HT Agitators

Diunggah oleh

Santoshkota123Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

HT Agitators

Diunggah oleh

Santoshkota123Hak Cipta:

Format Tersedia

HT Bulletin_9-1.

qxd

10/4/05

8:34 AM

Page 2

HT Agitators

Reliable

Proven Performance

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 3

Proven Performance

The HT agitator is Chemineers premium

product offering that features a gearbox specifically designed for mixing

applications. Available in both bottom

and top entering designs, this rugged

performer can be tailored to meet virtually any process from critical chemical

reactor systems to routine storage

applications. Its superior design offers

high strength, low wear, quiet operation, and minimum maintenance.

The reliable and rugged HT agitator

has provided long, trouble free service

in harsh, demanding applications. For

open or closed tanks, the HT agitator

is the industry standard of reliability

and technology in mixing.

Drive Features

Internal Shafting

Positive Lubrication

Low-speed internal shaft short bearing span

Splash lubrication continuously protects gearing

reduces deflection and harmful gear misalignment

Low-speed shafts have extra large cross sections

for maximum rigidity

and high-speed bearings

A dry well low-speed shaft seal prevents oil leakage

Lubrication options for high temperature service

or low speed applications include an external oil

Protective Finish

External surfaces are protected with a catalyzed

polyurethane finish suitable for indoor or

pump and an oil cooling system

Oil heaters are available for extremely low

temperature environments

outdoor installations.

Quiet Performance

Extra-Capacity Tapered

Roller Bearings

The high quality of the gears and other internal

The tapered roller design handles both the radial

components, and precise NC machining of the drive

housing contribute to quiet performance well below

maximum recommended noise levels of 85 dbA.

and axial loads common to agitator drive service

Standard tapered roller bearing service rating of

over 100,000 hours L-10 life throughout the drive

For simplified maintenance and prevention of housing wear, low-speed bearings are carrier mounted

and can be replaced without special tools

www.chemineer.com

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 6

Drive Internals

The first reduction helical change gears

are spline or taper hub mounted for easy

removal and replacement. Removing the

change gear cover provides direct access

to the change gears without the need to

disturb other internal parts or the motor.

Second reduction spiral bevel gearing

offers low wear for long service, and

provides class-leading efficiency for rightangle power transmission.

Magnetic drain plug is included as standard

Hardened helical gears precision hobbed and

shaved to exact tolerances for proper contact

and wear

Spiral bevel gearing is precision generated,

matched, lapped, and individually marked for

accurate fit and alignment

Easily accessible grease fittings lubricate low

speed shaft bearings

The chemical duty paint finish protects against

water, acid, or caustic environments, and is

extremely resistant to wear and abrasion

Rugged, fabricated gear drive housing

Dry well seal prevents process fluid contamination

1. High-speed shaft

11. Spiral bevel gear

2. High-speed bearing

cap

12. Low-speed shaft

3. Lip seal

4. High-speed shaft

bearings (2)

5. Bearing support

blocks (2)

All shafts are precision turned on NC lathes for

dimensional consistency and straightness

13. Upper low-speed

bearing

14. Bearing cap

Additional Features

15. Lower low-speed

bearing

Standard foot mounted motor

6. Change gear cover

16. Lower low-speed

bearing cap

7. Change pinion

17. Lip seal

8. Change gear

18. Dry well

9. Bevel pinion shaft

bearings (2)

19. Housing

Compact, high-efficiency, right-angle double

reduction drive

10. Spiral bevel pinion

www.chemineer.com

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 7

Shaft Seals

Seal Mounting

Single Mechanical Seal

The single dry-running mechanical seal is a suit-

Shaft seals attach directly to the integral ANSI mounting

able choice for applications where a pressurized

flange on pedestal-mounted agitators. All shaft seals

barrier between the tank contents and the outside

are also available as auxiliary units with beam

environment is not necessary.

mounted gearbox.

Shut-Off Systems

Optional shaft shut-off systems allow seal change

without the leakage of process fluid or pressure loss.

Types of Seals

A wide selection of shaft seals is available for closed

tank processes.

Lip Seal

Single Mechanical Seal

The spring-loaded elastomeric lip seal protects

process fluid from dust or atmospheric contamination

Split Mechanical Seal

in low pressure, lower temperature applications.

Split mechanical seals feature a two-piece design

that simplifies installation and maintenance.

Stuffing Box

Double Mechanical Cartridge Seal

A six-ring stuffing box incorporates a lantern ring and

grease fitting to maintain lubrication. A three-ring

Double mechanical seals can offer the most com-

design is available for low-pressure applications.

plete protection against leakage of hazardous or

flammable fluids, as well as long life and minimum

maintenance. Chemineers standard cartridge

includes an integral bearing in the cartridge to

reduce shaft deflection and increase seal life.

The cartridge construction greatly simplifies seal

removal and installation. The seal cartridge removes

Cha

as a unit, without disturbing the agitator drive.

Case

Size

Model

Stuffing Box

1

HTA

HTD

HTN

HTNS,

HTAL,

HTP

HTA

2

HTD

HTN

HTL

Mechanical & Seals

B

C

D

E

F

G

H

J

R

T

U

V

The cartridge unit can be rebuilt and statically or

dynamically bench tested prior to installation.

HTNS,

HTAL,

& HTL

HTP

HTA

HTD

HTN

HTNS,

HTAL,

& HTL

HTP

HTA

HTD

HTN

HTNS,

HTAL,

& HTL

HTA

HTD

HTN

HTNS,

HTAL,

& HTL

7-1/2" for all models

9" for all models

10-1/2" for all models

14" for all models

15" for all models

9" for all models

10" for all models

11-1/2" for all models

13-1/2" for all models

15-1/2" for all models

Mechanical seals are offered in materials selected for

the 31-1/2"

process.

well-known

13" The

40" seals

25-1/2" are

25-1/2"supplied

35"

15"from

43-1/2"

29-1/2" 29-1/2"

39-1/2" 16-1/2" 47-1/2" 32-1/2" 32-1/2"

29" are

9" available

38" 23-1/2"for

26-1/2"

7-1/2" 35" 20-1/2"

20-1/2" seals

seal 26"

manufacturers.

