Technical Data

Diunggah oleh

Leed ENHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Technical Data

Diunggah oleh

Leed ENHak Cipta:

Format Tersedia

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

2/4/13 11:51 AM

Date:

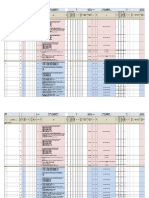

PRICE SUMMARY

Tag

CHILLER AFVX-E-5HR1

AHU-1

AHU-2

AHU-3

AHU-4

90572

Model

06-Feb-13

Location

Qty

AFVX-E 365-5HR

AHD2 AF 520 H M

AHD2 AF 080 H M

AHD2 AF 270 H M

AHD2 AF 240 H M

1

1

1

1

Page 1 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

2/4/13 11:51 AM

Date:

CHILLER AFVX-E-5HR-1

Tag:

PERFORMANCE SUMMARY

Location:

Screw Compressor Air Cooled Package Chiller

Model #

Quantity

AFVX-E 365-5HR

Manufacturer

DBM

1

Physical Specifications

Compressors (Qty)

Length (mm)

Width (mm)

Height (mm)

MSC 1230E(2)

11,379

2,235

3,099

Shipping weight (kg)

Operating weight (kg)

Refrigerant

Approx. refrigerant charge (kg)

14,101

14,427

R-134a

473

Conditions of service

Percent of full load

Capacity (kW)

Unit power (kW)

100%

1,345.55

367.58

Compressor power (kW)

Total Fan Power (kW)

Energy efficiency (COP, W/W)

NPLV (COP, W/W)

322.58

45.00

3.66

4.39

Evaporator

Models (Qty)

Fluid

Fluid flow rate (l/s)

Entering fluid temp. (C)

L2R(2)

Water

64.4

12.0

Leaving fluid temp. (C)

Fouling factor (m^2C/kW)

Pressure drop (kPa)

Fluid freezing point (C)

7.0

0.018

37.3

0.0

Condenser

Design ambient (C)

Altitude (m)

30.0

0

Fan Motor Power (kW) (Qty)

Fan size (mm) (Qty)

2.5 (18)

900 (18)

Electrical characteristics

Unit power supply

Unit max. fuse size (A)

400V/3ph/50Hz

1000

Unit rated load amps

Unit min. circuit ampacity (A)

Comp. rated load amps (A)

715

794

317/310

Notes

- Meets ASHRAE 90.1-2010 Path A chiller minimum efficiency

guidelines

- Outside the scope of AHRI Standard-550/590-2011.

- Refrigerant charge may vary. Unit nameplate will show final

factory charge.

NPLV Points

% Full load

kWr

Unit kWe

Comp. kWe

Fan kWe

COP

Ambient

Type

100%

1,345.55

367.58

322.58

45.00

3.66

30.0

Actual

75%

1,009.16

244.41

199.41

45.00

4.13

23.5

Actual

39%

519.17

113.84

96.34

17.50

4.56

17.1

Actual

25%

336.39

71.83

59.33

12.50

4.68

12.8

Actual

Standard Equipment

Unit Construction

Unit shall be constructed of heavy gauge G90 galvanized steel

All sheet metal parts are painted with oven baked epoxy /

polyester powder paint, sustaining 1000 hour salt spray test in

accordance with ASTM B-117

Rigid Structural base to prevent unit deformation and damage

during hoisting

Bolted construction for easy semi knockdown at site in case

hoisting problem

Cobalt chromed boths and nuts for maximum corrosion

resistance

Control panel IP54

Compressor

Compartmentalized to reduce noise

MSC rotary screw

Cast iron housing

IP21 Terminal box

Slide valve unloading

Suction check valve and service valve

Discharge check valve (Multiple compressor unit) or service

valve (Single compressor units)

Full hermetic design

Compressor oil sump heater(s)

Relief valve if required

Optical oil level sensor

Integral Oil separator

Integral lubration system using pressure differential

One (1) year warranty

Compressor liquid and vapour injection

Double Delta Starter

Air Cooled condenser

Inner ridged copper tubes

90572

Close blade tip clearance with the fan venturis to assure

06-Feb-13

Page 2 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

Date:

Tag:

PERFORMANCE SUMMARY

Aluminium fins

450 psig test pressure for condenser coils

Low noise direct driven propeller and axial fans

Galvanized steel tubesheet

2/4/13 11:51 AM

CHILLER AFVX-E-5HR-1

Location:

smooth, quiet operation

6 pole fan motor, IP55, class F insulation with class B

temperature rise

Evaporator

Flooded design for higher capacity and easy maintenance

Cleanable integral fin copper tubes for easy serviceability

Removable water heads

Optional Flanged water connection for quick installation and/or

service

Full pump-down capacity in condenser, therefore, pump out unit

not required

300 psig on refrigerant side design pressure(For R22 & R407C)

200 psig on refrigerant side design pressure (For R134a)

150 psig on water side design pressure

Drain and vent plugs

Relieve valve

1" thick PE foam closed cell evaporator insulation,thermal

conductivity 0.040W/m.K at 40C (0.28Btu in/hr.ft2F at 104F.)

1/2" thick PE foam closed cell suction line insulation/thermal

conductivity 0.040W/m.K at 40C (0.28Btu in/hr.ft2F at 104F)

Carbon steel header, shell and tube sheet

Code Compliance

Indicator lights

ASME std. B31.5 Refrigeration Piping code

Units conform to NEC,NEMA and ASHRAE 15 safety code for

mechanical refrigeration

Rated in accordance with AHRI 550/590 std.

IEEE

Compressor overloads,

each compressor

High motor temperature,

each compressor

High pressure, low

pressure, and freeze

Control power

Refrigerant Specialties

Liquid level float control

Flash economizer usage to boost capacity

Sight glass with moisture indicator

Liquid line solenoid

Replaceable core filter drier

Compressor MCCB and contactors

Compressor solid state overloads

Low voltage/phase failure/phase reversal relay

On-off switch in the unit control circuit and each compressor

control circuit

Charging and gauge connections

High Pressure relief valves

Refrigerant charge

Oil Charge

Discharge check valves on multiple compressor units

Standard Electrical Components

Fan control contactors

Control circuit transformer

Current transformer

Optional Ambient temperature sensor

Warranty and Testing

Analog readouts

Standard one year warranty on unit and on compressors

Factory run tested

Evaporator and condenser refrigerant pressure

Compressor amps (each compressor)

Water sensor: Evaporator leaving - Standard sensor to provide

temperature readout for water leaving the evaporator.

Controllers

Vision 2020i Advanced microprocessor based DDC controller

with 132x64 pixels DBG1 semi-graphic display panel with

menu driven software digital readout, pushbutton keyboard

Selection on English (Imperial) or metric display units

Remote monitoring via RS-485 port

Leaving chilled fluid temperature

Evaporator and condenser pressure

Single phase amp draw, each compressor

No. of compressor starts

Elapsed run time, each compressor

Oil level status

Fluid temperature reset value

Water flow switch status

External stop/start command status

Condenser fan cycling

Low ambient lockout

Identification of up to 99 most recent alarms with critical data

stamping

OPTIONAL (BMS Communication option)

Optional Ambient temperature sensor

Optional Return water temperature sensor

Optional Remote and stop signal

Digital readouts

Compressor contactor

status

Flow switch status

Oil level status

Number of compressor

starts

Elapsed compressor run

time

External enable/disable

status

Liquid injection solenoid

state

Capacity control Setpoints

Leaving water temperature

Freeze up temperature

High and low pressure

Amp limit

Ramp up

Unit Protection

High and low pressures

High discharge temperature

Freeze protection

Low pressure differential

Low oil level

Compressor run error and over current

Power loss

Chilled water flow loss

High/Low System voltage

Sensor error

Compressor anti-recycle

90572

06-Feb-13

Page 3 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Location: Dalat-Vietnam

Consultant: Mr. Phung

Date:

Tag:

PERFORMANCE SUMMARY

2/4/13 11:51 AM

CHILLER AFVX-E-5HR-1

Location:

Optional Equipment/Service Included

Accessories (Shipped Loose)

Spring isolators (SPG) - designed for 1" deflection, these housed spring assemblies have a neoprene friction pad on the bottom to help

prevent the passage of noise and a spring locking leveling bolt at the top. Neoprene inserts prevent contact between the steel upper

and lower housings. Suitable for more critical applications than RIS isolators.

