762 Energy-%2Band%2Bexergy-Based%2Bcomparison%2Bof%2Bcoal%2Band%2Bnuclear%2Bgenera

Diunggah oleh

Ricardo6Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

762 Energy-%2Band%2Bexergy-Based%2Bcomparison%2Bof%2Bcoal%2Band%2Bnuclear%2Bgenera

Diunggah oleh

Ricardo6Hak Cipta:

Format Tersedia

Exergy Int. J.

1(3) (2001) 180192

www.exergyonline.com

Energy- and exergy-based comparison of coal-red

and nuclear steam power plants

Marc A. Rosen

Department of Mechanical Engineering, Ryerson Polytechnic University, Toronto, ON, M5B 2K3, Canada

(Received 3 February 2000, accepted 2 April 2000)

Abstract The results are reported of energy- and exergy-based comparisons of coal-red and nuclear electrical generating stations.

Abstract

A version of a process-simulation computer code, previously enhanced by the author for exergy analysis, is used. Overall energy

and exergy eciencies, respectively, are 37% and 36% for the coal-red process, and 30% and 30% for the nuclear process. The

losses in both plants exhibit many common characteristics. Energy losses associated with emissions (mainly with spent cooling water)

account for all of the energy losses, while emission-related exergy losses account for approximately 10% of the exergy losses. The

remaining exergy losses are associated with internal consumptions, mainly in components which generate heat by combustion or

nuclear reactions, and in components which transfer heat across large temperature dierences. It is anticipated that the results will

prove useful to those involved in the improvement of existing and design of future electrical generating stations. 2001 ditions

scientiques et mdicales Elsevier SAS

Nomenclature

P

Q

Renergy

Rexergy

T

pressure

heat

net station condenser energy (heat) rejection rate

net station condenser exergy rejection rate

temperature

Greek symbols

energy efficiency

exergy efficiency

Subscripts

max

o

maximum

reference-environment state

1. INTRODUCTION

In this paper, a thermodynamic comparison of coalfired and nuclear electrical generating stations is performed using energy and exergy analyses. The comparisons are intended to identify areas where the potential

E-mail address: mrosen@acs.ryerson.ca (M.A. Rosen).

180

for performance improvement is high, and trends which

may aid in the design of future stations.

The coal-fired Nanticoke Generating Station (NGS)

and the Pickering Nuclear Generating Station (PNGS)

are selected as the representative stations on which the

comparisons are based [13]. Both stations are located

in Ontario, Canada and are operated by the provincial

electrical utility, Ontario Power Generation (formerly

Ontario Hydro). Reasons these stations are selected

include the following:

the individual units in each station have similar net

outputs (approximately 500 MWe);

a substantial base of operating data has been obtained

for them over several years (NGS has been operating

since 1981, and PNGS since 1971);

they are representative of present technology; and

they operate in similar physical environments.

Energy and exergy analyses [411] are used to perform thermodynamic performance comparisons in the

present study. Energy analysis is based on the first law

of thermodynamics, which is concerned with the conservation of energy. Exergy analysis is based on the second law, and generally allows process inefficiencies to

be better pinpointed than does an energy analysis, and

2001 ditions scientiques et mdicales Elsevier SAS. All rights reserved

S1164-0235(01)00024-3/FLA

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

efficiencies to be more rationally evaluated. Many researchers [411] propose that the thermodynamic performance of a process is best evaluated with exergy analysis.

Exergy is the work which can be produced by a stream or

system as it is brought into equilibrium with a reference

environment, and can be thought of as a measure of the

quality (or usefulness) of energy, work having the highest

quality. Exergy is consumed during real processes, and

conserved during ideal processes. The exergy consumption during a process is proportional to the entropy created due to process irreversibilities.

Applications of exergy analysis have increased in

recent years, and have included investigations of coalfired electricity generation using conventional [1220],

fluidized-bed combustion [21, 22] and combined-cycle

[2327] systems, as well as cogeneration [2830] and

nuclear electricity generation [3134].

