Hydrogenation

Diunggah oleh

Nelson GomesHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hydrogenation

Diunggah oleh

Nelson GomesHak Cipta:

Format Tersedia

i ~ APPLI

CATALEYDSIS

A: GENERAL

ELSEVIER

Applied Catalysis A: General 163 (1997) 101-109

Selective hydrogenation of cyclopentadiene to cyclopentene

over an amorphous NiB/SiO2 catalyst

Wei-Jiang

Wang, Ming-Hua

Qiao, Jun Yang, Song-Hai

Xie, Jing-Fa Deng*

Department of Chemistry, Fudan Universi~, Shanghai 200433, China

Received 5 December 1996; received in revised form 6 March 1997; accepted 11 March 1997

Abstract

An amorphous NiB/SiO2 catalyst, with a large specific surface area, was prepared by a reductive-impregnation method. The

selective hydrogenation of cyclopentadiene to cyclopentene was carried out in a continuous flow fix-bed reactor at

atmospheric pressure and with 10 g g cat -I h -l of cyclopentadiene feed. The catalyst showed high selectivity and stability.

Cyclopentene was obtained in 96--100% yield at complete conversion of cyclopentadiene at temperatures ranging from 80C

to 200C and no significant decrease of the activity was observed during the reaction period of 500 h. The catalyst sample was

characterized by ICP, XRD, DSC, SEM, XPS, BET and 02 adsorption. XRD measurement revealed that the amorphous state

was kept after catalytic reaction. Differential kinetic study showed that the hydrogenation proceeded according to a RidealEley mechanism. 1997 Elsevier Science B.V.

Keywords: Supported amorphous alloy; Nickel-boron alloy; Cyclopentadiene hydrogenation; Catalytic activity; Differential

kinetics

1. Introduction

The selective hydrogenation of cyclopentadiene to

cyclopentene is of great synthetic and industrial interest, because cyclopentene with a highly reactive double bond could be used as a basic material in industry

[1-3]. The hydrogenation of cyclopentadiene is a

consecutive reaction. The activation energy of the first

stage is higher than that of the second one [4--6], so

that it is impossible to convert cyclopentadiene to

cyclopentene completely, especially under the g a s -

*Corresponding author. Tel.: +86 21 65492222x3792; fax: +86

21 65341642; e-mail: knfan@fudan.ihep.ac.cn

0926-860X/97/$17.00 ~"~

~c5) 1997 Elsevier Science B.V. All rights reserved.

PII S0926-860X(97)00

125-7

solid phase reaction conditions used widely in industry. For most hydrogenation catalysts such as Pd, Pt,

Ni, Cu [7-10], at the low ratio of PH2/PD(Po: the

pressure of cyclopentadiene), cyclopentene is produced with 100% selectivity at low conversion of

cyclopentadiene, whereas the increase in P~:/Po or

W/Fo decreases the selectivity. The unconverted

cyclopentadiene at low conversion is easily polymerized on catalysts at the reaction temperature, which

leads to the deactivation of the catalysts and also to

low yields of cyclopentene. These phenomena are

commercially impracticable. For these reasons, it is

a crucial subject to prepare special catalysts in order to

obtain cyclopentene at nearly 100% selectivity at

complete conversion of cyclopentadiene.

102

W.-J. Wang et al./Applied Catalysis A: General 163 (1997) 101-109

It is well known that amorphous metal alloy

catalysts exhibited attractive selectivity and activity

for some reactions due to their isotropic structure,

devoid of any long-range ordering of the constituents

[11,12]. The application of these materials in

catalysis, however, is severely limited, since the

amorphous state is metastable, and thus is very

difficult to maintain under conditions where catalytic

reactions are carried out. Furthermore, the surface

area of amorphous films prepared by rapid-quenching

methods is too low and the shape of amorphous

alloy prepared by wet chemical reduction methods

is powder, which are both inconvenient for use of

the catalytic potential of these materials in technical

catalysis. One of the promising routes to solve

these problems has been developed by depositing

the amorphous alloys in high dispersion on a

suitable support. For example, the preparation

of amorphous nickel-(cobalt)-phosphorus alloys

deposited on silica has been reported previously

[13,14]. The results showed that these supported

amorphous alloy catalysts exhibited higher activity

and selectivity for the hydrogenation of styrene

with higher thermal stability than unsupported

counterparts.

