Ray Osborne Rotary Bending Presentation For ISTMA Technical Sessions

Diunggah oleh

Elaine JohnsonJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ray Osborne Rotary Bending Presentation For ISTMA Technical Sessions

Diunggah oleh

Elaine JohnsonHak Cipta:

Format Tersedia

Principles of Rotary Bending

Technology

&

Use of Rotary Bending

Technology for Processing of

Advanced, High-Strength Steels

(AHSS)

L. Ray Osborne

rosborne@anchordanly.com

Mechanical Engineer / Business Development Manager

What is Rotary Bending?

Rotary Benders are rotating

rocker-lever devices that work on

the principle of mechanical

advantage, and are used to

simplify tooling, improve part

quality and reduce tooling costs.

Rotary Bending provides tool

designers, tool builders and metal

formers a consistent means for

holding angular part tolerances

2

Where is Rotary Bending Used?

Progressive Stamping Dies

Value Proposition:

Reduced Part Marking

Precise Control of Final Bend Angles

Press Brake Tooling

Value Proposition:

Ergonomics and Safety

Reduced Part Marking

3

How Does Rotary Bending Work?

Step 2

Step 1

Downward

force clamps

the part.

Induced

rotation of the

Rocker bends

material around

the anvil while

requiring less

force

Step 4

Step 3

Rocker bends material beyond

final part angle to compensate

for material-memory springback

Rocker releases

material to allow

springback to

desired final part

angle

4

Rotary Bending Replaces Wipe-Action Tooling

Part Hold-Down

Wiping Action

Wipe

Punch

Hold-Down

Bottoming Action

Coining

Part

Stripper

Surface of part is

scraped, leaving long

marks

Rotary Bending replaces V-type Brake Tooling

Brake Punch

Work

Piece

Minimal shine marks

with standard polished

Rocker and no marks

with Delrin Insert

Back Stop

Brake Die

Press brake V-dies require

higher tonnages

Pronounced tool marks

from press brake V-die

6

Most Common Bend Types (cross sections)

90 Bend

Channel Bend

Over Square

Zee Bend

Other Bend Types

Short Leg

Hat Bend

Large Radius

Under Square

Return Bend

Open Zee

Common Rotary Bender Sizes

Capability of Common Rocker Diameters

20mm:

25 19 gauge material (mild CRS)

25mm:

19 14 gauge material (mild CRS)

35mm:

14 11 gauge material (mild CRS)

50mm:

11 8 gauge material (mild CRS)

65mm and 80mm are available for thicker and/or

high-strength materials

Common Construction Materials

LINER = Self-Lubricating C95400 Aluminum Bronze

SADDLE = Hardened AISI 4140 Steel

ROCKER = Induction-Hardened S7 Shock-Resistant Tool

Steel

10

Common Construction Materials

11

Rotary Bender Options

Dart Stiffeners can be produced

in the bent part with the simple

addition of hardened dowels

spaced as needed across the

throat of the Rocker.

Dart Stiffeners create an integral

gusset in the part and give it

rigidity.

12

Rotary Bender Options

Delrin is a special polymer which

can be inserted in the hardened

steel Rocker to bend pre-painted

materials, soft materials or stainless

steel without leaving tool marks.

Delrin provides long-lasting

durability with little to no abrasive

effect during part contact.

Delrin is mounted to the Rocker

using screws and can be easily

replaced.

13

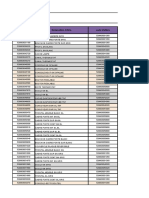

Market Segments for Rotary Bending

Appliance 40%

Specialty

Equipment 20%

HVAC 10%

Transportation 5%

Furniture 10%

Aerospace 5%

Electrical

Enclosures 10%

14

Application Engineering

Technical Data Required:

Material Properties

Material Thickness

Part Length

Bent Leg (Part Height)

Bend Radius

Part Angle (and Tolerance)

Areas Where Marks Are Unacceptable

Part Channel Dimensions, if Applicable

15

Test Bending Services

For Application Verification:

Determine Extent of Part Marking (if any)

Determine Amount of Material Springback

Guarantee Final Bend Angle and Desired Part

Geometry

16

AHSS Springback Study

17

AHSS Springback Study

Vertical

clearance

The effective strain field of

rotary bending is shown here

at the overbending stage.

Springback from FEM simulations

using elastic modulus E=150 and

210 Gpa is compared with

springback from experiments at

Anchor Danly in bending DP1000

at different vertical clearances.

