PQ FC 2G 08

Diunggah oleh

Nguyen Anh TuanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PQ FC 2G 08

Diunggah oleh

Nguyen Anh TuanHak Cipta:

Format Tersedia

Page : 1 of 2

Applicable code :

AWS D1.1-2010

PROCEDURE QUALIFICATION RECORDS (PQR)

Company name:

PQR No.

Revisions

Welding Process(es)

Type(s):

WPS No.:

POST WELD HEAT TREATMENT

Temperature

Time Range

Other

POSCO E&C VIET NAM

PQ-FC-2G-08

Date 26 Feb. 2015

None

FCAW

Machine

Manual

Automatic

Semi-automatic

WP-FC-2G-08

ELECTRICAL CHARACTERISTICS

Transfer Mode (GMAW):

JOINTS

Joint design:

Single V joint

Backing:

Yes

No

Backing Material (Type)

Base metal

Other

Root gap :

Root Face :

GrooveAngle :

600

Back gouging :

Yes

No

Gouging method :

N/A

BASE METALS

Material Specification :

ASTM 515

Type or grade:

60

Thickness:

Groove:

8mm

Fillet :

N/A

Pipe Diameter:

plate

Ceq of base metal:

N/A

Globular

Pulsed

DCEN

Size :

Type:

N/A

N/A

SHIELDING

Flux :

None

Electrode-Flux(class):

None

Gas (FCAW) : CO2

Percent Composition:

99.8%

(Mixture)

Flow rate:

15 l/min.

TECHNIQUE

String or Weave Bead

Orifice or Gas Cup Size

Interpass Cleaning

(Brushing, Grinding, etc.)

AWS A5.1

E71T-1C

1.2mm

??

none

none

none

none

Hyundai Welding Co. (KOREA)

Weave

19mm

Brushing & grinding

Method of Back Gouging

Oscillation

Contact Tube

to Work Distance

Multiple or Single

Pass (per Side)

Multiple or Single

Electrodes

JOINT SKETCH

POSITION

Position of Groove

Position of Fillet

Welding Progression:

Other

Short -Circuiting

Spray

Current :

AC

DCEP

Other :

N/A

Tungsten electrode (GTAW):

FILLER METALS

SFA No.

AWS Class

Elect/Filler Dia.:

Electrode/Filler trade name:

Electrode-Flux (class):

Flux -trade name

Non-Consumable Elect.

Non-Consumable Elect. Dia.

Manufacturer:

N/A

N/A

N/A

Arc Gouging

N/A

Multiple

Multiple

2G

N/A

N/A

N/A

PREHEAT

Preheat Temperature

280C (ambient)

Interpass Temperature

Min. (280C),

Max. (1050C)

WELDING PARAMETERS (Table #1)

Weld Layer.Pass

Process

Elect/Filler

AWS Class

Dia (mm)

Root

Fill

Cap

Cap

Cap

1

2

3.1

3.2

3.3

FCAW

FCAW

FCAW

FCAW

FCAW

E71T-1C

E71T-1C

E71T-1C

E71T-1C

E71T-1C

1.2

1.2

1.2

1.2

1.2

Cap

Cap

1.1

1.2

FCAW

FCAW

E71T-1C

E71T-1C

1.2

1.2

Prepared by :

Current

Polarity

Voltage (V)

Amp.

DCEP

140

DCEP

170

DCEP

180

DCEP

180

DCEP

180

Back Gouging

DCEP

180

DCEP

180

T.Speed

H. Input

(mm/min.) (Kj/mm)

22

400.0

25

25

25

25

436.4

24

25

369.2

452.8

558.1

545.5

533.3

Interpass

Temp.

(0C)

Width

(mm)

28

42

28

28

28

28

28

Reviewed by :

Approved by:

Name:

Name:

Name:

Signature:

Signature:

Signature:

Date:

Date:

Date:

Depth

(mm)

Page : 2 of 2

PROCEDURE QUALIFICATION RECORD (PQR)

(PQR No.: PQ-FC-2G-08 )

Applicable code :

AWS D1.1 - 2010

TENSILE TEST (Test report No: KT3-00738CK5/1)

Character of

Failure and

Location

Specimen No.