Special

33"

8"

1"

10"

8"

3/4"

10"

8" temperature

1"

high 8"pressure

and/or

applications.

8"

1"

1"

10-1/2" 41-1/2" 26-1/2" 26-1/2"

10"

8"

1"

43"

19"

51-1/2" 37-1/2" 37-1/2"

37"

12"

45"

12"

1-1/8"

12"

31-1/2" 31-1/2"

12"

1-1/4"

HTP

12"

1-1/8"

48"

12"

18

33-1/2" 33-1/2"

12"

HTD

16

46-1/2" 20-1/2" 55-1/2" 40-1/2" 40-1/2"

39-1/2" 13-1/2"

HTA

48-1/2" 21-1/

41"

14"

1-1/4"

12"

1-1/4

11"

5"

6"

5"

5"

6-1/2"

7"

6-1/2" 6-1/2"

7"

8-1/2"

7"

7"

8"

10"

8"

8"

9-1/2"

11"

9-1/2" 9-1/2"

10-1/2"

10"

10"

10"

10"

12-1/2"

11"

12-1/2" 12-1/2"

14"

12"

14"

14"

16"

13"

16"

16"

18-1/2"

14"

18-1/2" 18-1/2"

20-1/2"

17"

18-1/2"

17"

23"

25"

25-1/

5"

6-1/2"

7"

7-1/2"

9-1/2"

10-1/

5-1/2"

6-1/2"

7-1/2"

9-1/2

3-1/2" for all models

3" for all models

6" for all models

4-1/2" for all models

2-1/2" for all models

2" for all models

8"

www.chemineer.com

4" for all models

7-1/2" for all models

6-1/2" for all models

Double Mechanical Seal

HTP

8-1/2" for all models

9"

15"

8-1

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 10

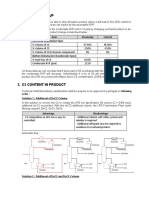

Seal Change Procedure

The double mechanical seal cartridge is removed in

four simple steps requiring no special tools or blocking:

Less than 1/2"

gap resulting

from drop

into mounting

flange catcher

bracket

1. Unbolt the spacer spool between the reducer output

and agitator extension shaft. The extension shaft drops

less than 12" into a catcher bracket in the mounting

flange to support the shaft and impeller weight.

2. Remove spacer spool.

3. Remove tapered shaft coupling half located above

the seal cartridge.

4. Unbolt and slide the entire seal assembly off the

Step 1

extension shaft.

Benefits

The gearbox does not need to be removed or disturbed during a seal change

The seal arrangement allows for a seal to be changed

faster and more consistently than any other system,

regardless of agitator size or age

A Jacks-n-Rails system is available to simplify

removal and installation of large cartridge seals

Seal shut-off available

Step 2

Shaft will not disengage from steady bearing

Step 3

Mounting Options

Adaptable to Any Tank

ions

6

TNS,

TAL, HTP

HTL

HTA

HTD

HTN

HT agitators are adaptable to any vertical mounting

configuration on open

7 or nozzle mounted

8 closed tanks.

9

HTNS,

HTAL,

& HTL

ls

16" for all models

Steel

dels

18" for all models

-1/2" 40-1/2"

48-1/2" 21-1/2" 58-1/2" 42-1/2" 42-1/2"

41"

14"

51"

12"

1-1/4"

12"

1-1/4"

12"

-1/2"

10-1/2"

11"

10-1/2" 10-1/2"

-1/2"

20-1/2"

15"

20-1/2" 20-1/2"

25-1/2"

10-1/2"

35"

35"

9-1/2"

28"

67-1/2" 50-1/2"

45-1/2" 17-1/2" 57-1/2" 40-1/2"

12" for all models

HTD

HTN

HTA

HTD

HTN

59"

30"

72"

48-1/2" 19-1/2" 61-1/2"

1-3/4"

16"

14-1/2" 13-1/2" 14-1/2"

68"

32"

78-1/2"

52-1/2"

22"

68"

20"

1-3/4"

20"

Model 6HTN-20 with double

mechanical cartridge seal

pedestal mounted to a

closed tank

16-1/2" 14-1/2" 16-1/2"

HT agitators can be supplied with a fabricated steel support

24-1/2" 16" 24-1/2" 24-1/2"

32-1/2" 18" 32-1/2"

29"

17"

29"

pedestal

directly

nozzle.

to mount

27" the agitator

29-1/2"

28"to the

vessel

5" for all models

models

for all models

pedestal design

includes a5-1/2"

standard

ANSI 6-1/2"

150forlballflange

High

8-1/2" for all models

56-1/2"

16" 1-1/2" Tanks

16"

16"

12" 1-1/4"

16"

On

Closed

4" for all models

The

dels

HTA

for all models plates

21-1/2"

all models

23-1/2"

for gear

all models

plate feet18-1/2"

or mounting

areforincluded

on

the

drive

22-1/2" for all models

25" for all models

28-1/2" for all models

to mount the agitator to beams or other supporting structures.

-1/2" 33-1/2"

HTNS,

HTA HTD HTN HTAL,

On HTPOpen

Tanks

& HTL

12-1/2"

14-1/2"

16-1/2"

pressure

custom flanges

are

available

11" and

for all models

14-1/2" for all models

13" for all

models

10"

11"

Bottom

entry applications

can

be flange

mounted,

or 12"

independently mounted with a separate seal assembly.

www.chemineer.com

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 11

Shaft Design

Both process and mechanical considerations determine

shaft design. Shafts are sized to resist torsional loads and

bending moments induced by hydraulic forces acting on

the impeller, as well as to avoid excessive vibration due

to coincidence of critical frequencies and operating speed.

