T.hald Implementation of A Finite Element Foundation Mod

Diunggah oleh

Ramon GutierrezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

T.hald Implementation of A Finite Element Foundation Mod

Diunggah oleh

Ramon GutierrezHak Cipta:

Format Tersedia

Copenhagen Offshore Wind 2005

IMPLEMENTATION OF A FINITE ELEMENT FOUNDATION MODULE

IN FLEX5 USING CRAIG-BAMPTON SUBSTRUCTURING

Tue Hald and Michael Hgedal

Loads, Aerodynamics and Control Group, Vestas Technology

Alsvej 21, DK-8900 Randers, Denmark,

email: tuha@vestas.com, tel: +45 9730 0000, fax: +45 9730 5638

SUMMARY

For aeroelastic analysis of wind turbines including tower and support structure the

Flex5 code developed by ye (1994,1999) is widely used within the wind industry. The

existing Flex5 foundation module uses a simple monopile model where model parameters may be modified to mimic more complex foundations. The foundation module is

limited in the ability to model substructures of arbitrary geometry and the correct stiffness and the correct energy dissipation from the soil, thus missing the correct load distribution below mudline.

Flex5 is a modal based programme and to maintain the modal scheme the original foundation module is substituted by a finite element (FE) model. This FE model is decomposed using a Craig-Bampton substructuring scheme and applied in Flex5 as a superelement. The new foundation module is based on tubular elements and is capable of

treating stiff floating foundation and flexible foundations of arbitrary geometry.

A special treatment of the soil-structure interaction is planned implemented in the FE

model using non-linear p-y springs as defined in API RP 2A LRFD, 1993.

KEY WORDS

Floating/Bottom-mounted foundation, mode shape, super-element, FE, Craig-Bampton

substructuring, soil-structure interaction

1. INTRODUCTION

The aeroelastic code Flex5 is widely used in assessing the loads and the structural response for wind turbines. The foundation module is based on two times two shape functions with 6 DOF at the interface point to the tower and the soil-structure boundary is

simulated by a 6 DOF constraint below mudline. By varying the depth of the 6-DOF

clamping and stiffness below the mudline, both angular deflection at the mudline and

horizontal deflection can be made to fit displacements of any structure. The fixity depth

is normally calibrated to fit the 1. natural frequency of the wind turbine support structure using a separate soil-structure interaction model such as a FE model.

1 of 11

Copenhagen Offshore Wind 2005

This approach works very well for numerous onshore and offshore locations but as offshore applications become more complex the simplified description in Flex5, only describing tubular monopile type and gravity type substructures, becomes too limited.

Figure 1 shows selected support structure concepts varying from the relatively simple

gravity base and monopile structure applicable in fairly shallow water being the only

types to date applied in existing commercial wind farms. For some of the existing offshore sites with a severe wave climate the wave loading is responsible for up to 50% of

the total loading in the tower. As future sites are in deeper water and the sites become

more exposed the wave loading increases and more complex or alternative support

structure configurations are necessary in order for the wind farms to be commercially

viable.

Besides the differences on complexity of the various structures, the soil-structure interaction is very different, especially the bucket foundation requires special geotechnical

attention. Additionally, as the turbines become larger and the hub height and top-head

mass increases, the natural frequency becomes design driving and a more accurate description of the soil-structure interaction is required.

Consequently it is decided to develop a FEM based foundation module integrated in to

the Flex5 code. The main objective is to be able to describe arbitrary geometries based

on tubular elements and it is intended to include a soil-structure interaction model enabling load assessment below mudline and evaluation of the natural frequency.

Figure 1 Different support structure concepts (DNV-OS-J101, Draft Feb 2004)

2. EXISTING FLEX5 FOUNDATION MODULE

The aeroelastic load model applied by Vestas is based on the Flex5 code developed by

ye (1999) combined with a model of the Vestas Converter System. The original Flex5

model has continuously been developed in order to encompass the special needs within

Vestas. In summary the present aeroelastic modelling tool (VTS: Vestas Turbine Simulator) comprises the following features:

36 DOF combined mode shape and multibody formulation

Each sub-structure is treated using linear Bernoulli-Euler beam theory

2 of 11

Copenhagen Offshore Wind 2005

Bearings/Actuators are modelled by lumped parameter models

Power control (Vestas Converter System) is implemented directly

All loads (Internal inertia and external loads) are based on the deformed state

External load models cover aerodynamic loads, gravity and hydrodynamic

loads

Foundation model is treated separately in FLEX5

The existing Flex5 foundation module is based on a super-element formulation with the

top node of the element linked to the tower bottom, also termed the interface point, in 6

DOF (Fx,Fy,Fz,Mx,My,Mz) forming the boundary to the support structure. The superelement is constructed from two shape functions derived as the static deformation of the

super-element from a unit deformation and a unit rotation of the top node. The shape

functions are calculated according to the actual geometrical properties specified by a

finite number of elements defining the entire support structure. The element formulation

is limited to tubular beam elements defined in the centerline of the tower, and consequently only monopile or monopile-type structures can be modelled, i.e. a tripod or

gravity base structure must be converted into an equivalent monopile with identical dynamics as the original structure at the interface to the tower.

Mass, damping and stiffness properties of the super-element and a generalized loading

on the element are calculated from the two static shape functions. The super-element

properties and generalized load are assembled into the global mass, damping and stiffness matrices and load vector for time domain solution of the equation of motion.