The work reported here forms part of a broader program by the author to investigate the thermodynamics

of production processes for electricity [20, 21, 31, 32],

and hydrogen and hydrogen-derived fuels [20, 35]. The

present work is a direct extension of previous studies

from that program on conventional nuclear [31, 32] and

coal-fired [20] electrical generation. In addition to these

processes for electricity generation, it is noted that the

author has investigated, as part of the program, several

advanced electrical generating processes, including pressurized fluid-bed combustion systems [21] and integrated

coal-gasification combined cycles [27], and several cogeneration processes [29, 30]. Although others have performed exergy-based analyses of electrical generating

stations [1219, 2226, 33, 34], the present work, by directly comparing coal-fired and nuclear systems based on

energy and exergy information, extends and broadens the

results of these studies. A preliminary comparison by the

author of coal-fired and nuclear electricity generation is

presented elsewhere [35].

2. PROCESS DESCRIPTIONS

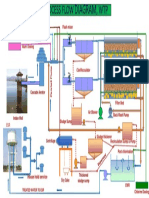

Detailed flow diagrams for single units of NGS and

PNGS are shown in figure 1. The symbols identifying

the streams are described in table I(a,b), and the main

process data in table II. Process descriptions reported

previously [13] for each are summarized below, in terms

of the four main sections identified in the caption of

figure 1.

2.1. Steam generation

Heat is produced and used to generate and reheat

steam. In NGS, eight pulverized-coal-fired natural circulation steam generators each produce 453.6 kgs1 steam

at 16.89 MPa and 538 C, and 411.3 kgs1 of reheat

steam at 4.00 MPa and 538 C. Air is supplied to the

furnace by two 1080 kW 600-rpm motor-driven forced

draft fans. Regenerative air preheaters are used. The flue

gas passes through an electrostatic precipitator rated at

99.5% collection efficiency, and exits the plant through

two multi-flued, 198 m high chimneys. In each unit of

PNGS, natural uranium is fissioned in the presence of a

moderator to produce heat, which is transferred from the

reactor to the boiler in the Primary Heat Transport Loop

(PTHL). The flow rate of pressurized heavy water (D2 O)

in the PTHL is 7724 kgs1 . The D2 O is heated from

249 C and 9.54 MPa to 293 C and 8.82 MPa in the nuclear reactor. Light-water steam (815 kgs1 at 4.2 MPa

and 251 C) is produced in the boiler and transported

through the secondary heat transport loop. Spent fuel is

removed from the reactor, and heat generated in the moderator is rejected.

2.2. Power production

The steam produced in the Steam Generation section is passed through a series of turbine generators

which are attached to a transformer. Extraction steam

from several points on the turbines preheats feedwater in several low- and high-pressure heat exchangers and one spray-type open deaerating heat exchanger.

The low-pressure turbines exhaust to the condenser at

5 kPa. Each unit of NGS has a 3600-rpm, tandemcompound, impulse-reaction turbine generator containing one single-flow high-pressure cylinder, one doubleflow intermediate-pressure cylinder and two double-flow

low-pressure cylinders. Steam exhausted from the highpressure cylinder is reheated in the combustor. Each unit

of PNGS has an 1800-rpm, tandem-compound, impulsereaction turbine generator containing one double-flow

high-pressure cylinder, and three double-flow low-pressure cylinders. Steam exhausted from the high-pressure

cylinder passes through a moisture separator and a closed

reheater (which uses steam from the boiler as the heat

source).

181

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

Figure 1. Process diagrams for single units of: (a) NGS, and (b) PNGS. The ow of uranium into and out of the nuclear reactor, and

the net heat delivered, are indicated. Lines exiting turbines represent ows of extraction steam. Stream S16 in gure 1 (b) represents

the mixed contents of the four indicated ows of extraction steam. The diagrams are each divided into four main sections: steam

generation (device A for NGS, and devices A-D for PNGS); power production (devices B-E for NGS, and E-I for PNGS); condensation

(device F for NGS, and J for PNGS); and preheating (devices G-K for NGS, and K-P for PNGS).

182

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

TABLE Ia

Stream data for a unit in NGS.

