Design and Implementation of A Data-Acquisition System

Diunggah oleh

Mokhtar HashimJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Design and Implementation of A Data-Acquisition System

Diunggah oleh

Mokhtar HashimHak Cipta:

Format Tersedia

Design and Implementation of a data-acquisition system to monitor

and control a photovoltaic power generation system

Maung Zaw Win Min

Abstract A computer-based data-acquisition system to

monitor and control photovoltaic power generation systems

using a novel method, based on Agilent data-acquisition board

(U2353A) and graphical programming software (Agilent Vee

Pro), has been designed and implemented. Prior to designing

the data-acquisition system, a small-sized PV power generation

system, consisting of a 20W BP Solar panel, batteries, a charge

controller and a DC-to-AC inverter, has been assembled. Light

dependent resistors have been utilized to measure the amount of

irradiance incident on the solar panel. A 4-channel relay card is

used to enable the switching of power supply from the inverter

to the grid power programmatically. At the same time, if the

power generation system is not producing the amount of power

that it should, based on the readings of the light sensor, the

program would also automatically send a sms to the user to

inform him of the condition. Besides these functions, the written

program is able to monitor the photovoltaic panels

instantaneous voltage and current, the voltage across the

inverter and the current flowing into it, hence the solar panels

output power and power being consumed by the electrical

appliances connected to the inverter. Although the size of the

power generation system being monitored in this project is

experimental, the data-acquisition system can always be

interfaced to larger power capacity renewable energy system

plants.

I. INTRODUCTION

Energy Information Administration of US estimated in

2005 that, 86% of primary energy production in the world

came from burning fossil fuels, with the remaining non-fossil

sources being hydroelectric 6.3%, nuclear 6.0%, and other

(geothermal, solar, wind, and wood and waste) 0.9 percent.[1]

Fossil fuels take millions of years to form, and reserves are

being depleted much faster than the rate at which they can be

replenished. Furthermore, burning fossil fuels produces

around 21.3 billion tones of carbon dioxide per year, which

is double of the amount that natural processes can absorb. [2]

Carbon dioxide is one of the greenhouse gases that enhances

radiative forcing and contributes to global warming, causing

major adverse effects, including reduced biodiversity and

rise in sea-level. This factor, coupled with that of dwindling

resources, is pushing a global movement towards the

generation of renewable energy to meet increased energy

needs.

According to European RES-E directive[3], renewable

energy sources include hydro power (large and small),

biomass (solids, bio-fuels, landfill gas, sewage treatment

plant gas and biogas), wind, solar, geothermal, wave and

Maung Zaw Win Min is with the National University of Singapore, 21

Lower Kent Ridge Road, Singapore 119077 (phone: 91088328; e-mail:

zwinmin@nus.edu.sg).

tidal energy and biodegradable waste. More specifically,

Renewable energy is energy that is derived from natural

processes that are replenished constantly. In its various

forms, it derives directly or indirectly from the sun, or from

heat generated deep within the earth. Renewable energy

systems convert these natural energy sources into useful

energy (electricity and heat).

The rapid evolution of renewable energy sources (RESs)

within the past two decades has led to the installation of

many RES power systems all over the world. Although they

are still not prevalent in Singapore currently, the trend seems

to suggest that the renewable energy sources will be taking a

more central role soon.

In this project, a computer-based data-acquisition (DAQ)

system for monitoring solar irradiance and photovoltaic

power generation systems operational parameters is

designed and implemented. Four light dependent resistors

are used to measure the solar irradiance incident on the solar

panels. The photovoltaic voltage and current, batterys

voltage and the power being consumed are the systems

parameters being monitored. The various data is captured by

the DAQ system and then is interfaced to the PC through

USB cable. The collected data are further processed,

displayed and saved using the Agilent VEE Pro software.

This system has the advantage of great flexibility in case

of changes, and more importantly, the ability to control the

PV power system from the computer. For example, this

system has implemented an automatic power supply switch

design to ensure uninterrupted power supply to the electrical

appliances connected to the PV power output. The monitor

program can also be remotely monitored over the internet.

The above mentioned DAQ system has been interfaced to

a low-power photovoltaic power system for test purposes,

but this DAQ system can certainly be extended to be used on

large power capacity Renewable Energy Sources plants.

II. A Stand-alone PV System with Battery Storage

A. Introduction

For experimental purpose, a low-power stand-alone PV

system with battery storage has been designed and

implemented in this project. In this chapter, each component

of the PV system will be described, and the rationale for

each choice explained. Overall, the PV generation system

consists of BP Solar SX-20U 20 W solar panel, Sunsei

CC10000 charge controller that allows up to 10 A of

charging current, Yuasa 12V, 7Ah rechargeable lead-acid

battery and Elektro Automatik EA-TWI 150-12 DC/AC

inverter.