Unfortunately,

the

phosphorus

component in amorphous alloys is easily lost during

catalytic runs [14] and the preparation methods

are unsuitable for supporting highly reactive

amorphous nickel-boron alloy on a support due to

the too rapid reduction of nickel ion by potassium

borohydride in water.

In this paper, the preparation of amorphous

nickel-boron alloy supported on silica by a new

method is reported. Its catalytic properties in the

hydrogenation of cyclopentadiene and characterization results obtained by ICR XRD, XPS, SEM,

DSC, BET and 02 adsorption methods are

discussed in detail. The reaction mechanism is

proposed on the basis of the differential kinetic

results.

2. Experimental

2.1. Materials

All chemicals employed were of reagent grade and

were used without further purification.

2.2. Catalyst preparation

The supported amorphous NiB/SiO2 catalyst

was prepared by a reductive impregnation method.

The impregnation was carried out by immersing 10 g

silica gel (200 m 2 g-1 surface area, 17.5 nm pore

diameter and 40-60 mesh, i.e., 0.45-0.30mm

particle size) in a 1 M potassium borohydride

solution (pH=13) for 2 h and then taking the silica

gel out of the solution. To remove the excessive

solution, the silica gel was washed with 10 ml of

95% ethanol and then dried under air at room temperature. Subsequently, the silica gel which had

adsorbed potassium borohydride was added into

10ml of 2 M nickel chloride solution at room

temperature with continuous stirring for 4 h. The

black particles obtained were washed with 15 ml of

0.01 M potassium borohydride aqueous solution and

then washed thoroughly with a large amount of

distilled water. Finally, the catalyst was dried in

nitrogen at 70C for 2 h.

Elemental analysis of the catalyst determined by

inductively coupled plasma (ICP) showed that the

nickel content was 4.3% by weight and the elemental

composition was NisoB2o (mol%).

2.3. Activity measurements and differential kinetic

experiment

Hydrogenation of cyclopentadiene was carried out

in a tubular glass fix-bed reactor (0.8 cm i.d.) in

continuous flow conditions and under atmospheric

pressure. The weight of catalyst was 1 g for each

experiment. Liquid cyclopentadiene, diluted with solvent to keep from polymerization (commonly with

95% ethanol and 1 : 1 volume ratio), was vaporized in

a bubbling-type evaporator at 95C, and then passed

through the reactor using nitrogen and hydrogen

mixture as the carrier gas.

Differential kinetic experiment was also carried out

under the same reaction conditions as those for activity measurements, but the weight of catalyst was 0.1 g

for each kinetic experiment.

The effluent was analyzed by a gas chromatographic method. The conversion and selectivity are

defined as follows:

Conversion(%) = [CPD]conv./[CPD]feed x 100,

(1)

W.-J. Wang et al./Applied Catalysis A: General 163 (1997) 101-109

Selectivity(%) = [CPE]/[CPD]conv. x 100.

(2)

103

3. Results and discussion

Here CPD and CPE stand for cyclopentadiene and

cyclopentene, respectively.

3.1. Catalytic activity

As mentioned above, the products of cyclopentadiene hydrogenation were cyclopentene and cyclopentane. To obtain cyclopentene as much as possible

at complete conversion of cyclopentadiene, the catalytic reactivity of amorphous NiB/SiO2 catalyst was

concerned about both selectivity to cyclopentene and

conversion of cyclopentadiene.

This catalyst did not need any activation process

before catalytic runs and immediately showed high

activity and selectivity once the hydrogenation started.

Since the cyclopentadiene hydrogenation is very

exothermic (AH1=-99.35 kJ tool J, AH2=-112.24

kJ mol-t), nitrogen together with 95% ethanol was

also mixed as heat transfer gas into the reactant feed.