18

Special Applications

Material = DP1000

Ultimate Tensile Strength (min.) = 1,000 MPa

(145,000 psi)

19

Special Applications

20

Special Applications

Interlaced, TwoStage Bending

Concept

21

Special Applications

Rotary-Bender

on Pressure Pad

+ Conventional

Aerial Cam

22

Special Applications

Rotary-Bender

on Pressure Pad

+ Conventional

Aerial Cam

23

Special Applications

Rotary-Bender on

Pressure Pad +

Roller-Actuated

Cam

24

www.anchordanly.com

Anda mungkin juga menyukai

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- 2015 Training Handbook PDFDokumen124 halaman2015 Training Handbook PDFAboo Khan100% (1)

- Form 1 AWS D1.1Dokumen2 halamanForm 1 AWS D1.1Bui Chi TamBelum ada peringkat

- All About GearsDokumen12 halamanAll About GearsIyappanBelum ada peringkat

- Die Design PresentationDokumen24 halamanDie Design PresentationIsrar Equbal100% (1)

- Good Woodworking July 2015 PDFDokumen92 halamanGood Woodworking July 2015 PDFJd DiazBelum ada peringkat

- Stabil Drill BrochureDokumen27 halamanStabil Drill Brochuretrinhtu7Belum ada peringkat

- Repair of Storage ShedDokumen37 halamanRepair of Storage ShedEr Sandip SuryawanshiBelum ada peringkat

- 44-Slider Crank Mechanism Using HacksawDokumen15 halaman44-Slider Crank Mechanism Using HacksawsathishBelum ada peringkat

- Gear Manufacturing Process and Quality ImprovementDokumen47 halamanGear Manufacturing Process and Quality ImprovementMuhammad UmarBelum ada peringkat

- Steel Structure FabricationDokumen5 halamanSteel Structure FabricationAditya PatilBelum ada peringkat

- Spinning: Department of Mechanical Engineering, BVCOE & RI NasikDokumen37 halamanSpinning: Department of Mechanical Engineering, BVCOE & RI NasikKaustubh JoshiBelum ada peringkat

- Technical Handbook of CladdingDokumen20 halamanTechnical Handbook of Claddingkaruma100% (1)

- Rapid Sheet Metal Design GuideDokumen17 halamanRapid Sheet Metal Design GuideNageswar ReddyBelum ada peringkat

- There's Always A Solution in SteelDokumen12 halamanThere's Always A Solution in Steeldarienko100% (1)

- Austenitic Ductile Iron Castings: Standard Specification ForDokumen7 halamanAustenitic Ductile Iron Castings: Standard Specification Forist93993Belum ada peringkat

- Ews-Itws Lab ManualDokumen167 halamanEws-Itws Lab ManualNetaji GandiBelum ada peringkat

- Cylinder Liner Manufacturing ProcessDokumen73 halamanCylinder Liner Manufacturing ProcessLikhith Dogiparthi50% (2)

- Water Tank Fabrication QAPDokumen2 halamanWater Tank Fabrication QAPYOGESHBelum ada peringkat

- Chapter 1 - Introduction To Cement ProductionDokumen6 halamanChapter 1 - Introduction To Cement ProductionMegan HuffmanBelum ada peringkat

- Hardfacing Product CatalogDokumen56 halamanHardfacing Product Catalogkaveh-bahiraeeBelum ada peringkat

- Fact Sheet: METAL REMOVAL/CUTTINGDokumen4 halamanFact Sheet: METAL REMOVAL/CUTTINGAl EnggBelum ada peringkat

- Robotic and CNC Deburring Tools: NEW CatalogDokumen12 halamanRobotic and CNC Deburring Tools: NEW Catalogspace2kBelum ada peringkat

- Quality Tool Holders PartnerDokumen81 halamanQuality Tool Holders PartnerbrineytoolingBelum ada peringkat

- Rigid Coupling 4Dokumen9 halamanRigid Coupling 4Yosia HutasoitBelum ada peringkat

- Project Presentation 3.0Dokumen35 halamanProject Presentation 3.0CH.SUMANTHBelum ada peringkat

- Tehnologia Materialelor F41Dokumen22 halamanTehnologia Materialelor F41andreeaoana45Belum ada peringkat

- Tungsten Carbide Tools Training ManualDokumen209 halamanTungsten Carbide Tools Training ManualMarin Ionut-EduardBelum ada peringkat

- Metal Spinning Guide: Processes, Equipment and ApplicationsDokumen63 halamanMetal Spinning Guide: Processes, Equipment and ApplicationsM PraveenBelum ada peringkat