Kinematics of the internal DOFs and sectional loads inside the super-element are distributed inside the super-element according to the shape functions. This approach is

very similar to the traditional FEM ignoring the effect of internal modes from the internal DOFs in the super-element. Figure 2 depicts the static shape function as well as the

shape functions for a selected internal DOFs in the super-element.

This approach describes the static response of the support structure (Inertia loads are

applied in deformed state) and the only error in the dynamic response is solely due to

inertia loads from possible internal modes. However, the effect from the internal modes

is expected to be negligible as the eigenfrequency of the internal modes typically are

much higher than the eigenfrequencies of interest.

Shape function, super-element DOF

15

Shape function, internal DOF

15

15

10

10

x+ 5

3 x

3 x

0.5

N3 ( x)

10

x+ 5

x+ 10

0.5

0.5

N3( x) , N1 ( x)

N4( x)

10

x+ 10

5

15

0

N4 ( x) , N2( x)

Figure 2 Super-element shape functions and internal shape functions for unit deformation and

unit rotation of node of master node and one internal slave node. 0 being 6 DOF constraint at

mudline and N1, N2, N3, N4 being cubic element shape functions.

3 of 11

Copenhagen Offshore Wind 2005

The tower is modelled using the 1. and 2. mode shape of tower and addition of the super-element simply results in a deformation of the full support structure including tower

and foundation equal to the tower modes, see Figure 3. The boundary towards the soil is

treated as a fixity constraint below mudline calibrated to fit the 1. mode natural frequency, which poses an additional limitation of the existing foundation module. The

correct stiffness and energy dissipation from the soil is not correct, in particular as the

fixity level of the 2. mode is different from the 1. mode. Furthermore, as no soil structure interaction is modelled it is not possible to obtain information about the distribution

of loads below mudline.

2. mode

1. mode

60

60

40

20

20

40

0.5

( 1 , z )

( 2 , z )

Figure 3 1. and 2. mode for tower and substructure.

The load impact depends on the shape of the 2. mode, i.e. the distribution of stiffness

over the entire structure. Hence for stiff substructures the load impact is limited whereas

flexible substructures contribute more to the 2. mode bending. In extreme cases the consequences on the loading can be up to 10% on the equivalent overturning moment in

tower bottom and 5% at mudline and tower top, respectively.

3. FEM FOUNDATION MODULE

In order to solve some of the limitations with the existing foundation module a new

foundation module based on finite elements is currently being developed. The new FEM

foundation module consists of the following features:

A stiff element model capable of treating floating substructures is applied and a

rigid body transformation of the foundation mass matrix to the interface point integrates the model in Flex5

Internal flexibility is introduced by applying a FEM model using tubular Timoshenko beam elements

Craig-Bampton substructuring is applied to transform the mass and stiffness matrix of the FE model to the interface point, consequently integrating the foundation model in Flex5 as a super-element similar to the original foundation module

The foundation module is capable of describing an arbitrary geometry using tubular

elements taking into account the external loads: gravity, elastic or pre-tensioned anchor

cables, buoyancy and hydrodynamic loading.

4 of 11

Copenhagen Offshore Wind 2005

4. ELEMENT FORMULATION

The applied elements are tubular Timoshenko beam elements described by:

6 DOF at each node

Outer diameter

Plate thickness

Water filling factor, 1 for full and 0 for empty

Mass and stiffness factor

Drag and added mass coefficient in normal and tangential direction

The element definition forms a 1212 mass and stiffness matrix as defined by Pedersen

and Jensen (2000) and Petersen (1990). From the elements the foundation mass matrix

and foundation stiffness matrix are assembled.

Floating model

For use in the floating model the mass matrix is reduced to a 66 matrix by a rigid body

mode shape transformation to the interface point, thus fitting exactly into the original

modal scheme of Flex5 by substituting the original super-element. The reduced mass

matrix is given in the form:

Sz

0

0

0

Sy

m

0

m

S x

0

0

Sz

0

m

Sy

0

0

Sx

~

M = rT M r =

J xx J xy J xz

Sz S y

0

Sz

0

S x J yx J yy J yz

J zz

0

J zx J zy

S y S x

where r : rigid body modes, 6N6 matrix

m : structural mass

S x : static moment about x-axis defining CoG

J xx : mass moment of inertia about x-axis defining the inertia tensor

Boundary conditions

In the floating model the foundation is assumed stiff, however the boundary condition is

an anchoring at specified nodes by either elastic or pre-tensioned anchor cables, thus

imposing a stiffness constraint to be implemented in the 66 foundation stiffness matrix. The effect of anchoring is calculated as the force/moment pr unit deformation by

imposing a unit deformation and unit rotation at each DOF individually.

In the FE model it is intended to include a soil-structure interaction model enabling load

assessment below mudline and evaluation of the natural frequency. The following soil

models are planned to be implemented in the foundation module:

An external 6x6 soil stiffness matrix is applied at mudline. This matrix must be

calculated beforehand in a separate soil-structure interaction model

The soil forces are applied as external loads to elements nodes by:

i. Linear stiffness model with linearization of p-y force deformation curves

at the Centre-of-Damage loads, or alternatively

ii. Non-linear stiffness model with full p-y curves

5 of 11

Copenhagen Offshore Wind 2005

Loading

External loads are calculated in the deformed state covering:

Buoyancy and gravity

3D hydrodynamic forces according to Morison equation with McCamy-Fuchs

correction for large volume structures

Elastic or pretensioned anchor forces

Non-linear structural inertia loads (with the linear terms being included in the

mass matrix)

Time integrator

In original Flex5 the time integrator is a 4 step Runge-Kutta-Nystrm (RKN) algorithm

for 2nd order differential equations. Unfortunately the RKN time integrator is only conditionally stable as it requires minimum 3 (here 4) steps pr. period of each mode, hence

a very small time step is required to resolve the highest frequencies.

