1 2 4ins

Diunggah oleh

Alberto S.Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1 2 4ins

Diunggah oleh

Alberto S.Hak Cipta:

Format Tersedia

Section 1-2-4

Instructor Notes

Residence Time Distribution in a Chlorine Contact Chamber

Susan E. Powers

Clarkson University

Pedagogical objectives and Student preparation

The three options available in this Residence Time Distribution laboratory offer a wide range of learning

objectives. It is intended that all students would receive the introductory materials, and then, based on the

particular class, students would receive specific instructions for Parts A, B or C. A bench-scale chlorine

contact chamber was originally built as part of a Senior Capstone Design class at Clarkson University in

1997. After it was built, we have found uses for it in several other classes as well. Some suggestions:

Senior Capstone Design Class: Parts A and B are appropriate for a senior capstone design class. The

students learn the application of dimensional analysis, regulatory compliance for drinking water, and

some basics of non-ideal reactors. Students would need a prior course in fluid mechanics and an

understanding of disinfection as part of water treatment processes. The CT regulations could certainly be

learned through completion of this lab.

Undergraduate water treatment or processes class: Part B tracer lab conducted in conjunction with

section on disinfection could give the students a greater understanding of pertinent regulations and the

complexities of real water treatment systems versus the ideal systems that are often taught at this level.

Students would need a basic understanding of ideal reactors and disinfection needs for water treatment.

Undergraduate laboratory class: Part B is suitable for teaching many fundamental laboratory techniques,

including generating and using calibration curves and spectrophotometry techniques. Requiring

replication of the lab could also be used to emphasize the uncertainties and errors in experimental

techniques and analysis.

Graduate processes class: Part C is most suitable for graduate students to observe non-ideal reactor

behavior and illustrate the application of mathematical models. Having the students generate their own

RTD data helps their level of interest in analysis and modeling of these data. Students would need to

have a fundamental understanding of non-ideal reactor behavior and modeling prior to completing this lab

as well as working knowledge of numerical integration and differentiation.

Description of the Laboratory Exercise

Time required

The time required to complete this laboratory depends on the scope of the project. Conducting a tracer

study for Part B requires a lab period that is at least two hours long. Part C requires the entire RTD curve

to be measured, and therefore takes longer (up to 3 hours). An entire semester can be built around parts A

and B, with the specific time in the lab somewhat dependent on the number of replicated experiments and

variables studied.

Apparatus and Reagents

The required equipment is listed in the laboratory description written for students. The primary

component needed for this lab is the Plexiglas reactor. The 1/35 scale model of the Canton Water

Treatment Plant (Attachment A) was built at Clarkson University for approximately $150 in Plexiglas

material costs. The photos included below illustrate this reactor. It could be possible to build a less

1

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

expensive non-ideal reactor for Parts B and C from large carboys in some arrangement, although the

concept of dimensional similitude with a real reactor would be lost.

Both the inflow and outflow need to be pumped; we used a Masterflex pump with two #17 pump heads

(Cole Parmer #7520-00). The use of one pump with two pump heads increases the probability that the

flow rates in the two streams will equal each other. It is recommended that new Masterflex tubing be

used in the pump heads to reduce the possibility that tubing degradation results in different flow rates. An

assortment of tubing and tubing connectors will also be required. The specific requirements will depend

on the specific equipment available.

We have found that green food color is an ideal tracer (blue or red would probably work too!!). The color

provides an easy way to visually observe fluid flow lines and reactor dead spaces and is easily detected by

spectrophometric methods. One small bottle of food color from a grocery store can be used for several

tracer studies. If multiple tracer experiments will be conducted, it is advised that the effluent from the

tracer study be collected and reused (with some additional make up food coloring).

Analytical apparatus

A spectrophotometer is required to analyze the concentration of green dye. A wavelength of

approximately 630 nm is appropriate, although this might vary some with the brand of food color. A scan

of absorbances in this vicinity is advised to maximize the analytical sensitivity. Having the capability to

measure absorbance in both 1 cm and 5 cm cells can increase the quality of the analysis, although the use

of only 1-cm cells is adequate (and typically all that is used in our labs).