B. Solar Panel

The solar panel chosen for this project is BP Solar SX20U. It has a module rated power of 20W, nominal voltage

of 12V, open-circuit voltage of 21V, short-circuit current of

1.3A, voltage at rated power of 16.8V and current at rated

power of 1.2A. These values are tested under standard test

conditions of irradiance of 1000W/m2, AM 1.5 spectrum,

and cell temperature of 25C. As this PV power system is

just for experimental purpose, there is not a need for a solar

panel with higher rated power. That, coupled with the fact

that the total cost of the entire setup should be under S$1000,

the amount given by Agilent Technologies for this project,

the price and electrical specifications of SX-20U manage to

strike a balance, making it first choice among all available

panels.

SX-20U consists of 36 semi-crystalline silicon solar cells

electrically configured as two series strings of 18 cells each.

These strings may be placed in series or in parallel in the

field, providing 6V or 12V nominal output, by moving leads

in the junction box. The cell strings are laminated between

sheets of ethylene vinyl acetate (EVA) and tempered glass.

Among its many features, the most salient one essential for

this projects purpose is its ability to provide sufficient

voltage to charge batteries efficiently in virtually any

climate.

C. Charge Controller

Sunsei CC10000 Charge Controller is chosen over other

available options, mainly due to its compatibility with almost

all types of batteries and solar panels and its high efficiency

of 98%. It operates at a nominal voltage of 12V and can

withstand a maximum charging current of 10A. It uses pulse

width modulation (PWM) to charge the battery in two stages:

boost and float charge. It also has over-charge protection, by

floating battery at safe voltage when battery is full, and

reverse leakage protection to prevent power loss at night.

Furthermore, its circuitry that controls the charging process

is 100% solid state, thus promising robust operation.

The operation of the Sunsei CC10000 is completely

automatic. It will regulate the charging of batteries during

conditions of heavy usage, or when left unattended for long

periods of time. On a typical day, as the charging starts for

the day and battery state of charge is low, charging will be

continuous and the Charging LED will be on all the time.

This is after the utilization of the battery the previous night,

leaving it discharged. The battery will be charged up to

14.5V, the Boost Voltage, and kept at this level for two

hours using PWM control. Then, the controller goes into

float mode and will maintain the battery at 13.7V indefinitely

as long as the load current does not surpass the charging

current.

D. Battery

To store the energy produced by the solar panel, Yuasa

NP7-12 lead-acid rechargeable battery was chosen. It has a

rated voltage of 12V and capacity of 7Ah. NP7-12 batteries

are uniquely constructed and the sealing technique applied

ensures no electrolyte leakage from case or terminals.

Furthermore, NP batteries utilize unique electrolyte

suspension system incorporating a micro-fine glass mat to

retain the maximum amount of electrolyte in the cells. The

electrolyte is retained in the separator material and there is

no free electrolyte to escape from the cells. The oxygen

recombination technology incorporated into the design of the

NP batteries effectively control the generation of gas during

usage. Also, the batteries are equipped with a simple, safe

low pressure venting system which releases excess gas and

automatically reseals should there be a build of gas within

the battery due to severe overcharge. On top of that, the

heavy duty lead calcium alloy grids provide an extra margin

of performance and life in both cyclic and float applications

and give unparalleled recovery from deep discharge. Lastly,

the use of the special separator material provides a very

efficient insulation between plates preventing inter-plate

short circuits and prohibiting the shedding of active

materials.

E.

DC-AC Inverter

The last component to make up the whole of this PV

power generation system is a DC-AC inverter to convert the

DC power, being produced by the solar panel, into AC

power. An inverter is added to this system to allow electrical

appliances, a majority of which utilizes AC power, to be

powered by it. Although the inverter eventually chosen

Elektro Automatik EA-TWI 150 has only a rated power

output of 140W, which is not sufficient to drive most home

appliances, it is sufficient for this projects purpose.

EA-TWI 150 takes in an input DC voltage of 12V and

outputs 230V 50Hz AC voltage. It has an efficiency of more

than 90% and outputs modified sine wave output voltage.

The unit is equipped with extensive protection facilities such

as overload, overheat and battery protection.

III. DATA ACQUISITION SYSTEM

With the PV power generation system in place, the dataacquisition system can then be designed to measure the

parameters of interest. The data-acquisition system is

essentially based on Agilent U2353A USB modular

multifunction data-acquisition device. Its analog input

channels are for voltage measurements whose dynamic

ranges can be set independently within the maximum ranges

of 10V. Since this range is lower than the voltages that are

to be measured, external signal conditioning, based on

voltage dividers and current shunts, is required to condition

the measured values to fall within the required range. Lastly,

the data-acquisition system also comprises of 4 light

dependent resistors circuits to measure the light intensity

incident on the solar panel.

A. Agilent U2353A

The main component of this data-acquisition system,

Agilent U2353A packs a wide array of features. However,

only those features that are utilized in this project will be

mentioned in this report. U2353A can sample up to 500

kSa/s with a resolution of 16 bits. This sampling rate,

however, depends on the number of channels specified in the

scan list by the user. This is because U2353A is designed

with multiplexing analog input. Hence, if two channels are

specified in the scan list, the maximum sampling rate is

actually 500 kSa/s divided by two, which is 250 kSa/s for

each channel. Regarding analog input channels, U2353A

provides 16 single-ended (SE) or 8 differential analog input

channels.