In the FE model the inclusion of all 6 DOF results in stiff systems, i.e. a large ratio between highest and lowest eigenfrequency, this is especially pronounced for the axial

stiffness of the monopile. Consequently a Newmark-Wilson algorithm (Clought and

Penzien, 1993) for linear step-by-step integration has been implemented.

The 2nd order differential equation system given in the form:

M u&& + C u& + K u = F G

is integrated on incremental form:

M 0 u&& + M u&& + C u& + K u = F G

where u&&, u&, u are approximated by Taylor expansions

The velocity increments are found as solution of effective equation:

K * u = F *

4u&

where F * = F + C (2u&0 ) + M 0 0 + 2u&&0 ( M M 0 )u&&

t

2C 4 M 0

K* = K +

+

t

t 2

The method assumes constant average acceleration and assumes in the present implementation that the foundation stiffness forces FK and damping forces FC can be written

on the form

FK = K u

FC = C u

In contrast to the RKN algorithm, the Newmark-Wilson algorithm is unconditionally

stable and is capable of treating stiffer systems without requiring small time steps.

6 of 11

Copenhagen Offshore Wind 2005

5. CRAIG-BAMPTON SUBSTRUCTURING

The Craig-Bampton method is a more practical method for solving large dynamic problems than a full finite element solution. The full size of the FE model is reduced by a

Craig-Bampton transformation which combines motion of boundary point with modes

of the structure assuming the boundary points are held fixed, and the reduced system is

coupling to other components in the specified boundary DOFs. The Craig-Bampton

transformation can be used to calculate physical responses from the Craig-Bampton

responses using load transformation matrices (LTM). Basically, the Craig-Bampton

substructuring is similar to other reduction schemes such as Guyan reduction and modal

decoupling, however unlike Guyan reduction, the method accounts for both mass and

stiffness as the Craig-Bampton mass and stiffness fully defines the system.

The methodology is in short described in the following by considering the equation of

motion (ignoring damping):

Mu&& + Ku = F (t )

The Craig-Bampton transform is defined as:

u I 0 ub

ub

u = b =

= CB

q

ui c i q

where

ub : boundary DOFs

ui : internal DOFs, i.e. ui = cT ub + iT q

c : static modes (or constrained modes) containing the deformation influence coefficients for internal DOFs

i : fixed base mode shapes containing the contribution from internal vibration modes

CB : Craig-Bampton transformation matrix

q : modal DOFs

Ignoring the inertia forces, the internal DOFs can be calculated by static condensation,

i.e. the static mode matrix is:

1

c = K ii K ib

When the Craig-Bampton transformation is inserted into the equation of motion and

T

, the modified equation of motion becomes:

premultiplied by CB

u&&

u

T

T

T Fb

CB

M CB b + CB

K CB b = CB

q&&

q

Fi

where the Craig-Bampton mass and stiffness matrices are defined as:

M bb M bq

T

M CB = CB

M CB =

M qb M qq

K bb

T

K CB = CB

K CB =

0

0

K qq

7 of 11

Copenhagen Offshore Wind 2005

The boundary matrix M bb contains the total mass properties translated to the boundary

points and the internal stiffness matrix K bb contains the stiffness associated with displacing one boundary DOF while all others are held fixed

The implementation in Flex5 is described in the following.

Equation of motion for the turbine without foundation (ignoring damping):

M mm M mb u&&m K mm K mb u m Fm

+

M

=

bm qq u&&b K bm K bb ub Fb

u DOF for tower + rotor/nacelle assembly

where {u} = m =

Boundary DOF for interface

ub

Equation of motion for the foundation (ignoring damping):

M bb M bi u&&b K bb K bi ub Fb

M

+

=

ib M ii u&&i K ib K ii ui Fi

u Boundary DOF for interface

where {u} = b =

ui Internal DOF for foundation

If the internal mode shapes (q = 0) are neglected similarly to the super-element formulation in the original Flex5 foundation module, the CB transformation reduces to the static

condensation method:

I

u I

u = b = ub =

ub

1

K ii K ib

ui c

and

M bi I

M

cT bb

= cT M ii c + M bi c + cT M ib + M bb

M ib M ii c

K bi I

K

T

K CB = CB

K CB = I cT bb

= K bb cT K ii c

K ib K ii c

T Fb

T Fb

T

FCB = CB

= I c = Fb + c Fi

F

F

i

i

T

M CB = CB

M CB = I

The final equation of motion in Flex5 (ignoring damping) becomes:

M mb

K mb u m Fm

M mm

u&&m K mm

+

=

M

bm M bb + M CB u&&b K bm K bb + K CB ub Fb + FCB

The solution of the equation of motion describes the deformation, velocity and acceleration of each individual master DOF, and the corresponding response of internal DOFs in

the FE model can subsequently be calculated.