Width

(mm)

Thickness

(mm)

Area

(mm2)

Ultimate Total

Load(kN)

Ultimate unit stress, Mpa

TS1

20.00

7.99

159.80

74.9

469

Base metal

TS2

20.00

8.02

160.40

77.1

481

Base metal

GUIDE BEND TEST (Test report No: KT3-00738CK5/1)

Specimen No.

RB1

Type of bend

Root bend

Result

Pass

RB2

Root bend

Pass

FB1

FB2

Face bend

Face bend

Pass

Pass

Remark

VISUAL INSPECTION

RADIOGRAPHIC-ULTRASONIC EXAMINATION

Appearance:

Undercut:

Acceptance

Acceptance

RT report No.:

UT report No.:

Piping porosity:

Convexity:

None

Acceptance

FILLET WELD TEST RESULT

Test date:

18-Dec-14

Minimum size multiple pass

Minimum size single pass

Witnessed by:

Other test:

Luu Tri Phu

As below

Macroetch

1.

N/A

Macroetch

1. N/A

2.

3.

2.

3.

MACROETCH TEST

Test report No.:

N/A

Result.: N/A

HARDNESS TEST

Test report No.:

N/A

Acceptance criteria (Vicker)

Result

Weld metal

HAZ

Base metal

N/A

N/A

N/A

N/A

N/A

N/A

Welder Name:

Tests conducted by:

N/A

N/A

Tensile strength, Mpa:

Yield point/strength, Mpa:

Elongation in 2 in., %:

Laboratory test No.:

N/A

N/A

N/A

N/A

N/A

Test location

N/A

N/A

N/A

Result: Acceptance

Result:

N/A

All -weld - metal tension test:

Test Location

IMPACT TEST

Test report No.:

GTC/POS/PQR/RT-005

N/A

Temp. (0C)

Acceptance criteria for weld metal & HAZ

Minimum average (J)

N/A

HOANG VAN LUONG

QUATEST 3

Minimum Single (J)

N/A

N/A

Clock No.:

Laborary

Test value

average (J)

Minimum Single (J)

N/A

N/A

N/A

Stamp No.:

Test number :

Per:

Test result

N/A

W-POS-210

PQ-FC-2G-08

Luu Tri Phu

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in conformance

with the requirements of clause 4 of AWS D1.1/D1.1M, (

2010

) Structural Welding Code-Steel.

year

Signed:

By:

Title:

Date:

POSCO E &C VIET NAM

(Manufacturer or contractor)

Anda mungkin juga menyukai

- Refractory Lining & Repair ProcedureDokumen11 halamanRefractory Lining & Repair ProcedureNguyen Anh TuanBelum ada peringkat

- Quality Control Plan For Ducting: Project Name: TokushimaDokumen4 halamanQuality Control Plan For Ducting: Project Name: TokushimaNguyen Anh TuanBelum ada peringkat

- 12414-00-1763 - Rev.0 - PT ProcedureDokumen13 halaman12414-00-1763 - Rev.0 - PT ProcedureNguyen Anh TuanBelum ada peringkat

- 12414-00-1761 - Rev.0 - RT ProcedureDokumen39 halaman12414-00-1761 - Rev.0 - RT ProcedureNguyen Anh TuanBelum ada peringkat

- 2010v01 Inspection Is Not QaDokumen2 halaman2010v01 Inspection Is Not QaNguyen Anh TuanBelum ada peringkat

- 4-Welding Painting Repair-PDokumen8 halaman4-Welding Painting Repair-PNguyen Anh TuanBelum ada peringkat

- Corrosion Management Issue119 LowresDokumen36 halamanCorrosion Management Issue119 LowresNguyen Anh Tuan100% (1)

- 12414-00-1765 - Rev.0 - VT ProcedureDokumen12 halaman12414-00-1765 - Rev.0 - VT ProcedureNguyen Anh TuanBelum ada peringkat