90572

06-Feb-13

Page 4 of 17

SPEC ver. 7.0, 13240

Big C - Dalat

Project:

Consultant: Mr. Phung

Location: Dalat-Vietnam

2/4/13 11:51 AM

Date:

AHU-1

Tag:

PERFORMANCE SUMMARY

Location:

CS3 Air Handler

Model #

Manufacturer

Fan ratings version

AHD2 AF 520 H M

DBM

3CS10

Quantity

Insulation (entire unit)

Wall thickness

1

2.5 # Polyurethane

2" (50 mm)

A. Section 16 Mixing box section

Inlet location(s)

Dampers

Access panels

Panel hand

Top and back

Air foil low leak

One

Left

Liners

View port

Marine light

Pressure drop (kPa)

Solid GI

Yes

Yes

0.03

B. Section 7 Short cooling coil section (includes prefilter)

Coil size

Drain pan

Large

Stainless

Pre-filter media

Liners

Pressure drop (kPa)

92% Arr. washable

Solid GI

0.29

Refer coil performance as below.

C. Section 23 Access section w/panel

Access panels

One

Panel hand

Liners

Left

Solid GI

D. Section 1 Horizontal draw-thru fan section XM

Fan type

Arrangement

Motor type

Motor voltage

Motor power (kW)

Motor insulation class

Motor hand

Drive

Air flow (m^3/s)

External static @Actual (kPa)

Internal static @Actual (kPa)

Airfoil (standard)

Horizontal front

TEFC

380V/3/50

37.28

F

Left

Fixed

22.53

0.50

0.37

Total static @Actual (kPa)

Break power @Actual (kW)

Rotations per minute

Altitude (m)

Coldest dry bulb temp (C)

Access panels

Liners

View port

Marine light

Pressure drop (kPa)

Internal isolation

0.87

32.21

968

0

21.1

One

Solid GI

Yes

Yes

0.05

Spring (standard)

Supply Fan Sound Power(dB)

Frequency (Hz)

63

125

250

500

1k

2k

4k

8k

Overall

At inlet

107

113

106

98

87

89

82

50

At discharge

112

115

106

98

87

89

82

27

Air Handler Coil

Coil Tag

Model #

Manufacturer

Qty

Location

Footnotes

#1

A W Q 5 Y - 72T x 150 RH

DBM

Section B - Coil A

A,B,C

Air properties

Air flow (m^3/s)

Altitude (m)

Face velocity (m/s)

Air pressure drop (kPa)

Entering air DB / WB

(C)

Leaving air DB / WB (C)

Air properties measured

at

Fluid properties

22.528

0

2.59

0.227

25.3 / 19.7

11.0 / 11.0

Actual

Fluid

Fluid flow rate (l/s)

Fluid velocity (m/s)

Entering fluid temp. (C)

Leaving fluid temp. (C)

Fluid pressure drop

(kPa)

Construction

Water

32.3

2.9

7.0

12.0

182.3

Coil

Total capacity (kW)

Sensible capacity (kW)

674.0

387.0

Type / tubes in face

Finned height (mm)

Finned length (mm)

Face area (m^2)

Rows / fin spacing

(fins/cm)

Number of feeds

Casing construction

Supply connections

(qty@in)

Return connections

(qty@in)

Connection type

Fin material

Header material

A (1/2" OD) /

72

2,286

3,810

8.71

5 / 5.51

90

Air handler

2@3

2@3

MPT

Standard

aluminium

Standard

steel

Footnotes

A.Fluid velocity/pressure drop high.

90572

06-Feb-13

B.Fluid pressure drop limit could not be met.

C.Stacked coils required.

Page 5 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Location: Dalat-Vietnam

Consultant: Mr. Phung

Date:

Tag:

PERFORMANCE SUMMARY

90572

06-Feb-13

2/4/13 11:51 AM

AHU-1

Location:

Page 6 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Location: Dalat-Vietnam

Consultant: Mr. Phung

Date:

Tag:

PERFORMANCE SUMMARY

2/4/13 11:51 AM

AHU-1

Location:

Supply Fan Specification

Air handler model

Fan type

Style

Altitude (m)

90572

AHD2 AF 520 H M

Airfoil (standard/1000)

Draw-thru

0

06-Feb-13

Air flow (m^3/s)

Static pressure @ Altitude (kPa)

Rotations per minute

Brake power @ Altitude (kW)