Potential problems and remedies

The only difficulty that we have had with the lab has been due to density gradients that arise between the

fluid in the reactor and the tracer solution. We have found that temperature differences of only a few

degrees can result in density differences sufficient to cause the tracer to either float or sink, dramatically

changing the RTD. Filling the carboys and reactor at least 24 hours prior to the tracer experiment is

advised so that all fluids equilibrate at the same temperature.

Expected results

The bench-scale model of the Canton chlorine contact chamber has significant mixing and behaves in a

manner similar to a CMFR. Modeling this as 2 or 3 CMFRs in series greatly improves the quality of the

E(t) and F(t) curve fits. Actual T10 values are less than required by CT regulations during the winter

months (T=0.5 deg. C; C=1.0 mg/L chlorine). The actual residence time is large enough when the

chlorine contact chamber is operated at approximately 50% of its volume capacity or greater. Photos

illustrating the lab set up and copies of spreadsheet analyses of a tracer study are included below.

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

Tracer Study in a non-ideal reactor

1/20/00

sample

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

initial time, seconds fill duration, sec absorbance C/Co

210

4

0.023

0.040

300

3

0.044

0.076

390

3

0.06

0.103

480

3

0.085

0.147

571

3

0.108

0.186

720

3

0.132

0.228

840

3

0.158

0.272

961

3

0.19

0.328

1140

3

0.259

0.447

1350

3

0.315

0.543

1530

3

0.366

0.631

1710

3

0.402

0.693

1890

3

0.435

0.750

2070

3

0.464

0.800

2250

3

0.472

0.814

2430

3

0.485

0.836

2610

3

0.508

0.876

2820

3

0.512

0.883

3040

3

0.529

0.912

1.0

0.9

0.8

0.7

C/Co

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0

500

1000

1500

2000

2500

3000

3500

Time (sec)

ml/sec

average initial volumetric flowrate (start pump):

8.83 (average of 3 measurements)

volumetric flow rate at 47 minutes:

9.62 (average of 2 measurements)

average volumetric flow rate at inlet:

7.43 (average of 3 measurements)

average flowrate

Dimensions

Big section -

Little Section

8.32 (weighting influent and effluent flowrates equa

(problems with old tubing affecting flow rates)

Length

Width

Height (front)

Height (back)

VOLUME (initial)

57.8

46.2

5.3

4.3

1.28E+04

cm

cm

cm

cm

mL

Length

Width

Height (front)

Height (back)

VOLUME (initial)

10.5

20

5.3

5.3

1.11E+03

cm

cm

cm

cm

mL

TOTAL VOLUME

(problems with leveling the reactor)

1.39E+04

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

Understanding required residence times

CT(90) values (mg*min/L)

At T=0.5

At T=0.5 C

C

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

pH=6.0

pH=6.5

pH=6.3

137

163

153

141

168

157

145

172

161

148

176

165

152

180

169

155

184

172

157

189

176

162

193

181

165

197

184

pH=6.0

pH=6.5

46

47

48

49

51

52

52

54

55

160

pH=6.3

54

56

57

59

60

61

63

64

66

51

52

54

55

56

57

59

60

61

(CT90 values = CT99.9/3)

Required Residence Time (m

CT(99.9) values from SDWA (mg*min/L)

Other Temps

C

120

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

100

80

60

40

20

0.0

CT(90)

C

T=5.0

163

168

172

176

180

184

189

193

197

T=0.5

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

T=10.0

117

120

122

125

127

130

132

135

138

T=5.0

54

56

57

59

60

61

63

64

66

T=15.0

88

90

92

94

95

98

99

101

104

T=10.0

39

40

41

42

42

43

44

45

46

T=20.0

59

60

61

63

64

65

66

68

69

T=15.0

29

30

31

31

32

33

33

34

35

44

45

46

47

48

49

50

51

52

T=20.0

20

20

20

21

21

22

22

23

23

0.5

T=25.0

29

30

31

31

32

33

33

34

35

1.5

2.0

2.5

160

T=25.0

15

15

15

16

16

16

17

17

17

1.0

Chlorine Concentration (mg/L)

Required Residence Time (m

T=0.5

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

pH=6.0

pH=6.5

pH=6.3

Required Residence time (min)

pH=6.0

pH=6.5

pH=6.3

114

136

127

78

93

87

60

72

67

49

59

55

42

50

47

37

44

41

33

39

37

30

36

33

28

33

31

CT(99.9), pH=6.5

C

T=0.5 deg. C

a)