Stream

S1

S2

S3***

S4

S5A

S8

S10

S11

S12

S13

S14

S15

S20

S21

S22

S25

S33

S34

S35

S36

S37

S38

S39

S40

S41

S42

Q5

Q6

P1

P8

P15

Mass flow rate*

(kgs1 )

41.74

668.41

710.15

710.15

453.59

42.84

367.85

367.85

58.82

18 636.00

18 636.00

410.75

367.85

410.75

15.98

26.92

309.62

10.47

23.88

12.72

11.16

58.23

367.85

453.59

453.59

453.59

Temperature

( C)

15.00

15.00

1673.59

119.44

538.00

323.36

35.63

35.73

188.33

15.00

23.30

323.36

360.50

538.00

423.23

360.50

35.63

253.22

209.93

108.32

60.47

55.56

124.86

165.86

169.28

228.24

Pressure

(Nm2 )

1.01 105

1.01 105

1.01 105

1.01 105

1.62 107

3.65 106

4.50 103

1.00 106

1.21 106

1.01 105

1.01 105

3.65 106

1.03 106

4.00 106

1.72 106

1.03 106

4.50 103

3.79 105

2.41 105

6.89 104

3.45 104

1.33 104

1.00 106

1.00 106

1.62 107

1.62 107

Vapor

fraction**

SOLID

1.0

1.0

1.0

1.0

1.0

0.0

0.0

0.0

0.0

0.0

1.0

1.0

1.0

1.0

1.0

0.93

1.0

1.0

1.0

1.0

0.0

0.0

0.0

0.0

0.0

Energy flow rate

(MW)

1367.58

0.00

1368.00

74.39

1585.28

135.44

36.52

37.09

50.28

0.00

745.95

1298.59

1211.05

1494.16

54.54

88.64

774.70

32.31

71.73

35.77

30.40

11.37

195.94

334.86

347.05

486.75

5.34

5.29

0.57

523.68

12.19

Exergy flow rate

(MW)

1426.73

0.00

982.85

62.27

718.74

51.81

1.20

1.70

11.11

0.00

10.54

496.81

411.16

616.42

20.02

30.09

54.07

9.24

18.82

7.12

5.03

0.73

30.41

66.52

77.57

131.93

0.00

0.00

0.57

523.68

12.19

The composition of all streams is 100% H2 O, except that, on a volume basis, the composition of S1 is 100% carbon, of S2 is 79% N2 and

21% O2 , and of both S3 and S4 is 79% N2 , 6% O2 and 15% CO2 .

** Vapour fraction is listed as 0.0 for liquids and 1.0 for superheated vapours.

*** S3 (not shown in figure 1) represents the hot product gases for adiabatic combustion.

2.3. Condensation

Cooling water from Lake Ontario condenses the steam

exhausted from the turbines. The flow rate of cooling

water is adjusted so that a specified temperature rise in

the cooling water is achieved across the condenser.

(feedwater heaters). (The overall efficiency of the station

is increased by raising the temperature of the feedwater

to an appropriate level before heat is added to the cycle

in the steam generation section.)

3. APPROACH

2.4. Preheating

The temperature and pressure of the feedwater are

increased in a series of pumps and heat exchangers

The analyses and comparisons of NGS and PNGS are

performed using a computer code developed by enhancing a state-of-the-art process simulator, Aspen Plus [36],

183

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

TABLE Ib

Stream data for a unit in PNGS.

Stream

S1

S2

S3A

S4

S5A

S6

S7

S9

S10

S11

S12A

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S39

S40

Q1

Q2

Q9

Q10

P1

P2

P3

P4

P8

*

Mass flow rate*

(kgs1 )

7724.00

7724.00

7724.00

1000.00

1000.00

1956.83

1956.83

698.00

603.00

61.00

61.00

55.00

603.00

83.00

498.00

22.00

83.00

581.00

581.00

581.00

150.00

150.00

753.00

753.00

753.00

24 073.00

24 073.00

95.00

753.00

Temperature

( C)

291.93

249.38

249.00

64.52

43.00

15.00

26.00

151.83

160.00

254.00

254.00

176.66

237.97

60.81

23.32

186.05

60.81

23.32

23.40

100.20

134.00

134.17

123.69

124.20

163.94

15.00

26.00

160.00

254.00

Pressure

(Nm2 )

8.82 106

9.60 106

8.32 106

1.01 105

1.01 105

1.01 105

1.01 105

5.00 105

5.00 105

4.25 106

4.25 106

9.28 106

4.50 105

2.07 104

2.86 103

2.55 105

2.07 104

2.86 103

1.48 106

1.40 106

3.04 105

1.48 106

1.40 106

5.40 106

5.35 106

1.01 105

1.01 105

6.18 105

4.25 106

Vapor

fraction**

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.88

1.0

1.0

0.0

0.90

1.0

0.95

0.90

1.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.03

1.0

Energy flow rate

(MW)