Coldest dry bulb (C)

Page 7 of 17

SPEC ver. 7.0, 13240

23

0.87

968

32

21.1

Project:

Big C - Dalat

Location: Dalat-Vietnam

Consultant: Mr. Phung

Date:

Tag:

PERFORMANCE SUMMARY

90572

06-Feb-13

2/4/13 11:51 AM

AHU-1

Location:

Page 8 of 17

SPEC ver. 7.0, 13240

Big C - Dalat

Project:

Consultant: Mr. Phung

Location: Dalat-Vietnam

2/4/13 11:51 AM

Date:

AHU-2

Tag:

PERFORMANCE SUMMARY

Location:

CS3 Air Handler

Model #

Manufacturer

Fan ratings version

AHD2 AF 080 H M

DBM

3CS10

Quantity

Insulation (entire unit)

Wall thickness

1

2.5 # Polyurethane

2" (50 mm)

A. Section 16 Mixing box section

Inlet location(s)

Dampers

Access panels

Panel hand

Top and back

Air foil low leak

One

Left

Liners

View port

Marine light

Pressure drop (kPa)

Solid GI

Yes

Yes

0.03

B. Section 7 Short cooling coil section (includes prefilter)

Coil size

Drain pan

Large

Stainless

Pre-filter media

Liners

Pressure drop (kPa)

92% Arr. washable

Solid GI

0.22

Refer coil performance as below.

C. Section 23 Access section w/panel

Access panels

One

Panel hand

Liners

Left

Solid GI

D. Section 1 Horizontal draw-thru fan section TM

Fan type

Arrangement

Motor type

Motor voltage

Motor power (kW)

Motor insulation class

Motor hand

Drive

Air flow (m^3/s)

External static @Actual (kPa)

Internal static @Actual (kPa)

Airfoil (standard)

Horizontal front

TEFC

380V/3/50

5.59

F

Left

Fixed

3.89

0.25

0.30

Total static @Actual (kPa)

Break power @Actual (kW)

Rotations per minute

Altitude (m)

Coldest dry bulb temp (C)

Access panels

Liners

View port

Marine light

Pressure drop (kPa)

Internal isolation

0.55

3.84

1786

0

21.1

One

Solid GI

Yes

Yes

0.05

Spring (standard)

Supply Fan Sound Power(dB)

Frequency (Hz)

63

125

250

500

1k

2k

4k

8k

Overall

At inlet

83

83

88

83

79

77

72

68

91

At discharge

94

88

90

83

79

77

72

68

96

Air Handler Coil

Coil Tag

Model #

Manufacturer

Qty

Location

Footnotes

#1

A W P 4 - 28T x 66 RH

DBM

Section B - Coil A

Air properties

Air flow (m^3/s)

Altitude (m)

Face velocity (m/s)

Air pressure drop (kPa)

Entering air DB / WB

(C)

Leaving air DB / WB (C)

Air properties measured

at

Fluid properties

3.889

0

2.61

0.164

25.3 / 19.7

13.4 / 13.0

Actual

Fluid

Fluid flow rate (l/s)

Fluid velocity (m/s)

Entering fluid temp. (C)

Leaving fluid temp. (C)

Fluid pressure drop

(kPa)

Construction

Water

4.4

2.0

7.0

12.0

55.4

Coil

Total capacity (kW)

Sensible capacity (kW)

92.0

55.8

Type / tubes in face

Finned height (mm)

Finned length (mm)

Face area (m^2)

Rows / fin spacing

(fins/cm)

Number of feeds

Casing construction

Supply connections

(qty@in)

Return connections

(qty@in)

Connection type

Fin material

Header material

A (1/2" OD) /

28

889

1,676

1.49

4 / 4.72

18

Air handler

1@2

1@2

MPT

Standard

aluminium

Standard

steel

Footnotes

A.Stacked coils required.