- 12414-00-1762 - Rev.0 - MT ProcedureDokumen14 halaman12414-00-1762 - Rev.0 - MT ProcedureNguyen Anh TuanBelum ada peringkat

- 12414-00-1760 - Rev.0 - Ut ProcedureDokumen22 halaman12414-00-1760 - Rev.0 - Ut ProcedureNguyen Anh TuanBelum ada peringkat

- Quality Assurance CourseDokumen63 halamanQuality Assurance CourseNguyen Anh Tuan100% (1)

- Regulation of Wood Packaging Material in International Trade ISPM 15Dokumen22 halamanRegulation of Wood Packaging Material in International Trade ISPM 15erharsinghBelum ada peringkat

- Corrective Action Request (CAR) - Rev 0: Stop Here. Submit CAR To N.A.TuanDokumen1 halamanCorrective Action Request (CAR) - Rev 0: Stop Here. Submit CAR To N.A.TuanNguyen Anh TuanBelum ada peringkat

- Fb40rev1 Audit-Checkliste EN15085 ENGDokumen14 halamanFb40rev1 Audit-Checkliste EN15085 ENGNguyen Anh TuanBelum ada peringkat

- SC C06 Cag HBK PRC STDokumen26 halamanSC C06 Cag HBK PRC STNguyen Anh Tuan100% (2)

- E401 1000 Air Cooled CondensersDokumen4 halamanE401 1000 Air Cooled CondensersNguyen Anh TuanBelum ada peringkat

- 01 Outokumpu Portfolio Wallchart May 2015 PDFDokumen4 halaman01 Outokumpu Portfolio Wallchart May 2015 PDFNguyen Anh TuanBelum ada peringkat

- Global Safety Management at POSCODokumen49 halamanGlobal Safety Management at POSCONguyen Anh TuanBelum ada peringkat

- MGT Sys Track - 1 - M Boudreaux - Risk MGTDokumen33 halamanMGT Sys Track - 1 - M Boudreaux - Risk MGTVenkatesan KattappanBelum ada peringkat

- AISC Steel Construction Manual 14th EditionDokumen2 halamanAISC Steel Construction Manual 14th EditionNguyen Anh TuanBelum ada peringkat

- Paint Application Record: Condition of Surface PreperationDokumen2 halamanPaint Application Record: Condition of Surface PreperationNguyen Anh TuanBelum ada peringkat

- Stemming The TideDokumen48 halamanStemming The TideDevika Hemalatha DeviBelum ada peringkat

- AISC Steel Construction Manual 14th EditionDokumen2 halamanAISC Steel Construction Manual 14th EditionNguyen Anh TuanBelum ada peringkat

- A Training Presentation On The N7Dokumen69 halamanA Training Presentation On The N7Nguyen Anh TuanBelum ada peringkat

- Documented InformationDokumen5 halamanDocumented InformationbkssdgBelum ada peringkat

- Iso9001 2015 Process ApprDokumen7 halamanIso9001 2015 Process ApprHaitham NegmBelum ada peringkat

- AWS - CMWS-2005 - Certified Welding Supervisor Manual For Quality and Productivity ImprovementDokumen449 halamanAWS - CMWS-2005 - Certified Welding Supervisor Manual For Quality and Productivity ImprovementNguyen Anh Tuan94% (16)

- H2FC-Materials-WS Hydrogen Embrittlement of Steels JorcinDokumen40 halamanH2FC-Materials-WS Hydrogen Embrittlement of Steels JorcinNguyen Anh TuanBelum ada peringkat

- ElectricDokumen42 halamanElectricAbd ZouhierBelum ada peringkat

- Documents - Tips TCVN Iso 90042011 Iso 90042009Dokumen64 halamanDocuments - Tips TCVN Iso 90042011 Iso 90042009Nguyen Anh TuanBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Effect of Element (SR, Ti, B, and MG) Modification On Microstructure To Increase Micro-Hardness of A356 Aluminum AlloyDokumen10 halamanThe Effect of Element (SR, Ti, B, and MG) Modification On Microstructure To Increase Micro-Hardness of A356 Aluminum AlloyLilian Jefferson MalavaziBelum ada peringkat

