Painting Inspection Procedure PDF

Diunggah oleh

Phạm Văn ĐảngDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Painting Inspection Procedure PDF

Diunggah oleh

Phạm Văn ĐảngHak Cipta:

Format Tersedia

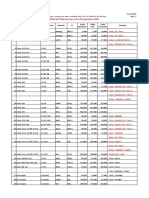

Painting audit

Project

Product

Workshop

Inspector

Audit object

No

Linkou FF unit 2

Hopper frame

DDC1

Steven Chen

Painting

Painting Sequence

10 pcs

Description

Status

Remark

+ DDC have no painting procedure, only show the record

chart for painting requirement.

+ Where is the painting procedure , can you ask them?

+ Yes. See the attached photo.

Painting procedure

Show simple chart according to Alstom

specification

Yes

+ Are they applying stripe coat to corners, edges , to

hard to coat area before starting paint?

+ Yes, the worker applying the coat to the corners,

edges,

+ Are they mixing paint as per recommendation of paint

manufacturer?

+ Yes, during audit on workshop, the mixing paint

according the paint instruction of paint manufacturer.

+ The paints and color are in line with ALSTOM painting

specification.

Paint

Primer: resist 78, grey

Yes, follow painting procedure

+ Are they using paint(primer, intermediate, final) and

thinner from the same paint manufacturer?

Yes, referred as photo.

+ Poor painting area, there are welding, grinding,

cleaning operating nearly.

Painting area

Not good

1. Have you found any dust or any foreign particles

before painting on the steel?

No;

2. Are they removing the dust, etc by compress air

before painting?

Yes, removing the dust by compress air before painting.

3. Are they doing blasting and painting on the same area

and time?

+ There are different area for blasting and painting.

+ The blasting machine show as attach photo.

Surface treat process

Blasting

Yes,

1. Is the blasting machine have all components (pressure

gauge, moisture separator, etc)

+ Can you give details report (name of the parts,

calibration status any)

+ The DDC QC cannot show the surface inspection card.

Surface inspection

SSPC-10

No inspection card to be compared after 1. How are they comparing the blasted surface profile,

whether the required profile achieved or not. They may

blasting

use ISO comparator or tape to check the surface profile.

+ One of the major reason of coating failure is due to

poor surface preparation.

+ DDC was informed that the painting operating area

shall prepared the measured tools.

Temperature and humidity

Time control

No measured tools presented

Painting sequence was controlled each

layer

Yes

+ Can you check temperature, humidity during painting

for a particular product?

+ Please check the DDCs painting report of the same

component.

+ As surveillance on workshop, the painting separate to

paint, and control.

1. Are they maintaining any log sheet against each coat

to confirm the curing time of the paint as per paint data

sheet.

+ How they are preparing the inspection report? Who is

recording all the details?

+ We are receiving painting report against a batch of

fabricated parts with same date and time.

Spot check thickness

Thickness to be check after drying.

Yes

1. Are they checking wet film thickness to confirm the

required DFT during painting. We can control higher

DFT, if we check wet film thickness in regular interval

during painting against each coat.

Refer photo

+ No, they checking the dry film thickness only;

Anda mungkin juga menyukai

- Painting Inspector Hand BookDokumen5 halamanPainting Inspector Hand BookAmaan Khan100% (7)

- Questions For Paint InspectorDokumen20 halamanQuestions For Paint InspectorHosam Ahmed100% (3)

- Painting and Coating Inspector Interview QuestionsDokumen7 halamanPainting and Coating Inspector Interview Questionsவிஷ்ணு ராஜசெல்வன்100% (2)

- Coating Interview QuestionDokumen1 halamanCoating Interview QuestionMatthew Baker100% (3)

- Painting - Training PPT 1Dokumen24 halamanPainting - Training PPT 1vijay padale80% (5)

- Quallity Control JPCLDokumen37 halamanQuallity Control JPCLSerhan ÜnverBelum ada peringkat

- BGAS PaperDokumen9 halamanBGAS PaperMuhammad AsifBelum ada peringkat

- Qstns 1Dokumen29 halamanQstns 1Shawn Leo100% (2)

- CBT 3Dokumen9 halamanCBT 3SUNIL RAJPUT100% (1)