- Jigs and Fixtures by Earnest.Dokumen17 halamanJigs and Fixtures by Earnest.Akeju AyodeleBelum ada peringkat

- TK Materials Australia ProductCatalogue LOCKEDDokumen24 halamanTK Materials Australia ProductCatalogue LOCKEDSugianto BarusBelum ada peringkat

- Forging Process DocumentDokumen22 halamanForging Process DocumentPriti DixitBelum ada peringkat

- Lab Session: 01 ObjectiveDokumen9 halamanLab Session: 01 ObjectiveAhmad Bin SadiqBelum ada peringkat

- Chapter III Project ReportDokumen5 halamanChapter III Project ReportBarnadeep DasBelum ada peringkat

- Louvers for Heat Exchangers & CondensersDokumen5 halamanLouvers for Heat Exchangers & Condensersthanhphuc1011Belum ada peringkat

- Machining Guide for Dura-Bar Ductile IronDokumen4 halamanMachining Guide for Dura-Bar Ductile IronricassterBelum ada peringkat

- Gear Rack, Gears, Pinions, & Related Products: Standard & CustomDokumen32 halamanGear Rack, Gears, Pinions, & Related Products: Standard & CustomKunaSudharshanBelum ada peringkat

- Suruburi by S.C.RewlingsDokumen8 halamanSuruburi by S.C.RewlingsMihnea OrzaBelum ada peringkat

- Chapter3 - Cutting Tools For CNC MachinesDokumen46 halamanChapter3 - Cutting Tools For CNC MachinesTharun Kumar Chõwdâry100% (1)

- Steel Deck Fastening System PDFDokumen68 halamanSteel Deck Fastening System PDFwilfred lotinoBelum ada peringkat

- Design N3Dokumen100 halamanDesign N3Charanjit SinghBelum ada peringkat

- Invicta Metal Stamping CatalogueDokumen12 halamanInvicta Metal Stamping CatalogueVbBelum ada peringkat

- Lab 01Dokumen17 halamanLab 01sisacs2002Belum ada peringkat

- Belflex Bellows Coupling CatalogDokumen6 halamanBelflex Bellows Coupling CatalogDarkedgeBelum ada peringkat

- ARME Vol.3 No.2 July Dec 2014pp.43 47Dokumen5 halamanARME Vol.3 No.2 July Dec 2014pp.43 47Anis dakhlaouiBelum ada peringkat

- Dual Side Shaper MachineDokumen6 halamanDual Side Shaper MachineKarthik DmBelum ada peringkat

- Dormer Multicut2011Dokumen26 halamanDormer Multicut2011marcelocamaraBelum ada peringkat

- Sathyabama University: Design Practice of Jigs, Fixtures and Press Tools Lab - SPRX 4011Dokumen35 halamanSathyabama University: Design Practice of Jigs, Fixtures and Press Tools Lab - SPRX 4011wabdushukurBelum ada peringkat

- Hard Turning of Hot Work Tool Steel (Dac10)Dokumen38 halamanHard Turning of Hot Work Tool Steel (Dac10)mohitkpatelBelum ada peringkat

- Dawit SolomonDokumen24 halamanDawit Solomondawit solomonBelum ada peringkat

- Metals Guide PDF Catalog July 2012Dokumen538 halamanMetals Guide PDF Catalog July 2012Ahmed BdairBelum ada peringkat

- Special Steel Sheet: Cat - No.B1E-005-05Dokumen16 halamanSpecial Steel Sheet: Cat - No.B1E-005-05wahyuBelum ada peringkat

- Tool Steel SeminarDokumen23 halamanTool Steel SeminarioanchiBelum ada peringkat

- Die Max Die SpringsDokumen16 halamanDie Max Die SpringsCarlos GranadaBelum ada peringkat

- CYCLOTRONDokumen25 halamanCYCLOTRONsaifBelum ada peringkat

- Break ElongationDokumen3 halamanBreak ElongationPHILIPANTHONY MASILANGBelum ada peringkat

- Ergo Plast Pvt. LTD.: Manufactured byDokumen4 halamanErgo Plast Pvt. LTD.: Manufactured byAvinash ShuklaBelum ada peringkat

- Project Report ON "Resistance Spot Welding": Department of Mechanical Engineering Gitam University VisakhapatnamDokumen32 halamanProject Report ON "Resistance Spot Welding": Department of Mechanical Engineering Gitam University VisakhapatnamAbhinashBelum ada peringkat