Shafting is straightened to tight tolerances less than

0.003 inches total run out per foot of shaft length (0.25 mm

per meter) for long seal life and smooth operation.

Custom couplings, impellers, shafting, and steady bearings

are available upon request, including sanitary designs.

Types

Shafting is supplied in a single piece design or in rigidly

coupled sections for easy installation. For large diameter

shafts, pipe shafting is a viable option with couplings and

impeller hubs welded to the shafting.

Couplings

Standard top-entering shaft seal

arrangement. Model HTN

pedestal-mounted agitator.

To facilitate assembly in the field, extension shafts are

attached to the drive shaft with flanged rigid couplings,

therefore shafts do not need to be installed through the

gearbox. The couplings can either be removable tapered

bore coupling halves or welded coupling halves. Intank couplings simplify installation of long shafts.

Steady Bearings

Bottom-entering

shaft seal used

with a flexibly

coupled,

independently

mounted

HBP drive.

Steady bearings are available to help support extremely

long shafts. Cup tripod, bracket, and pad-type steady

bearings are standard design options.

Extended Keyways

Extended keyways for adjusting impeller location offer

process and design flexibility.

Cup Tripod

Steady Bearing

www.chemineer.com

Bracket Steady Bearing

Welded Coupling

Removable Coupling

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 12

Process Technology & Innovation

Chemineer brings proven technical expertise to each

Laser Induced Fluorescence (LIF) enables the user

mixing solution, from basic mixer and impeller

to gain a fundamental understanding of mixing

design through complex process application analysis.

by tracking the path and diffusion of injectants

Combined with proprietary data evaluation method-

in agitated vessels and static mixers

ology and extensive field experience, Chemineer

CEDS (Chemineer Expert Design System) the

provides the most accurate application evaluation

industry leader in agitator design and analysis soft-

possible. Let Chemineer optimize your process, saving

ware. This proprietary program suite optimizes

you time and money, by applying our experience and

process performance, in addition to mechanical

state-of-the-art tools, such as:

integrity, strength, and reliability.

Chemineers high-tech customer test lab offers the

most advanced testing techniques in industry

Computational Fluid Dynamics (CFD) provides visual

projections of mixer performance in the mixing tank

ChemScale the industry standard method for

effective mixer selection that helps to optimize the

agitator design for your specific process needs

The Chemineer Liquid Agitation series of articles is

by generating a series of mathematical models of

available with agitation process and mechanical

fluid flows (Bulletin 750 is available with addi-

details

tional information.)

A library of Chemineer technical articles is available

Digital Particle Image Velocimetry (DPIV)provides

on the web site at www.chemineer.com/techarticles

instantaneous flow visualization and quantitative

measurement of the fluid velocity field in the mixing

tank (Bulletin 755 is available with additional infor-

Capabilities bulletin, 712, is available with additional

information

mation.)

Laser Doppler Anemometry (LDA) corroborates

time averaged DPIV data, especially for velocity

fields in the vicinity of the impeller

Examples of CFD Modeled Flow Fields

www.chemineer.com

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 9

Dimensions

LIFTING LUGS

CASE 1-6 (3) EYES

CASE 7-10 (4) LUGS

2"

MAX.

LIFTING LUGS

CASE 1-6 (3) EYES

CASE 7-10 (4) LUGS

4"

MAX.

P

DIA.

P

DIA.

H

U

2" MAX.

2" MAX.

R

M

M

L

H

U

P

DIA.

P

DIA.

4 HOLE DRILLING

CASE 1-6 "S" DIA.

6 HOLE DRILLING

CASE 7-10 "S" DIA.

P

DIA.

LIFTING LUGS

CASE 1-6 (3) EYES

CASE 7-10 (4) LUGS

4"

MAX.

P

DIA.

D

E

G MAX.

H MIN.

J MIN.

AUXILIARY LIPSEAL

(OPTIONAL)

AUXILIARY

STUFFING BOX

(OPTIONAL)

IN-TANK COUPLING

(OPTIONAL)

'F'-150# ANSI FLANGE

BOLT HOLES

3

STRADDLE CL.

'F'-150# ANSI FLANGE

BOLT HOLES

3

STRADDLE CL.

2

2

HTD

HTA

HTN

Dimensions

CASE

SIZE

MODEL

1

HTA

HTNS,

HTD HTN HTAL, HTP

& HTL

HTNS,

HTD HTN HTAL, HTP

& HTL

HTA

HTNS,

HTD HTN HTAL, HTP

& HTL

HTA

HTNS,

HTD HTN HTAL, HTP

& HTL

HTA

HTNS,

HTD HTN HTAL, HTP

& HTL

7-1/2" for all models

9" for all models

10-1/2" for all models

14" for all models

15" for all models

9" for all models

10" for all models

11-1/2" for all models

13-1/2" for all models

15-1/2" for all models

31-1/2"

13"

40"

25-1/2" 25-1/2"

35"

26"

7-1/2"

35"

20-1/2" 20-1/2"

29"

9"

38"

8"

3/4"

10"

8"

1"

10"

8"

1"

15"

43-1/2" 29-1/2" 29-1/2"

23-1/2" 23-1/2"

8"

1"

39-1/2" 16-1/2" 47-1/2" 32-1/2" 32-1/2"

33"

10-1/2" 41-1/2" 26-1/2" 26-1/2"

8"

1"

10"

8"

1"

43"

19"

51-1/2" 37-1/2" 37-1/2"

37"

12"

45"

12"

1-1/8"

12"

31-1/2" 31-1/2"

12"

1-1/4"

