Tension Lift Frame Assembly

Diunggah oleh

Argonauta_navegadorHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tension Lift Frame Assembly

Diunggah oleh

Argonauta_navegadorHak Cipta:

Format Tersedia

TENSION LIFT FRAME

Innovative design suits coiled tubing and intervention

operations on MODUs

ICONs Tension Lift Frames (TLF) enable the successful

deployment of the down-hole completion tubing string

and tubing hanger in the well head, and coiled tubing

operations in MODUs.

Our TLF range is a fully tested, field proven integrated

system which has been used in a number of successful

well developments. When considering sourcing a

tension lift frame, the following advantages make

our product the logical choice:

Safety: ICONs TLF range has been designed with

safety in mind, and has a proven track record of

being easy and safe to install. It has been utilised on

numerous rigs for different clients, and time and

again has been safely rigged up and rigged down.

Rig-up Time: Minimising rig downtime is the single

most effective method of reducing overall project

costs. We believe that ICONs TLF achieves the

minimum rig downtime of any tension lift frame

currently available on the market. Our design has

been refined to enable quick and easy rig up and rig

down whilst complying with the most stringent

safety standards. Our system has been proven to

achieve a critical path rig up time of 3 to 4

hours.

Reliability: ICON has developed a fully tested, field

proven system. By following our maintenance

schedule, you can be sure that our TLF will be

certified and ready for deployment whenever it is

required.

Adaptability: Our system, although fully developed,

can be easily adapted to create differing working

windows, to allow access at varying levels, and to

interface with different surface test trees and

travelling blocks, giving the customer the flexibility of

requesting a unique solution if required. We have the

engineering resources and experience to adapt our

design to suit your requirements, without taking

away the peace of mind that comes from selecting a

field proven and tested system.

Quality: Our system is designed and fabricated to

meet stringent quality standards. ICON is an ISO

9001 quality accredited company that has a fully

integrated management system that encompasses all

aspects of project quality assurance and control. We

have experience in working with 3rd party verifiers,

including DNV, Lloyds and Bureau Veritas, in order

to meet all relevant code requirements.

ICON TLF Installed Inside a Drilling Derrick

Storage: Deck space is almost always an issue on a

rig. By utilising individual components such as bail

arms and spreader beams, our TLFs minimise the

amount of deck space required whilst still achieving

the large working windows that are typically

required.

Proven Experience: ICON has extensive experience

in the design and manufacture of TLFs. We have

worked with the high strength steels required to

interface with high strength, alloy steel bail arms,

and have developed a fabrication methodology that

alleviates any concerns about fatigue or microcracking.

We

understand

the

operational

requirements present in the offshore oil and gas

industry.

WE DELIVER PROJECTS THAT ARE OF THE HIGHEST

QUALITY,

MEET

STRINGENT

HSE

AND

DOCUMENTATION STANDARDS, ARE ON BUDGET

AND ON SCHEDULE.

1

Copyright ICON Engineering Pty Ltd 2012

ICON Engineering Pty Ltd

Level 1, 50 Kings Park Road

West Perth WA 6006, Australia

PO Box 915, West Perth WA 6872

Tel: +61 8 6313 5500

Fax: +61 8 6313 5599

Email: busdev@iconeng.com.au

Web: www.iconeng.com.au

TENSION LIFT FRAME

Innovative design suits coiled tubing and intervention

operations on MODUs

Standard Features

150 to 750 short tons (136 to 681 MT) standard

load ratings are available.

Standard 6 to 8 working widths are available,

larger widths available upon request.

Short Bail Arms interface with the rigs top drive

and the Upper Spreader Beam.

Upper Spreader Beam will be sized to create the

required working window and support a sheave,

winch or hoist for hauling in equipment.

Long Bail Arms interface with the upper and lower

spreader beam. Bail arm length will be selected to

accommodate

project

specific

equipment

requirements while minimising cost and stack up

height.

Lower Spreader Beam assembly complete with

access platform mounting points. This will include a

split insert and hang off collar customised to

interface with the project specific Surface Flow Tree.

Interface Testing Being Undertaken at ICONs Yard

Optional Features

ICON can tailor the TLF to meet a Clients unique

requirements. Optional features include:

Winch/Hoist for the installation of wire line and coil

tubing equipment. This will be selected to meet

Client requirements.

Access Platform between the long bails to allow

access to the lower end of the wire line lubricator

and the BOP. This can be single or dual level.