8 of 11

Copenhagen Offshore Wind 2005

Accuracy

Apparently, the present implementation of the Craig-Bampton decoupling seems to be a

crude approximation of the real conditions with a dynamic structure exposed to external

loading. This, however, is not the case as the static response is determined without errors and the only error in the dynamic response is due to possible internal vibration

modes affecting the inertia forces. Typically, the internal vibration modes are of very

high frequencies leaving them unimportant.

In order for the error only to arise from internal modes the contribution form the external loading to the deformation of the interface node must be represented correctly. I.e.

the condensed loads and stiffness must provide the correct deformation of the interface

node for an external load acting at any node.

If the condensed 6 DOF transformation matrix is supplemented by an additional N-6

DOFs represented by shape functions corresponding to the unit deformations of the internal DOF, see Figure 2, the following transformation is obtained:

I 0 ub

u=

c I ui

where the shape functions for the internal DOFs have 1 in the diagonal and 0 for all

other DOFs.

The condensed coordinates for the additional DOF now defines the deformation relative

to the deformation determined by the first 6 shape functions. Subsequently the condensed stiffness can be calculated:

K CB 0 ub Fb

0 K u = F

2 i

i

Because of the block structure it is observed that any external loading will be transformed to the condensed load only through the first 6 DOFs while the remaining internal DOFs cannot contribute to the deformation. Hence full accuracy with respect to the

static deformation of the interface node is achieved by only 6 DOFs.

If necessary for the description of internal loading in the FE model additional DOFs and

mode shapes must be implemented in the global system of equations. The new mass and

stiffness matrices are simply defined by the CB transformation with q 0 and the time

integrator requires an update to be capable of solving for more DOFs.

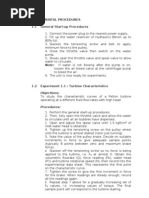

6. VERIFICATION - TEST CASE

The FE model is compared to the original Flex5 foundation model based on the test case

described below:

WTG model is an artificial 1.0 MW

Monopile with OD = 3000 mm and t = 30 mm fixed at mudline -3m

Shear stiffness neglected, i.e. the Timoshenko elements converts to BernoulliEuler elements.

Tower interface at 12.0m

Steady wind speed: 12-14-16 m/s

No wave loading

9 of 11

Copenhagen Offshore Wind 2005

Wind speed

[m/s]

17

FEM dt=0.005

15

FEM, dt=0.02

Flex5, dt=0.005

13

Flex5, dt=0.02

11

0

10

15

20

25

Tim e

30

35

40

45

50

[s ec]

[kW]

950

Power

1050

850

FEM dt=0.005

FEM, dt=0.02

Flex5, dt=0.005

Flex5, dt=0.02

750

0

10

15

20

25

Downwind tower top [kN]

Tim e

35

40

45

50

250

200

FEM dt=0.005

150

FEM, dt=0.02

100

Flex5, dt=0.005

50

Flex5, dt=0.02

0

0

10

15

20

25

Tim e

Found. Defl. GX4 [m]

30

[s ec]

30

35

40

45

50

[s ec]

0.03

FEM dt=0.005

0.02

FEM, dt=0.02

Flex5, dt=0.005

0.01

Flex5, dt=0.02

0

0

10

15

20

25

Tim e

30

35

40

45

50

[s ec]

Figure 4 Comparative run test for monopile foundation in original Flex5 module and FE model

Figure 4 shows the wind speed, power output and downwind force in tower top and

downwind foundation deflection at foundation top for simulations run with the original

Flex5 foundation module and the FM module for two different time steps. The results

show good correlation for a time step of 0.02 sec and almost identical results are observed for a time step of 0.005 sec.

7. OUTLOOK

Some of the present limitations of the existing foundation module in Flex5 lacking the

ability to model substructures of arbitrary geometry has been discussed and premises for

a fully general FE model using Timoshenko tubular beam elements have been described. The FE model is decomposed using Craig-Bampton substructuring in order to

construct a super-element which fits in to the original modal scheme of Flex5.

Using the Craig-Bampton substructuring a super-element with 6 DOF at the interface

point can be constructed. This super-element is almost identical to the original superelement in Flex5 in case a monopile is modelled by Bernoulli-Euler beam elements,

10 of 11

Copenhagen Offshore Wind 2005

except for the additional axial and rotational stiffness. Simulation with the FE model

shows very good agreement with the original foundation module in Flex5.

The FE model differs mainly in its ability to model structures of arbitrary geometry and

both floating as well as bottom-mounted structures can be modelled. Furthermore, the

FE model is prepared for full soil-structure interaction as the foundation in case of a

pilled foundation simply is extended below mudline and the soil is modelled as soil

spring forces in the element nodes. Other foundation types such as gravity based or

bucket foundations are implemented directly by imposing a stiffness constraint in the

foundation stiffness matrix at the effected DOFs.

Further work on the soil-structure interaction for various foundation concepts is part of

a joint project between Vestas, Aalborg University, Ris National Laboratory, Elsam

Engineering A/S and MBD supported by the Danish Energy Council under the EFP

programme. The soil-structure model will be verified against data from ongoing measurements from the Horns Reef wind farm.

ACKNOWLEDGEMENT

The former Vestas employee Erik Nim is gratefully acknowledged for initiating the

work and for developing the floating foundation model.

REFERENCES

API RP 2A-LRFD, Recommended Practice for Planning, Designing and Constructing

Fixed Offshore Platforms Loads and Resistance Factor Design, ed. 1, American Petroleum Institute, 1993.