12"

1-1/8"

48"

12"

18"

33-1/2" 33-1/2"

12"

HTD

16"

46-1/2" 20-1/2" 55-1/2" 40-1/2" 40-1/2"

39-1/2" 13-1/2"

HTA

48-1/2" 21-1/2

41"

14"

1-1/4"

12"

1-1/4"

11"

5"

6"

5"

5"

6-1/2"

7"

6-1/2" 6-1/2"

7"

8-1/2"

7"

7"

8"

10"

8"

8"

9-1/2"

11"

9-1/2" 9-1/2"

10-1/2"

10"

10"

10"

10"

12-1/2"

11"

12-1/2" 12-1/2"

14"

12"

14"

14"

16"

13"

16"

16"

18-1/2"

14"

18-1/2" 18-1/2"

20-1/2"

15"

17"

18-1/2"

21-1/2"

23"

25"

25-1/2

5"

6-1/2"

7"

9-1/2"

10-1/2

5-1/2"

6-1/2"

7-1/2"

9-1/2"

www.chemineer.com

3-1/2" for all models

3" for all models

6" for all models

4-1/2" for all models

U

V

2-1/2" for all models

2" for all models

HTA

8"

4" for all models

7-1/2" for all models

6-1/2" for all models

8"

4" f

8-1/2" for all models

9"

8-1/2

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 8

Dimensions

(3) LIFTING EYES

LIFTING LUGS

CASE 1-6 (3) EYES

CASE 7-10 (4) LUGS

4"

MAX.

2" MAX.

Motor Dimensions

2" MAX.

P

DIA.

P

DIA.

1150

RPM

H

U

H.P.

U

U

1

N

4 HOLE DRILLING

"S" DIA.

P

DIA.

DIA.

145T

13"

182T

14-3/8"

184T

15-3/8"

7-1/2

213T

18"

10

215T

19-1/2"

7-1/2

15

254T

22-7/8"

10

20

256T

24-5/8"

15

25

284T

26-5/8"

20

30

286T

28-1/8"

25

40

324T

29-5/8"

30

50

326T

31-1/8"

40

60

364TS

30-3/4"

50

75

365TS

31-3/4"

P

DIA.

E

F

'F'-150# ANSI FLANGE

BOLT HOLES

3

---

1-1/2

K

B

FRAME

7-3/4"

1750

RPM

STRADDLE CL.

HTNS, HTAL, HTL

HTP

75

100

405TS

35"

100

125

444TS

38-1/2"

125

150

445TS

40-1/2"

150

200

447TS

200

250

447TS

250

300

449TS

9-1/4"

11"

12-3/4"

14-1/2"

16-7/8"

18-1/2"

20-7/8"

23-7/8"

47-1/2"

25"

51-1/2"

29"

Mounting Dimensions

MOUNTING DIMENSIONS

CASE

SIZE

1HTD

1HTP

2HTD

16"

2HTP

3HTD

4HTD

4HTP

5HTD

5HTP

6HTD

6 HTP

7HTD

HTA

25"

22-1/2"

25"

25"

16"

34"

38-1/2"

41"

10"

11-1/2"

16-1/2"

16-1/2"

18-1/2"

21"

22"

26"

33"

3-1/4"

4-1/4"

4-3/4"

7-1/4"

7-1/4"

8-1/4"

9-1/4"

9-1/2"

11-1/2"

15"

5-5/8"

7-1/4"

7"

7-1/4"

8"

7-1/4"

9-1/8"

11-1/4"

10"

11-1/4"

11-1/4"

18"

15-3/4"

17-3/4"

19"

21"

5/8"

3/4"

5/8"

3/4"

3/4"

3/4"

7/8"

7/8"

7/8"

7/8"

7/8"

7/8"

1"

1-1/8"

1-1/8"

1-1/8"

16-1/2"

16-1/2"

HTNS,

HTD HTN HTAL, HTP

& HTL

HTA

HTNS,

HTD HTN HTAL,

& HTL

HTA

HTD HTN

HTA

HTD HTN

16" for all models

18-1/2" for all models

21-1/2" for all models

23-1/2" for all models

18" for all models

22-1/2" for all models

25" for all models

28-1/2" for all models

48-1/2" 21-1/2" 58-1/2" 42-1/2" 42-1/2" 56-1/2"

41"

14"

51"

35"

35"

12"

1-1/4"

12"

1-1/4"

12"

12"

1-1/4"

9-1/2"

10-1/2"

11"

10-1/2" 10-1/2"

8-1/2"

20-1/2"

15"

20-1/2" 20-1/2"

25-1/2"

10-1/2"

els

16"

9-1/2"

1-1/2"

16"

16"

12-1/2" for all models

24-1/2"

16"

27"

24-1/2" 24-1/2"

12-1/2"

10"

30"

72"

48-1/2" 19-1/2" 61-1/2"

16"

1-3/4"

16"

26-1/2" for all models

36" for all models

32"

78-1/2"

74"

52-1/2"

22"

68"

20"

1-3/4"

20"

16-1/2" 14-1/2" 16-1/2"

HTD HTN

37"

88-1/2"

61"

24"

75-1/2"

24"

1-3/4"

24"

18-1/2" 17-1/2" 18-1/2"

17"

29"

32-1/2"

18"

32-1/2"

37"

21"

37"

28"

29-1/2"

35-1/2"

14-1/2"

13" for all models

68"

HTA

29"

5-1/2" for all models

11" for all models

59"

14-1/2" 13-1/2" 14-1/2"

5" for all models

8-1/2" for all models

67-1/2" 50-1/2"

45-1/2" 17-1/2" 57-1/2" 40-1/2"

4" for all models

odels

28"

10

odels

33-1/2" 33-1/2"

45"

20-1/2"

8"

dels

40-1/2" 40-1/2"

10HTD

13"

6

HTP

9HTD

Chart

HTNS,

HTAL,

& HTL

8HTD

16-1/2"

18"

3HTP

11"

6-1/2" for all models

16-1/2"

14-1/2" for all models

12"

7-1/2" for all models

18-1/2"

Dimensions are for totally enclosed

and explosion-proof motors.