140

10

10

10

10

11

11

11

11

12

pH=6.5

b)

140

T=0.5

T=5.0

T=10.0

T=15.0

T=20.0

T=25.0

120

100

80

60

40

20

0

0.0

Residence Time (min)

C

T=0.5

T=5.0

T=10.0

T=15.0

T=20.0

T=25.0

0.4

136

98

73

49

37

24

0.6

93

67

50

33

25

17

0.8

72

51

38

25

19

13

1

59

42

31

21

16

10

1.2

50

35

26

18

13

9

1.4

44

31

23

15

12

8

1.6

39

28

21

14

10

7

1.8

36

25

19

13

9

6

2

33

23

17

12

9

6

0.5

1.0

1.5

2.0

2.5

Chlorine Concentration (mg/L)

CT values required for one log-removal of Giardia: a) as a function of pH;and, b) as a function of temper

and, b) as a function of temperature.

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

Analysis of compliance with CT regulations

depends primarily on water depth and temperature

scaling factor = 35

T10 (BS)

Depth (BS)

390 sec

4.8 cm

(from data curve)

Conversion to full-scale time (t*SF^0.5)

T10 (FS)

38.5 min

Conversion to full-scale depth (D*SF)

D(FS)

5.5 ft

Limiting factor for compliance

lowest chlorine conc

lowest temp

actual pH

1 mg/L

0.5 deg. C

6.3

CT values from 40 CFR 141.74

CT90 required in New York State

CT90 = CT99.9/3

CT(99.9)

CT(90)

Residence time (C=1 mg/L)

165 min

55 min

165 min*mg/L

55 min*mg/L

Since actual T10 value (38.5 min) is less than the required (55 min), the canton water treatment

plant is not in compliance when the water depth is shallow (5.5 ft)

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

Analysis of Moments

NOTES:

time

sec

0

210

300

390

480

571

720

840

961

1140

1350

1530

1710

1890

2070

2250

2430

2610

2820

3040

3500

4000

4500

(F(t))

C/Co

0

0.039655

0.075862

0.103448

0.146552

0.186207

0.227586

0.272414

0.327586

0.446552

0.543103

0.631034

0.693103

0.75

0.8

0.813793

0.836207

0.875862

0.882759

0.912069

(1), (2)

E(t)

dF/dt

0.000189

0.000253

0.000354

0.000393

0.000457

0.000338

0.00032

0.000415

0.00058

0.000554

0.000473

0.000417

0.00033

0.000297

0.000177

0.000101

0.000172

0.000119

8.42E-05

0.000133

0.00008

0.00004

0

SUMS

Zero

Moment

E(t) dt

(3)

First

Moment

t E(t) dt

(4)

(3)

(4)

First

Second

Second

Moment

Moment

Moment

t E(t) dt -tm)^2 E(t) dt^2 E(t) dt

0.046379

0.027328

0.033621

0.038248

0.036167

0.04903

0.044125

0.060222

0.101537

0.107841

0.080073

0.067241

0.056466

0.042672

0.025

0.024569

0.02626

0.021374

0.023917

0.049043

0.03

0.01

1.001112

9.739655

8.198276

13.11207

18.35893

20.65121

35.30131

37.06464

57.87291

115.7519

145.586

122.5116

114.9828

106.7198

88.3319

56.25

59.70259

68.53846

60.27574

72.7089

171.6492

120

45

1.55E+03

4.869828

6.968534

11.59914

16.63778

19.00563

31.64861

34.41716

54.22951

106.6643

134.2626

115.305

108.931

101.6379

84.49138

54

57.49138

66.17507

58.03143

70.07799

160.3694

112.5

42.5

1.45E+03

83068.49

42583.83

45108.11

43651.47

34543.97

33638.91

22137.3

20772.25

16927.73

4240.974

26.83865

1757.982

6592.548

11613.84

12309.3

19099.45

29599.96

34566.66

53219.7

186808.4

180323.8

87124.87

9.70E+05

84127.78

39143.03

41186.58

39544.76

31033.14

31876.2

19914.91

18304.15

16352.77

4612.59

11.17546

1902.03

6845.519

11904.78

12538.19

19381.84

29963.17

34105.79

52260.35

162125.2

158449.8

78298.46

8.94E+05

1. last 3 points extrapolated to provide sum(E dt)=1.00

2. Numerical differentiation by central difference FD approach

3. Using end point time as "t"

4. Using average time (over dt) as "t"

Analysis of results -

Depends on which t used for moment analysis

avg. t

max t

1.45E+03 1.55E+03

8.94E+05 9.70E+05

Mean residence time=

Variance=

1.0

0.0007

0.9

0.0006

0.7

0.0005

0.6

0.0004

E(t)