Certified Shipping Baskets and Skids can be

supplied to transport all equipment.

Full Completions Equipment Installation and

Interface Testing can be conducted at our Perth

based yard. This allows personnel to complete

interface testing and training for hauling in and

making up connections for PCE equipment.

Indicative Schematic of ICONs Standard TLF

ICON ALSO HAS A RANGE OF COMPENSATED

TENSION LIFT FRAMES (CTLFS) IF A HEAVE

COMPENSATED SOLUTION IS REQUIRED.

2

Copyright ICON Engineering Pty Ltd 2012

ICON Engineering Pty Ltd

Level 1, 50 Kings Park Road

West Perth WA 6006, Australia

PO Box 915, West Perth WA 6872

Tel: +61 8 6313 5500

Fax: +61 8 6313 5599

Email: busdev@iconeng.com.au

Web: www.iconeng.com.au

Anda mungkin juga menyukai

- 1HD-T - 1 Land Cruiser Engine Service ManualDokumen26 halaman1HD-T - 1 Land Cruiser Engine Service ManualMichael Dzidowski86% (7)

- Highh Mast LightingDokumen6 halamanHighh Mast LightingAyman SaberBelum ada peringkat

- High Mast Catalogue-CU PhoscoDokumen44 halamanHigh Mast Catalogue-CU PhoscoGuha Arnab100% (1)

- VHF Low Loss Band-Pass Helical Filter For 145 MHZ - English NewDokumen33 halamanVHF Low Loss Band-Pass Helical Filter For 145 MHZ - English NewSharbel AounBelum ada peringkat

- Innovex Product Catalog 2018Dokumen92 halamanInnovex Product Catalog 2018EduardoBelum ada peringkat

- Figure Union Identification Instructions-NEWDokumen4 halamanFigure Union Identification Instructions-NEWArgonauta_navegadorBelum ada peringkat

- Sluice Gates - Slide Gates - PenstocksDokumen28 halamanSluice Gates - Slide Gates - Penstocksnazar750100% (2)

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDokumen75 halamanWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieBelum ada peringkat

- Powershift TransmissionsDokumen27 halamanPowershift TransmissionsJonathanDavidDeLosSantosAdornoBelum ada peringkat

- Aluminium GMAW GuideDokumen32 halamanAluminium GMAW GuideDaniel Salinas100% (2)

- Hemispherical Head Design ToolDokumen1 halamanHemispherical Head Design Toolnaveen_86Belum ada peringkat

- RD339 (1MB File) Spreader BeamsDokumen20 halamanRD339 (1MB File) Spreader BeamsnamasralBelum ada peringkat

- Protection Systems TransformerDokumen14 halamanProtection Systems Transformerrajabharath12Belum ada peringkat

- Atm Storage CBIDokumen8 halamanAtm Storage CBIJeEJyZaBelum ada peringkat

- Builder's Greywater Guide Branched DrainDokumen4 halamanBuilder's Greywater Guide Branched DrainGreen Action Sustainable Technology GroupBelum ada peringkat

- Kirby Corporate BrochureDokumen48 halamanKirby Corporate Brochurecpersels001Belum ada peringkat

- Riser and ConductorDokumen12 halamanRiser and Conductoraskannancv100% (1)

- Cuplok Access Scaffold System-11Dokumen24 halamanCuplok Access Scaffold System-11JijithpillaiBelum ada peringkat

- Offcom Completa - v.01Dokumen7 halamanOffcom Completa - v.01Argonauta_navegadorBelum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design ToolMohammad Kamal HabbabaBelum ada peringkat

- Highh Mast LightingDokumen6 halamanHighh Mast LightingAsghar KhanBelum ada peringkat

- MIL STD 120 Gage InspectionDokumen216 halamanMIL STD 120 Gage Inspectionokamo100% (4)

- Cooling TowerDokumen72 halamanCooling TowerRobert Nixon100% (1)

- Deploying Certificates Cisco Meeting Server: Design your certificates for CMS services and integrate with Cisco UCM Expressway and TMSDari EverandDeploying Certificates Cisco Meeting Server: Design your certificates for CMS services and integrate with Cisco UCM Expressway and TMSBelum ada peringkat

- KONE - Travel Master 110Dokumen8 halamanKONE - Travel Master 110ratnasekhar_gBelum ada peringkat

- WBIFR Systems GuideDokumen27 halamanWBIFR Systems GuideneerajtrvBelum ada peringkat