Clought, R.W., Penzien, J.; Dynamics of Structure, Second Edition, pp. 121-126 and

328-330, McGraw-Hill, New York. 1993.

Craig Jr, R.R., Bampton, M.C.C.; Coupling of Substructures for Dynamic Analysis,

AIAA Journal Vol. 6, No. 7, July 1968.

Gradin, M., Rixen, D.; Mechanical Vibrations Theory and Application to Structural

Dynamics; 2. edition, Wiley, 1997.

Petersen, J.T., Kinematically Nonlinear Finite Element Model of a Horizontal Axis

Wind Turbine. Part 1: Mathematical Model and Results, Ph.D.-thesis. Ris National

Laboratory, 1990.

Terndrup Pedersen, P., Juncher Jensen, J.; Strength of Maritime Structures, Part 1:

Loads and Global Analysis (in Danish); Den private ingenirfond, Lyngby, 1982.

Terndrup Pedersen, P., Juncher Jensen, J.; Strength of Maritime Structures, Part 2: Numerical Methods (in Danish), Inst. for Skibs- og Havteknik, Lyngby 2000.

ye, S.; FLEX 4 User Manual; Lyngby, 1994.

ye, S.; FLEX 5 User Manual; Lyngby, 1999.

11 of 11

Anda mungkin juga menyukai

- Seidel Offshore Wind 2005Dokumen10 halamanSeidel Offshore Wind 2005Donald.KBelum ada peringkat

- FSI PaperDokumen10 halamanFSI PaperHasan AdelBelum ada peringkat

- Integrated Load and Strength Analysis For Offshore Wind Turbines With Jacket StructuresDokumen8 halamanIntegrated Load and Strength Analysis For Offshore Wind Turbines With Jacket StructuresChunhong ZhaoBelum ada peringkat

- FB-Multipier - Extended Validation SetDokumen37 halamanFB-Multipier - Extended Validation SetAleksiey PellicciaBelum ada peringkat

- Dynamic Analysis of Wind Turbines Including Soil-Structure InteractionDokumen10 halamanDynamic Analysis of Wind Turbines Including Soil-Structure InteractionsuzanavilaBelum ada peringkat

- GL Offshore Wind Turbine Jacket Design PaperDokumen8 halamanGL Offshore Wind Turbine Jacket Design PaperJolly JackBelum ada peringkat

- Suction Bucket FoundationDokumen17 halamanSuction Bucket FoundationKeith JenningsBelum ada peringkat

- Parametric Modelling of Large Wind Turbine Blades: Paul A. Bonnet, and Geoff DuttonDokumen15 halamanParametric Modelling of Large Wind Turbine Blades: Paul A. Bonnet, and Geoff DuttonhoudiefaBelum ada peringkat

- The Modelling of Suction Caisson Foun-Dations For Multi-Footed StructuresDokumen172 halamanThe Modelling of Suction Caisson Foun-Dations For Multi-Footed StructuresNguyen Thanh Duc BKBelum ada peringkat

- 117 EOW2009presentationDokumen9 halaman117 EOW2009presentationJACKBelum ada peringkat

- Aero-Structural Blade Design of A High-Power Wind Turbine: Bruno M. Tojo and Andr e C. MartaDokumen14 halamanAero-Structural Blade Design of A High-Power Wind Turbine: Bruno M. Tojo and Andr e C. MartaMIGUEL ANGEL DURON SAAVEDRABelum ada peringkat

- Aeroelastic Coupling Analysis of The Flexible Blade of A Wind TurbineDokumen9 halamanAeroelastic Coupling Analysis of The Flexible Blade of A Wind Turbinemohdsolihat1Belum ada peringkat

- Effect of Eccentricity On Analysis and Design of Isolated FootingsDokumen18 halamanEffect of Eccentricity On Analysis and Design of Isolated Footingsप्रभु नाथ सिंहBelum ada peringkat

- Frame Design To EC3Dokumen2 halamanFrame Design To EC3Paul KarijaBelum ada peringkat

- Improved Design of Transversally Stiffened Steel Plate Girders Subjected To Patch LoadingDokumen21 halamanImproved Design of Transversally Stiffened Steel Plate Girders Subjected To Patch LoadingPieter MeulendijksBelum ada peringkat

- Aeroelastic Coupling Analysis of The FleDokumen9 halamanAeroelastic Coupling Analysis of The Flehaythem.mejri.proBelum ada peringkat

- Fatigue of Grouted Joint ConnectionsDokumen5 halamanFatigue of Grouted Joint Connectionsscrane@Belum ada peringkat

- Development of A Lightweight Tubular Space FrameDokumen7 halamanDevelopment of A Lightweight Tubular Space FrameJony M. TemnikarBelum ada peringkat

- HFFB Vs HFPI ASCE Structures Congress May 18-21-2006 St. Louis Missouri USA 633Dokumen10 halamanHFFB Vs HFPI ASCE Structures Congress May 18-21-2006 St. Louis Missouri USA 633gauravBelum ada peringkat

- Madeira - Computational Mechanics in Timber Structure DesignDokumen10 halamanMadeira - Computational Mechanics in Timber Structure DesignSidney RossiBelum ada peringkat

- Calculation of Stress Time Signals of Multi-Bolted JointsDokumen8 halamanCalculation of Stress Time Signals of Multi-Bolted JointsdemercatoBelum ada peringkat

- Multiple-Grooved Magnetic Traction SheavesDokumen14 halamanMultiple-Grooved Magnetic Traction SheavesJorge Prado DiazBelum ada peringkat