- Scribd: BrowseDokumen41 halamanScribd: Browsemudassar aliBelum ada peringkat

- Screwdriver Bits CatalogDokumen161 halamanScrewdriver Bits CatalogHariram BishnoiBelum ada peringkat

- SAPH 440 MaterialDokumen16 halamanSAPH 440 MaterialDinesh SharmaBelum ada peringkat

- Sumitomo WRCX-RED EndmillsDokumen4 halamanSumitomo WRCX-RED Endmillscentaurus553587Belum ada peringkat

- Aluminum Machining GuideDokumen5 halamanAluminum Machining Guidechristian gonzalezBelum ada peringkat

- Cam Sheet Cutting ReportDokumen57 halamanCam Sheet Cutting ReportJAYAPRABHAKARAN N NBelum ada peringkat

- PP & Ce-Unit 2 (Notes) - Part ADokumen51 halamanPP & Ce-Unit 2 (Notes) - Part ASYLVIA ANITABelum ada peringkat

- Effects of Steel Alloys on PropertiesDokumen9 halamanEffects of Steel Alloys on PropertiesMina RemonBelum ada peringkat

- Digital Die Design SystemDokumen52 halamanDigital Die Design SystemElaine Johnson0% (1)

- Modeling and Simulation For: EveryoneDokumen38 halamanModeling and Simulation For: EveryoneElaine JohnsonBelum ada peringkat

- Forming Limits of Weld Metal in Aluminum Alloys and Advanced High-Strength SteelsDokumen19 halamanForming Limits of Weld Metal in Aluminum Alloys and Advanced High-Strength Steelsakhileshsingh28Belum ada peringkat

- Mold SpecDokumen1 halamanMold SpecElaine JohnsonBelum ada peringkat

- 12th LS-DYNA Conference 2012 AgendaDokumen17 halaman12th LS-DYNA Conference 2012 AgendaElaine JohnsonBelum ada peringkat

- Neu Gebauer 2012Dokumen6 halamanNeu Gebauer 2012Elaine JohnsonBelum ada peringkat

- 840 D ISO Turning PDFDokumen235 halaman840 D ISO Turning PDFElaine JohnsonBelum ada peringkat

- Magnesium With HariDokumen9 halamanMagnesium With HariElaine JohnsonBelum ada peringkat

- Soldadura de Materiales DiferentesDokumen5 halamanSoldadura de Materiales DiferentesLeidy Silvana Chacón VelascoBelum ada peringkat

- Zhao 2007Dokumen4 halamanZhao 2007Elaine JohnsonBelum ada peringkat

- Gangadhar2015 PDFDokumen10 halamanGangadhar2015 PDFElaine JohnsonBelum ada peringkat

- Ltu Lic 0596 Se PDFDokumen61 halamanLtu Lic 0596 Se PDFElaine JohnsonBelum ada peringkat

- AI Applications To Metal Stamping Die Design A Review PDFDokumen7 halamanAI Applications To Metal Stamping Die Design A Review PDFElaine JohnsonBelum ada peringkat

- Utilization of "Dynaform" Simulation SoftwareDokumen6 halamanUtilization of "Dynaform" Simulation SoftwareElaine JohnsonBelum ada peringkat

- Session14 Paper2Dokumen11 halamanSession14 Paper2Elaine JohnsonBelum ada peringkat

- 17 - AHSS Forming Simulation For Shear Fracture and Edge Cracking PDFDokumen37 halaman17 - AHSS Forming Simulation For Shear Fracture and Edge Cracking PDFElaine JohnsonBelum ada peringkat

- Wang2002 PDFDokumen4 halamanWang2002 PDFElaine JohnsonBelum ada peringkat

- Generate Taper Blank with Solid MeshDokumen13 halamanGenerate Taper Blank with Solid MeshElaine JohnsonBelum ada peringkat

- Etapost Newfeature 20140630Dokumen17 halamanEtapost Newfeature 20140630Elaine JohnsonBelum ada peringkat

- Jayahari 2015Dokumen9 halamanJayahari 2015Elaine JohnsonBelum ada peringkat

- 02 MFGS Design Optimization and Form Ability Analysis Avibha EngineeringDokumen6 halaman02 MFGS Design Optimization and Form Ability Analysis Avibha EngineeringlfsijBelum ada peringkat

- 10 3901@cjme 2014 0515 094Dokumen8 halaman10 3901@cjme 2014 0515 094Elaine JohnsonBelum ada peringkat

- Tipping Rotation Center in Tool PositionDokumen4 halamanTipping Rotation Center in Tool PositionElaine JohnsonBelum ada peringkat