Nitrogen, showing no significant effect on the cyclopentadiene hydrogenation (Fig. I) with its flow-rate in

the range 40-160 ml min-', was used to adjust the contact time of the reactant with the catalyst in the reaction.

The effects of PH2/PDratio at different Fo (cyclopentadiene feed) values on the catalytic activity were

2.4. Characterization of catalyst

X-ray diffraction (XRD) patterns of support and

the NiB/SiO2 catalysts were performed using a

Rigaku Dmax-rA with nickel filtered Cu Ks

radiation. Differential scanning calorimetry (DSC)

measurements were conducted under nitrogen

(99.99%) atmosphere on a Dupont 9900 computerthermal analysis system. The morphology of the

samples was determined by scanning electron

microscopy (SEM) performed on a Hitachi HUl lB STEM and H600 STEM instruments. X-ray

photoelectron spectroscopy (XPS) spectra were

recorded with a PHI-5000C ESCA system using A1

K,~ radiation. The base pressure of the analysis

chamber was 10 -8 Pa and the energy was 46.95 eV.

All binding energies were calibrated using contaminated carbon (Cls=284.6 eV). The metallic specific

surface areas of the samples were measured according

to a method described in [15].

"- ~

100

I00

90.0

90.0

80.0

80 0

..~

8

~2

70.0

70.0

20

40

60

80

100

120

140

160

I80 2 0 0

Feed-rate(ml.min"t)

Fig. 1. Effect of N2 feed-rate on CPD conversion and CPE selectivity (CPD feed=10 g cat-t h , H2 : CPD=I.4, temperature

120C).

W.-J. Wanget al./Applied Catalysis A." General 163 (1997) 101-109

104

O ~ O O O O O

q

r.,,i

I00

100

90.0

90.0

80.0

80.0

II

G~

g g g g g g g g ~

qq

o

~

0

gga~ggggg

0q.

~[

(.9

oo oo ooo oo oo ooo o~ o q q

'R.

80

110

140

]70

200

Temperature(C)

0 0 0 0

Fig. 2. Effect of reaction temperature on CPD conversion and

CPE selectivity (CPD f e e d = 1 0 g cat 1 h - l , H 2 : C P D = I . 6 : 1

( G H S V = 2 4 000-1).

g g g g g g g ~ >

=o

e~

o

~gggggggg

II

ggggggg~gg

7

o

~ggg~ggggg

e'~

o

=

Q q o q q q o q

~ g g g g g g g g

"2.

gggggggggg

r.~

II

G)

o

"7

eq

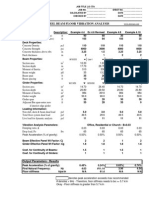

studied, as shown in Table 1. The suitable PH2/PD ratio

in order to maintain the selectivity to cyclopentene

higher than 96% at complete conversion of cyciopentadiene varied with changing the cyclopentadienefeed. Clearly, the increase in the cyclopentadiene feed

required high H 2 : cyclopentadiene ratio to maintain

the 100% conversion, but the selectivity slightly

decreased. At the highest cyclopentadiene feed,

16 g g cat t h-~, the selectivity was about 96%, but

the optimum cyclopentadiene feed was 1 0 - 1 2 g g

cat-t h i. Thus, in the present work, the cyclopentadiene feed was controlled at 10 g cat t h-i for most

catalytic runs.

The variation of reaction temperature from 80C to

200C showed little effect on the catalytic reactivity,

as shown in Fig. 2. A further increase in temperature

led to a decrease in the reactivity, which was due to

cyclopentadiene polymerization on the catalyst.

These results indicate that the amorphous NiB/SiO2

catalyst has high selectivity and activity compared

with other commonly used hydrogenation catalysts in

the present reaction conditions. For example, on Pd/

A1203 (Pd: 0.5 wt%), the selectivity and conversion

are 33% and 70% in the present work; and also 90%

and 92.5% at higher pressure in Ref. [7]; on Ni/SiO2

(Ni: 4.6 wt%) 84% and 100% in the present work; on

NiS/SiO2 93.5% and 99% in Ref. [9] (no LHSV value

was given, but according to our knowledge, it may be

0.5 h-t), respectively. If the amorphous NiB/SiO2 was

105

W.-J. Wang et al./Applied Catalysis A: General 163 (1997) 101-109

treated at 400C for 2 h in nitrogen, its activity and

selectivity remained unchanged, while in the case of

the treatment at 450C for 2 h in nitrogen, the best

selectivity was 94% at 100% conversion.

