05 602 PS10EX Pressure Switch (Ex-Proof)

Diunggah oleh

Adam SamyJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

05 602 PS10EX Pressure Switch (Ex-Proof)

Diunggah oleh

Adam SamyHak Cipta:

Format Tersedia

EXPLOSION PROOF (HIGH / LOW) PRESSURE SWITCH

05 PS10-EX

FEATURES

y

Designed for Detection of a Water Flow condition in

Automatic Fire Sprinkler Systems in Hazardous

Locations

Both Switch Operates on Pressure Decrease at

6 PSI +/- 1 PSI and Pressure Increase at 5 PSI

+/- 1 PSI

Maximum Differential : 1 PSI

Cast Aluminium, NEMA 4 and 7 Rated Enclosure

Switch Contacts are Two Sets SDPT (Form C).

Rated 15.0 amps at 125/250 VAC and 2.0 amps at

30 vdc

Connection : 1/2" NPT Male

Dimensions : 6 diameter x 7 Height

UL / CSFM Listed and FM Approved

Typical Applications include wet systems with alarm check or dry pipe systems. The pressure switch may also

be used to provide a low pressure supervisory signal. Suitable for hazardous locations classified as Class 1,

Division 1, Groups B, C & D; Class II, Division 1, Groups E, F & G and Class III, Division 1,

Installation and Test Procedure

WET SYSTEM:

Method 1 : When using the pressure switch and control unit with a retard, connect the switch into alarm port

piping and the input side of the retard chamber and electrically connect the switch to control unit that provides

a retard to compensate for surges. Ensure that no shutoff valves are present between the alarm check valve

and the pressure switch.

Method 2 : When using the pressure switch for local bell application or with a control that does not provide a

retard feature, the switch must be installed on the alarm outlet side of the retard chamber of the sprinkler

system.

Testing : Accomplished by opening the inspector's end-of-the test valve. Allow time to compensate for system

or control retard.

CAUTION : Method 2 is not applicable for remote station service use.

WET SYSTEM WITH EXCESS PRESSURE:

Connect the pressure switch into alarm port piping extending from alarm check valve. Retard provisions are

not required. Ensure that no shutoff valves are present between the alarm and check valve and the switch.

Testing : Accomplished by opening the water bypass test valve or the inspector's end-of-the test valve. When

using end-of-line, allow time for excess pressure to bleed off.

DRY SYSTEM:

Connect the pressure switch into the piping that extends from the intermediate chamber of the dry sprinkler

valve. Install on the outlet side of the inline check valve of the piping. Ensure that no shutoff valves are

present between the dry sprinkler valve and the pressure switch.

Testing : Accomplished by opening the water bypass test valve.

CAUTION: The above tests may also activate other circuit closer or water motor gongs that are present on the

system.

EXPLOSION PROOF (HIGH / LOW) PRESSURE SWITCH

05 PS10-EX

PRESSURE SWITCH

TERMINATION

NOTE: To prevent leakage, apply teflon tape

sealant to male threads only.

WARNING: Use of pipe joint cement may result

in obstruction of aperture and loss of signal.

CAUTION: When this device is to be installed in an area that is classified as HAZARDOUS, the person

responsible for safety in the area should be contacted to determine if the tools and operations required for the

installation of the device and associated components are permitted in the area. To reduce the risk of ignition of

hazardous atmospheres, disconnect supply circuits before opening cover. Keep cover tight while circuits are live.

Cover screws must be torqued to 45-50 in. lbs.

ENGINEER/ARCHITECT SPECIFICATIONS

Pressure type waterflow switches shall be a Model PS10-EX as manufactured by Potter Electric Signal Co. of St. Louis, Mo. and

shall be installed on the sprinkler systems as shown on the drawings and/or specified herein.

Switches shall be provided with a 1/2" NPT male pressure connection to be connected into the alarm check valve of a wet

sprinkler system or into the intermediate chamber of a dry pipe system and shall be actuated by any flow of water to or in excess

of the discharge from one sprinkler head.

Switches shall have a maximum service pressure rating of 250 PSI and shall be factory adjusted to operate on pressure increase

at 6 1 PSI. There shall be two (2) SPDT contacts rated at 15.0 Amps at 125/250VAC and 2.5 Amps at 30VDC.

The switch housing shall be weather proof and oil resistant with a NEMA 4 rating. The cover shall incorporate tamper resistant

screws.

The unit shall be listed by Underwriters Laboratories, Inc. and CSFM and approved by Factory Mutual. It shall be rated for use in

hazardous locations classified as Class I, Groups B, C, D, Div. 1; Class II, Groups E, F, G, Div. 1; Class III, Div. 1.