90572

06-Feb-13

Page 9 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

Date:

Tag:

PERFORMANCE SUMMARY

2/4/13 11:51 AM

AHU-2

Location:

Supply Fan Specification

Air handler model

Fan type

Style

Altitude (m)

90572

AHD2 AF 080 H M

Airfoil (standard/450)

Draw-thru

0

06-Feb-13

Air flow (m^3/s)

Static pressure @ Altitude (kPa)

Rotations per minute

Brake power @ Altitude (kW)

Coldest dry bulb (C)

Page 10 of 17

SPEC ver. 7.0, 13240

4

0.55

1,786

4

21.1

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

Date:

Tag:

PERFORMANCE SUMMARY

90572

06-Feb-13

2/4/13 11:51 AM

AHU-2

Location:

Page 11 of 17

SPEC ver. 7.0, 13240

Big C - Dalat

Project:

Consultant: Mr. Phung

Location: Dalat-Vietnam

2/4/13 11:51 AM

Date:

AHU-3

Tag:

PERFORMANCE SUMMARY

Location:

CS3 Air Handler

Model #

Manufacturer

Fan ratings version

AHD2 AF 270 H M

DBM

3CS10

Quantity

Insulation (entire unit)

Wall thickness

1

2.5 # Polyurethane

2" (50 mm)

A. Section 16 Mixing box section

Inlet location(s)

Dampers

Access panels

Panel hand

Top and back

Air foil low leak

One

Left

Liners

View port

Marine light

Pressure drop (kPa)

Solid GI

Yes

Yes

0.03

B. Section 7 Short cooling coil section (includes prefilter)

Coil size

Drain pan

Large

Stainless

Pre-filter media

Liners

Pressure drop (kPa)

92% Arr. washable

Solid GI

0.25

Refer coil performance as below.

C. Section 23 Access section w/panel

Access panels

One

Panel hand

Liners

Left

Solid GI

D. Section 1 Horizontal draw-thru fan section TM

Fan type

Arrangement

Motor type

Motor voltage

Motor power (kW)

Motor insulation class

Motor hand

Drive

Air flow (m^3/s)

External static @Actual (kPa)

Internal static @Actual (kPa)

Airfoil (standard)

Horizontal front

TEFC

380V/3/50

29.83

F

Left

Fixed

13.39

0.40

0.33

Total static @Actual (kPa)

Break power @Actual (kW)

Rotations per minute

Altitude (m)

Coldest dry bulb temp (C)

Access panels

Liners

View port

Marine light

Pressure drop (kPa)

Internal isolation

0.73

19.73

1420

0

21.1

One

Solid GI

Yes

Yes

0.05

Spring (standard)

Supply Fan Sound Power(dB)

Frequency (Hz)

63

125

250

500

1k

2k

4k

8k

Overall

At inlet

89

91

95

94

89

84

80

75

100

At discharge

100

96

97

94

89

84

80

75

104

Air Handler Coil

Coil Tag

Model #

Manufacturer

Qty

Location

Footnotes

#1

A W Q 5 - 52T x 118 RH

DBM

Section B - Coil A

A,B

Air properties

Air flow (m^3/s)

Altitude (m)

Face velocity (m/s)

Air pressure drop (kPa)

Entering air DB / WB

(C)

Leaving air DB / WB (C)

Air properties measured

at

Fluid properties

13.389

0

2.71

0.191

25.3 / 19.7

13.0 / 12.5

Actual

Fluid

Fluid flow rate (l/s)

Fluid velocity (m/s)

Entering fluid temp. (C)

Leaving fluid temp. (C)

Fluid pressure drop

(kPa)

Construction

Water

16.2

2.0

7.0

12.0

76.5

Coil

Total capacity (kW)

Sensible capacity (kW)

338.1

199.0

Type / tubes in face

Finned height (mm)

Finned length (mm)

Face area (m^2)

Rows / fin spacing

(fins/cm)

Number of feeds

Casing construction

Supply connections

(qty@in)

Return connections

(qty@in)

Connection type

Fin material

Header material

A (1/2" OD) /

52

1,651

2,997

4.95

5 / 3.94

65

Air handler

2@3

2@3

MPT

Standard

aluminium

Standard

steel

Footnotes

A.Fluid pressure drop limit could not be met.

90572

06-Feb-13

B.Stacked coils required.