- D-002 System Requirements Well Intervention EquipmentDokumen70 halamanD-002 System Requirements Well Intervention Equipmentbrucce13Belum ada peringkat

- Transfer Solutions Loading EquipmentDokumen33 halamanTransfer Solutions Loading EquipmentPimpisValentasBelum ada peringkat

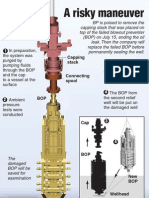

- Diagram of The Blowout PreventerDokumen1 halamanDiagram of The Blowout PreventerThe State NewspaperBelum ada peringkat

- Aluminum Floating Roofs, Seals & Oil/Water CoversDokumen8 halamanAluminum Floating Roofs, Seals & Oil/Water CoversLDPBelum ada peringkat

- Factors Effecting PerformanceDokumen47 halamanFactors Effecting Performancebembie83Belum ada peringkat

- Catalog Bucket Elevator and Bucket FMCDokumen33 halamanCatalog Bucket Elevator and Bucket FMCPercy TorresBelum ada peringkat

- Hydraulic Buffer For ElevatorDokumen32 halamanHydraulic Buffer For ElevatorFERNSBelum ada peringkat

- #01 DSLBrochureDokumen36 halaman#01 DSLBrochureKiryaki FrancisBelum ada peringkat

- Engine Roof - Support - SystemsDokumen8 halamanEngine Roof - Support - SystemsAustinBelum ada peringkat

- Hydraulic BuffersDokumen30 halamanHydraulic Buffersfurosh023Belum ada peringkat

- Swing Lo 2012 Product BookDokumen72 halamanSwing Lo 2012 Product BookLeviBelum ada peringkat

- Offshore SteelDokumen42 halamanOffshore SteelPuvas NandakwangBelum ada peringkat

- 8803 CS Systems Brochure - EN 1 PDFDokumen20 halaman8803 CS Systems Brochure - EN 1 PDFAnonymous jW9BkgbQmEBelum ada peringkat

- Voltas LTD: Internship ReportDokumen14 halamanVoltas LTD: Internship ReportbelkarabhiBelum ada peringkat

- Big Foot Systems Product GuideDokumen24 halamanBig Foot Systems Product GuidehellwhynotBelum ada peringkat

- Bilco UK-Catalog-14Dokumen60 halamanBilco UK-Catalog-14Anthony Angell-AllpassBelum ada peringkat

- Bollards BrochureDokumen44 halamanBollards Brochure8fsv8vpt84Belum ada peringkat

- Enfriadores-Modine Air Blast Cooler - A4 PDFDokumen16 halamanEnfriadores-Modine Air Blast Cooler - A4 PDFAlejandro GarcíaBelum ada peringkat

- Keltbray Piling Capability Document (Circa 2013)Dokumen31 halamanKeltbray Piling Capability Document (Circa 2013)sandycastleBelum ada peringkat

- Saudi Cranes CatalogueDokumen21 halamanSaudi Cranes CatalogueNarayan PrasadBelum ada peringkat

- 2013 Hot StabDokumen8 halaman2013 Hot StabsiswoutBelum ada peringkat

- 05fd3059b7e730dacb756f9e61a425f5Dokumen12 halaman05fd3059b7e730dacb756f9e61a425f5yzmouseBelum ada peringkat

- TDITBI CALevel3 CatalogDokumen24 halamanTDITBI CALevel3 Catalogbladeliger22Belum ada peringkat

- Meeka Machinery PVT LTDDokumen32 halamanMeeka Machinery PVT LTDMeeka Machinery Pvt. Ltd.Belum ada peringkat

- Your Most Responsive Partner For Control SolutionsDokumen20 halamanYour Most Responsive Partner For Control SolutionsROI MADE SASBelum ada peringkat

- BVI FlexiTube 7-2012Dokumen8 halamanBVI FlexiTube 7-2012nguyenvanhai19031981Belum ada peringkat

- Tynegangway Brochure PDFDokumen12 halamanTynegangway Brochure PDFghanbari8668Belum ada peringkat

- Giraffe EngDokumen13 halamanGiraffe Engmuhammad afrizalBelum ada peringkat

- Modus Operandi - Proflex - Self Supported Roof - All Technical DetailsDokumen19 halamanModus Operandi - Proflex - Self Supported Roof - All Technical Detailsuday Ravi100% (1)