EXPLOSION PROOF (HIGH / LOW) PRESSURE SWITCH

05 PS10-EX

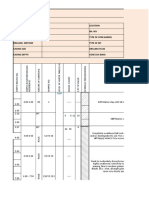

ORDERING INFORMATION

Mode

Descriptio

05 PS10-E

Stock No.

Pressure switch with two sets SPDT contact

Hex Key

1350102

5250073

TYPICAL SPRINKLER APPLICATIONS

CAUTION: Closing of any shutoff valves between the alarm check valve and the PS10-EX will render the PS10-EX

inoperative. To comply with NFPA-72 any such valve shall be electrically supervised with a supervisory switch

such as Potter Model BVS.

TYPICAL ELECTRICAL CONNECTIONS

SWITCH TERMINAL CONNECTIONS

CLAMPING PLATE TERMINAL

CAUTION:

An uninsulated section of a single conductor should not be

looped around the terminal and serve as two separate

connections. The wire must be severed, thereby providing

supervision of the connection in the event that the wire

becomes dislodged from under the terminal.

Anda mungkin juga menyukai

- ManualDokumen79 halamanManualAdam SamyBelum ada peringkat

- 2000 Flyer v2Dokumen2 halaman2000 Flyer v2Adam SamyBelum ada peringkat

- 2Dokumen8 halaman2Adam SamyBelum ada peringkat

- S103C E - Magnetici Flowmter CH2200 - 2500 Flanged PipeDokumen7 halamanS103C E - Magnetici Flowmter CH2200 - 2500 Flanged PipeAdam SamyBelum ada peringkat

- GSR High TempratureDokumen3 halamanGSR High TempraturestruanBelum ada peringkat

- FJN 501 eDokumen2 halamanFJN 501 eAdam SamyBelum ada peringkat

- Code of Practice forThermalOilHeaters PDFDokumen56 halamanCode of Practice forThermalOilHeaters PDFarjmandquestBelum ada peringkat

- General CatalogDokumen115 halamanGeneral CatalogAdam SamyBelum ada peringkat

- Select Proper Magnetic Flowmeter SizeDokumen1 halamanSelect Proper Magnetic Flowmeter SizeAdam SamyBelum ada peringkat

- 2/2 Way Solenoid Valve - BC-40Dokumen1 halaman2/2 Way Solenoid Valve - BC-40Adam SamyBelum ada peringkat

- Pressure Switch in Hydraulic or Pneumatic Design For Mining and ChemistryDokumen2 halamanPressure Switch in Hydraulic or Pneumatic Design For Mining and ChemistryAdam SamyBelum ada peringkat

- 4204 Livello Ad Ultrasuoni ENGDokumen2 halaman4204 Livello Ad Ultrasuoni ENGAdam SamyBelum ada peringkat

- S103C E - Magnetici Flowmter CH608 ConverterDokumen2 halamanS103C E - Magnetici Flowmter CH608 ConverterAdam SamyBelum ada peringkat

- Product Catalogue: Minicomb EDSDokumen8 halamanProduct Catalogue: Minicomb EDSAdam SamyBelum ada peringkat

- SGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Dokumen2 halamanSGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Adam SamyBelum ada peringkat

- Honeywell Sensing Switch 5000 Series ProductsheetDokumen2 halamanHoneywell Sensing Switch 5000 Series ProductsheetAdam SamyBelum ada peringkat

- PressureDokumen2 halamanPressureAdam SamyBelum ada peringkat

- Sor Adjustable Dead Band Pressure SwitchDokumen16 halamanSor Adjustable Dead Band Pressure SwitchAdam SamyBelum ada peringkat

- Pressure Switches For Process Applications Gi496Dokumen8 halamanPressure Switches For Process Applications Gi496Adam SamyBelum ada peringkat

- 05 602 PS10EX Pressure Switch (Ex-Proof) .Dokumen8 halaman05 602 PS10EX Pressure Switch (Ex-Proof) .Adam SamyBelum ada peringkat

- 6900DZ - 2013 12 06pRESSUREDokumen2 halaman6900DZ - 2013 12 06pRESSUREAdam SamyBelum ada peringkat

- 6900DZ - 2013 12 06pRESSUREDokumen2 halaman6900DZ - 2013 12 06pRESSUREAdam SamyBelum ada peringkat

- Interruptor de Presion - AscoDokumen9 halamanInterruptor de Presion - AscoJosephGutierrezBelum ada peringkat

- Tipe SwitchDokumen1 halamanTipe Switchdwi mahadiyanBelum ada peringkat

- Adjustable Explosion Proof Pressure SwitchDokumen2 halamanAdjustable Explosion Proof Pressure SwitchAdam SamyBelum ada peringkat

