QCR-QAC-GTL-056

H H

Painting Inspector

GAM.-QCR-QAC-GTL-056

H H

T.13.376.799

a) Visual Inspection

4.5

In process inspection of

final coat of film

thickness, colour, coating

system,

b) wet Film

Thickness 100%

c)Dry film

Thickness Para

3.5.1

T-4.250.900

T-4.250.916

DEP30.48.00.31

T.13.376.799

Manufacturers

recommendation

Painting Inspector

d) Adhesion check

Para 3.5.3

4.6

Wet sponge holiday

testing (if applicable)

100%

T-4.250.900

T-4.250.916

4.7

Hot Dip Galvanizing

touch up

100%

T-4.250.900

T-4.250.916

4.8

Inspection of repair /

touch up of paintings

/coatings. (Field joints of

Above ground & buried

carbon steel lines etc)

100%

T-4.250.900

T-4.250.916

T-4.250.919 Rev. C

DEP30.48.00.31

T.13.376.799 Para

3.5.2

No holidays

DEP30.48.00.31,D

EP30.48.40.31,BS

EN ISO 1461 (or)

ASTM A 123

T.13.376.799

DEP30.48.00.31

Manufacturers

recommendation

Page 7

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-032

C2 ASU Construction Works

ITP FOR PAINTING AND COATING

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 05.01.2009 REV. G

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

4.9

Color coding and

stenciling of identification

on equipment / piping.

100%

T-4.250.928

4.10

Final Coating inspection

& Punch Listing

100%

T-4.250.900

T-4.250.916

4.11

4.12

Flawless Start-up Initiative

(FSI) - Cleanliness

Disposal of high risk wastes

such as catalyst drums,

chemical drums for first fill,

paint cans

T-4.250.919 Rev. C

Test Frequency

Internal Cleaning

100%

Reference Document

T.13.377.360 Rev E

& T.4.096.688

T.13.377.450-Construction

waste Management

Procedure

Acceptance Criteria

T.13.376.799

DEP30.48.00.31

Project

Requirements

T.13.376.799

DEP30.48.00.31

Visual confirmation

No external materials

inside the pipe &

Internal Cleaning

before lifting into

Structure.

Check & ensure in

Hazard area

,flammable area any

paint material

Responsible Party

Painting Inspector

Painting Inspector

Site Engineer

Painting Supervisor

Page 8

Verifying Documents

Visual

Visual

C2 ASU PEARL GTL PROJECT

RAS LAFFAN INUSTRIAL CITY

MAR

(Material Acceptance Report)

Project: QSGTL PEARL GTL PROJECT

MAR No.:

Date:

Manufacturer:

PO/Subcontract

Number :

Description of the Proposed Material:

Nos:

QTY:

Note:

Civil / Buildings

Mech. / Piping

Civil

Involved

Discipline:

Mechanical

Electrical

Instrumental

Welding

Others

..

Location & Usage of the Delivered Material:

Applicable Specifications & Technical Details:

Proposed material complies with applicable project specification

Attachments:

Inspection Report

Release Note

Yes

Mill Certificates

Data Sheets

No

Others

Comments:

Carried out By

Accepted By

GAMA REP.

VENDOR REP.

LINDE REP.

QSGTL REP.

GAM-QCR-QAC-GTL-051

DATE

NAME

SIGNATURE

C2 ASU PEARL GTL PROJECT

Q A T A R

RAS LAFFAN INDUSTRIAL CITY

PINHOLE & HOLIDAY TESTING REPORT

Subcontract Ref.:

Report No.

Item Description:

Inspection Date:

Item Location / Area:

Test Code No.:

System:

ITP No.:

Subsystem:

Ref.Drg./Doc.

Used Measuring and test equipment ref. (if applicable):

HOLIDAY DETECTOR

DETAILS

Make: _________

Date

Identification No.:

Pipe

T.D.F.T

Ident. No.

Dia (inch) Microns

K.V.Range:

KV

Settings

H.D Result

Damages

Pinholes

Remarks:

Accepted By

ORGANIZATIONS

THIRD PARTY

REP.

GAMA REP.

LINDE REP.

QSGTL or its PMC

REP.

GAM-QCR-QAC-GTL-053

DATE

NAME

SIGNATURE

Remarks

C2 ASU PEARL GT PROJECT

RAS LAFFAN INDUSTRIAL CITY

PAINTING INSPECTION REPORT

QATAR

Report No.:

Item Description:

System:

Item Location / Area:

Ref. DWG / Documents:

Used Measuring and test equipment ref. (if applicable):

Working Conditions

Internal / External

Inspection Date:

Test Code No.:

Subsystem:

ITP No.:

Paint Spec:

Compr. Air Temp.