- Tower Field Service 092015Dokumen8 halamanTower Field Service 092015Shankar CoolBelum ada peringkat

- CCL Pre TensioninglrDokumen12 halamanCCL Pre TensioninglrjejeferminBelum ada peringkat

- Aerospace Products BrochureDokumen15 halamanAerospace Products BrochurempsctBelum ada peringkat

- Effective Fall Prevention Measures For Working at HeightDokumen59 halamanEffective Fall Prevention Measures For Working at HeightakubestlahBelum ada peringkat

- Advancetech Products Data SheetDokumen3 halamanAdvancetech Products Data SheetRanjit S KashyapBelum ada peringkat

- Steelway Group Brochure 2010Dokumen8 halamanSteelway Group Brochure 2010Laura EddowesBelum ada peringkat

- Limit SwitchDokumen16 halamanLimit SwitchNam PhanBelum ada peringkat

- Boss_Scaffold_Tower_Spec_SheetDokumen12 halamanBoss_Scaffold_Tower_Spec_Sheetrichardmunslow31Belum ada peringkat

- Böllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Dokumen3 halamanBöllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Eldori1988Belum ada peringkat

- Al Burraq Aluminium For Aluminium & Glass Works in UAEDokumen27 halamanAl Burraq Aluminium For Aluminium & Glass Works in UAEShakeel AhmadBelum ada peringkat

- CIPLDokumen8 halamanCIPLbountymaniBelum ada peringkat

- Brochure Pl3005e Pl4809e Stagev en 21 20057591 ADokumen20 halamanBrochure Pl3005e Pl4809e Stagev en 21 20057591 AdeepakgkdBelum ada peringkat

- BrochureDokumen4 halamanBrochureJulius Ceasar SanorjoBelum ada peringkat

- Industrial: Gas Hydraulic BuffersDokumen15 halamanIndustrial: Gas Hydraulic BuffersJovie GrohlBelum ada peringkat

- Transporter BrochureDokumen8 halamanTransporter BrochuresandrofriasBelum ada peringkat

- Crane KitsDokumen18 halamanCrane KitsMiguel MachadoBelum ada peringkat

- SystemVerilog for Hardware Description: RTL Design and VerificationDari EverandSystemVerilog for Hardware Description: RTL Design and VerificationBelum ada peringkat

- 2.1-16'' 30MDokumen1 halaman2.1-16'' 30MArgonauta_navegadorBelum ada peringkat

- 2.1-16'' 20MDokumen1 halaman2.1-16'' 20MArgonauta_navegadorBelum ada peringkat

- 1.13-16'' 30MDokumen1 halaman1.13-16'' 30MArgonauta_navegadorBelum ada peringkat

- 1.13-16'' 10MDokumen1 halaman1.13-16'' 10MArgonauta_navegadorBelum ada peringkat

- 2.1-16'' 10MDokumen1 halaman2.1-16'' 10MArgonauta_navegadorBelum ada peringkat

- 1.13-16'' 5MDokumen1 halaman1.13-16'' 5MArgonauta_navegadorBelum ada peringkat

- 2.1-16'' 2MDokumen1 halaman2.1-16'' 2MArgonauta_navegadorBelum ada peringkat

- 2.1-16'' 15MDokumen1 halaman2.1-16'' 15MArgonauta_navegadorBelum ada peringkat

- 2.1-16'' 5MDokumen1 halaman2.1-16'' 5MArgonauta_navegadorBelum ada peringkat

- 1.25-32'' 10M - 2.5'' 2900Dokumen1 halaman1.25-32'' 10M - 2.5'' 2900Argonauta_navegadorBelum ada peringkat

- 1.13-16'' 15MDokumen1 halaman1.13-16'' 15MArgonauta_navegadorBelum ada peringkat

- 1.13-16'' 20mDokumen1 halaman1.13-16'' 20mArgonauta_navegadorBelum ada peringkat

- 1.11-16'' 15MDokumen1 halaman1.11-16'' 15MArgonauta_navegadorBelum ada peringkat

- 1.13-16'' 2MDokumen1 halaman1.13-16'' 2MArgonauta_navegadorBelum ada peringkat

- API 53 Principais Mudanças - 4edição Vs 3 EdiçãoDokumen39 halamanAPI 53 Principais Mudanças - 4edição Vs 3 EdiçãoArgonauta_navegadorBelum ada peringkat