F(t)

0.8

0.5

0.4

0.0003

0.0002

0.3

0.2

0.0001

0.1

0.0000

0.0

0

1000

2000

3000

4000

5000

1000

2000

3000

4000

5000

Time (sec)

Time (sec)

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

Analysis of experimental system as ideal reactors

Flowrate (mL/s)

Volume (mL)

Theoretical residence time (s)

8.32

1.39E+04

1.67E+03

1. Single CMFR

2. PFR

C/Co=1-exp(-t/theta)

C/Co=1 for t>theta

t(s)

C/Co

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1.0

0.9

0.8

0.7

0.6

F(t)

C/Co

0 0.00E+00

100 5.80E-02

200 1.13E-01

300 1.64E-01

400 2.13E-01

500 2.58E-01

600 3.01E-01

700 3.42E-01

800 3.80E-01

900 4.16E-01

1000 4.50E-01

1100 4.82E-01

1200 5.12E-01

1300 5.40E-01

1400 5.67E-01

1500 5.92E-01

1600 6.16E-01

1670 6.31E-01

1670 6.31E-01

1700 6.38E-01

1800 6.59E-01

1900 6.79E-01

2000 6.97E-01

2100 7.15E-01

2200 7.31E-01

2300 7.47E-01

2400 7.62E-01

2500 7.76E-01

2600 7.89E-01

2700 8.01E-01

2800 8.12E-01

2900 8.23E-01

3000 8.34E-01

0.5

0.4

0.3

expt. dat

0.2

single cmfr

0.1

PFR

0.0

0

500

1000

1500

2000

2500

3000

3500

4000

Time (sec)

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

Analysis of experimental system as a series of CMFRs

Determine # reactors from moment analysis

avg t

max t

n=tm^2/variance

2.36E+00 2.47E+00

Theoretical residence time (s)

1673

To avoid problems with defining a factorial of a non integer - approximate this as

n=

2

To generate E(t) curve - see equation 70 in Chapter 4 of L&B text

F(t) curve generated from numerical integration of E(t) curve

E(t)

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

1.0

2600

0.9

2700

2800

0.8

2900

0.7

3000

0.6

3100

0.5

3200

0.4

3300

0.3

3400

0.2

3500

0.1

3600

0.0

3700

0

3800

3900

4000

E(t) dt

F(t)

0

0

0.000127 0.00634

6.34E-03

0.000225 0.017593

2.39E-02

0.0003 0.026228

5.02E-02

0.000354 0.032695

8.29E-02

0.000393 0.037371

1.20E-01

0.000419 0.040578

1.61E-01

0.000433 0.042588

2.03E-01

0.000439 0.04363

2.47E-01

0.000439 0.043897

2.91E-01

0.000432 0.043549

3.34E-01

0.000422 0.042723

3.77E-01

0.000409 0.041529

4.19E-01

0.000393 0.040063

4.59E-01

0.000375 0.038399

4.97E-01

0.000357 0.036602

5.34E-01

0.000338 0.034722

5.69E-01

0.000318 0.032801

6.01E-01

0.000299 0.030873

6.32E-01

0.00028 0.028962

6.61E-01

0.000262 0.02709

6.88E-01

0.000244 0.025272

7.14E-01

0.000227 0.02352

7.37E-01

0.00021 0.021842

7.59E-01

0.000195 0.020243

7.79E-01

0.00018 0.018728

7.98E-01

0.000166 0.017297

8.15E-01

0.000153 0.01595

8.31E-01

0.000141 0.014688

8.46E-01

0.000129 0.013507

8.59E-01

0.000119 0.012406

8.72E-01

0.000109 0.011382

8.83E-01

9.97E-05 0.010431

8.94E-01

9.13E-05 0.00955

9.03E-01

8.34E-05 0.008735

9.12E-01

7.62E-05 0.007982

9.20E-01

6.96E-05 0.007288

9.27E-01

6.34E-05 0.006649

9.34E-01

1000 0.006062

2000

3000

5.78E-05

9.40E-01

5.26E-05 0.005522 Time (sec)