Agitator output speed, shaft diameter

and extension, impeller design and

other optional features to suit application.

Larger and smaller flanges available,

however in most cases, the smaller

than standard flange dictates on

centerline bolt holes and studs.

Varies per case and shaft diameter

selection. Refer to certified assembly

drawing for actual dimension.

16-1/2" for all models

13-1/2"

www.chemineer.com

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 5

Aftermarket & Technical Support

Quality Assurance

Troubleshooting

HT agitators are manufactured in the Chemineer factory,

A Chemineer engineer can be made available for

providing us with total control of product design and

troubleshooting your HT agitator. The engineer will

quality. Every drive is run tested, then opened for a

know your equipment and through years of experi-

complete internal inspection. Gears are individually

ence and technical expertise can pinpoint problems

examined, tooth contact is checked for compliance

quickly, saving you downtime and labor.

with strict engineering standards, and are inspected

to AGMA Quality 10 standards.

Parts

Our large inventory supports your stock and provides

Sales

quick fulfillment of maintenance and repair needs.

Chemineers extensive network of representatives is on

Emergency parts are shipped from our stock within

call, ready to assist you with all of your agitation needs,

24 hours. In addition to a wide selection of standard

including installation, maintenance, and modifications.

replacement items such as bearings, seals, and

motors, we stock complete drives and internal sub-

Installation

assemblies. Our drive exchange program offers a

replacement drive for rapid conversion.

Chemineer offers expert help on installation, whether

your application requires one or multiple HT agitators.

Our sales or field service engineers can quickly and

Warranty

efficiently supervise the installation and start-up of

For added peace of mind the HT agitator is backed by

your agitator installation.

a comprehensive two-year product warranty.

Maintenance

Chemineer engineers can provide seminars to thoroughly

review procedures recommended for installation, operation, and maintenance of our agitators. We can help

make your maintenance task easier and more efficient.

www.chemineer.com

10

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 4

How is the Chemineer

HT Gearbox Superior?

Output Shaft Requirements

Commercial gearboxes usually have smaller output

select larger and more expensive gearboxes to handle the

bending moments associated with large overhung loads.

shafts that are poorly suited for agitator duties, leading

to higher gear deflections, more noise, and lower reliability. For optimum mechanical integrity, it is beneficial

to design the low speed shaft so that the shaft diameter

between the bearings is large and the distance between

the bearings is small. Commercial units tend to use

AGMA Ratings when

Applied to Agitators

AGMA established a general purpose standard intended

to be able to be applied to gearboxes used in a wide

range of industrial applications. Agitators have particular

smaller shaft diameters that can result in the need to

duties that make reliance on AGMA service

factors inappropriate. A standard commercial

gearbox tends to use smaller shafts and larger

bearing spans that result in deflection, wear,

and shorter lifespan. To obtain adequate drive

life a high service factor must be applied.

The Chemineer HT gearbox is unique and

superior because it is designed specifically for

agitator duties. In comparison with a general

purpose gear-drive of the same nominal AGMA

torque rating, it has much longer bearing and

gear lives, which translate lower maintenance

costs and greater productivity. It also has a

very substantial output shaft with sealing by

a true dry well to avoid the risk of leaking

lubricant down the shaft.

Refurbished Mixer Gearbox Program

Chemineer stocks refurbished HT gearboxes for an economical,

quick replacement for units in disrepair. All refurbished gearboxes meet the same high quality standards as new Chemineer

gearboxes. Additional features of the refurbished mixer gearbox

program include:

Delivery on HT gearboxes in 24 hours or less

High quality refurbishments built in-house to Chemineer and

AGMA standards

A credit toward the purchase of any refurbished gearbox

upon returning your old gearbox

Accepting worn out gearboxes from any original mixer

manufacturer

One-year warranty against material defects and workmanship

www.chemineer.com

11

HT Bulletin_9-1.qxd

10/4/05

8:34 AM

Page 1

Impeller Technology

Chemineers impeller technology is effectively applied

high shear blending and viscous mixing. Whether it

across your spectrum of applications ensuring

is R&D or production phase, we have the expertise

successful, repeatable results from lab scale to

to solve your mixing challenges.

full scale operations.

Impeller bulletin, 710, is available with additional

Chemineers mixing expertise includes high flow, low

information.

shear liquid-liquid/solids blending, gas dispersion,

HE-3

SC-3

Maxflo W

Helix Impeller

Smoothline

Maxflo W

BT-6 Gas Dispersion

Impeller

Kenics

Chemineer, Inc.

P.O. Box 1123

Dayton, Ohio 45401

Telephone: (937) 454-3200

Fax: (937) 454-3379

Chemineer, Ltd.

7 Cranmer Road

West Meadows

Derby DE21 6XT

England

Telephone: 44-1332-363175

Fax: 44-1332-290323

Chemineer, Inc.

125 Flagship Drive

North Andover, MA 01845

Telephone: (978) 687-0101

Fax: (978) 687-8500

www.kenics.com

www.greercomixers.com

P4 Pitched Blade

Turbine

Prochem

Prochem, Inc.

994 Westport Crescent Unit #A3

Mississauga, Ontario L5T 1G1

Canada

Telephone: (905) 670-9486

Fax: (905) 670-9120

Your Local Contact:

Chemineer Sales Offices:

Mexico

Singapore

China

Bulletin 711

For the nearest sales office call 1-800-643-0641 or go to www.chemineer.com

2005 by Chemineer, Inc.