The stability of the catalytic activity was also very

excellent. For about 500 h, a 97-100% yield of cyclopentene was obtained at 120C and 10 g g cat -~ h -1 of

cyclopentadiene was kept. This shows a possibility to

apply the amorphous NiB/SiO2 catalyst to commercial

cyclopentene production.

488.9 C

437.5 C ~

210C

3.2. Characterization

BET nitrogen surface area of the catalyst sample

was about 180 m 2 g-t. Its nickel dispersion measured

by oxygen uptake at 25C using a pulse chromatographic technique was 0.30. These results show that

the amorphous NiB/SiO2 has larger surface area and

higher nickel dispersion.

Fig. 3 shows the XRD patterns of four NiB/SiO2

samples. The patterns of (b) and (c) were almost the

same. After subtracting the background spectrum of

SiO2, a broad peak at 20=45 was observed. This was

attributed to the NiB alloy in the amorphous state. The

pattern of (d) indicated that the amorphous state still

remained, but on the pattern of (e), the diffraction

peaks of some crystal, which was analyzed to be

nickel crystallite, had appeared. DSC spectra, as

_=

20

40

60

80

20()

Fig. 3. X-ray diffraction patterns of (a) SiO2, (b) original NiB/

SiO> (c) NiB/SiO2 after 500 h of hydrogenation at 120C, (d) NiB!

SiO2 treated in N2 for 2 h at 400C, and (e) NiB/SiO2 treated in N2

for 2 h at 450C.

100

200

300

400

500

600

Temperature(C)

Fig. 4. DSC spectra of NiB/SiO2.

shown in Fig. 4, exhibited that there were three

exothermic peaks at 412.7C, 437.5C and 488.9C,

while on the unsupported counterpart at 144.1C,

253.4C and 341.4C, respectively [16]. This illustrates that the crystalline transformation temperature

of the amorphous NiB/SiO2 is higher than that of the

unsupported counterpart. The SEM photograph in

Fig. 5 shows the surface morphology of three NiB/

SiO2 samples. Pictures (a) and (b) revealed that the

NiB alloy was cottony, which was considered to be the

amorphous state, but the density of the amorphous

alloy on picture (b) seemed to be larger than that on

picture (a). Picture (c) indicated that NiB alloy was

slightly agglomerated, thus we concluded that some

crystallization had occurred. These phenomena were

exactly corresponding to those in the XRD and DSC

experiments. All these results indicate that the supported amorphous nickel-boron alloy has much higher

thermal stability. This property is considered to be

mainly due to the lower metal loading and high alloy

dispersion, the results are meaningful for the application of amorphous alloys in catalysis.

XPS spectra of Ni2p3/2 and B l s in the amorphous

NiB/SiO2 catalyst are shown in Fig. 6. Compared with

the spectra of pure nickel metal foil (852.8 eV) and

nickel oxide (854.5 eV), the peak at 852.0 eV in the

NiEp3/2 level is ascribed to metallic Ni and that at

855.4 eV to oxidized nickel. In the B l s level, two kinds

of higher binding energy than 189.4 eV for elementary

W.-J. Wang et al./Applied Catalysis A: General 163 (1997) 101-109

106

Magnific~ion:100~.~

B were assigned to boron interacting with nickel

(191 eV) and to oxidized boron (194 eV), respectively

[16-19]. From these results, it can be immediately

concluded that the boron donates electrons to nickel.

The same results were obtained on the amorphous NiB

alloy powder [ 16].

The surface composition calculated from the XPS

spectra using the relative peak area sensitivities was

Niv0B3o (mol%). Compared with the bulk composition

of NisoB2o determined by ICP spectrometry, the surface of the catalyst is metalloid rich.