Time (hrs.)

Air

WB

O

Temp

( C)

DB

Dew Point (O C)

Relative Humidity %

Metal Temp. (O C)

1. Hygrometer

Insp. Equipment Used

Identification #

2. DP / RH Calculator

3. Temperature Gauge

4. Hypodermic Needle

Gauge

5. Surface Profile Gauge

6. WFT Gauge

7. DFT Gauge

Surface Cleaning with fresh water

SURFACE PREPARATION

PROFILE MEASUREMENT TAPE

From: ________________hrs.

To: ________________hrs.

Grit Blasting

Machine Sl.No.

Nozzle Pressure

Grit Type

Wire Brushing

Manual / Power

Grade

mm

PSIG

Surface Finish

Surface Profile

Microns

*PAINT APPLICATION

From: ______________ hrs. To: _______________ hrs.

Manual / Auto

Coating Manufacturer:

Paint:

Batch No.

Product/Coat

Mix

Ratio

Application

Methods

Airless Spray Machine Sl. No.

Total

Colour

WFT DFT

DFT

Overcoat

Time

A.

B.

Intermediate A.

Coat

B.

A.

Top Coat

B.

Further Inspection Required:

Conducted :

Corrective action if necessary:

Primer

Accepted By

ORGANIZATIONS

DATE

NAME

THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL or its PMC REP.

*Priming application will be done within 4 hrs after surface preparation.

GAM-QCR-QAC-GTL-055, Rev-1

SIGNATURE

Q A T A R

C2 ASU PEARL GT PROJECT

RAS LAFFAN INDUSTRIAL CITY

REPAIR & TOUCHUP PAINTING

INSPECTION REPORT

System:

Item Description:

Item Location / Area:

Subsystem:

Ref. DWG / Documents:

Used Measuring and test equipment ref. (if applicable):

Working Conditions

Internal / External

Report No.:

Inspection Date:

Test Code No.:

ITP No.:

Paint Spec:

Insp. Equipment Used

Identification #

1. Whirling Hygrometer

Time (hrs.)

Air

WB

O

Temp

( C)

DB

Dew Point (O C)

Relative Humidity

%

Metal Temp. (O C)

2. DP / RH Calculator

3. Temperature Gauge

4. WFT Gauge

5. DFT Gauge

SURFACE PREPARATION

From: ________________

To: ________________

Method of

Cleaning

PAINT APPLICATION

From: ______________ hrs. To: _______________ hrs.

Coating Manufacturer:

Paint:

Batch No.

Product/Coat

Mix

Ratio

Application

Methods

Airless Spray Machine Sl. No.

Total

Colour WFT DFT

DFT

DATE

NAME

Overcoat

Time

A.

B.

A.

Intermediate

B.

A.

Top coat

B.

Remarks:

Primer

Accepted By

ORGANIZATIONS

THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL or its PMC REP.

GAM-QCR-QAC-GTL-056, Rev-1

SIGNATURE

QATAR

C2 ASU PEARL GT PROJECT

RAS LAFFAN INDUSTRIAL CITY

ADHESION INSPECTION REPORT

Report No.:

Item Description:

System:

Item Location / Area:

Ref. DWG / Documents:

Inspection Date:

Test Code No.:

Subsystem:

ITP No.:

Paint Spec:

1. Type Of Inspection:-

2.Inspection Item:-

3.Inspection Results:-

4. Remarks:-

ORGANIZATIONS

Accepted By

THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL or its PMC

REP.

GAM-QCR-QAC-GTL-167

DATE

NAME

SIGNATURE

Anda mungkin juga menyukai

- Painting Inspection ReportDokumen1 halamanPainting Inspection Reportakturkam8571% (7)

- Method Statement Sandblasting Rev. 0Dokumen7 halamanMethod Statement Sandblasting Rev. 0spazzbgt80% (10)

- ITP - Concrete Works PDFDokumen2 halamanITP - Concrete Works PDFntah8483% (35)

- Painting Inspection ReportDokumen1 halamanPainting Inspection Reportsandipthummar1743100% (3)

- Itp For Steel Structure Erection (Content) Rev.1Dokumen3 halamanItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (5)

- ITP For Painting WorksDokumen27 halamanITP For Painting Workssree50% (2)

- Method Statement For Blasting and Painting of Process EquipmentDokumen11 halamanMethod Statement For Blasting and Painting of Process EquipmentNnamdi Amadi100% (3)