9548.21

7875.44

7861.16

207.02

117.02

0.00

90.00

1705.50

1629.83

166.88

63.57

138.70

1733.17

204.00

1125.10

61.06

15.89

20.15

211.55

207.88

75.04

75.27

344.21

347.93

476.02

0.00

1107.20

75.70

2060.02

1673.00

90.00

5.56

5.50

14.28

3.73

1.00

0.23

544.78

Exergy flow rate

(MW)

2984.23

2201.64

2188.64

15.99

5.34

0.00

1.67

500.40

476.54

64.62

17.78

44.60

508.35

28.10

44.40

16.03

1.13

0.17

1.13

26.50

12.29

12.50

53.16

56.53

96.07

0.00

20.61

23.70

797.70

1673.00

90.00

0.00

0.00

14.28

3.73

1.00

0.23

544.78

All streams are modelled as 100% H2 O. Streams S1, S2, S3A, S4 and S5A are actually reactor-grade D2 O.

fraction is listed as 0.0 for liquids and 1.0 for superheated vapours.

** Vapour

for exergy analysis [37]. The reference-environment

model used by Gaggioli and Petit [5] and Rodriguez [6] is

used in the evaluation of energy and exergy quantities, but

with a reference-environment temperature To of 15 C

(the approximate mean temperature of the lake cooling

water). The reference-environment pressure Po is taken

to be 1 atm, and the chemical composition is taken to con-

184

sist of air saturated with water vapor, and the following

condensed phases at 15 C and 1 atm: water (H2 O), gypsum (CaSO4 2H2 O), and limestone (CaCO3 ). In addition

to properties in Aspen Plus data banks, which include

steam properties based on the 1967 ASME steam tables,

base enthalpy and chemical exergy values reported elsewhere [5, 6] are used. The base enthalpy of a component

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

TABLE II

Main process data for single units in NGS and PNGS* .

Section

Steam generation gection

Furnace

Coal consumption rate at full load (kgs1 )

Flue gas temperature ( C)

Nuclear reactor

Heavy water mass flow rate (kgs1 )

Heavy water temperature at reactor inlet ( C)

Heavy water temperature at reactor outlet ( C)

System pressure at reactor outlet header (MPa)

Boiler (heat-exchanger component)

Feed water temperature ( C)

Total evaporation rate (kgs1 )

Steam temperature ( C)

Steam pressure (MPa)

Reheat evaporation rate (kgs1 )

Reheat steam temperature ( C)

Reheat steam pressure (MPa)

Power production section

Turbine

Condenser pressure (kPa)

Generator

Gross power output (MW)

Net power output (MW)

Condensation section

Cooling water flow rate (m3 s1 )

Cooling water temperature rise ( C)

*

NGS

PNGS

47.9

120

724

249

293

8.8

253

454

538

16.9

411

538

4.0

171

815

251

4.2

505

542

515

18.9

8.3

23.7

11

Compiled from data presented elsewhere [13].

(at To and Po ) is evaluated from the enthalpies of the stable components of the environment (at To and Po ). The

base enthalpy of a fuel is equal to the enthalpy change

in forming the fuel from the components of the environment (the same environment used in exergy calculations).

A compound which exists as a stable component of the

reference environment is defined to have an enthalpy of

zero at To and Po .

For simplicity, the net heat produced by the uranium

fuel is considered the main energy input to PNGS, and

D2 O is modelled as H2 O, coal as pure graphite (C) and

air as 79% nitrogen and 21% oxygen by volume. Also, it

is assumed that

the turbines have isentropic and mechanical efficiencies of 80% and 95%, respectively;

the generators and transformers are each 99% efficient,

and heat losses from their external surfaces occur at 15 C

(i.e., To );

the input to and output from the nuclear reactor of

uranium is a steady-state process; and

all heat rejected by the moderator cooler is produced

in the moderator. Ontario Power Generation [2] actually

observes for each PNGS unit that, of the 90 MWt rejected

by the moderator cooler, 82 MWt is produced in the

moderator, 2.6 MWt is transferred from the fuel channel

to the moderator, and 6.1 MWt is produced in other

reactor components (1.1 MWt in the shield, 0.1 MWt in

the dump tank, 2.4 MWt in the calandria and 2.5 MWt in

the calandria tubes) and then transferred to the moderator.