U2353A also features a 24-bit programmable generalpurpose digital I/O (GPIO), which is TTL compatible. The

24-bit GPIO are segmented into four channels (CH 501 to

504). Channel 501 and 502 consists of eight data bit while

channel 503 and 504 consists of four data bit. All four

channels are programmable as input and output. This feature

is utilized in this project to drive a 4-channel relay card to

implement the power supply switch function, which will be

described in chapter ??.

Other than the above-mentioned features, U2353A also

have two D/A channels that are available. The two analog

outputs are capable of supplying output voltages in the range

of 0 to 10V and 10V. Each DAC channel drives a

maximum current of 5mA. The two analog outputs can be

used as voltage sources to the devices under test. In addition

to this, the analog outputs are also used to output predefined

function generators or any arbitrary waveform. The

predefined waveforms are sine wave, square wave, triangle

wave, sawtooth wave and noise wave. In this project, the

analog output is used as a voltage source to the light

dependent resistors circuit. This provides an almost constant

voltage source, while reducing the area that would have been

necessary for a voltage regulator to be constructed.

B. Voltage Divider

Figure 1 Single Ended Analog Input

Figure 2 Differential Analog Input

A single-ended connection is applicable when the analog

input signal is referenced to a ground and can be shared with

other analog input signals. The differential input mode

provides two inputs that respond to the difference of the

signal voltage. As can be seen from the diagram above-right,

the analog input of U2353A has its own reference ground or

signal return path. The differential mode can be used for

common-mode noise rejection. This analog input feature is

used to collect the electrical parameters, such as solar panels

voltage and current, batterys voltage and current and the

readings from four light dependent resistors, which will be

explained in greater details below.

The voltages that are to be monitored solar panels

voltage and batterys terminal voltage exceed the analog

input range of 10V of U2353A. Thus, there is a need to

condition the signal and bring it down to the acceptable

range before interfacing it to the data-acquisition module.

This is achieved by voltage divider circuits, designed to

obtain a negligible power dissipation and influence on the

measured values. These measured values are then converted

back to the actual values inside the VEE program being run

on the PC.

To measure the voltage across the solar panel, whose

voltage can reach up to 21V, the above potential divider is

utilized. The resistors values are chosen to be high so as to

limit the amount of current that will be drawn through this

branch. To reduce 0-21V range to 0-10V range means that

the measured voltage should be reduced to approximately

half its value before being collected by the data-acquisition

module. Hence, the values of the resistors indicated in the

diagram above should accomplish the task.

The same method applies to the battery terminal voltage.

For the battery, however, the maximum voltage that it is

expected to reach is 14.5V. Hence, reducing the measured

values down to two-third will fit the input range better. To

achieve this, the resistors values should be 12 k and 6 k,

with the data-acquisition module reading the voltage across

the 12 k resistor.

C. Current sense resistor

Caddock precision current sense resistors are used to

measure the current flowing through the wires. These current

sense resistors utilize Caddocks Micronox resistance films

to achieve a low cost resistor with non-inductive

performance. The resistors terminals are constructed for

Kelvin connections to the circuit board, which means that as

the picture shows, the current sense resistors are equipped

with four terminals, two for carrying the measured current,

and two for resistors voltage drop to be measured. This way,

the data acquisition module only measures the voltage

dropped across the precision resistance itself, without any

stray voltages dropped across current carrying wires or wireto-terminal connection resistances.

Shunt resistors function as current measurement devices

by dropping a precise amount of voltage for every amp of

current through them, the voltage drop being measured by a

voltmeter. In this sense, a precision shunt resistor "converts"

a current value into a proportional voltage value. Thus,

current may be accurately measured by measuring voltage

dropped across the shunt.

The current sense resistor used for this project has a

resistance value of 0.01, so only a modest amount of

voltage will be dropped at full current, hence having

negligible effect on the current that is to be measured.

D. Light dependent resistor

As mentioned above, this data acquisition systems

objective is to monitor that the photovoltaic generation

system is performing at its expected level. To know what its

expected level is, there is a need to measure the electrical

parameters under its normal working condition. That,

however, would only be one side of the equation. The other

side will consist of the light intensity that is incident on the

photovoltaic panel. With that information, the monitor

program can then decide if the power being generated is in

accordance to the amount of light intensity being received.

Hence, it is necessary for light dependent resistor to be

included in this data acquisition system.

A light dependent resistor is an electronic component

whose resistance decreases with increasing incident light

intensity. The relationship between the resistance RL and

light intensity (lux) for a typical light dependent resistor is

RL =

500

k

lux

Figure 3 Light dependent resistor to measure the light

intensity

With the light dependent resistor connected to 5V through

a 3.3k resistor, the output voltage of the light dependent

resistor is

Vo = 5

RL

( R L + 3.3)

Rearranging the equations, we get the light intensity

2500

500)

Vo

lux =

.