Chemineer, CEDS and ChemScale are registered trademarks of Chemineer, Inc.

Printed in U.S.A.

5M PPI 905

Anda mungkin juga menyukai

- ServiceKitsForSPAndAgitators E10046 PDFDokumen8 halamanServiceKitsForSPAndAgitators E10046 PDFgilbertogatoBelum ada peringkat

- Lorbrand Idler CatalogueDokumen88 halamanLorbrand Idler CatalogueJakesBelum ada peringkat

- Falk Quadrive M4107 To M4608Dokumen56 halamanFalk Quadrive M4107 To M4608Anonymous ntE0hG2TPBelum ada peringkat

- Ultra Max Drive Selection GuideDokumen74 halamanUltra Max Drive Selection GuideLuis Enrique Lee100% (2)

- Lightnin Impeller Technology PDFDokumen8 halamanLightnin Impeller Technology PDFNaila TheExplore HorisonBelum ada peringkat

- Intralox (Eng)Dokumen37 halamanIntralox (Eng)Angel David Osorio RiveroBelum ada peringkat

- 301 110 - Falk Ram Mixer Reducers - Selection ManualDokumen28 halaman301 110 - Falk Ram Mixer Reducers - Selection ManualAzhar HussainBelum ada peringkat

- Conveyor Belt Technique: Design and CalculationDokumen161 halamanConveyor Belt Technique: Design and CalculationMarianne Hernández100% (1)

- Instructions: Mixer ManualDokumen46 halamanInstructions: Mixer ManualJose VidalBelum ada peringkat

- Coupling CatalogDokumen84 halamanCoupling CatalogTuan buivietBelum ada peringkat

- Inquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteDokumen5 halamanInquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteCik MinnBelum ada peringkat

- A Technical Reference Manual For Plate Heat Exchangers in Refrigeration & Air Conditioning ApplicationsDokumen176 halamanA Technical Reference Manual For Plate Heat Exchangers in Refrigeration & Air Conditioning Applicationsmdalt9180Belum ada peringkat

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Dokumen16 halamanZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamBelum ada peringkat

- Water WastewaterDokumen20 halamanWater WastewaterterryjoseeBelum ada peringkat

- Flexible Couplings: ElflexDokumen8 halamanFlexible Couplings: ElflexSUNIL TVBelum ada peringkat

- Catalogo de Reductores de VelocidadDokumen74 halamanCatalogo de Reductores de VelocidadAnonymous Nyv3dRBelum ada peringkat

- Install, Service and Maintain Side-Entry AgitatorsDokumen22 halamanInstall, Service and Maintain Side-Entry AgitatorsPetros IosifidisBelum ada peringkat

- Raven 3800 MixerDokumen3 halamanRaven 3800 Mixersantosh kumar100% (1)

- Agitator RNE-SeriesDokumen8 halamanAgitator RNE-SeriesGrNjBelum ada peringkat

- Chain DriveDokumen212 halamanChain DriveFrancisco ToroBelum ada peringkat

- SEW Compact Constant Speed Reducer MC SeriesDokumen195 halamanSEW Compact Constant Speed Reducer MC SeriesDênis DáyolBelum ada peringkat

- Ej PDFDokumen20 halamanEj PDFduongpnBelum ada peringkat

- Expansion JointsDokumen17 halamanExpansion Jointsravi00098Belum ada peringkat

- LSP LowSpeedHighPressurePumps E00522Dokumen7 halamanLSP LowSpeedHighPressurePumps E00522Sigit PramonoBelum ada peringkat

- Boston ReducersDokumen356 halamanBoston ReducersVicente Banda ZuñigaBelum ada peringkat

- Goulds LF 3171: Low Flow, High Head Vertical Sump PumpDokumen4 halamanGoulds LF 3171: Low Flow, High Head Vertical Sump PumpPaul CastroBelum ada peringkat

- Agitator DesignDokumen2 halamanAgitator Designnaruto256100% (1)

- Service Factor RatingsDokumen4 halamanService Factor Ratingschu42Belum ada peringkat

- LIGHTNIN Top Entry Mixers Agitadores ImpellersDokumen12 halamanLIGHTNIN Top Entry Mixers Agitadores ImpellersJosue QuirozBelum ada peringkat

- BR BoilerHouseComponents enDokumen24 halamanBR BoilerHouseComponents enKonsultio Dario KrausseBelum ada peringkat

- Agitator Design: HP CalculationDokumen32 halamanAgitator Design: HP CalculationJose Heli Vallejos CoronadoBelum ada peringkat

- Industrial Air Systems Components GuideDokumen45 halamanIndustrial Air Systems Components GuidewagcherBelum ada peringkat

- Large Size Conveyor ChainDokumen156 halamanLarge Size Conveyor ChainManatchaiSanBelum ada peringkat

- 5510 Rexnord Bucket Elevators CatalogDokumen12 halaman5510 Rexnord Bucket Elevators CatalogAwir Strange ManBelum ada peringkat

- Quad RingDokumen32 halamanQuad RingTrelleborgSealsBelum ada peringkat

- S-Wall™ Sidewall Conveyor Belting: Technical ManualDokumen44 halamanS-Wall™ Sidewall Conveyor Belting: Technical ManualVasant HiremathBelum ada peringkat

- Thermascrew: Advanced FeaturesDokumen3 halamanThermascrew: Advanced FeaturesFLIRIDIR1678Belum ada peringkat

- EleconDokumen72 halamanEleconPranit BangeraBelum ada peringkat

- Renold Conveyor Chain Catalogue Designer GuideDokumen41 halamanRenold Conveyor Chain Catalogue Designer Guidedeep200Belum ada peringkat

- Section 3: Designer Guide Specification GuidelinesDokumen27 halamanSection 3: Designer Guide Specification GuidelinesSebaVergaraBelum ada peringkat