It is further assumed that the temperature at which heat

can be produced by fissioning uranium can theoretically

be so high that the quantities of energy and exergy

of the heat can be considered equal. This assumption

has a major effect on the exergy efficiencies discussed

subsequently. If as an alternative fission heat is taken to

be available at the temperature at which it is actually

produced (i.e., at the thermal neutron flux-weighted

185

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

average temperature of about 880 C), the exergy of the

heat is about 75% of the energy.

4. ANALYSIS

Energy and exergy efficiencies are evaluated as ratios

of products to inputs. For the overall stations, the energy

efficiency is evaluated as

=

Net energy output with electricity

Energy input

(1)

and the exergy efficiency as

=

Net exergy output with electricity

Exergy input

(2)

For most of the other plant components and sections,

similar expressions are applied to evaluate efficiencies.

Efficiencies are not readily defined for the condensers,

as the purpose of such devices is to reject waste heat

rather than generate a product. However, the merit of

the condensers with respect to the overall plant can be

assessed for comparative purposes by evaluating the net

station condenser heat (energy) rejection rate Renergy ,

where

Renergy =

Heat rejected by condenser

Net electrical energy produced

(3)

and comparing it to an analogous quantity developed by

the author, the net station condenser exergy rejection

rate Rexergy , where

Rexergy =

Exergy rejected by condenser

Net exergy produced

(4)

5. RESULTS

Simulation and analysis data (including energy and

exergy values) are summarized along with specified data

in table I(a,b) for the streams identified in figure 1.

Exergy-consumption values for the devices are listed, according to process-diagram sections, in table III. Figures 2 and 3 illustrate the net energy and exergy flows and

exergy consumptions for the four main process-diagram

sections described in the caption of figure 1. The data are

summarized in overall energy and exergy balances in figure 4.

Regarding result validity, it is observed that:

186

simulated stream property values are within 10% of the

values measured at the stations (for properties for which

data are recorded),

energy and exergy values and efficiencies for the

overall processes and for process subsections are in broad

agreement with the literature for similar processes [12

34], and

exergy-analysis results for PNGS and NGS are relatively insensitive to the composition of the reference environment.

On the last point, it is noted that the exergies of

only the coal and stack gas depend on the choice of

the chemical composition of the environment, and that,

for most electrical generating stations, the results of

energy and exergy analyses are not significantly affected

by reasonable and realistic variations in the choice of

reference-environment properties [38].

6. DISCUSSION

6.1. Overall process eciencies

Overall energy () and exergy efficiency () values

are evaluated for the overall processes using equations (1)

and (2), respectively.

For NGS, where coal is the only input source of energy

or exergy,

=

(524 13) MW

(100%) = 37%

1368 MW

and

(524 13) MW

(100%) = 36%

1427 MW

The small difference in the efficiencies is due to the fact

that the specific chemical exergy of coal is slightly greater

than its specific base enthalpy.

For PNGS, where fission heat is treated as the only

input source of energy and exergy,

=

(545 19) MW

(100%) = 30%

1763 MW

and

(545 19) MW

(100%) = 30%

1763 MW

Ontario Power Generation [2] reports = 29.5% for

PNGS. Although for each station the energy and exergy

efficiencies are similar, these efficiencies differ markedly

for many station sections.

=

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

Figure 2. Simplied process diagrams for single units of: (a) NGS and (b) PNGS, indicating net energy ow rates (MW) for streams.

Stream widths are proportional to energy ow rates. Sections of stations shown are steam generation (S.G.), power production (P.P.),

condensation (C.), and preheating (P.). Streams shown are electrical power (P), heat input (Q) and heat rejected (Qr).

Figure 3. Simplied process diagrams for single units of: (a) NGS, and (b) PNGS, indicating net exergy ow rates for streams and

consumption rates (negative values) for devices. Stream widths are proportional to exergy ow rates, and shaded regions to exergy

consumption rates. All values are in MW. Other details are as in gure 2.