- MS-24 Hydrotest Pipeline ProcedureDokumen13 halamanMS-24 Hydrotest Pipeline Proceduresosi2020100% (13)

- 027-ITP For Pre - Cast Concrete PDFDokumen11 halaman027-ITP For Pre - Cast Concrete PDFKöksal Patan75% (4)

- GASOLINE STORAGE TANK INSPECTION AND TEST PLANDokumen1 halamanGASOLINE STORAGE TANK INSPECTION AND TEST PLANAmer Y KBelum ada peringkat

- ITP - Fabrication of Structural SteelDokumen2 halamanITP - Fabrication of Structural Steelsahad100% (6)

- 048-Itp For Installation of Hvac Unit PDFDokumen8 halaman048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 023-Itp Concrete Works PDFDokumen32 halaman023-Itp Concrete Works PDFKöksal Patan100% (5)

- 030-Itp For Ug GRP Piping PDFDokumen22 halaman030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDokumen10 halaman044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 043-ITP FOR Water Proofing (Buildings) PDFDokumen13 halaman043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- Itp For InsulationDokumen14 halamanItp For InsulationHytham El-NoubyBelum ada peringkat

- Blasting and Painting ProcedureDokumen9 halamanBlasting and Painting Procedureisukuru67% (12)

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Dokumen24 halamanItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Inspection Test Plan For Fabrication & Erection 2016Dokumen14 halamanInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- ITP (Test Procedure) PDFDokumen2 halamanITP (Test Procedure) PDFkrishnit100% (1)

- Inspection and Test PlanDokumen58 halamanInspection and Test PlanTouil Houssem100% (1)

- Surface Preparation & Painting Procedure: List of ContentDokumen20 halamanSurface Preparation & Painting Procedure: List of Contentsherviny50% (4)

- Painting ProcedureDokumen8 halamanPainting ProcedureSunday Paul50% (2)

- Blasting & Painting Report for Project NOV OCS/BPR/1115/001Dokumen2 halamanBlasting & Painting Report for Project NOV OCS/BPR/1115/001vinothBelum ada peringkat

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDokumen10 halaman045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 050-Itp For Installation of Air Intake Filter PDFDokumen17 halaman050-Itp For Installation of Air Intake Filter PDFKöksal PatanBelum ada peringkat

- 015-MS For Night Works PDFDokumen16 halaman015-MS For Night Works PDFKöksal Patan80% (5)

- 015-Method Statement For Painting Works (Building) PDFDokumen21 halaman015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 050-Itp For Installation of Air Intake Filter PDFDokumen17 halaman050-Itp For Installation of Air Intake Filter PDFKöksal PatanBelum ada peringkat

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDokumen10 halaman045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 043-ITP FOR Water Proofing (Buildings) PDFDokumen13 halaman043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- Thi Công Chống Thấm Chop MBS Marina-Bay-SandsDokumen5 halamanThi Công Chống Thấm Chop MBS Marina-Bay-SandsTrần KhươngBelum ada peringkat

- Paint Job - Tennis RacquetDokumen22 halamanPaint Job - Tennis RacquetMario MauerBelum ada peringkat

- 026-Itp For Structural Steel PDFDokumen18 halaman026-Itp For Structural Steel PDFKöksal Patan100% (11)

- 033-Itp For Piping Installation Ag and Ug PDFDokumen13 halaman033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Itp PaintingDokumen14 halamanItp PaintingNamta George100% (4)

- ITP Blasting Painting.Dokumen2 halamanITP Blasting Painting.mohd as shahiddin jafri100% (4)

- Itp Concrete CoatingDokumen4 halamanItp Concrete Coatingkaml100% (1)

- Duties of Tank InspectorDokumen1 halamanDuties of Tank InspectorJawed AlamBelum ada peringkat

- Internal Painting Works ITPDokumen2 halamanInternal Painting Works ITPPrasanna Kumar100% (1)

- 005-Ms-Painting and Repair Works PDFDokumen24 halaman005-Ms-Painting and Repair Works PDFKöksal Patan100% (1)

- INSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSDokumen2 halamanINSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSRanjan KumarBelum ada peringkat

- UG PIPING COATINGDokumen10 halamanUG PIPING COATINGcloud23Belum ada peringkat

- SA04C2-T-MET-AAG-00037 Hydrotest Method StatementDokumen25 halamanSA04C2-T-MET-AAG-00037 Hydrotest Method StatementABAID ULLAH100% (2)

- Zee-Method Statement For Construction Steel Platform ErectionDokumen8 halamanZee-Method Statement For Construction Steel Platform Erectionzeeshansheikh7Belum ada peringkat