- En - 5.11.37105 602 PS10Switch (Ex-Proof)Dokumen3 halamanEn - 5.11.37105 602 PS10Switch (Ex-Proof)Adam SamyBelum ada peringkat

- Barksdale 7000pRESSUREDokumen4 halamanBarksdale 7000pRESSUREAdam SamyBelum ada peringkat

- P RESSUREDokumen5 halamanP RESSUREAdam SamyBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Liebherr LN 252-1 Zinco AltoDokumen6 halamanLiebherr LN 252-1 Zinco AltowiroBelum ada peringkat

- TEST YOUR KNOWLEDGE - WELDED JOINTS QUIZDokumen2 halamanTEST YOUR KNOWLEDGE - WELDED JOINTS QUIZkalpanaadhi100% (1)

- Asme Sa 213 Grade t92 TubesDokumen1 halamanAsme Sa 213 Grade t92 TubesFerroPipEBelum ada peringkat

- P 615 SN 4147526Dokumen52 halamanP 615 SN 4147526Dan Alin MirceaBelum ada peringkat

- Ritter Solar GMBH & Co. KGDokumen30 halamanRitter Solar GMBH & Co. KGMagdyBelum ada peringkat

- 370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFDokumen468 halaman370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFTomasz Cz100% (1)

- Steel Erection ITPDokumen26 halamanSteel Erection ITPIksan Adityo MulyoBelum ada peringkat

- QSB3.3 Parts Catalog 68331277Dokumen91 halamanQSB3.3 Parts Catalog 68331277Галина КарташоваBelum ada peringkat

- Chapter8 - Design Theory & Procedure PDFDokumen407 halamanChapter8 - Design Theory & Procedure PDFJunwhan KimBelum ada peringkat

- Top 25 ASA Product ListDokumen1 halamanTop 25 ASA Product Listmizan sallehBelum ada peringkat

- NEC 316.10 Ampacity Table For Cable Conductor SizingDokumen1 halamanNEC 316.10 Ampacity Table For Cable Conductor SizingHumayun RazaBelum ada peringkat

- Medidor Digital B&W-4Dokumen2 halamanMedidor Digital B&W-4Aaron Quispe PinedaBelum ada peringkat

- Voyager II IOM Cooling - Gas FiredDokumen64 halamanVoyager II IOM Cooling - Gas FiredSadiq AmeerBelum ada peringkat

- Fastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatDokumen2 halamanFastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatRay RamiloBelum ada peringkat

- Assignment-10 CE39 NOC20Dokumen7 halamanAssignment-10 CE39 NOC20jayadeep ksBelum ada peringkat

- Scrutiny Report of Building PlanDokumen7 halamanScrutiny Report of Building PlanSubirBhowmikBelum ada peringkat

- Bolts Torque CalculatorDokumen3 halamanBolts Torque CalculatorAlexandre LaraBelum ada peringkat

- Assignment Road Constuction IIDokumen6 halamanAssignment Road Constuction IIKry ThanakBelum ada peringkat

- 04 Marl Chemical Park PDFDokumen36 halaman04 Marl Chemical Park PDFAnusha Rajagopalan100% (1)

- SB Brace Frame For Single Sided Walls Instructions For Assembly and UseDokumen84 halamanSB Brace Frame For Single Sided Walls Instructions For Assembly and UseYaser IsmailBelum ada peringkat

- Master Architects - International StyleDokumen13 halamanMaster Architects - International StylesakshiBelum ada peringkat

- Air Hoists & TrolleyDokumen12 halamanAir Hoists & TrolleyHimindra ChaaubeBelum ada peringkat

- NewwDokumen7 halamanNewwIrfanmaulana ardiansyahBelum ada peringkat

- Ingersoll Rand AC185D Operators ManualDokumen284 halamanIngersoll Rand AC185D Operators ManualAntonio Carrion100% (2)

- Connection and Fastening Guide: Recommendations For The Construction of Code-Compliant DecksDokumen40 halamanConnection and Fastening Guide: Recommendations For The Construction of Code-Compliant DecksbassigwBelum ada peringkat

- LONG TERM CONSTRUCTION REVENUEDokumen5 halamanLONG TERM CONSTRUCTION REVENUERoxell CaibogBelum ada peringkat

- Bore LogDokumen4 halamanBore LogVardhanBelum ada peringkat

- The Finite Element Analysis For Fork Based On ANSYSDokumen3 halamanThe Finite Element Analysis For Fork Based On ANSYSPacy MugishoBelum ada peringkat

- 2 NDDokumen3 halaman2 NDAgnes AsilBelum ada peringkat

- ICS - Group ProfileDokumen60 halamanICS - Group ProfileShaikh Abdulsaboor SapruBelum ada peringkat