9.45E-01

4.79E-05 0.005027

9.50E-01

t(s)

E(t)

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

3000

3100

3200

3300

expt data

3400

n=2

3500

n=3

3600

3700

4000

5000

3800

3900

4000

E(t) (Sec^-1)

F(t)

t(s)

for n=

E(t) dt

0

2.41E-05

8.06E-05

1.52E-04

2.25E-04

2.94E-04

3.54E-04

4.03E-04

4.40E-04

4.65E-04

4.80E-04

4.85E-04

4.83E-04

4.74E-04

4.59E-04

4.40E-04

4.19E-04

3.95E-04

3.70E-04

3.45E-04

3.19E-04

2.94E-04

2.70E-04

2.47E-04

2.25E-04

2.04E-04

0.0007

1.84E-04

1.66E-04

0.0006

1.49E-04

0.0005

1.34E-04

1.20E-04

0.0004

1.07E-04

9.51E-05

0.0003

8.45E-05

0.0002

7.50E-05

6.64E-05

0.0001

5.87E-05

0.0000

5.19E-05

0

4.57E-05

4.03E-05

3.54E-05

0.001205

0.005233

0.011604

0.018833

0.025959

0.032397

0.037827

0.042109

0.045227

0.04724

0.048254

0.048399

0.047811

0.046626

0.044972

0.042963

0.040703

0.038278

0.035762

0.033216

0.030689

0.028219

0.025835

0.023559

0.021406

0.019384

0.0175

0.015753

0.014143

0.012667

0.011318

0.010092

0.00898

0.007975

0.00707

0.006257

0.005529

1000

0.004879

0.004298

0.003782

3

F(t)

0

1.20E-03

6.44E-03

1.80E-02

3.69E-02

6.28E-02

9.52E-02

1.33E-01

1.75E-01

2.20E-01

2.68E-01

3.16E-01

3.64E-01

4.12E-01

4.59E-01

5.04E-01

5.47E-01

5.87E-01

6.26E-01

6.61E-01

6.95E-01

7.25E-01

7.54E-01

7.79E-01

8.03E-01

8.24E-01

8.44E-01

8.61E-01

8.77E-01

8.91E-01

9.04E-01

9.15E-01

9.25E-01

9.34E-01

9.42E-01

9.49E-01

9.55E-01

9.61E-01

2000

3000

9.66E-01

9.70E-01

Time (sec)

9.74E-01

4000

AEESP Environmental Engineering Processes Laboratory Manual

5000

(v1.0)

Section 1-2-4

Analysis of reactor with dead volume

First, to determine if dead volume calculations appropriate,

compare actual and trheoretical mean residence times.

tm

theta

1.45E+03 sec

1.67E+03 sec

(based on average time approach)

Because theta>tm, there is dead volume in our reactor

The effective volume can be determined from the expt. tm:

Veff=Q*tm

Vol total

1.21E+04 mL

1.39E+04 mL

fraction dead volume

0.13

Now - since we know that there is dead volume - try a multiparameter model to fit the data

1. Plot data as 1-F(t) vs. t/theta

0

0.0

F(t)

0

0.039655

0.075862

0.103448

0.146552

0.186207

0.227586

0.272414

0.327586

0.446552

0.543103

0.631034

0.693103

0.75

0.8

0.813793

0.836207

0.875862

0.882759

0.912069

t/theta

1-F(t)

0.00E+00

1.00E+00

1.25E-01

9.60E-01

1.79E-01

9.24E-01

2.33E-01

8.97E-01

2.87E-01

8.53E-01

3.41E-01

8.14E-01

4.30E-01

7.72E-01

5.02E-01

7.28E-01

5.74E-01

6.72E-01

6.81E-01

5.53E-01

8.07E-01

4.57E-01

9.14E-01

3.69E-01

1.02E+00

3.07E-01

1.13E+00

2.50E-01

1.24E+00

2.00E-01

1.34E+00

1.86E-01

1.45E+00

1.64E-01

1.56E+00

1.24E-01

1.69E+00

1.17E-01

1.82E+00

8.79E-02

ln(1-F(t))