The results in the characterization mentioned above

could explain the good catalytic properties of the

catalyst obtained in cyclopentadiene hydrogenation;

the high activity is attributable to high dispersed

metallic nickel and the active site of the amorphous

nickel-boron is also metallic nickel [t6]. The higher

selectivity is ascribed to the amorphous state of nickel

which makes the active site of the catalyst chemically

and structurally isotropic [ 11,12]. When the catalyst is

crystallized, the activities of active sites at different

faces would be different, which results in a decrease of

the selectivity. The excellent stability of the catalytic

reactivity seems to result from the high crystalline

transformation temperature of the nickel-boron alloy

supported on silica.

3.3. K i n e t i c s t u d i e s

Magnii]cati~ln ~0 0 ( ~ [11)

Kinetic studies were carried out under differential

conditions, i.e., the conversion was maintained at

approximately 5%. When GHSV>5000 h -], the external diffusion was negligible and the intraparticle

diffusion was completely eliminated, if the particle

size was reduced to 40 mesh in the present work.

The dependence of the cyclopentadiene hydrogenation rate on the partial pressure of cyclopentadiene and

hydrogen was investigated. In the present studies, the

selectivity to cyclopentene was 100%. Furthermore,

the addition of 10 mol% of cyclopentene or cyclopentane into the feed did not influence the reaction rate.

Therefore, the reaction rate re) can be expressed as

m 11

$q~Or~m

Magnil]clllof~ IO00o O0

Fig. 5. SEM pictures of (a) original NiB/SiO2 sample, (b) NiB/

SiO2 sample treated in N2 for 2 h at 400C, and (c) NiB/SiO2

sample treated in N2 for 2 h at 450C.

rD = F D X = kDPDPH2,

(3)

where FD is the cyclopentadiene feed in mol s- 1, X the

conversion in percent of cyclopentadiene converted

and PD is the pressure of cyclopentadiene, respectively. If GHSV in the reactor is fixed by adjusting the

W.-J. Wang et al./Applied Catalysis A: General 163 (1997) 101-109

Ni2v3t2

107

Bls

852.0 eV

194.0 eV

Binding Energy(eV)

Fig. 6. XPS spectra of Nizp3/2 and BI~ in the NiB/SiO2 catalyst.

nitrogen flow-rate

simply by

PD oc VD :x FD,

(4)

rD = kDPn2 = k e x p ( - E / R T ) P H : ,

Plq2 :x v~q2,

(5)

where k is the pre-exponential factor, and E is the

activation energy. The activation energy was measured

between 80C and 160C and found to be 6.93

kJ mol - l . The average pre-exponential factor k was

calculated to be 2.610 -3 mol g cat - t atm -~ s

Hence the rate of the reaction can be rewritten as

where VD and VH2 are the flow-rate of cyclopentadiene

and hydrogen, respectively. Then

rD = F D X = k v ~~mvn

D

H2

or

X

1 ~m--I

n

= tc~r

D v.2.

(6)

When vH2 remained constant, then

log X oc (m - 1) log FD.

(7)

The logarithm of the conversion is plotted against

the logarithm of the cyclopentadiene feed in Fig. 7,

which exhibits a series of parallel lines depending on

the reaction temperature. Their slope, - 1 , indicates

that the reaction rate upon the cyclopentadiene is zero

order. If FD is constant, then

logX oc n log Vn~.

(8)

Fig. 8 shows the plots of log X to log vIq2, which

also exhibits a series of parallel lines related with

the reaction temperature. The slope, 1, indicates

that the reaction rate upon hydrogen velocity is

the first order, thus the reaction rate ro is expressed

(9)

rD = 2.6 10 -3 e x p ( - 8 3 5 / T ) P m

(10)

with E / R = 8 3 5 mol -j K -1 if E is in J and R in

J mol - t K -1.