- 02 - Optimum Topology Design For The Concentrated Force Diffusion Structure of Strap-On Launch VehicleDokumen5 halaman02 - Optimum Topology Design For The Concentrated Force Diffusion Structure of Strap-On Launch VehicleKalyude DiógenesBelum ada peringkat

- Blade-Resolved CFD Simulations of A Periodic Array of NREL 5 MW Rotors With and Without TowersDokumen17 halamanBlade-Resolved CFD Simulations of A Periodic Array of NREL 5 MW Rotors With and Without Towersmirage_et_rafale9572Belum ada peringkat

- 1862 Differential Equations Used To Analyse and Observe Effect of Impact Loads On Wind TurbineDokumen10 halaman1862 Differential Equations Used To Analyse and Observe Effect of Impact Loads On Wind TurbineDouglas Cruz100% (1)

- Effect of Eccentricity On Analysis and Design of Isolated FootingsDokumen20 halamanEffect of Eccentricity On Analysis and Design of Isolated FootingsAlexandros PapamarinopoulosBelum ada peringkat

- Optimization and Performance of Bifacial Solar Modules: A Global PerspectiveDokumen19 halamanOptimization and Performance of Bifacial Solar Modules: A Global Perspectiveshajahan anikkadanBelum ada peringkat

- HFFB Vs HFPI ASCE Structures Congress May 18-21 2006 St. Louis Missouri USA 633 PDFDokumen10 halamanHFFB Vs HFPI ASCE Structures Congress May 18-21 2006 St. Louis Missouri USA 633 PDFHCStepBelum ada peringkat

- Eurosteel Subsequent ModificationsDokumen11 halamanEurosteel Subsequent ModificationsMuraliBelum ada peringkat

- Dynamics and Control of Spar-Type Floating Offshore Wind Turbines With Tuned Liquid Column DampersDokumen25 halamanDynamics and Control of Spar-Type Floating Offshore Wind Turbines With Tuned Liquid Column DampersDhirendra Kumar PandeyBelum ada peringkat

- Energies 12 00659 PDFDokumen28 halamanEnergies 12 00659 PDFPonniyin SelvanBelum ada peringkat

- Aeroelastic Analysis of A Floating Offshore Wind Turbine in Platform-Induced Surge Motion Using A Fully Coupled CFD-MBD MethodDokumen42 halamanAeroelastic Analysis of A Floating Offshore Wind Turbine in Platform-Induced Surge Motion Using A Fully Coupled CFD-MBD MethodGerry RyanBelum ada peringkat

- Effect of Eccentricity on Footing Analysis & DesignDokumen22 halamanEffect of Eccentricity on Footing Analysis & DesignAyon SenguptaBelum ada peringkat

- Finite Element Analysis of The Tower CraDokumen4 halamanFinite Element Analysis of The Tower CraMadhu KolatiBelum ada peringkat

- Solving Wind Farm Layout Optimization with Mixed Integer Programming and Constraint Programming ModelsDokumen16 halamanSolving Wind Farm Layout Optimization with Mixed Integer Programming and Constraint Programming ModelsvsukrishnaBelum ada peringkat

- DTU Wind Energy E 0046Dokumen91 halamanDTU Wind Energy E 0046ssnivashanBelum ada peringkat

- Traction Versus Slip in A Wheel-Driven Belt Conveyor: Mechanism and Machine TheoryDokumen10 halamanTraction Versus Slip in A Wheel-Driven Belt Conveyor: Mechanism and Machine TheoryWashington MoraisBelum ada peringkat

- Applsci 11 00730 v2Dokumen25 halamanApplsci 11 00730 v2CharbelBelum ada peringkat

- Structural Optimization Procedure of A Composite Wind Turbine Blade For Reducing Both Material Cost and Blade WeightDokumen20 halamanStructural Optimization Procedure of A Composite Wind Turbine Blade For Reducing Both Material Cost and Blade WeightNasser ShelilBelum ada peringkat

- Sika FRP Design Program ManualDokumen10 halamanSika FRP Design Program ManualYoshua Yang100% (1)

- Planetary Gear SystemDokumen11 halamanPlanetary Gear SystemNikhil NairBelum ada peringkat

- InTech-Structural Analysis of Complex Wind Turbine Blades Flexo Torsional Vibrational ModesDokumen28 halamanInTech-Structural Analysis of Complex Wind Turbine Blades Flexo Torsional Vibrational ModesMahmoud MoussaBelum ada peringkat

- Ship Collisions With Pile-Supported StructuresŠEstimates of Strength and Ductility Requirements PDFDokumen6 halamanShip Collisions With Pile-Supported StructuresŠEstimates of Strength and Ductility Requirements PDFsimolas123Belum ada peringkat

- Buckling Considerations and Cross Sectional Geometry Development For Topology Optimised Body in WhiteDokumen13 halamanBuckling Considerations and Cross Sectional Geometry Development For Topology Optimised Body in WhiteSairam PeddiBelum ada peringkat

- An Offshore Wind Turbine Foundation DesignDokumen9 halamanAn Offshore Wind Turbine Foundation Designhany seifBelum ada peringkat

- Effect of Eccentric Loading on Footing DesignDokumen6 halamanEffect of Eccentric Loading on Footing DesignPratik RaoBelum ada peringkat