3 .3

(

The lux is the SI unit of illuminance and luminous

emittance. It is used in photometry as a measure of the

intensity of light, with wavelengths weighted according to

the luminosity function, a standardized model of human

brightness perception. Appendix A shows a table of

examples of light sources and their corresponding

illuminance.

The light dependent resistor utilized in this project is

NORP12 from RS. It is made of two cadmium sulphide

photoconductive cells with spectral responses similar to that

of the human eye. Cadmium sulphide is a high resistance

semiconductor. If light falling on the device is of high

enough frequency, photons absorbed by the semiconductor

give bound electrons enough energy to jump into the

conduction band. The resulting free electron (and its hole

partner) conduct electricity, thereby lowering resistance.

NORP12 has a resistance range from 400 to 1M.

With a circuit similar to the one shown above, the light

dependent resistor will receive its voltage supply from

U2353A analog output, while Vo in the diagram is measure

by U2353A analog input. The input configuration utilized

here will be single-ended, different from the differential

input employed for the measurement of voltages and

currents. This is due to the fact that the light dependent

resistor is already connected to the U2353As reference

ground as it is receiving the voltage supply. Hence, a singleended input will be sufficient.

The data acquisition system now is able to measure light

intensity and use it to evaluate if the electrical parameters

being measured are within the acceptable range. One

possible anomaly that can occur is when tree branches shade

part of the photovoltaic panel, thus affecting the power

output. If the light sensor is beyond the shade, the monitor

program will be able to take note of the discrepancy and

trigger off. However, if the light sensor falls under the shade

as well, the monitor program will not capture this triggering

event. Hence, four light dependent resistors circuits are

included in the data acquisition system. This can also help to

improve the accuracy as the average of the four readings is

taken if they dont differ beyond a certain range.

With the data acquisition system complete, the readings

measured are transferred to the PC via the USB cable from

U2353A. A monitor and control program in the PC will then

process, display and store all the data, monitor for unusual

events and trigger off control actions.

IV. Program to monitor and control a photovoltaic

generation system

Now we will describe in details the program designed to

monitor and control a photovoltaic generation system. This

program was written in the hope that users of this program

can have a clear and concise picture of the photovoltaic

systems performance at a glance. Currently, photovoltaic

systems are still rather expensive to install. Hence, for

average consumers to take the plunge and install such a

system at home, they would want to know how the system is

performing and how much power it is producing for them.

Besides the reassurance that it offers, it can also ensure

that if any situation is causing the photovoltaic system to not

perform at its expected level, the owner can be informed

early and remedies can be carried out. One scenario is that of

branches or litter shading part or whole of the photovoltaic

array. The power output will then differ from what the light

intensity sensor suggests that it should be producing. The

owner then can go and check on the photovoltaic array.

Another scenario will be that of the charge controller

breaking down and the battery not being charged. When

there is sunlight, as suggested by the light intensity sensor,

but the battery is still not being charged, the owner will then

know that a fault has occurred and the charge controller can

be repaired. To prevent owners from having to monitor the

program constantly, the program is able to send a sms to the

owner when such triggering events occur, allowing them to

take the necessary actions.

Making use of a 4-channel relay card, the program is also

able to switch the connected electrical appliances to grid

power supply when the photovoltaic array is not producing

sufficient power and the battery has a state of charge lower

than 50%. This ensures uninterrupted power supply for

critical appliances, such as computers.

VEE Pro 8 also allows remote monitoring, hence offering

the owners the convenience of checking the monitor program

from work or anywhere with a computer connected to the

internet.

A. Display of voltages, Currents, Powers and Light intensity

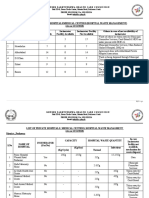

Figure 4 Wiring of the whole system

The above diagram shows the points at which the voltages

and currents are measured. The multiplication of V1 and I1

should give the instantaneous power output of the

photovoltaic panel. At the same time, the multiplication of

V2 and I2 will give the power being consumed by the

inverter. Neglecting the power lost in the inverter due to its

efficiency, that will be the power being consumed by the

electrical appliances. At the same time, V2 will be the

terminal voltage of the battery. Thus, this value can be used

to monitor the batterys state of charge.

As mentioned in chapter 5, the voltages are attenuated by

the potential dividers. So, in the VEE program, after it has

obtained the measured reading, it is required to multiply the

reading with appropriate constants according to the values of

the resistors used. For the solar panel where two resistors of

10 k each are used, the readings are multiplied with 2.

Figure 5 Screenshot of VEE program in detail view

This is the screenshot of part of the Program where the

solar panels voltage, current and power are being processed,

plotted and stored. As the screen space is limited, not every

object can be squeezed into it. The batterys voltage, current

and power consumed are processed in a similar manner to

the diagram above. In the diagram, the Time Stamp object

gets the current date and time and send it to To File object,

which is used to write to the text file indicated in the

program. This is used to log the electrical parameters in a

text file and saved for future reference.