Table 2 gives the rates of cyclopentadiene consumption calculated from Eq. (10) at several reaction

temperatures, when hydrogen pressure and cyclo-

Table 2

Observed and calculated rates of reaction as a function of the

reaction temperature

T(C)

robs (10 6 m o l s - l )

real (10 6 m o l s 1)

80

100

3.03

3.78

3. l 8

3.61

120

4.17

4.05

140

160

4.38

4.78

4.48

4.92

PHi_=0.13 atm, PCVD=0.25 atm, 0.1 g of catalyst.

108

W.-J. Wang et al./Applied Catalysis A: General 163 (1997) 101-109

1.0

0.8

0.6

0.4

0.2

1.1

1.2

1.3

1.4

1.5

1.6

Log Pm

Fig. 7. The logarithm of the CPD conversion vs. the logarithm of the CPD feed plots (conditions: PH2=0.2 atm, GHSV=24000 1).

0.8

0.6

X

o

0.4

0.2

140"C

o 160 C

NN~.%NN~eNN~Q

1.2

1.6

1.4

1.8

2.0

2.2

Log FCI,D

Fig. 8. The logarithm of the CPD conversion vs. the logarithm of the PH2 plots (conditions: P0=0.25 atm, GHSV=24000 i).

pentadiene pressure are 0.13 and 0.25 atm, respectively. Very good agreement was found between the

calculated and observed rates of reaction.

According to rate-equation (10), which is different

from those obtained on NiS [5] and on Pd [20] but

similar to that on Cu/A1203 [21 ], for the bimolecular

W.-J. Wang et al./Applied Catalysis A: General 163 (1997) 101-109

reaction studied here we propose a Redeal-Eley (R-E)

type mechanism. For a Langmuir-Hinshelwood (L-H)

type mechanism, we must suppose that the adsorption of hydrogen and cyclopentadiene are non-competitive, and assume that the adsorption of hydrogen is

weak and cyclopentadiene strong, thus we could

obtain Eq. (10). As the active sites of the amorphous

NiB/SiO2 catalyst are all elemental nickel and isotropic, such non-competitive adsorption is not realistic. Based on the R-E type mechanism, i.e., strongly

adsorbed cyclopentadiene reacting with hydrogen

directly from the gas phase [22], our mechanism,

which is identical with that on Cu/A1203 [21], can

be written as follows:

CPD + catalyst = CPD-catalyst

(11)

CPD-catalyst + H2 --~ CPE + catalyst

(12)

If ~D and KD are the surface coverage and adsorption coefficient of cyclopentadiene, respectively, and

the rate-determining step is Eq. (12), one may

write

(13)

~)D = K D P D / ( I + K D P D ) ,

rD = kD~DPH2 = kDKDPDPH2 / (1 + KDPD ).

Assuming that cyclopentadiene

adsorbed, i.e., KDPD>>I,

rD = kDP.2.

is

strongly

(14)

This is identical with the rate equation obtained in

kinetic experiments.

4. Conclusions

It was shown that an amorphous nickel-boron alloy

supported on silica was very helpful for selective

hydrogenation of cyclopentadiene to cyclopentene

at low temperature in gas-solid phase. The catalyst

activity was very stable for a long time on stream. The

results in catalyst characterization showed that the

amorphous state was maintained over 80-120C. The

differential kinetic study revealed that the reaction

mechanism was of the Rideal-Eley type with cyclopentadiene strongly adsorbed on the catalyst. To our

109

knowledge, the present report is the first one on the

behavior of amorphous alloy catalyst which may be

applied to commercial catalytic processes in gas-solid

phase reaction.

Acknowledgements

This work was supported by the National Natural

Science Foundation of China and China Petrochemical Corporation.

References

[1] G. Natta, J. Polymer Sci. 51 (1961) 463.

[2] N. Calderon, R.L. Hinrichs, Chem. Tech. 4 (1974) 627.

[3] Goodyear Tire, Rubber, US Patent, 3751499 (1973),

3819734 (1974), 3915 891 (1975), 4 131 627 (1978); Gulf

Res. Dev., US Patent, 4062907 (1977); Kanegabuchi Chem.