- Calculating No-Load Loss in Power Transformers with Five-Limb CoresDokumen10 halamanCalculating No-Load Loss in Power Transformers with Five-Limb CoresAkash VermaBelum ada peringkat

- Collapse Load Analysis of Yield-Line ElementsDokumen7 halamanCollapse Load Analysis of Yield-Line ElementsAlaa Elsisi100% (1)

- Appendix K Slab-Wall ModelDokumen6 halamanAppendix K Slab-Wall Modelce_rashidBelum ada peringkat

- Analysis Assignment 2 - 2021Dokumen8 halamanAnalysis Assignment 2 - 2021kameshBelum ada peringkat

- Cable Bowden Actuator Force FeddbackDokumen6 halamanCable Bowden Actuator Force FeddbackAb Imō PectoreBelum ada peringkat

- Response of Inelastic SDOF Systems To Earthquake LoadingDokumen71 halamanResponse of Inelastic SDOF Systems To Earthquake LoadingludwingBelum ada peringkat

- Use of A Wave Energy Converter As A Motion Suppression Device For Floating Wind TurbinesDokumen11 halamanUse of A Wave Energy Converter As A Motion Suppression Device For Floating Wind TurbinesmahdiBelum ada peringkat

- Seismic Virtual Team FAQs - Foundation Modeling and Analysis TechniquesDokumen2 halamanSeismic Virtual Team FAQs - Foundation Modeling and Analysis TechniquesRC Dela RocaBelum ada peringkat

- Magazine of Concrete Research - 61!6!2009-Slab DeflectionDokumen42 halamanMagazine of Concrete Research - 61!6!2009-Slab DeflectionSyed RaziuddinBelum ada peringkat

- W GONG Finite Element Analysis of A Wind Turbine TowerDokumen46 halamanW GONG Finite Element Analysis of A Wind Turbine TowerJiawa LuBelum ada peringkat

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionDari EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionPenilaian: 4 dari 5 bintang4/5 (4)

- NGen 2018 V (1.2) - Release NoteDokumen6 halamanNGen 2018 V (1.2) - Release NoteRamon GutierrezBelum ada peringkat

- Set Citizen Watch Time ZoneDokumen37 halamanSet Citizen Watch Time Zoneseeker348Belum ada peringkat

- Tutorial: C I V I LDokumen23 halamanTutorial: C I V I LRamon GutierrezBelum ada peringkat

- Mat and ParamsDokumen20 halamanMat and ParamsRamon GutierrezBelum ada peringkat

- NCHRP RPT 584Dokumen119 halamanNCHRP RPT 584Ramon Gutierrez100% (1)

- CE Marking For Wind Turbines PDFDokumen2 halamanCE Marking For Wind Turbines PDFRamon GutierrezBelum ada peringkat

- NumericalDokumen663 halamanNumericalJingzhou Wang100% (4)

- Norten EnglishDokumen29 halamanNorten EnglishRamon GutierrezBelum ada peringkat

- Design and Analysis of Heavily Loaded Reinforced Concrete Link Beams For Burj DubaiDokumen10 halamanDesign and Analysis of Heavily Loaded Reinforced Concrete Link Beams For Burj DubaiJoão Rocha de Lima100% (1)

- Manual Fagus 7Dokumen157 halamanManual Fagus 7Ramon Gutierrez100% (1)

- Midas Midas Gen Gen: Advanced Webinar Advanced WebinarDokumen23 halamanMidas Midas Gen Gen: Advanced Webinar Advanced WebinarRamon Gutierrez100% (1)

- MIDAS Civil 2013 Analysis ReferenceDokumen400 halamanMIDAS Civil 2013 Analysis ReferenceFernando Viloria0% (1)

- Design and Analysis of Heavily Loaded Reinforced Concrete Link Beams For Burj DubaiDokumen10 halamanDesign and Analysis of Heavily Loaded Reinforced Concrete Link Beams For Burj DubaiJoão Rocha de Lima100% (1)

- FAGUS6 - Materials and Analysis ParametersDokumen15 halamanFAGUS6 - Materials and Analysis ParametersRamon GutierrezBelum ada peringkat

- Eerc91 17Dokumen140 halamanEerc91 17Ma GhBelum ada peringkat

- Petra - PG 9 2010Dokumen28 halamanPetra - PG 9 2010Ramon GutierrezBelum ada peringkat

- Constitutive Models of ConcreteDokumen37 halamanConstitutive Models of ConcreteRamon Gutierrez100% (1)

- CA2679646A1 Patente ATS EnglishDokumen23 halamanCA2679646A1 Patente ATS EnglishRamon GutierrezBelum ada peringkat

- Stress-Strain Model of Unconfined and Confined Concrete and Stress-Block ParametersDokumen112 halamanStress-Strain Model of Unconfined and Confined Concrete and Stress-Block ParametersGabrielaSanMartínBelum ada peringkat

- RHEOCRETE222Plus Eng307Dokumen2 halamanRHEOCRETE222Plus Eng307Ramon GutierrezBelum ada peringkat

- Analysis and design of a 1-MW wind turbine steel towerDokumen10 halamanAnalysis and design of a 1-MW wind turbine steel towertstamaBelum ada peringkat

- Precast 1 Concepts PDFDokumen111 halamanPrecast 1 Concepts PDFRaymond Chan100% (5)

- M - IMP - Prestressed Hollow Core Design To Bs8110Dokumen295 halamanM - IMP - Prestressed Hollow Core Design To Bs8110Ramon GutierrezBelum ada peringkat