- Reactors Ppt4Dokumen55 halamanReactors Ppt4DanishBelum ada peringkat

- Reactor Geometry and Agitator SelectionDokumen26 halamanReactor Geometry and Agitator SelectionChemical Engineering100% (2)

- Product Manual for Tyre-Flex CouplingDokumen28 halamanProduct Manual for Tyre-Flex CouplingJason Wei Han LeeBelum ada peringkat

- Sismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsDokumen5 halamanSismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsasddBelum ada peringkat

- Kmkat19 eDokumen234 halamanKmkat19 eV OviBelum ada peringkat

- Rotor Clip Catalog PDFDokumen276 halamanRotor Clip Catalog PDFouribesanzBelum ada peringkat

- Catalog PDFDokumen448 halamanCatalog PDFykuscuBelum ada peringkat

- Proto 108 - Pliers, Clamping, Cutting (p.739-788)Dokumen50 halamanProto 108 - Pliers, Clamping, Cutting (p.739-788)Lazzarus Az GunawanBelum ada peringkat

- en Roller Screw CatalogueDokumen140 halamanen Roller Screw CataloguecycypacoBelum ada peringkat

- Inverted Tooth Chains & Sprockets For Power Transmission - 601-306Dokumen32 halamanInverted Tooth Chains & Sprockets For Power Transmission - 601-306Jhon Edison Guerrero GalindoBelum ada peringkat

- Structural Health MonitoringDari EverandStructural Health MonitoringDaniel BalageasBelum ada peringkat

- Bettis HD-Series ActuatorsDokumen6 halamanBettis HD-Series Actuatorstxlucky80Belum ada peringkat

- Caterpillar Filter ไส้กรอง กรองลม กรองน้ำมันDokumen19 halamanCaterpillar Filter ไส้กรอง กรองลม กรองน้ำมันParinpa KetarBelum ada peringkat

- Oil SkimmerDokumen4 halamanOil SkimmerManish KhakhraBelum ada peringkat

- 2008 Filter and Fluid Application Guide2Dokumen16 halaman2008 Filter and Fluid Application Guide2KAPDSCBelum ada peringkat

- Centritec PDFDokumen2 halamanCentritec PDFmr_bucixBelum ada peringkat

- 902Dokumen12 halaman902Victor M. Mejia DiazBelum ada peringkat

- Loctite Type and ApplicationsDokumen35 halamanLoctite Type and ApplicationsgksamyBelum ada peringkat

- NOV Prochem Bulletin 720 - v02Dokumen10 halamanNOV Prochem Bulletin 720 - v02saulomonBelum ada peringkat

- Cat D6GDokumen16 halamanCat D6GShailesh Khodke75% (4)

- EOT Spec RefDokumen22 halamanEOT Spec RefSantoshkota123Belum ada peringkat

- Canadian Citizenship Study Questions & Answers: Aboriginal PeoplesDokumen14 halamanCanadian Citizenship Study Questions & Answers: Aboriginal PeoplesMuhammad RizwanBelum ada peringkat

- ReadMe Uconeer - Units Conversion For EngineersDokumen3 halamanReadMe Uconeer - Units Conversion For EngineersRaja DhanasekaranBelum ada peringkat

- Load CalculationDokumen6 halamanLoad CalculationSantoshkota123Belum ada peringkat

- PMP IN 45 DAYSDokumen10 halamanPMP IN 45 DAYSgolfmaniac48% (21)

- Document Checklist: Application For Canadian Citizenship Under Subsection 5 (1) Adults (18 Years of Age and Older)Dokumen1 halamanDocument Checklist: Application For Canadian Citizenship Under Subsection 5 (1) Adults (18 Years of Age and Older)Santoshkota123Belum ada peringkat

- Fav SongsDokumen1 halamanFav SongsSantoshkota123Belum ada peringkat

- MF 216 N Manual PDFDokumen522 halamanMF 216 N Manual PDFSantoshkota123Belum ada peringkat

- Dust Collection Design and Maintenance GuideDokumen36 halamanDust Collection Design and Maintenance GuideMadan YadavBelum ada peringkat

- Yogiji Maharaj Ni Bodh Kathao: Swaminarayan Satsang Darshan Part 98 DVDDokumen1 halamanYogiji Maharaj Ni Bodh Kathao: Swaminarayan Satsang Darshan Part 98 DVDSantoshkota123Belum ada peringkat

- Sites LondonDrugs SiteDokumen2 halamanSites LondonDrugs SiteSantoshkota123Belum ada peringkat

- Bear Smart Brochure Web PDFDokumen2 halamanBear Smart Brochure Web PDFSantoshkota123Belum ada peringkat

- Invoice 12035 From Braeside Community AssociationDokumen1 halamanInvoice 12035 From Braeside Community AssociationSantoshkota123Belum ada peringkat

- 27 Nakshatra PadasDokumen13 halaman27 Nakshatra PadasAstrologer in Dubai Call 0586846501Belum ada peringkat

- Moving ChecklistDokumen1 halamanMoving ChecklistSantoshkota123Belum ada peringkat

- Aditya Hridyam StotramDokumen16 halamanAditya Hridyam StotramApunka_NaamBelum ada peringkat

- Online Payment ReceiptDokumen2 halamanOnline Payment ReceiptSantoshkota123Belum ada peringkat

- 304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFDokumen16 halaman304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFAndressa EgerBelum ada peringkat

- Wescaapplication PDFDokumen5 halamanWescaapplication PDFnavidBelum ada peringkat

- Bag Filter Calculation PDFDokumen4 halamanBag Filter Calculation PDFArun Gupta71% (7)

- 27 Nakshatra PadasDokumen13 halaman27 Nakshatra PadasAstrologer in Dubai Call 0586846501Belum ada peringkat