Figure 6 Screenshot of the program in panel's view

B. Switching Power Supply

In a lot of applications, it is critical that the power supply

is not interrupted, so as to prevent loss of data or damage of

chilled food, to name a couple of examples. Hence, the

monitor and control program has the function to switch the

power supply to grid power supply when the photovoltaic

array is not receiving sufficient light intensity and the

batterys state of charge is low as well.

This function is implemented by using a 4-channel relay

card.

Figure 7 Circuit diagram of the relay card

The above diagram shows the circuit diagram of this relay

card. It is controlled by 4 TTL inputs to switch on or off the

4 relays. These TTL inputs are supplied by U2353A digital

output channels.

Singapore, an island with sunlight all year round. A

photovoltaic generation system, however, is rather

expensive. Hence, a monitor and control program that

operates from a computer or laptop, thus having their great

processing speed and large memory space at its disposal, to

ensure that the photovoltaic systems working parameters are

within the expected range will allow the users peace of mind

and full utilization of the systems potential. This small

amount of extra cost shouldnt deter the users from installing

the data acquisition system and this program, as they will

earn back the money very soon through decreased down time

and optimum usage of their photovoltaic power system.

The experimental low-power stand-alone photovoltaic

generation system, assembled for this projects sake, shows

that there are many areas with a photovoltaic system that can

go wrong. For example, loose contact alone can cause the

whole system to perform badly.

Furthermore, the data acquisition system and the monitor

program are very flexible to new additions and changes.

Hence, there is no limit on the extensions to this system that

can be done. One improvement that can be done to this

system is to use the readings from the four light dependent

resistors circuits to make a solar tracker, so as to have

maximum sunlight falling on the solar panel at all times.

Another improvement that can be done is to connect more

electrical appliances to the power outlet from the inverter,

but with relay switches in between. Hence, the owners will

be able to switch on or off the electrical appliances from

work when they see that the photovoltaic array is producing

sufficient power. This can be done easily by making use of

remote access feature of Microsoft Windows, which will

give the users the control of the computer. They can then

send out TTL logic highs and lows to switch on or off the

switches.

Acknowledgment

Figure 8 The connections of inverter, grid power and

power outlet to relay card

The four relays were used to connect to the grid power,

inverter power supply and a power outlet in the above

configuration. So, during normal operation, the electrical

appliance connected to the power outlet will receive its

power from the inverter. But, when the program sends out

1111 to the four inputs, so that the four relays will switch

to normally open side, the electrical appliance will now

receive its power from the grid power.

V. Conclusion

With the global warming effects becoming increasingly

harsh on mankind, the trend seems to be that people are

becoming more accepting of renewable energy sources.

Among them, solar energy is the one that is most suitable for

I would like to express my gratitude to Agilent

Technologies for their sponsorship and loaning of the

equipment. It was indeed a joy to learn from their engineers,

Mr Neo Eng Chye and Mr Yee Yue Fei, and their extensive

literature on their devices and applications were a great help

as well.

REFERENCES

1)

2)

3)

4)

5)

International Energy Annual 2005

(http://www.eia.doe.gov/iea/overview.html) retrieved on 07

September 2007.

US Department of energy on greenhouse gases

(http://www.eia.doe.gov/oiaf/1605/ggccebro/chapter1.html) retrieved

on 07 September 2007.

Nikos Hatziargyriou, Hiroshi Asano, Reza Iravani and Chris Marna,

Microgrids, IEEE power and energy magazine, pp 78-94, July 2007

Agilent U2300A Series USB Multifunction Data Acquisition Devices

Users Guide, 2nd edition, April 30, 2007.

VEE pro user guide, eighth edition, February 2004.

Anda mungkin juga menyukai

- Efficiency Improvement in Solar Power GenerationDokumen19 halamanEfficiency Improvement in Solar Power GenerationKIU PUBLICATION AND EXTENSIONBelum ada peringkat

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDari EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsBelum ada peringkat

- Solar Panel SystemDokumen9 halamanSolar Panel SystemShimeles TilayeBelum ada peringkat

- Solar Electricity Generation System with a DIY Sun-Tracking PropositionDari EverandSolar Electricity Generation System with a DIY Sun-Tracking PropositionBelum ada peringkat

- Solar Panel SystemDokumen9 halamanSolar Panel SystemShimeles TilayeBelum ada peringkat

- Description: Medium Residential 5kva 9-12Kwh Per Day Complete Off-Grid Solar SystemDokumen7 halamanDescription: Medium Residential 5kva 9-12Kwh Per Day Complete Off-Grid Solar SystemMuhammad Sharif JanjuaBelum ada peringkat

- Balancing Cost and Performance in A PV/Wind/Battery Hybrid Power SystemDokumen5 halamanBalancing Cost and Performance in A PV/Wind/Battery Hybrid Power SystemKhubaib AhmedBelum ada peringkat

- Project: Solar Powered Induction Motor DriveDokumen75 halamanProject: Solar Powered Induction Motor DriveDebanjan ChatterjeeBelum ada peringkat

- Full Paper MARTEC .Docx (Afiq)Dokumen6 halamanFull Paper MARTEC .Docx (Afiq)Mohd AfiqBelum ada peringkat