- Field Joint Coating Procedure for PipelinesDokumen8 halamanField Joint Coating Procedure for PipelinesAllouh Mohammed75% (4)

- Procedure for holiday testingDokumen2 halamanProcedure for holiday testingSaptarshi MandalBelum ada peringkat

- ItpDokumen7 halamanItpJose Sherin100% (1)

- Itp Civil WorkDokumen9 halamanItp Civil WorkChristian Albert Sinaga RumajarBelum ada peringkat

- 002-BOLT TIGHTENING (Structural) PDFDokumen22 halaman002-BOLT TIGHTENING (Structural) PDFKöksal Patan82% (11)

- ITP ManifoldDokumen7 halamanITP ManifoldvinothBelum ada peringkat

- MS For Pressure Test-ReDokumen9 halamanMS For Pressure Test-Reanishdev6Belum ada peringkat

- Itp PipingDokumen4 halamanItp PipingkennethBelum ada peringkat

- KNPC tank cleaning and painting proceduresDokumen10 halamanKNPC tank cleaning and painting proceduresMohamed RizwanBelum ada peringkat

- 3-23 - Painting Works Inspection and Test Plan (PL212533-SP-ETG-5231-00)Dokumen2 halaman3-23 - Painting Works Inspection and Test Plan (PL212533-SP-ETG-5231-00)Walid Amdouni100% (1)

- GRP Installation GuideDokumen13 halamanGRP Installation GuidepparreraBelum ada peringkat

- ITP SampleDokumen2 halamanITP Sampleeiman_zerep50% (2)

- Inspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDokumen2 halamanInspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDinesh100% (1)

- MS - Dolly Test ProcedureDokumen4 halamanMS - Dolly Test ProcedureRahul Moottolikandy100% (1)

- Inspection and Test Plan For Steel StrucDokumen6 halamanInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Repair and Modification ITPDokumen8 halamanRepair and Modification ITPShewale PravinBelum ada peringkat

- Method Statement For Surface Preparation PaintingDokumen9 halamanMethod Statement For Surface Preparation Paintingjamil100% (3)

- Tank Erection ProcedureDokumen29 halamanTank Erection ProcedureVisas Siva100% (3)

- ITP CIVIL WORK-Rev-1Dokumen6 halamanITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- Itp For Piping Fabrication and Erection CorrectionDokumen4 halamanItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- 016-CIVIL - MS Anchor Bolt Installation PDFDokumen14 halaman016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 034-ITP For Air Cooled Steam Condenser PDFDokumen41 halaman034-ITP For Air Cooled Steam Condenser PDFKöksal PatanBelum ada peringkat

- 017-CIVIL-MS For Installation of Fence & Gate PDFDokumen18 halaman017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 016-CIVIL - MS Anchor Bolt Installation PDFDokumen14 halaman016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 013-MS For Mass Concrete Works PDFDokumen26 halaman013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDokumen18 halaman012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanBelum ada peringkat

- 014-MS For General Scaffolding PDFDokumen33 halaman014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDokumen23 halaman014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanBelum ada peringkat

- 013-MS Utilization of Hilti DX 76 PDFDokumen51 halaman013-MS Utilization of Hilti DX 76 PDFKöksal PatanBelum ada peringkat

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDokumen16 halaman012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 011-Method Statement For Repair of Concrete Works PDFDokumen25 halaman011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 049-Itp For Lighting and Small Power (Building) PDFDokumen15 halaman049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDokumen18 halaman046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanBelum ada peringkat

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDokumen17 halaman010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanBelum ada peringkat

- 010-MS For Grouting PDFDokumen33 halaman010-MS For Grouting PDFKöksal PatanBelum ada peringkat

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDokumen28 halaman047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanBelum ada peringkat

- 009-Civil-Ms Concrete Works PDFDokumen27 halaman009-Civil-Ms Concrete Works PDFKöksal PatanBelum ada peringkat

- 009-Method Statement - Main Erection Sequence For Acc PDFDokumen68 halaman009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 039-Itp For Embedded Plate PDFDokumen7 halaman039-Itp For Embedded Plate PDFKöksal PatanBelum ada peringkat

- 040-ITP For Repair of Steam Distribution Manifold PDFDokumen11 halaman040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanBelum ada peringkat

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDokumen25 halaman007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanBelum ada peringkat

- 041 - ITP For Painting (Building) PDFDokumen12 halaman041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDokumen23 halaman008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanBelum ada peringkat