- Comm Guide One PDFDokumen128 halamanComm Guide One PDFsusvarBelum ada peringkat

- How Canadians Govern Themselves8Dokumen58 halamanHow Canadians Govern Themselves8Santoshkota123Belum ada peringkat

- Want To Work in Oil GasDokumen186 halamanWant To Work in Oil GasSantoshkota1230% (1)

- Bhaktachintamani 1Dokumen88 halamanBhaktachintamani 1Santoshkota123Belum ada peringkat

- Applicant GuideDokumen89 halamanApplicant GuideSantoshkota123Belum ada peringkat

- Canadian Citizenship Study Questions & Answers: Aboriginal PeoplesDokumen14 halamanCanadian Citizenship Study Questions & Answers: Aboriginal PeoplesMuhammad RizwanBelum ada peringkat

- 39 Excel 2003 MacrosDokumen63 halaman39 Excel 2003 Macrosstjon1954Belum ada peringkat

- Premchand Ki Mashoor KahaniyanDokumen150 halamanPremchand Ki Mashoor KahaniyanBhupendra Chauhan96% (25)

- MS Project 2007 Tutorial-Final VersionDokumen61 halamanMS Project 2007 Tutorial-Final Versionlimmil100% (1)

- Condensate RVP: Item Previously Current Overhead Debutanizer SpecDokumen3 halamanCondensate RVP: Item Previously Current Overhead Debutanizer SpecRizal FauziBelum ada peringkat

- Crane Lift PlanDokumen4 halamanCrane Lift PlanAmin HatimiBelum ada peringkat

- ChirunduDokumen61 halamanChirunduJared MakoriBelum ada peringkat

- NSL Custody Requirements Effort Estimation Sheet Final v0 1Dokumen46 halamanNSL Custody Requirements Effort Estimation Sheet Final v0 1Prakash KolheBelum ada peringkat

- Driving Business Benefits from IT ArchitectureDokumen12 halamanDriving Business Benefits from IT ArchitectureSiddharth AgrawalBelum ada peringkat

- CCB Charter TemplateDokumen1 halamanCCB Charter TemplateRich HuebnerBelum ada peringkat

- Boeing Passivation PDFDokumen12 halamanBoeing Passivation PDFCicero Gomes de Souza100% (1)

- NN44400 106 01.05 Fundamentals Predictive OutboundDokumen143 halamanNN44400 106 01.05 Fundamentals Predictive OutboundEvan HatchellBelum ada peringkat

- HSBC Guide To Treasury ManagementDokumen308 halamanHSBC Guide To Treasury ManagementkunalwarwickBelum ada peringkat

- AVEVA NET BrochureDokumen8 halamanAVEVA NET BrochuresennimalaiBelum ada peringkat

- ThyssenKrupp Gyratory CrushersDokumen12 halamanThyssenKrupp Gyratory CrushersSokitome100% (1)

- Business Processing Model and Notation (BPMN)Dokumen24 halamanBusiness Processing Model and Notation (BPMN)Peter R. Egli100% (2)

- Vintage Airplane - Jan 2013Dokumen60 halamanVintage Airplane - Jan 2013Aviation/Space History Library100% (2)

- Available Cars For Sale DECEMBER 27 2019 PDFDokumen9 halamanAvailable Cars For Sale DECEMBER 27 2019 PDFkennethBelum ada peringkat

- Composite Materials AbstractDokumen3 halamanComposite Materials Abstractguhan7890Belum ada peringkat

- Case Study Fiat GroupsDokumen4 halamanCase Study Fiat GroupsFatimah KhanBelum ada peringkat

- CDMP Exam Outlines V - 1 - 2Dokumen6 halamanCDMP Exam Outlines V - 1 - 2jerrymei100% (1)

- TM 9-707 Basic Half-Track Vehicles 1943Dokumen450 halamanTM 9-707 Basic Half-Track Vehicles 1943KiwiBig_DBelum ada peringkat

- Astm C478-97Dokumen8 halamanAstm C478-97troyscribdBelum ada peringkat

- IMPORTANT TERMS & CONDITIONS OF TENDERDokumen66 halamanIMPORTANT TERMS & CONDITIONS OF TENDERpasamvBelum ada peringkat

- Embedded Systems UNC PDFDokumen526 halamanEmbedded Systems UNC PDFIrán Samir Percia VelásquezBelum ada peringkat

- Architectural Reviewers - Air Passenger TerminalsDokumen13 halamanArchitectural Reviewers - Air Passenger TerminalsJenny Jane Sarmiento VeraqueBelum ada peringkat

- Quality Core Tools APQP FMEA MSA SPC PPAPDokumen14 halamanQuality Core Tools APQP FMEA MSA SPC PPAPالعاب الاطفال- jeux enfantsBelum ada peringkat

- End-Of-Life Vehicle Recovery in ChinaDokumen8 halamanEnd-Of-Life Vehicle Recovery in ChinaHarshit GoyalBelum ada peringkat

- Llyods Register Choking ResinDokumen2 halamanLlyods Register Choking ResinKarsa SambasBelum ada peringkat

- Comparison of Residential Design Standards in PD 957 & BP 220Dokumen2 halamanComparison of Residential Design Standards in PD 957 & BP 220Black FuryBelum ada peringkat

- Cost Estimate Form for 3D Modelling ProjectDokumen1 halamanCost Estimate Form for 3D Modelling ProjectMohamadSyahmiBelum ada peringkat

- White Paper-Simplifying Oracle Retail Data ConversionDokumen6 halamanWhite Paper-Simplifying Oracle Retail Data ConversionSuman RamineniBelum ada peringkat

- RAF List May 1940Dokumen644 halamanRAF List May 1940Robert MacDonaldBelum ada peringkat

- Dics 6100 PDFDokumen97 halamanDics 6100 PDFBf Ipanema100% (1)