Ind., Japan Kokai, 49-31642, 50-14657; Nissan Chem. Ind.,

Japan Kokai, 49-35358; Sakai Chem., Japan Kokai, 49125340; Shell. Inst. Res., Ger. Often., 2 127625 (1971).

[4] P. Kripylo, Chem. Tech. 28 (1976) 22.

[5] H. Sakamoto, K. Takasaki, Y. Harano, T. Imoto, J. Appl.

Chem. Biotechnol. 24 (1974) 759.

[6] H. Hiral, S. Komatsuzaki, N. Toshima, Bull. Chem. Soc. Jpn.

57 (1984) 488.

[7] V.M. Kothari, Ger. Often. 2315002 (1973); US Appl.,

250802 (1973).

[8] J.R. Bernerd, J. Chem. Phys. Chem. Biol. 74 (1977) 475.

[9l E.B. Fountain, Ger. Often. 2217625 (1970).

[10] G. Pajonk, Bull. Soc. Chem. Fr. (1975) 983.

[11] S. Yoshida, H. Yamashita, T. Funabiki, T. Yonezawa, J. Chem.

Soc., Faraday Trans. I. 80 (1984) 1435.

[12] A. Molnar, G.H. Smith, M. Bartok, Adv. Catal. 36 (1988)

329.

[13] J.F. Deng, X.P. Zhang, Appl. Catal. 37 (1988) 339.

[14] J.E Deng, X.P. Zhang, Solid State Ionics 32/33 (1989) 1006.

[15] D.K. lvana, Appl. Catal. 42 (1988) 121.

[16] J.E Deng, J. Yang, S.S. Sheng, H.R. Chen, G.X. Xing, J.

Catal. 150 (1994) 434.

[17] Y. Okamoto, Y. Nitta, T. Imanaka, S. Teranishi, J. Chem. Soc.,

Faraday Trans. 175 (1979) 2027.

[18] J.A. Schreifels, P.C. Maybury, W.E. Swartz, J. Catal. 65

(1980) 195.

[19] J. Tamaki, H. Takagaki, T. Imanaka, J. Catal. 108 (1987) 256.

[20] P. Kripylo, E Turek, Chem. Tech. 27 (1975) 605.

[21] J. Chaouki, C. Chavarie, Appl. Catal. 187 (1986) 199.

[22] E.K. Redeal, Concepts in Catalysis, Academic Press, London,

1980.

Anda mungkin juga menyukai

- Detect Anionic Surfactants in MixturesDokumen11 halamanDetect Anionic Surfactants in MixturesNelson GomesBelum ada peringkat

- Interpretation of Fire DebrysDokumen12 halamanInterpretation of Fire DebrysNelson Gomes100% (1)

- Allara 2006Dokumen99 halamanAllara 2006Nelson GomesBelum ada peringkat

- Organohalogen Compounds, Volumes 60-65, Dioxin 2003 Boston, MADokumen4 halamanOrganohalogen Compounds, Volumes 60-65, Dioxin 2003 Boston, MANelson GomesBelum ada peringkat

- Simple Methods For Characterization of Metals in Historical Textile ThreadsDokumen8 halamanSimple Methods For Characterization of Metals in Historical Textile ThreadsNelson GomesBelum ada peringkat

- Central Laboratory Test Methods Determination of Suspended Particulate Matter in The Atmosphere (High Volume Method)Dokumen46 halamanCentral Laboratory Test Methods Determination of Suspended Particulate Matter in The Atmosphere (High Volume Method)cocoashishBelum ada peringkat

- Ada 074490Dokumen115 halamanAda 074490Nelson GomesBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Ion exchange water treatmentDokumen86 halamanIon exchange water treatmentShabbir OsmaniBelum ada peringkat

- A Detailed Lesson Plan in Physics UAMDokumen5 halamanA Detailed Lesson Plan in Physics UAMZishan Ul HaqBelum ada peringkat

- Exclusive or InclusiveDokumen30 halamanExclusive or InclusiveMary Christine IgnacioBelum ada peringkat