Page 12 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

Date:

Tag:

PERFORMANCE SUMMARY

2/4/13 11:51 AM

AHU-3

Location:

Supply Fan Specification

Air handler model

Fan type

Style

Altitude (m)

90572

AHD2 AF 270 H M

Airfoil (standard/710)

Draw-thru

0

06-Feb-13

Air flow (m^3/s)

Static pressure @ Altitude (kPa)

Rotations per minute

Brake power @ Altitude (kW)

Coldest dry bulb (C)

Page 13 of 17

SPEC ver. 7.0, 13240

13

0.73

1,420

20

21.1

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

Date:

Tag:

PERFORMANCE SUMMARY

90572

06-Feb-13

2/4/13 11:51 AM

AHU-3

Location:

Page 14 of 17

SPEC ver. 7.0, 13240

Big C - Dalat

Project:

Consultant: Mr. Phung

Location: Dalat-Vietnam

2/4/13 11:51 AM

Date:

AHU-4

Tag:

PERFORMANCE SUMMARY

Location:

CS3 Air Handler

Model #

Manufacturer

Fan ratings version

AHD2 AF 240 H M

DBM

3CS10

Quantity

Insulation (entire unit)

Wall thickness

1

2.5 # Polyurethane

2" (50 mm)

A. Section 16 Mixing box section

Inlet location(s)

Dampers

Access panels

Panel hand

Top and back

Air foil low leak

One

Left

Liners

View port

Marine light

Pressure drop (kPa)

Solid GI

Yes

Yes

0.03

B. Section 7 Short cooling coil section (includes prefilter)

Coil size

Drain pan

Large

Stainless

Pre-filter media

Liners

Pressure drop (kPa)

92% Arr. washable

Solid GI

0.23

Refer coil performance as below.

C. Section 23 Access section w/panel

Access panels

One

Panel hand

Liners

Left

Solid GI

D. Section 1 Horizontal draw-thru fan section TM

Fan type

Arrangement

Motor type

Motor voltage

Motor power (kW)

Motor insulation class

Motor hand

Drive

Air flow (m^3/s)

External static @Actual (kPa)

Internal static @Actual (kPa)

Airfoil (standard)

Horizontal front

TEFC

380V/3/50

18.64

F

Left

Fixed

11.47

0.40

0.31

Total static @Actual (kPa)

Break power @Actual (kW)

Rotations per minute

Altitude (m)

Coldest dry bulb temp (C)

Access panels

Liners

View port

Marine light

Pressure drop (kPa)

Internal isolation

0.71

14.45

1281

0

21.1

One

Solid GI

Yes

Yes

0.05

Spring (standard)

Supply Fan Sound Power(dB)

Frequency (Hz)

63

125

250

500

1k

2k

4k

8k

Overall

At inlet

86

87

93

90

84

79

76

71

96

At discharge

97

92

95

90

84

79

76

71

101

Air Handler Coil

Coil Tag

Model #

Manufacturer

Qty

Location

Footnotes

#1

A W Q 5 - 52T x 106 RH

DBM

Section B - Coil A

Air properties

Air flow (m^3/s)

Altitude (m)

Face velocity (m/s)

Air pressure drop (kPa)

Entering air DB / WB

(C)

Leaving air DB / WB (C)

Air properties measured

at

Fluid properties

11.472

0

2.58

0.176

25.3 / 19.7

12.9 / 12.5

Actual

Fluid

Fluid flow rate (l/s)

Fluid velocity (m/s)

Entering fluid temp. (C)

Leaving fluid temp. (C)

Fluid pressure drop

(kPa)

Construction

Water

13.9

1.7

7.0

12.0

54.8

Coil

Total capacity (kW)

Sensible capacity (kW)

289.9

171.2

Type / tubes in face

Finned height (mm)

Finned length (mm)

Face area (m^2)

Rows / fin spacing

(fins/cm)

Number of feeds

Casing construction

Supply connections

(qty@in)

Return connections

(qty@in)

Connection type

Fin material

Header material

A (1/2" OD) /

52

1,651

2,692

4.45

5 / 3.94

65

Air handler

2@3

2@3

MPT

Standard

aluminium

Standard

steel

Footnotes

A.Stacked coils required.