0

-0.040463

-0.078894

-0.109199

-0.15847

-0.206049

-0.258235

-0.318023

-0.396881

-0.591587

-0.783298

-0.997052

-1.181245

-1.386294

-1.609438

-1.680897

-1.809151

-2.086362

-2.14352

-2.431202

0.5

1.0

1.5

2.0

-0.5

-1

ln(1-F(t))

Expt data

t

0

210

300

390

480

571

720

840

961

1140

1350

1530

1710

1890

2070

2250

2430

2610

2820

3040

-1.5

-2

-2.5

-3

t/theta

2. For analysis - determine linear portion of the curve

eyeball line - looks like could do a linear regression of points after the 10th

ln(1-f(t))=-1.573(t/theta)+0.428

0

determine value of t/theta for ln(1-F(t))=0

this equals p(1-m)

0.272 =Vpf/Vtot

-Slope=1/((1-p)(1-m))=

1.573

(1-p)(1-m)=

0.636 =Vcmfr/Vtot

remainder = m =

0.092 =Vd/Vtot

ln(1-F(t))

0=-1.573(t/theta)+0.428

t/theta= p(1-m)

-0.5

0.0

0.5

1.0

1.5

2.0

-1

-1.5

-2

-2.5

y = -1.5725x + 0.4283

2

R = 0.9899

-3

t/theta

Fraction of dead volume determined by this analysis similar to that determined based on tm and theta alone

10

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

3. To determine E(t) and F(t) curves =>

Determine F(t) curves from eqn. 73 in L&B text - only for t/theta>p(1-m) (0.272)

E(t) curve from Numerical integration

Plot these curves over series CMFR curves and expt data

F(t)

E(t)

0.00E+00

0.00E+00

0.00E+00

0.00E+00

0.00E+00

0.00E+00

0.00E+00

0.00E+00

0.00E+00

0.00E+00

0.00E+00

4.11E-02

6.36E-04

1.27E-01

8.22E-04

2.05E-01

7.48E-04

2.77E-01

6.81E-04

3.42E-01

6.20E-04

4.01E-01

5.64E-04

4.54E-01

5.14E-04

5.03E-01

4.67E-04

5.48E-01

4.26E-04

5.89E-01

3.87E-04

6.25E-01

3.53E-04

6.59E-01

3.21E-04

6.90E-01

2.92E-04

7.17E-01

2.66E-04

7.43E-01

2.42E-04

7.66E-01

2.20E-04

7.87E-01

2.01E-04

8.06E-01

1.83E-04

8.23E-01

1.66E-04

8.39E-01

1.51E-04

8.54E-01

1.38E-04

8.67E-01

1.25E-04

8.79E-01

1.14E-04

8.90E-01

1.04E-04

9.00E-01

9.46E-05

9.09E-01

8.61E-05

9.17E-01

7.84E-05

9.24E-01

7.13E-05

9.31E-01

6.49E-05

9.37E-01

5.91E-05

9.43E-01

5.38E-05

9.48E-01

4.90E-05

9.53E-01

4.46E-05

9.57E-01

4.06E-05

9.61E-01

3.69E-05

9.64E-01

3.52E-05

1.0

0.9

0.8

0.7

0.6

F(t)

0

100

200

300

400

450

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

3000

3100

3200

3300

3400

3500

3600

3700

3800

3900

4000

0.5

0.4

expt data

0.3

n=2

0.2

n=3

0.1

Dead volume

0.0

0

1000

2000

3000

4000

5000

Time (sec)

0.0009

0.0008

0.0007

0.0006

E(t)

t/theta

t

0.00E+00

5.98E-02

1.20E-01

1.79E-01

2.39E-01

2.69E-01

2.99E-01

3.59E-01

4.18E-01

4.78E-01

5.38E-01

5.98E-01

6.57E-01

7.17E-01

7.77E-01

8.37E-01

8.96E-01

9.56E-01

1.02E+00

1.08E+00

1.14E+00

1.20E+00

1.25E+00

1.31E+00

1.37E+00

1.43E+00

1.49E+00

1.55E+00

1.61E+00

1.67E+00

1.73E+00

1.79E+00

1.85E+00

1.91E+00

1.97E+00

2.03E+00

2.09E+00

2.15E+00

2.21E+00

2.27E+00

2.33E+00

2.39E+00

0.0005

0.0004

0.0003

0.0002

0.0001

0.0000

0

1000

2000

3000

4000

5000

Time (sec)

Note equation referenced in above spreadsheet from Draft textbook by Lawler, D. and Benjamin, M.