- Painting Inspection Grade 2Dokumen17 halamanPainting Inspection Grade 2Midhun K Chandrabose100% (3)

- Coating PaintingDokumen8 halamanCoating Paintingdeva0170% (2)

- BGas Painting Multiple Choice 2Dokumen17 halamanBGas Painting Multiple Choice 2Abdul Gafoor86% (14)

- Dewpoint: Coating & Painting InspectionDokumen6 halamanDewpoint: Coating & Painting InspectionMeet Patel100% (1)

- DFT RulesDokumen4 halamanDFT RulesSalahuddin Farooqui100% (1)

- Report PaintDokumen1 halamanReport PaintEhsan KhanBelum ada peringkat

- File SSPC Pci Study Guide PDFDokumen3 halamanFile SSPC Pci Study Guide PDFmicah50% (2)

- Coating QaDokumen17 halamanCoating Qasbmmla100% (9)

- Coating Inspector ResumeDokumen4 halamanCoating Inspector Resumetulasirao.nammiBelum ada peringkat

- ABDULLA QAQC Painting& Coating InspectorDokumen5 halamanABDULLA QAQC Painting& Coating InspectorawaisBelum ada peringkat

- Procedure of Apcs-113cDokumen8 halamanProcedure of Apcs-113cNoman AhmedBelum ada peringkat

- Blaster Sprayer Trade TestDokumen7 halamanBlaster Sprayer Trade TestSteven Flynn100% (1)

- Paint Inspection BasicDokumen6 halamanPaint Inspection BasicmaddyBelum ada peringkat

- AnswersDokumen4 halamanAnswersWaseem YounisBelum ada peringkat

- Surface PreparationDokumen3 halamanSurface PreparationMohamed Reda Hussein80% (5)

- BGAS Painting Grade 1Dokumen83 halamanBGAS Painting Grade 1Durairaj ABelum ada peringkat

- Painting QuestionsDokumen3 halamanPainting Questionsmubashar100% (1)

- I Corr Inspector Exam Sample Questions Level 2Dokumen1 halamanI Corr Inspector Exam Sample Questions Level 2Gabriel Pana83% (6)

- Revision Questions PA 10 Specific Page 23-12Dokumen2 halamanRevision Questions PA 10 Specific Page 23-12Bayu Falen100% (2)

- Painting & Coating-1Dokumen17 halamanPainting & Coating-1sattanathan07100% (10)

- CBT 8Dokumen5 halamanCBT 8SUNIL RAJPUTBelum ada peringkat

- The Coating Inspectors HandbookR3.1Dokumen64 halamanThe Coating Inspectors HandbookR3.1Akhter Khan100% (11)

- Coating Crew SupervisorDokumen4 halamanCoating Crew Supervisorimtiaz100% (1)

- Painting Procedure Template PDFDokumen14 halamanPainting Procedure Template PDFjohn100% (1)

- Bgas Grade 1 QuestionsDokumen8 halamanBgas Grade 1 QuestionsRameshBelum ada peringkat

- Jotun Resist 86Dokumen5 halamanJotun Resist 86Ansar AliBelum ada peringkat

- Resume For Painting InspectorDokumen3 halamanResume For Painting InspectorMITHUNBelum ada peringkat

- 1-Frosio Chapter 1 Inspector Duties and BehaviourDokumen84 halaman1-Frosio Chapter 1 Inspector Duties and BehaviourtaiBelum ada peringkat

- Calculation QuestionsDokumen5 halamanCalculation QuestionsFaisal100% (1)

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureDokumen34 halaman000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- Paint Receiving ProcedureDokumen4 halamanPaint Receiving ProcedureHaytham Elsayed100% (1)

- Painting Maual For Power Sector ErectionDokumen32 halamanPainting Maual For Power Sector Erectionnagarathinam82Belum ada peringkat

- 1.10 Duplicate Counter Sample N Y: DeadlineDokumen6 halaman1.10 Duplicate Counter Sample N Y: DeadlineHasan Mehedi Pial100% (1)

- Painting ProcedureDokumen17 halamanPainting Procedurestdshop75% (4)

- ITCC in Riyadh Residential Complex J10-13300 09900-1 PaintingDokumen11 halamanITCC in Riyadh Residential Complex J10-13300 09900-1 PaintinguddinnadeemBelum ada peringkat