- D 001Dokumen51 halamanD 001E_Amr_SorourBelum ada peringkat

- Ball Injector O&m InstructionDokumen12 halamanBall Injector O&m InstructionArgonauta_navegadorBelum ada peringkat

- 2.starting Up ANSYSDokumen2 halaman2.starting Up ANSYSnishantsinghbmeBelum ada peringkat

- Introduction AnsysDokumen1 halamanIntroduction AnsysRicardo BrancoBelum ada peringkat

- FCE Well Testing Alert Rev 1 - CompletDokumen6 halamanFCE Well Testing Alert Rev 1 - CompletOscar Gomez GonzalezBelum ada peringkat

- Introduction AnsysDokumen1 halamanIntroduction AnsysRicardo BrancoBelum ada peringkat

- Pipe Fittings Type ApprovalDokumen5 halamanPipe Fittings Type ApprovalArgonauta_navegadorBelum ada peringkat

- Presentation On BAJAJDokumen19 halamanPresentation On BAJAJVaibhav AgarwalBelum ada peringkat

- BSC Prospectus 2019-20Dokumen37 halamanBSC Prospectus 2019-20Gaurav VamjaBelum ada peringkat

- Item No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesDokumen23 halamanItem No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesSaša StankovićBelum ada peringkat

- ESG Service Information: BackgroundDokumen6 halamanESG Service Information: BackgroundAbdulSattarBelum ada peringkat

- Alpema Standerd For Brazed Aluminium Plate-Fin Heat ExchDokumen78 halamanAlpema Standerd For Brazed Aluminium Plate-Fin Heat ExchBilal NazirBelum ada peringkat

- Vlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyDokumen12 halamanVlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyRaghul VishnuBelum ada peringkat

- RS-485 2X227 AWG SFUTP PVC - 9FY7F1V129 - V - 1 - R - 1Dokumen2 halamanRS-485 2X227 AWG SFUTP PVC - 9FY7F1V129 - V - 1 - R - 1jeffv65Belum ada peringkat

- Chapter-Iv: Profile of The Hindu News PaperDokumen5 halamanChapter-Iv: Profile of The Hindu News PaperMurugan SaravananBelum ada peringkat

- Stereoscopic Restitution Instruments: Materi Kuliah GD3204 Fotogrametri I, Semester I-2009/2010Dokumen50 halamanStereoscopic Restitution Instruments: Materi Kuliah GD3204 Fotogrametri I, Semester I-2009/2010ththaalBelum ada peringkat

- Plett DawsonDokumen270 halamanPlett DawsonRaghu0% (1)

- RCE Unpacking Ebook (Translated by LithiumLi) - UnprotectedDokumen2.342 halamanRCE Unpacking Ebook (Translated by LithiumLi) - Unprotecteddryten7507Belum ada peringkat

- Tyre ManufacturingDokumen18 halamanTyre ManufacturingniteshkrisBelum ada peringkat

- Module 8 SAHITA ConcreteDokumen11 halamanModule 8 SAHITA ConcreteHarrybfnBelum ada peringkat

- BNF Syntax of Ruby - Less than 40 character title for Ruby BNF syntax documentDokumen2 halamanBNF Syntax of Ruby - Less than 40 character title for Ruby BNF syntax documentChristian FerrazBelum ada peringkat

- Infantry WeaponsDokumen61 halamanInfantry WeaponsKaran SahotaBelum ada peringkat

- Scrap NFL PanipatDokumen9 halamanScrap NFL PanipatJitenderSinghBelum ada peringkat

- PET ImagingDokumen54 halamanPET ImagingNana AkwaboahBelum ada peringkat

- Design of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockDokumen10 halamanDesign of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockStalynMEcBelum ada peringkat

- Chapter 11B: Survey of Database SystemsDokumen17 halamanChapter 11B: Survey of Database SystemsMurtaza MoizBelum ada peringkat

- Gysmi-Note UC3845BDGDokumen1 halamanGysmi-Note UC3845BDGfrance locatelBelum ada peringkat

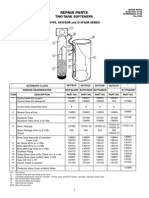

- Star S07FS32DR Water Softener Repair PartsDokumen1 halamanStar S07FS32DR Water Softener Repair PartsBillBelum ada peringkat

- ISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)Dokumen16 halamanISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)SantoshBelum ada peringkat

- 7.qad-Dpr-11 ImteDokumen4 halaman7.qad-Dpr-11 ImteDhinakaranBelum ada peringkat