This equation describes complex mixing behavior as having three components CMFR, PFR, and dead

space.

1

t

F (t ) = 1 exp

p (1 m

(1 p )(1 m)

where: 1-m is the effective fraction of the usable tank volume, p is the fraction behaving as a PFR and 1p the fraction behaving as a CMFR. (Note, Levenspiel defines the same equation as F())

11

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Section 1-2-4

Analysis of the extent of chlorine conversion

reaction rate constant 2.77778E-05 sec^-1

Completely segregated model

Bench scale

time

E(t)

sec

sec^-1

0 0.000189

210 0.000253

300 0.000354

390 0.000393

480 0.000457

571 0.000338

720 0.00032

840 0.000415

961 0.00058

1140 0.000554

1350 0.000473

1530 0.000417

1710 0.00033

1890 0.000297

2070 0.000177

2250 0.000101

2430 0.000172

2610 0.000119

2820 8.42E-05

3040 0.000133

3500 0.00008

4000 0.00004

4500

0

Converted to full scale

time

E(t)

exp(-kt)E(t)dt

sec

0 3.19188E-05

0

1242 4.27434E-05 0.051302085

1775 5.99056E-05 0.030362164

2307 6.63818E-05 0.033150613

2840

7.7286E-05 0.038029408

3378 5.70722E-05

0.02797356

4260 5.41696E-05 0.042421848

4970 7.01373E-05 0.043372393

5685 9.81156E-05 0.059975089

6744

9.3648E-05 0.082228738

7987 7.99571E-05 0.079572122

9052 7.04295E-05 0.058326394

10116 5.58579E-05 0.044910549

11181 5.01912E-05 0.039178189

12246 2.99528E-05 0.022699056

13311 1.70002E-05 0.012507737

14376 2.91433E-05 0.020816867

15441 2.01761E-05 0.013991617

16683 1.42328E-05 0.011124453

17985 2.25198E-05

0.01778509

20706 1.35225E-05 0.020703928

23664 6.76123E-06 0.010364537

26622

0

0

sum

0.760796437

With the completely segregated model, it indicates that Ceff=0.76*Co

So, for Co=4 mg/L, Ceff=

3.04 mg/L chlorine

Using data from the series CMFR, know the conversion can be determined as:

Ceff/Co=(1+k theta)^-n

from previous work, know theta =

scaling to the full scale => theta=

for n=2, Ceff/Co=

for n=3, Ceff/Co=

1.67E+03 seconds for the bench scale reactor

9.90E+03 sec

0.62

0.48

Quite a large difference!!

for n=2, Ceff=

for n=3, Ceff=

2.46 mg/L chlorine

1.93 mg/L chlorine

These different methods for predicting effluent concentrations for chlorine result

in substantially different estimates. This would be especially important when deciding

if the water treatment plant complies with CT rules.

12

AEESP Environmental Engineering Processes Laboratory Manual

(v1.0)

Anda mungkin juga menyukai

- E WasteDokumen33 halamanE WasteAlberto S.Belum ada peringkat

- Learn English verbs with this chart of infinitives, past tense, and participlesDokumen4 halamanLearn English verbs with this chart of infinitives, past tense, and participlesAlberto S.Belum ada peringkat

- Zapata PDFDokumen7 halamanZapata PDFAlberto S.Belum ada peringkat

- Diomi Mamma....Dokumen7 halamanDiomi Mamma....Alberto S.Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Sovtek 5881 Wxt/6L6 WGC Tube GuideDokumen8 halamanSovtek 5881 Wxt/6L6 WGC Tube GuideKon GekasBelum ada peringkat

- Past Progressive WorksheetDokumen3 halamanPast Progressive WorksheetSantiago VargasBelum ada peringkat