- Tradeoff Lucas PDFDokumen11 halamanTradeoff Lucas PDFGustavo CunhaBelum ada peringkat

- New Approach in Size Optimization and Performance Prediction Photovoltaic Hybrid Power SystemsDokumen4 halamanNew Approach in Size Optimization and Performance Prediction Photovoltaic Hybrid Power SystemsAkis ApostolidisBelum ada peringkat

- Maximum Power Point Tracking of Solar Panel Using Inverse Sepic ConverterDokumen6 halamanMaximum Power Point Tracking of Solar Panel Using Inverse Sepic ConverterIOSRjournalBelum ada peringkat

- DESIGN AND IMPLEMENTATION OF 1.5kVA PURE SINEWAVE INVERTERDokumen49 halamanDESIGN AND IMPLEMENTATION OF 1.5kVA PURE SINEWAVE INVERTERemmanuel akojiBelum ada peringkat

- Solar Charge Controller With A Data Acquisition System Based On ArduinoDokumen9 halamanSolar Charge Controller With A Data Acquisition System Based On ArduinoolumideBelum ada peringkat

- 824 June 2019Dokumen8 halaman824 June 2019Katta VenkateshBelum ada peringkat

- PV Battery Wind-Turbine Public-Grid Hybrid Poker Supply For Telecom. - Equipment System Management ControlDokumen9 halamanPV Battery Wind-Turbine Public-Grid Hybrid Poker Supply For Telecom. - Equipment System Management ControlJubari FikriBelum ada peringkat

- Photovoltaic System Efficiency Improvement MethodsDokumen24 halamanPhotovoltaic System Efficiency Improvement MethodsradiBelum ada peringkat

- Practical Electrical Devices&machinesDokumen6 halamanPractical Electrical Devices&machinesKusiimaBelum ada peringkat

- Design and ConstructionDokumen47 halamanDesign and Constructionemmanuel akojiBelum ada peringkat

- Design and Implementation of A Solar Charge Controller With Variable OutputDokumen12 halamanDesign and Implementation of A Solar Charge Controller With Variable OutputEmmanuel SundayBelum ada peringkat

- Modified Algorithm For Drift Avoidance in PV System Using Neural NetworkDokumen6 halamanModified Algorithm For Drift Avoidance in PV System Using Neural NetworkIIR indiaBelum ada peringkat

- Designing A Solar-Cell-Driven LED Outdoor Lighting System: Power Supply Design SeminarDokumen25 halamanDesigning A Solar-Cell-Driven LED Outdoor Lighting System: Power Supply Design Seminarggolden597Belum ada peringkat

- Design and Implementation of A Novel High-Performance Stand-Alone Photovoltaic LED Lighting SystemDokumen4 halamanDesign and Implementation of A Novel High-Performance Stand-Alone Photovoltaic LED Lighting SystemAntonio IsaacBelum ada peringkat

- Design and Implementation of A G P Photovoltaic Maximum Power Point TrackerDokumen55 halamanDesign and Implementation of A G P Photovoltaic Maximum Power Point TrackerBilal KanjBelum ada peringkat

- Dodatak BDokumen3 halamanDodatak Bmonalester CruzBelum ada peringkat

- Implementation of Solar Tracking Mechanism Based On Mobile PV PanelDokumen4 halamanImplementation of Solar Tracking Mechanism Based On Mobile PV PanelIJARTETBelum ada peringkat

- Automatic Solar Irrigation Pump Control System Based On Soil Moisture SensorDokumen23 halamanAutomatic Solar Irrigation Pump Control System Based On Soil Moisture SensorSrinivas Reddy MandaBelum ada peringkat

- CHAPTER 3 TECHNICAL ASPECT Solar Powered GeneratorDokumen47 halamanCHAPTER 3 TECHNICAL ASPECT Solar Powered GeneratorRed SecretarioBelum ada peringkat

- Basic Components Needed For SolarDokumen6 halamanBasic Components Needed For Solarhmha83Belum ada peringkat

- Highly Efficient Analog Maximum Power Point Tracking (AMPPT) in A Photovoltaic SystemDokumen11 halamanHighly Efficient Analog Maximum Power Point Tracking (AMPPT) in A Photovoltaic SystemSusmita PandaBelum ada peringkat

- Emma ProjectDokumen48 halamanEmma ProjectChristianBelum ada peringkat

- Design and Implementation of A Solar Charge Controller With Variable OutputDokumen12 halamanDesign and Implementation of A Solar Charge Controller With Variable OutputManish kumar100% (1)

- Final Paper R-2022Dokumen11 halamanFinal Paper R-2022Hafedh AbidBelum ada peringkat

- Sola - PDFR Charge Controller1Dokumen12 halamanSola - PDFR Charge Controller1Deepak NayakBelum ada peringkat

- 1.1 Water Pumping Systems and Photovoltaic PowerDokumen54 halaman1.1 Water Pumping Systems and Photovoltaic Powerthawpeek2006100% (1)

- Final Year Project ProposalDokumen14 halamanFinal Year Project ProposalBilalHassan100% (1)