90572

06-Feb-13

Page 15 of 17

SPEC ver. 7.0, 13240

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

Date:

Tag:

PERFORMANCE SUMMARY

2/4/13 11:51 AM

AHU-4

Location:

Supply Fan Specification

Air handler model

Fan type

Style

Altitude (m)

90572

AHD2 AF 240 H M

Airfoil (standard/710)

Draw-thru

0

06-Feb-13

Air flow (m^3/s)

Static pressure @ Altitude (kPa)

Rotations per minute

Brake power @ Altitude (kW)

Coldest dry bulb (C)

Page 16 of 17

SPEC ver. 7.0, 13240

11

0.71

1,281

14

21.1

Project:

Big C - Dalat

Consultant: Mr. Phung

Location: Dalat-Vietnam

Date:

Tag:

PERFORMANCE SUMMARY

90572

06-Feb-13

2/4/13 11:51 AM

AHU-4

Location:

Page 17 of 17

SPEC ver. 7.0, 13240

Anda mungkin juga menyukai

- Dim Ewwqc1013b Xs ModelDokumen1 halamanDim Ewwqc1013b Xs ModelLeed ENBelum ada peringkat

- CP02 Design Data ListDokumen26 halamanCP02 Design Data ListLeed ENBelum ada peringkat

- CP02 CD Documents StatusDokumen4 halamanCP02 CD Documents StatusLeed ENBelum ada peringkat

- Question 3: How Do You React, What Happens, When You Believe That Thought?Dokumen2 halamanQuestion 3: How Do You React, What Happens, When You Believe That Thought?Leed EN100% (1)

- RPUB00003Dokumen40 halamanRPUB00003Ko PaukBelum ada peringkat

- CS3 50Hz 60HzDokumen12 halamanCS3 50Hz 60HzLeed ENBelum ada peringkat

- 1Dokumen18 halaman1Leed ENBelum ada peringkat

- 7-QC-QA Plan For ProjectDokumen99 halaman7-QC-QA Plan For ProjectJaouad Id BoubkerBelum ada peringkat

- 1Dokumen18 halaman1Leed ENBelum ada peringkat

- Q21302221Konia DunhamBush Big C Dalat 2TDokumen1 halamanQ21302221Konia DunhamBush Big C Dalat 2TLeed ENBelum ada peringkat

- Carbon Steel Pipe and Fittings GuideDokumen10 halamanCarbon Steel Pipe and Fittings GuideavazcBelum ada peringkat

- Pham Hung Residences Offices Floor Plan, PDFDokumen11 halamanPham Hung Residences Offices Floor Plan, PDFLeed ENBelum ada peringkat

- CLCP IomDokumen44 halamanCLCP IomLeed ENBelum ada peringkat

- IT Services Design Firm ExperienceDokumen2 halamanIT Services Design Firm ExperienceLeed ENBelum ada peringkat

- Bs 6100 1-3-2Dokumen24 halamanBs 6100 1-3-2Leed ENBelum ada peringkat

- RPUB00003Dokumen40 halamanRPUB00003Ko PaukBelum ada peringkat

- Tri-Services Color MappingsDokumen1 halamanTri-Services Color MappingsATRSBOOKSBelum ada peringkat

- ColumnsDokumen10 halamanColumnsnahzemBelum ada peringkat

- Section HH2Dokumen8 halamanSection HH2Leed ENBelum ada peringkat

- CLCP IomDokumen44 halamanCLCP IomLeed ENBelum ada peringkat

- Section HH2Dokumen8 halamanSection HH2Leed ENBelum ada peringkat

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CCIP How2 ExtractDokumen3 halamanCCIP How2 ExtractLeed ENBelum ada peringkat

- Reinforced Concrete Council - Tiltup10Dokumen4 halamanReinforced Concrete Council - Tiltup10Gyorgy AdrienneBelum ada peringkat

- BS 5628-2Dokumen68 halamanBS 5628-2Leed EN100% (5)

- Early Striking and Improved BackproppingDokumen4 halamanEarly Striking and Improved Backproppingrami1964100% (1)

- Reinforcement Standard en 10080 and The ECDokumen1 halamanReinforcement Standard en 10080 and The ECLeed ENBelum ada peringkat

- BS 5628-3Dokumen136 halamanBS 5628-3Leed EN100% (5)

- Eurocode 1 Part 2,6 - DDENV 1991-2!6!1997Dokumen35 halamanEurocode 1 Part 2,6 - DDENV 1991-2!6!1997afqan1Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- BS1452 Grade 250 Cast Iron SpecificationDokumen2 halamanBS1452 Grade 250 Cast Iron SpecificationSyed Shoaib RazaBelum ada peringkat