- An Introduction To Software DevelopmentDokumen19 halamanAn Introduction To Software Developmentsanjeewani wimalarathneBelum ada peringkat

- SF3300Dokumen2 halamanSF3300benoitBelum ada peringkat

- Civil Services Lios ProceedingsDokumen5 halamanCivil Services Lios ProceedingsallumuraliBelum ada peringkat

- Cheatsheet HomebrewDokumen1 halamanCheatsheet HomebrewfredmnBelum ada peringkat

- 7310 Installation InstructionsDokumen2 halaman7310 Installation InstructionsmohamedBelum ada peringkat

- Your IndiGo Itinerary July - SN9NVMDokumen5 halamanYour IndiGo Itinerary July - SN9NVMaagama gurukulBelum ada peringkat

- Heat Transfer DoeDokumen32 halamanHeat Transfer DoeArt RmbdBelum ada peringkat

- METACOGNITION MODULEDokumen4 halamanMETACOGNITION MODULEViolet SilverBelum ada peringkat

- MEM - Project Pump and TurbineDokumen22 halamanMEM - Project Pump and TurbineAbhi ChavanBelum ada peringkat

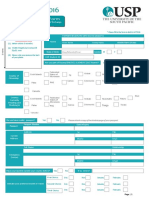

- Jene Sys 2016 ApplicationformDokumen4 halamanJene Sys 2016 ApplicationformReva WiratamaBelum ada peringkat

- Green Schools Project LAC PlanDokumen2 halamanGreen Schools Project LAC PlanJolly Mar Tabbaban Mangilaya100% (1)

- Tanbin Chowdhury ResumeDokumen2 halamanTanbin Chowdhury ResumeTanbin RafeeBelum ada peringkat

- ISO 18794. Café. Análisis Sensorial. Vocabulario. Ingles PDFDokumen16 halamanISO 18794. Café. Análisis Sensorial. Vocabulario. Ingles PDFluigi sanchezBelum ada peringkat

- Using Accelerometers in A Data Acquisition SystemDokumen10 halamanUsing Accelerometers in A Data Acquisition SystemueidaqBelum ada peringkat

- Agriculture DisciplineDokumen3 halamanAgriculture DisciplineUmair FaheemBelum ada peringkat

- Chapter 4.1 Decision Theory Part 2Dokumen38 halamanChapter 4.1 Decision Theory Part 2ernieBelum ada peringkat

- PistonDokumen247 halamanPistonmeyyiti01Belum ada peringkat

- 列印|單字總是背不住?教你輕鬆記憶法! (How to Memorize Vocabulary Perfectly With Minimal Effort) - VoiceTube《看影片學英語》Dokumen4 halaman列印|單字總是背不住?教你輕鬆記憶法! (How to Memorize Vocabulary Perfectly With Minimal Effort) - VoiceTube《看影片學英語》John LamBelum ada peringkat

- Crises ManagementDokumen19 halamanCrises ManagementJinenus MosisaaBelum ada peringkat

- 20 ASL Circular-1 PDFDokumen3 halaman20 ASL Circular-1 PDFAlagu MurugesanBelum ada peringkat

- Life Orientation September 2022 EngDokumen9 halamanLife Orientation September 2022 EngTondaniBelum ada peringkat

- Slides Iso 17021 Be LacDokumen117 halamanSlides Iso 17021 Be Lacjorge.s1943Belum ada peringkat

- Sensors & Accessories User ManualDokumen114 halamanSensors & Accessories User ManualAbrakain69Belum ada peringkat

- Model HA-310A: Citizens BandDokumen9 halamanModel HA-310A: Citizens BandluisBelum ada peringkat

- Family Values, Livelihood Resources and PracticesDokumen285 halamanFamily Values, Livelihood Resources and PracticesRogelio LadieroBelum ada peringkat

- ACE Personal Trainer Manual Chapter 13Dokumen59 halamanACE Personal Trainer Manual Chapter 13Đạt NguyễnBelum ada peringkat

- Parameter ranges and attenuation values for RRH configurationsDokumen121 halamanParameter ranges and attenuation values for RRH configurationscharantejaBelum ada peringkat

- India MedTech 23 CompendiumDokumen326 halamanIndia MedTech 23 Compendiumudiptya_papai2007Belum ada peringkat