- 1213 A Micro Controller Based Solar Panel TracDokumen10 halaman1213 A Micro Controller Based Solar Panel Tracvenu_sbpBelum ada peringkat

- Design and Implementation of Three Phase To Single Phase Solid State TransformerDokumen37 halamanDesign and Implementation of Three Phase To Single Phase Solid State TransformerUsha SreeBelum ada peringkat

- Solar Cell System Design-2Dokumen12 halamanSolar Cell System Design-2spotifyladderBelum ada peringkat

- Wo-Loop Con Aximizing Erfo Mance O Grid-Connected - Fuel Cell Ihybrid PowerDokumen6 halamanWo-Loop Con Aximizing Erfo Mance O Grid-Connected - Fuel Cell Ihybrid PowerVelagandula AvinashBelum ada peringkat

- Solar 3Dokumen19 halamanSolar 3Asif MuhammadBelum ada peringkat

- Modeling and Simulation of PV Array and Its Performance Enhancement Using MPPT (P&O) TechniqueDokumen8 halamanModeling and Simulation of PV Array and Its Performance Enhancement Using MPPT (P&O) Techniqueeditor9891Belum ada peringkat

- Project Main Documentation (1) .Docx Edit-1Dokumen66 halamanProject Main Documentation (1) .Docx Edit-1Best Dp's EverBelum ada peringkat

- Experiment No. - : TitleDokumen5 halamanExperiment No. - : TitleRoma WankhedeBelum ada peringkat

- Frequency and Voltage Stabilit-IRO-Journals-4 4 4Dokumen20 halamanFrequency and Voltage Stabilit-IRO-Journals-4 4 4aliebadizahedan.375Belum ada peringkat

- Chapter One Smps InverterDokumen10 halamanChapter One Smps Inverterolawale gbadeboBelum ada peringkat

- Design and Development of Microcontroller Based Solar Charge ControllerDokumen4 halamanDesign and Development of Microcontroller Based Solar Charge ControllerolumideBelum ada peringkat

- A Proficient Solar Panel Efficiency MeasurementDokumen6 halamanA Proficient Solar Panel Efficiency MeasurementGabi GBelum ada peringkat

- 68Dokumen60 halaman68Naziya BegumBelum ada peringkat

- Design of A 50 KW Solar PV Rooftop SystemDokumen9 halamanDesign of A 50 KW Solar PV Rooftop SystemvmramakrishnanBelum ada peringkat

- Research PaperDokumen10 halamanResearch PaperAlok AgarwalBelum ada peringkat

- Modelling A 30kw Standalone Solar Powered Irrigation SystemDokumen5 halamanModelling A 30kw Standalone Solar Powered Irrigation SystemtabendaaarzuBelum ada peringkat

- Power Quality Improvement For Grid Connected Wind Energy System Using FactsDokumen70 halamanPower Quality Improvement For Grid Connected Wind Energy System Using FactsKaruna Reddy Yennapusa91% (11)

- Maximum Power Point TrackerDokumen6 halamanMaximum Power Point Trackervharish23100% (1)

- Design of A 50 KW Solar PV Rooftop SystemDokumen9 halamanDesign of A 50 KW Solar PV Rooftop SystemKo Mya SanBelum ada peringkat

- Automatic Transfer Switch For DC System ApplicatioDokumen9 halamanAutomatic Transfer Switch For DC System ApplicatioEmmanuel Eduardo Hernandez Rodriguez (Chemma)Belum ada peringkat

- How To Design & Install A Solar PV SystemDokumen10 halamanHow To Design & Install A Solar PV Systemnooruddinkhan100% (1)

- ChaptersDokumen47 halamanChaptersAitha DeepakBelum ada peringkat

- A New Controller Scheme For Photovoltaics PowerDokumen10 halamanA New Controller Scheme For Photovoltaics PowerHakan PolatkanBelum ada peringkat

- MVD 1&2 SDS R134aDokumen8 halamanMVD 1&2 SDS R134ajessie rylesBelum ada peringkat

- Hospital Waste Water TreatmentDokumen5 halamanHospital Waste Water TreatmentNP100% (1)

- A Fly Ash Particles Media Filters For Decentralized Wastewater Treatment SystemsDokumen10 halamanA Fly Ash Particles Media Filters For Decentralized Wastewater Treatment SystemsDEBAKANTA MALLICKBelum ada peringkat

- Speech by Governor James Ongwae During World Water Day 2018 CelebrationsDokumen8 halamanSpeech by Governor James Ongwae During World Water Day 2018 CelebrationsJamesOngwaeBelum ada peringkat

- Water Treatment Lecture 5 EENVDokumen51 halamanWater Treatment Lecture 5 EENVshamashergyBelum ada peringkat

- Women's Care Center Opens in East HoustonDokumen8 halamanWomen's Care Center Opens in East HoustonAnonymous 2SN9zjvBelum ada peringkat

- CITY STAR February 2023 EditionDokumen16 halamanCITY STAR February 2023 Editioncitystar newsBelum ada peringkat