- Simpack Wind 2010 Swe LoadsimulationsDokumen26 halamanSimpack Wind 2010 Swe LoadsimulationsRamon Gutierrez100% (1)

- CE Marking For Wind TurbinesDokumen2 halamanCE Marking For Wind TurbinesRamon GutierrezBelum ada peringkat

- DD Cen TS 1992-4-1-2009Dokumen68 halamanDD Cen TS 1992-4-1-2009Kovacs Zsolt-IstvanBelum ada peringkat

- Guideline For The Certification of Wind Turbines Edition 2010 R0 2Dokumen389 halamanGuideline For The Certification of Wind Turbines Edition 2010 R0 2Asid ZullahBelum ada peringkat

- Wind Turbine Foundations and Tower Installation: by Amy MurphyDokumen1 halamanWind Turbine Foundations and Tower Installation: by Amy MurphyRamon GutierrezBelum ada peringkat

- NP EX19 11a JinruiDong 2Dokumen11 halamanNP EX19 11a JinruiDong 2Ike DongBelum ada peringkat

- Vacuum Distillation Solar Saltwork PDFDokumen3 halamanVacuum Distillation Solar Saltwork PDFabdulBelum ada peringkat

- Water SupplyDokumen27 halamanWater SupplyLnazerA.CeceBelum ada peringkat

- Design Technology HL Paper 1Dokumen16 halamanDesign Technology HL Paper 1zerleneBelum ada peringkat

- Gasketed Plate Heat Exchanger: Mme 9516 Hvac 1 Project PresentationDokumen16 halamanGasketed Plate Heat Exchanger: Mme 9516 Hvac 1 Project PresentationrudyBelum ada peringkat

- LEA Digital Control Systems eDokumen12 halamanLEA Digital Control Systems eproesantBelum ada peringkat

- Chapter-4 Work, Energy and Momentum PDFDokumen6 halamanChapter-4 Work, Energy and Momentum PDFMohammad Fuad HasanBelum ada peringkat

- ASHRAE Terminology - Complete ListDokumen382 halamanASHRAE Terminology - Complete ListJose Luis ZIMICBelum ada peringkat

- Pelton Turbine CharacteristicsDokumen10 halamanPelton Turbine CharacteristicsViknesh MjBelum ada peringkat

- PGCIL Standard Formats for Substation OperationDokumen39 halamanPGCIL Standard Formats for Substation Operationramesh epili100% (1)

- General Description: Range ZNDokumen7 halamanGeneral Description: Range ZNAykut BacakBelum ada peringkat

- Vacon NXP NXC User Manual Dpd01286b SeDokumen104 halamanVacon NXP NXC User Manual Dpd01286b SeRelativity81Belum ada peringkat

- Natural Gas Prices and Charts - Data From QuandlDokumen4 halamanNatural Gas Prices and Charts - Data From QuandlPrakarn KorkiatBelum ada peringkat

- Decimator G-String schematic and parts listDokumen6 halamanDecimator G-String schematic and parts listАлексей КурниковBelum ada peringkat

- Honeywell Pressuretrol Switch L404F 2004Dokumen8 halamanHoneywell Pressuretrol Switch L404F 2004PlinioPadillaBelum ada peringkat

- Engines-Tpe331 10Dokumen2 halamanEngines-Tpe331 10Hasan Basri Azis75% (4)

- Alpaccess: Wind Turbine Maintenance & RepairsDokumen7 halamanAlpaccess: Wind Turbine Maintenance & RepairsDragos StateBelum ada peringkat

- Dual Nature of Matter and RadiationDokumen6 halamanDual Nature of Matter and RadiationGayatriBelum ada peringkat

- Martempering and Austempering Final SlideDokumen25 halamanMartempering and Austempering Final SlidekeirthBelum ada peringkat

- Design Calculation of Wind Turbine BladeDokumen3 halamanDesign Calculation of Wind Turbine BladeIslahuddinBelum ada peringkat

- 60-8015 - Check List For Electrical Heat Tracing System RFQDokumen3 halaman60-8015 - Check List For Electrical Heat Tracing System RFQDinesh RajBelum ada peringkat

- EV Dale Spencer PDFDokumen22 halamanEV Dale Spencer PDFprabhu agarwalBelum ada peringkat

- Additive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Dokumen35 halamanAdditive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Mazhar HussainBelum ada peringkat

- NURS 1013 Lecture 1 - History and DefinitionDokumen21 halamanNURS 1013 Lecture 1 - History and DefinitionMonique Christie100% (1)

- Technical Presentation PDFDokumen78 halamanTechnical Presentation PDFMd NazriBelum ada peringkat

- 2106T0642 TK70 Concrete PumpDokumen128 halaman2106T0642 TK70 Concrete Pumpviemey1952100% (3)

- Quot & BQ Maintenance Panel C-1 AreaDokumen2 halamanQuot & BQ Maintenance Panel C-1 AreaferdinanBelum ada peringkat

- SPM Trial 2010 Physics Qa JohorDokumen88 halamanSPM Trial 2010 Physics Qa JohorEric MitchellBelum ada peringkat

- 8th BGS Congress Programme FinalDokumen44 halaman8th BGS Congress Programme FinalAna Maria CiupercaBelum ada peringkat

- Cellular Respiration: Nelson Biology Pages 204 - 228Dokumen60 halamanCellular Respiration: Nelson Biology Pages 204 - 228allie3d100% (14)