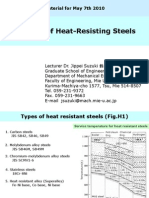

- Welding of Heat-Resisting SteelDokumen43 halamanWelding of Heat-Resisting SteelaunginternetBelum ada peringkat

- Furnace Linings Ferrous 01Dokumen12 halamanFurnace Linings Ferrous 01Jennifer Nicky Shaker100% (1)

- Brazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessDokumen23 halamanBrazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessAd Man GeTigBelum ada peringkat

- Case HardeningDokumen84 halamanCase HardeningMduduzi Magiva Mahlangu100% (1)

- Frontier Alloy Steels LTD: DatedDokumen8 halamanFrontier Alloy Steels LTD: DatedsushilpanwarBelum ada peringkat

- Aerospace Materials GuideDokumen6 halamanAerospace Materials Guidesnuffit11Belum ada peringkat

- CLASSIFICATION AND EFFECTS OF CORROSIONDokumen18 halamanCLASSIFICATION AND EFFECTS OF CORROSIONSalem GarrabBelum ada peringkat

- Nes 771Dokumen50 halamanNes 771jra9090Belum ada peringkat

- Swing Check Valve - Flanged Ends: Schematic DrawingDokumen1 halamanSwing Check Valve - Flanged Ends: Schematic Drawingbhima irabattiBelum ada peringkat

- Mil A 8625Dokumen20 halamanMil A 8625Jose MoralesBelum ada peringkat

- Analyses of Pig Iron 1900Dokumen230 halamanAnalyses of Pig Iron 1900OceanBelum ada peringkat

- Metallographic Preparation of Zinc Coatings: Notes ApplicationDokumen6 halamanMetallographic Preparation of Zinc Coatings: Notes ApplicationkhurshedlakhoBelum ada peringkat

- 4826Dokumen11 halaman4826kundank_32Belum ada peringkat

- Advisory Circular: Aircraft Maintenance Engineer Licence - Examination Subject 3 Aircraft MaterialsDokumen35 halamanAdvisory Circular: Aircraft Maintenance Engineer Licence - Examination Subject 3 Aircraft MaterialsKobyscusBelum ada peringkat

- Leaflet Ferroxyl Test Kit NewDokumen2 halamanLeaflet Ferroxyl Test Kit NewShailesh DeshmukhBelum ada peringkat

- Classification of AlloysDokumen9 halamanClassification of AlloysPritamBelum ada peringkat

- TPS Extended Surface Tubes 2018Dokumen32 halamanTPS Extended Surface Tubes 2018Aarti ChameBelum ada peringkat

- Transition ElementsDokumen22 halamanTransition ElementsSarosh AliBelum ada peringkat

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Dokumen3 halamanAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88Belum ada peringkat

- Lab Test: Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDokumen6 halamanLab Test: Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodBelum ada peringkat

- Application of Components Made by Aerospace Materials: Chapter # 3Dokumen28 halamanApplication of Components Made by Aerospace Materials: Chapter # 3Kamirul NaimBelum ada peringkat

- Spot WeldingDokumen37 halamanSpot WeldingSabhari Natarajan100% (1)

- Sandvik EbookDokumen36 halamanSandvik EbookvivianeBelum ada peringkat

- A 30Dokumen1 halamanA 30AnuranjanBelum ada peringkat

- Chapter - 01Dokumen41 halamanChapter - 01Sandarenu WickramasingheBelum ada peringkat

- Astm A313 2003Dokumen7 halamanAstm A313 2003ArefkhanBelum ada peringkat

- Fabrication ReportDokumen6 halamanFabrication ReportAliff FazzBelum ada peringkat

- 450-211 - MGDokumen1 halaman450-211 - MGbolobaneitorBelum ada peringkat

- 2015-Formation Mechanisms of White Layers Induced byDokumen10 halaman2015-Formation Mechanisms of White Layers Induced byLucas Bonino SilvaBelum ada peringkat