- Planetary NetworksDokumen2 halamanPlanetary NetworksNiñabeth David100% (1)

- Two Rooms, Kitchen, BathroomDokumen2 halamanTwo Rooms, Kitchen, BathroomVALERIA ISABEL CORCUERA IRRIBARRENBelum ada peringkat

- Washer Drier ManualDokumen37 halamanWasher Drier ManualAlby_99Belum ada peringkat

- Samsung Mono Controller Kit ManualDokumen48 halamanSamsung Mono Controller Kit Manualllincee MBelum ada peringkat

- DARPAN Entry ListDokumen6 halamanDARPAN Entry ListArun MohanBelum ada peringkat

- Envi Latex Wall Paint MSDSDokumen4 halamanEnvi Latex Wall Paint MSDSrumahsketchBelum ada peringkat

- F AY 12091 Naia RenewDokumen2 halamanF AY 12091 Naia RenewTalha NafeesBelum ada peringkat

- Ieltsmaterial Com IELTS SpeakingDokumen127 halamanIeltsmaterial Com IELTS Speakingravshan778Belum ada peringkat

- Solid Waste Management Opportunities Challenges GujaratDokumen14 halamanSolid Waste Management Opportunities Challenges GujaratRahul Kumar AwadeBelum ada peringkat

- Corrugated Plate Interceptor: Applications For CPI SystemsDokumen2 halamanCorrugated Plate Interceptor: Applications For CPI SystemsFelipe BrainBelum ada peringkat

- Biogas:: HistoryDokumen6 halamanBiogas:: HistorysarayooBelum ada peringkat

- Twisted Pair PDFDokumen4 halamanTwisted Pair PDFAlexa Marrie BautistaBelum ada peringkat

- HH-1096G A4 Flexicon Bag-DumperDokumen7 halamanHH-1096G A4 Flexicon Bag-Dumperalfin tupingBelum ada peringkat

- Authors: J.Alex ChristopherDokumen47 halamanAuthors: J.Alex ChristopherAlex ChristopherBelum ada peringkat

- Plastic Bags ThesisDokumen8 halamanPlastic Bags Thesisheathergonzaleznewhaven100% (2)

- High Density Polyethylene GF4950: DescriptionDokumen1 halamanHigh Density Polyethylene GF4950: Descriptioncesar1scribdBelum ada peringkat

- Instructions For Use: AR4W07PDokumen18 halamanInstructions For Use: AR4W07Pnoxy58Belum ada peringkat

- United States Patent (10) Patent No.: US 8.481.295 B2Dokumen37 halamanUnited States Patent (10) Patent No.: US 8.481.295 B2Reva DeddyBelum ada peringkat

- Incenrator Details 12 Nov 2018Dokumen17 halamanIncenrator Details 12 Nov 2018ptaxBelum ada peringkat

- Slip FormsDokumen31 halamanSlip Formssabareesan09Belum ada peringkat

- Technical Visit Bio-Gas Power PlantDokumen4 halamanTechnical Visit Bio-Gas Power PlantAsyraf ZailudinBelum ada peringkat

- MSDS - IC - Cleaner Norma PDFDokumen8 halamanMSDS - IC - Cleaner Norma PDFDhea sylvia frasiscaBelum ada peringkat

- Clean Room HandbookDokumen80 halamanClean Room HandbookPecingina Dalia DanielBelum ada peringkat

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDari EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosPenilaian: 5 dari 5 bintang5/5 (1)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsDari EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsBelum ada peringkat

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4.5 dari 5 bintang4.5/5 (543)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDari EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesPenilaian: 5 dari 5 bintang5/5 (1)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDari EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgePenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDari EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Electronics All-in-One For Dummies, 3rd EditionDari EverandElectronics All-in-One For Dummies, 3rd EditionPenilaian: 5 dari 5 bintang5/5 (2)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDari EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceBelum ada peringkat

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDari Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersPenilaian: 5 dari 5 bintang5/5 (1)

- A Mind at Play: How Claude Shannon Invented the Information AgeDari EverandA Mind at Play: How Claude Shannon Invented the Information AgePenilaian: 4 dari 5 bintang4/5 (53)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDari EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonPenilaian: 5 dari 5 bintang5/5 (2)

- Heat Transfer Engineering: Fundamentals and TechniquesDari EverandHeat Transfer Engineering: Fundamentals and TechniquesPenilaian: 4 dari 5 bintang4/5 (1)

- Build Your Own Electronics WorkshopDari EverandBuild Your Own Electronics WorkshopPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDari EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Current Interruption Transients CalculationDari EverandCurrent Interruption Transients CalculationPenilaian: 4 dari 5 bintang4/5 (1)

- Practical Power Distribution for IndustryDari EverandPractical Power Distribution for IndustryPenilaian: 2.5 dari 5 bintang2.5/5 (2)

- Teach Yourself Electricity and Electronics, 6th EditionDari EverandTeach Yourself Electricity and Electronics, 6th EditionPenilaian: 3.5 dari 5 bintang3.5/5 (15)