- h11.h13 SynopsisDokumen3 halamanh11.h13 SynopsisSahil NegiBelum ada peringkat

- rr321401 Principles of Machine DesignDokumen8 halamanrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- Tutorial 2Dokumen3 halamanTutorial 2rafidah mazlanBelum ada peringkat

- And Thermal Conductivity and Uses The VBA Functions For Those PropertiesDokumen6 halamanAnd Thermal Conductivity and Uses The VBA Functions For Those PropertiesselisenBelum ada peringkat

- Technical Specification of The ProjectDokumen6 halamanTechnical Specification of The ProjectyeabtsegaBelum ada peringkat

- New Construction Spec Sheet Free PDF Template DownloadDokumen1 halamanNew Construction Spec Sheet Free PDF Template DownloadsharfiBelum ada peringkat

- Installation and maintenance manual for FLOWMAX-90 condensing water heaterDokumen93 halamanInstallation and maintenance manual for FLOWMAX-90 condensing water heaterRogers ShawBelum ada peringkat

- Jaquar FaucetsDokumen20 halamanJaquar Faucetssonalsonal303Belum ada peringkat

- Study Brinell Hardness Testing MachineDokumen31 halamanStudy Brinell Hardness Testing MachineAnonymous vvO0nZWflrBelum ada peringkat

- CP203 Schindler Interior DesignDokumen22 halamanCP203 Schindler Interior DesignLABO MRT-KOTABelum ada peringkat

- Reinforcing Plate Vessel Shell: API 579-1/ASME FFS-1 2016 Fitness-For-ServiceDokumen60 halamanReinforcing Plate Vessel Shell: API 579-1/ASME FFS-1 2016 Fitness-For-ServiceALEXANDER ALFONSO100% (1)

- Efs Lm6000cmpst-Efs 2015newDokumen2 halamanEfs Lm6000cmpst-Efs 2015newMohamed AhmedBelum ada peringkat

- Thermoplastic Yellow Paint MTCDokumen1 halamanThermoplastic Yellow Paint MTCchitranjan4kumar-8Belum ada peringkat

- Gas Cooker - Google SearchDokumen1 halamanGas Cooker - Google SearchDaphine NabisereBelum ada peringkat

- Design, Dimensioning and Execution of Precast SFRC Arch SegmentsDokumen18 halamanDesign, Dimensioning and Execution of Precast SFRC Arch Segmentshfdfghj jggfghBelum ada peringkat

- Hempafloor Prime 100Dokumen2 halamanHempafloor Prime 100Noman AhmedBelum ada peringkat

- Large Blast Furnace Technologies by NIPPON STEEL ENGINEERINGDokumen5 halamanLarge Blast Furnace Technologies by NIPPON STEEL ENGINEERINGsmelt_928471401Belum ada peringkat

- CH 6 - Diaphragm - Analysis - Fundamentals and Design ExampleDokumen164 halamanCH 6 - Diaphragm - Analysis - Fundamentals and Design ExampleCarson Baker100% (1)

- Hose Quotation List: Description Quantity SpecificationDokumen1 halamanHose Quotation List: Description Quantity SpecificationLegend AnbuBelum ada peringkat

- Carbon Nanotube Synthesis ReportDokumen7 halamanCarbon Nanotube Synthesis ReportSrikanth ReddyBelum ada peringkat

- Cvg2140 - Tutorial 2 (SFDBMD)Dokumen2 halamanCvg2140 - Tutorial 2 (SFDBMD)Fadey FaridBelum ada peringkat

- Article CoolingIndia May 2012Dokumen5 halamanArticle CoolingIndia May 2012Ganesh PMBelum ada peringkat

- Reinforced Concrete DesignDokumen48 halamanReinforced Concrete DesignSamBelum ada peringkat

- Heating SystemDokumen13 halamanHeating SystemFatima GonzalesBelum ada peringkat

- Surflex: N - M F HDokumen2 halamanSurflex: N - M F HJohn Shane100% (1)

- Casting Da 1Dokumen4 halamanCasting Da 1Sherin SipriBelum ada peringkat

- Alun Thomas ArticleDokumen10 halamanAlun Thomas ArticleTansel YılmazBelum ada peringkat

- Aspen Flare System AnalyzerDokumen10 halamanAspen Flare System Analyzerharyonodaniel50% (2)

- Sikagrout 215Dokumen2 halamanSikagrout 215Riska Anshar PramonoBelum ada peringkat