- Surface Cleaning and PaintingDokumen3 halamanSurface Cleaning and PaintingTridib Dey100% (1)

- Paint Inspection Checklist I PDFDokumen1 halamanPaint Inspection Checklist I PDFanush_swaminathan0% (1)

- Paint Inspection Checklist IDokumen1 halamanPaint Inspection Checklist Inageswara rao gundugulaBelum ada peringkat

- Nace Peer Review QuestionDokumen7 halamanNace Peer Review QuestionJoshua100% (13)

- Graffity Protection PB 4 013 2006 en 64860 PDFDokumen18 halamanGraffity Protection PB 4 013 2006 en 64860 PDFLivia MironBelum ada peringkat

- SF - PaintingDokumen7 halamanSF - Paintingibrahim shanBelum ada peringkat

- Roush Paint Appearance Standard As-100-1Dokumen6 halamanRoush Paint Appearance Standard As-100-1Radulović RaduleBelum ada peringkat

- TL 226 en 2018Dokumen13 halamanTL 226 en 2018Michal BílekBelum ada peringkat

- Substrates.) (The Following Interior Substrates:)Dokumen36 halamanSubstrates.) (The Following Interior Substrates:)Sean ChanBelum ada peringkat

- Scope: Painting ProcedureDokumen2 halamanScope: Painting Procedureคุณพ่อน้อง บิ๊กบอสBelum ada peringkat

- Inspection Report PSI : Product DescriptionDokumen13 halamanInspection Report PSI : Product DescriptionAnonymous wVcSUm6oBelum ada peringkat

- Painting Specfication ASSENT Doc No: PR-2019-05-007: 076551C-0000R-MR 1 8 0 0 1 0 1Dokumen23 halamanPainting Specfication ASSENT Doc No: PR-2019-05-007: 076551C-0000R-MR 1 8 0 0 1 0 1j fBelum ada peringkat

- HB Project - Painting Procedure For Steel StructuresDokumen7 halamanHB Project - Painting Procedure For Steel StructuresNgoc Quy100% (1)

- Mechanical PaintingDokumen15 halamanMechanical Paintingjack.simpson.changBelum ada peringkat

- Checklist For Painting Work of Structural SteelDokumen3 halamanChecklist For Painting Work of Structural Steelajit karandikar78% (9)

- Method Statement For Painting WorksDokumen5 halamanMethod Statement For Painting WorksJoe_Average78% (9)

- BS en 10279-2000 PDFDokumen10 halamanBS en 10279-2000 PDFPhạm Văn Đảng100% (1)

- Guidesteelworkssupervision PDFDokumen78 halamanGuidesteelworkssupervision PDFPhạm Văn ĐảngBelum ada peringkat

- en 13067 2003 PDFDokumen36 halamanen 13067 2003 PDFPhạm Văn Đảng100% (1)

- The Structure of Financial Supervision PDFDokumen256 halamanThe Structure of Financial Supervision PDFPhạm Văn ĐảngBelum ada peringkat

- CJ 46-X100D Drilling Jack-Up Unit PDFDokumen2 halamanCJ 46-X100D Drilling Jack-Up Unit PDFPhạm Văn Đảng0% (1)

- Bike Racks PDFDokumen8 halamanBike Racks PDFPhạm Văn ĐảngBelum ada peringkat

- 72 - Welding Distortion PDFDokumen1 halaman72 - Welding Distortion PDFPhạm Văn ĐảngBelum ada peringkat

- Maritime Stress Sales Catalog QA04-05, REV 4Dokumen20 halamanMaritime Stress Sales Catalog QA04-05, REV 4Phạm Văn ĐảngBelum ada peringkat

- 24 - Steel Repair Procedures Operations Manual Ny DotDokumen45 halaman24 - Steel Repair Procedures Operations Manual Ny DotJustin Morse75% (4)

- ITW Cored Wire Catalogue ENG PDFDokumen70 halamanITW Cored Wire Catalogue ENG PDFPhạm Văn ĐảngBelum ada peringkat

- Analysis of Plate Straightening ApproachesDokumen90 halamanAnalysis of Plate Straightening ApproachesPhạm Văn ĐảngBelum ada peringkat