- 008-CIVIL-MS Backfilling Works PDFDokumen16 halaman008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 038-Itp For Coldboxes PDFDokumen25 halaman038-Itp For Coldboxes PDFKöksal PatanBelum ada peringkat

- Polyken Pipeline #1027,: Primers #1019Dokumen3 halamanPolyken Pipeline #1027,: Primers #1019Azmi SyariefBelum ada peringkat

- Fosroc Nitocote EP410: Constructive SolutionsDokumen4 halamanFosroc Nitocote EP410: Constructive SolutionsVJ QatarBelum ada peringkat

- Grupo Stoncor Description - Stonhard Carboline Fibergrate PDFDokumen22 halamanGrupo Stoncor Description - Stonhard Carboline Fibergrate PDFAndres OsorioBelum ada peringkat

- TDS Fosroc Nitoseal PS200 Saudi ArabiaDokumen4 halamanTDS Fosroc Nitoseal PS200 Saudi ArabiaSHAIK ASIMUDDINBelum ada peringkat

- RIMA wheel brake catalogueDokumen16 halamanRIMA wheel brake catalogueRodrigo Figueiredo AssisBelum ada peringkat

- Waterproofing Specifications for BridgesDokumen6 halamanWaterproofing Specifications for BridgesAbdul Wahab JamilBelum ada peringkat

- PDE-CMG-G00-EC-0001-000-05-DPP-1 PES-Y1 PaintingDokumen36 halamanPDE-CMG-G00-EC-0001-000-05-DPP-1 PES-Y1 PaintingNamta GeorgeBelum ada peringkat

- Brochure Thermal Insulating CoatingDokumen2 halamanBrochure Thermal Insulating CoatingVictor De AlvaBelum ada peringkat

- 2016 Industrial-Coatings SelGuide r1 LResDokumen40 halaman2016 Industrial-Coatings SelGuide r1 LResjoy7898Belum ada peringkat

- Chen Kee SpecDokumen5 halamanChen Kee Spectyn de guzmanBelum ada peringkat

- Presentation 2Dokumen63 halamanPresentation 2Karma TsheringBelum ada peringkat

- Body Echo 2002Dokumen127 halamanBody Echo 2002Tomas DominguezBelum ada peringkat

- TDS Proofex 3000 Saudi ArabiaDokumen3 halamanTDS Proofex 3000 Saudi Arabiarangarajan1989Belum ada peringkat

- Moisture Cured Urethane CoatingsDokumen11 halamanMoisture Cured Urethane Coatingszavisa2Belum ada peringkat

- Astm D2672 (1996)Dokumen4 halamanAstm D2672 (1996)hussein100% (1)

- Apex Ultima: Product BenefitsDokumen2 halamanApex Ultima: Product BenefitssudhakarrrrrrBelum ada peringkat

- Taralac Tds Epoxy Floor Solvent Free CoatingDokumen3 halamanTaralac Tds Epoxy Floor Solvent Free CoatingRitesh DoshiBelum ada peringkat

- Becca SpecsDokumen11 halamanBecca SpecsAlyanna Panganiban100% (1)

- PPG Amercoat 370 Data SheetDokumen3 halamanPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- Flexothane P: Pouring Grade Polyurethane Joint SealantDokumen2 halamanFlexothane P: Pouring Grade Polyurethane Joint Sealantengramir07Belum ada peringkat

- AP-T310-16 Selection Design of Initial Treatments For Sprayed Seal SurfacingsDokumen23 halamanAP-T310-16 Selection Design of Initial Treatments For Sprayed Seal SurfacingsFranklinBelum ada peringkat

- Is.6509.1985 Expansion JointsDokumen25 halamanIs.6509.1985 Expansion JointsHaneefa ChBelum ada peringkat

- Sikaflex PRO 3 WFDokumen4 halamanSikaflex PRO 3 WFfrahliaBelum ada peringkat

- TDS Cat Tembok Altex Naturetone PDFDokumen1 halamanTDS Cat Tembok Altex Naturetone PDFMunafri HairilBelum ada peringkat

- Nitowrap FRC: Constructive SolutionsDokumen2 halamanNitowrap FRC: Constructive SolutionsbinodBelum ada peringkat

- 1309267060binder2Dokumen38 halaman1309267060binder2CoolerAdsBelum ada peringkat

- Hempadur Primer 1530yDokumen4 halamanHempadur Primer 1530yRodrigo CondorettyBelum ada peringkat

- Royale Luxury Emulsion: Product BenefitsDokumen2 halamanRoyale Luxury Emulsion: Product BenefitsMoin RazaBelum ada peringkat