- DF592 EfldDokumen7 halamanDF592 EfldElaine JohnsonBelum ada peringkat

- ADMET Sheet Metal Testing Guide July 2013Dokumen9 halamanADMET Sheet Metal Testing Guide July 2013Elaine JohnsonBelum ada peringkat

- Boundary From Surfaces in Curve EditorDokumen4 halamanBoundary From Surfaces in Curve EditorElaine JohnsonBelum ada peringkat

- BSE Tip Curve Binder With SheetDokumen5 halamanBSE Tip Curve Binder With SheetElaine JohnsonBelum ada peringkat

- Sheet Metal Drawing Tools & TechniquesDokumen10 halamanSheet Metal Drawing Tools & TechniquesLoveofyouth ReddyBelum ada peringkat

- Prediction of Tensile and Deep Drawing PDFDokumen27 halamanPrediction of Tensile and Deep Drawing PDFElaine JohnsonBelum ada peringkat

- Connectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeDokumen4 halamanConnectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeAnonymous cDWQYsjd9Belum ada peringkat

- Module 6 in ConChem 3rd GradingDokumen5 halamanModule 6 in ConChem 3rd Gradingjohncarlodc99Belum ada peringkat

- Thermowise Storage Vessels IntDokumen12 halamanThermowise Storage Vessels IntIrishadoreStevlandOliphantBelum ada peringkat

- Knowsley SK Limited - Designer and Manufacturer of Fire Fighting EquipmentDokumen4 halamanKnowsley SK Limited - Designer and Manufacturer of Fire Fighting Equipmentgireeshkumarb3874100% (1)

- YOSHITAKE SL-1S 1F Sight GlassDokumen1 halamanYOSHITAKE SL-1S 1F Sight GlassJohn Marvin ValenzuelaBelum ada peringkat

- Solution of Assignment 5Dokumen5 halamanSolution of Assignment 5Reza Borah100% (1)

- Composites Catalogue - Atul LTDDokumen7 halamanComposites Catalogue - Atul LTDSolai LBelum ada peringkat

- Nomenclature Plastique ActualiséeDokumen15 halamanNomenclature Plastique ActualiséeSoufiane RatiBelum ada peringkat

- MSS SP-110Dokumen16 halamanMSS SP-110Suedson RibeiroBelum ada peringkat

- Business: Mining Ironmaking Steelmaking Continuous Casting Industrial Furnaces Steel Rolling ECO SolutionDokumen3 halamanBusiness: Mining Ironmaking Steelmaking Continuous Casting Industrial Furnaces Steel Rolling ECO SolutionSamira MahmoodiBelum ada peringkat

- BS 4479-2-1990Dokumen15 halamanBS 4479-2-1990윤규섭Belum ada peringkat

- Fastener-Class Coatings From WhitfordDokumen6 halamanFastener-Class Coatings From WhitfordWK SinnBelum ada peringkat

- ASME B31.3-2016 Postweld Heat Treatment TableDokumen1 halamanASME B31.3-2016 Postweld Heat Treatment TableSumner TingBelum ada peringkat

- DRW 0001Dokumen9 halamanDRW 0001nishadhrajvasavaBelum ada peringkat

- 2019 RWD Safety Shower and Eye Wash E-CatalogueDokumen26 halaman2019 RWD Safety Shower and Eye Wash E-Cataloguenguyenphuong.cap.ssgBelum ada peringkat

- Catalogue Product M-Plus FilterDokumen40 halamanCatalogue Product M-Plus FilterAdrian Samuel ThenochBelum ada peringkat

- Application of Membrane Separation Technology To Cheese ProductionDokumen2 halamanApplication of Membrane Separation Technology To Cheese ProductionfBelum ada peringkat

- Din en 84 Iso 1207Dokumen7 halamanDin en 84 Iso 1207ezequieltoniBelum ada peringkat

- Casting Process IDokumen31 halamanCasting Process IArpit JainBelum ada peringkat

- Precision Ground 20mm Ballscrew with 2.5mm LeadDokumen1 halamanPrecision Ground 20mm Ballscrew with 2.5mm LeadRadovan KnezevicBelum ada peringkat

- Avesta Rust Remover 410 Stainless Steel CleanerDokumen2 halamanAvesta Rust Remover 410 Stainless Steel CleanerVijay OfficialBelum ada peringkat

- Product Data Sheet: Bisalloy Protection 400 SteelDokumen1 halamanProduct Data Sheet: Bisalloy Protection 400 SteelAli TalebiBelum ada peringkat