- Stokes1989 FSW OverviewDokumen15 halamanStokes1989 FSW OverviewGamini SureshBelum ada peringkat

- Lesson Plan ME-220 Engineering MaterialsDokumen2 halamanLesson Plan ME-220 Engineering MaterialsHajiasifAliBelum ada peringkat

- Load Flow AnalysisDokumen79 halamanLoad Flow AnalysisKeshav ChanjalBelum ada peringkat

- A Review of Ballute Technology For Planetary AerocaptureDokumen10 halamanA Review of Ballute Technology For Planetary AerocaptureCamiloRamirezSanabriaBelum ada peringkat

- Process Control and HazopDokumen12 halamanProcess Control and HazopCosmin FloreaBelum ada peringkat

- ACS Style: Table Joseph Henry Press: Washington, DC, 2003 PP 145-158Dokumen2 halamanACS Style: Table Joseph Henry Press: Washington, DC, 2003 PP 145-158aklima_sharminBelum ada peringkat

- Class 6 Assignment 15 2022-23Dokumen27 halamanClass 6 Assignment 15 2022-23Debaprasad MukherjeeBelum ada peringkat

- AISC DG11 ExamplesDokumen7 halamanAISC DG11 ExamplesMarcel Toruño MendezBelum ada peringkat

- Introduction To Lattice EnergyDokumen16 halamanIntroduction To Lattice EnergyRohan AhmedBelum ada peringkat

- Motion and Time Class 7, 2022Dokumen61 halamanMotion and Time Class 7, 2022Theia JacobBelum ada peringkat

- Civil Engineering BE IVDokumen12 halamanCivil Engineering BE IVkamalnitrrBelum ada peringkat

- Converters and InterfacesDokumen140 halamanConverters and InterfacesMartin LundeenBelum ada peringkat

- Smart ValveDokumen4 halamanSmart ValveCoordinadorIngBelum ada peringkat

- Physical Processes Resulting in Geysers in Rapidly Filling Storm-Water TunnelsDokumen11 halamanPhysical Processes Resulting in Geysers in Rapidly Filling Storm-Water TunnelsJoko NugrohoBelum ada peringkat

- Experiment 101 Newton's Second Law of MotionDokumen9 halamanExperiment 101 Newton's Second Law of MotionQuirino Arzadon IVBelum ada peringkat

- Refrigerant properties and thermodynamic processesDokumen3 halamanRefrigerant properties and thermodynamic processesKgotsofalang Kayson NqhwakiBelum ada peringkat

- Iecex FMG 12.0022XDokumen6 halamanIecex FMG 12.0022XFrancesco_CBelum ada peringkat

- 2019 Cre Ii L24-26Dokumen32 halaman2019 Cre Ii L24-26Aman PrasadBelum ada peringkat

- University of Perpetual Help System DALTA Calamba CampusDokumen23 halamanUniversity of Perpetual Help System DALTA Calamba CampusJ HBelum ada peringkat

- Math Test Item FSC Part 2Dokumen38 halamanMath Test Item FSC Part 2Fakhar AbbasBelum ada peringkat

- Curriculum Vitae for Electrical EngineerDokumen2 halamanCurriculum Vitae for Electrical EngineerMeheryar KhanBelum ada peringkat

- Hysteresis in Ferromagnetic Materials ExperimentDokumen8 halamanHysteresis in Ferromagnetic Materials ExperimentbpmurtaBelum ada peringkat

- Catalog 2011Dokumen84 halamanCatalog 2011Marlou RabinaBelum ada peringkat

- The Sciences An Integrated Approach 8th Edition by James Trefil Ebook PDFDokumen41 halamanThe Sciences An Integrated Approach 8th Edition by James Trefil Ebook PDFcrystal.wright360100% (32)

- Deterministic Performance EstimationDokumen36 halamanDeterministic Performance EstimationErwdukBelum ada peringkat

- DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DTDokumen16 halamanDX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DTMimosaBelum ada peringkat

- Autobiography of Swami JnananandaDokumen45 halamanAutobiography of Swami Jnananandalifesoneric100% (4)