- Neom Nwa Dat 2021 021 Air ValveDokumen5 halamanNeom Nwa Dat 2021 021 Air ValveES RAABelum ada peringkat

- M-501 Rev 5 Surface Prep & CoatingDokumen24 halamanM-501 Rev 5 Surface Prep & Coatingmareepierre003Belum ada peringkat

- Nord Lock Steel Construction Washers User ManualDokumen4 halamanNord Lock Steel Construction Washers User ManualThoncatBelum ada peringkat

- Optimization of Surface Roughness in Honing of Engine Cylinder Liners With Sic Honing StonesDokumen7 halamanOptimization of Surface Roughness in Honing of Engine Cylinder Liners With Sic Honing StonesHoang LamBelum ada peringkat

- Acristar FineDokumen1 halamanAcristar FineChristinaBelum ada peringkat

- New Price List Per 1 Sept 2018Dokumen2 halamanNew Price List Per 1 Sept 2018RizkiMohamadRezaBelum ada peringkat

- Tomahawk 1000Dokumen4 halamanTomahawk 1000asesoriaprofesionalambientalBelum ada peringkat

- EKS - Feburary 2023 - 570 - FinalDokumen2 halamanEKS - Feburary 2023 - 570 - FinalMONEY WEALTH HUBBelum ada peringkat

- BCM Unit 5Dokumen113 halamanBCM Unit 5Keerthi k.cBelum ada peringkat

- High-Speed SteelDokumen5 halamanHigh-Speed SteelVysakh VasudevanBelum ada peringkat

- Description: Technical Data SheetDokumen4 halamanDescription: Technical Data SheetjohnBelum ada peringkat

- Moldmaking Directions PDFDokumen1 halamanMoldmaking Directions PDFAurumCorBelum ada peringkat

- X-Shield SF PrimerDokumen2 halamanX-Shield SF Primernader enanyBelum ada peringkat

- Welding of Railway Tracks-Explain The Suitable Process With Merits and DemeritsDokumen12 halamanWelding of Railway Tracks-Explain The Suitable Process With Merits and DemeritsPradeep Kumar Prakash100% (1)

- Asian Apcolite Shine PaintDokumen4 halamanAsian Apcolite Shine PaintSantoshBelum ada peringkat

- Tempering Behavior of The Fusion Boundary Region of Anf22 - 625 Weld OverlayDokumen14 halamanTempering Behavior of The Fusion Boundary Region of Anf22 - 625 Weld OverlayAnonymous GhPzn1xBelum ada peringkat

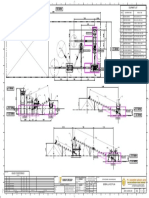

- Crushing Plant Basir Group Rev.dDokumen1 halamanCrushing Plant Basir Group Rev.dachmatBelum ada peringkat

- Tool and Cutter PDFDokumen15 halamanTool and Cutter PDFKiwishooter50% (4)

- 1.4006 en PDFDokumen2 halaman1.4006 en PDFutkuBelum ada peringkat

- PDS M365Dokumen2 halamanPDS M365prabhunmayBelum ada peringkat

- Product Spesification NCLDokumen6 halamanProduct Spesification NCLramadhani ilhamBelum ada peringkat

- Chemi ProjectDokumen9 halamanChemi ProjectCh'ng Song ShuBelum ada peringkat

- PM 6 - ApplicationsDokumen21 halamanPM 6 - ApplicationsShivraj ChouguleBelum ada peringkat

- Aluminium Paste PresentationDokumen44 halamanAluminium Paste PresentationKrishna Yeole100% (1)

- 32 Samss 031 PDFDokumen9 halaman32 Samss 031 PDFFlorin Daniel AnghelBelum ada peringkat

- Group 4 - OXY LaundryDokumen4 halamanGroup 4 - OXY LaundrywildanBelum ada peringkat

- RCC ReferenceDokumen1 halamanRCC ReferenceSahil Khan100% (1)

- Recovery Boiler History and Future VakkilainenDokumen14 halamanRecovery Boiler History and Future VakkilainennotengofffBelum ada peringkat

- Air Filter EDokumen35 halamanAir Filter EGonzalo Aranda UribeBelum ada peringkat

- Ul94 Versus Ul746c PDFDokumen4 halamanUl94 Versus Ul746c PDFCiclair RamosBelum ada peringkat