6.2. Eciencies and losses in steam

generators

Exergy consumptions in the Steam Generation sections of the stations are substantial, accounting for 659

MW (or 72%) of the 916 MW total exergy losses for

NGS, and 1027 MW (or 83%) of the 1237 MW total exergy losses for PNGS.

Of the 659 MW of exergy consumed in this section

for NGS, 444 MW is due to combustion, and 215 MW to

heat transfer.

Of the 1027 MW of exergy consumed in this section

for PNGS, 47 MW is consumed in the boiler, 9 MW in

the moderator cooler, 1 MW in the heavy-water pump,

and 970 MW in the reactor. The exergy consumptions in

the reactor can be broken down further by hypothetically

breaking down into steps the processes occurring within

it (figure 5): heating of the moderator, heating of the fuel

pellets (to their maximum temperature of approximately

2000 C), transferring the heat within the fuel pellets

to the surface of the pellets (at approximately 400 C),

transferring the heat from the surface of the fuel pellets

187

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

Figure 4. Overall energy and exergy balances for single units of: (a) NGS, and (b) PNGS. The left and right halves of the energy balances

represent respectively energy inputs and energy outputs. The left and right halves of the exergy balances represent respectively exergy

inputs and exergy outputs and consumptions (exploded section of balance). Cooling water and air inputs are not shown because they

contain zero energy and exergy. The PNGS reactor represents only the ssion reactor, not all devices in the Steam Generation section.

to the cladding surface (at 304 C), and transferring the

heat from the cladding surface to the primary coolant and

then to the preheated boiler feedwater to produce steam.

The energy and exergy efficiencies for the Steam

Generation section, considering the increase in energy or

exergy of the water as the product, for NGS are

[(1585 487) + (1494 1299)] MW

(100%)

1368 MW

= 95%

and

=

The Steam Generation sections of NGS and PNGS appear significantly more efficient on an energy basis than

on an exergy basis. Physically, this discrepancy implies

that although 95% of the input energy is transferred to

the preheated water, the energy is degraded as it is transferred. Exergy analysis highlights this degradation.

Two further points regarding PNGS are noted:

[(719 132) + (616 497)] MW

(100%) = 49%

1427 MW

and for PNGS are

188

(2267 64 476) MW

(100%) = 95%

(1763 + 14) MW

(862 18 96) MW

=

(100%) = 42%

(1763 + 14) MW

The step in which heat is generated by fissioning

uranium (also shown for completeness in figure 5) is,

by previous assumption, outside the boundary of the

nuclear reactor considered here. The energy and exergy

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

TABLE III

Breakdown by section and device of exergy consumptions (in MW) in single units of NGS and PNGS.

Section/Device

Steam generation section

Reactor

D2 OH2 O heat exchanger

D2 O pump

Moderator cooler

NGS

PNGS

659.0

969.7

47.4

1.1

9.0

659.0

Power production section

High-pressure turbine(s)

Intermediate-pressure turbine(s)

Low-pressure turbine(s)

Generator

Transformer

Moisture separator

Closed steam reheater

26.4

22.3

59.2

5.3

5.3

1027.2

36.9

79.7

5.5

5.5

0.2

15.0

118.5

Condensation section

Condenser

43.1

142.8

24.7

43.1

Preheat section

Low-pressure heat exchangers

Deaerating heat exchanger

High-pressure heat exchangers

Hot well pumps

Heater condensate pumps

Boiler feed pumps

10.7

5.1

6.4

0.1

1.6

1.8

16.4

0.04

0.03

0.43

1.1

Total

efficiencies calculated for PNGS could be significantly

different if this step were considered. In this case, the

energy and exergy of the fresh and spent nuclear fuel

would be required. The question of what are the exergies

of nuclear fuels is not completely resolved. Researchers

usually only deal with the heat delivered by nuclear fuels,

and most argue that the exergy of nuclear-derived heat is

equal or nearly equal to the exergy because the heat can

potentially be produced at very high temperatures.

Since D2 O is modelled as H2 O, the chemical exergy

of D2 O is neglected. Neglecting the chemical exergy

of D2 O does not significantly affect the exergy analysis

results here because, since the D2 O is contained in

the closed Primary Heat Transport loop of the Steam

Generation section and used only as a heat-transfer

medium, it is only the physical exergy of the D2 O stream

that is of interest.

24.7

23.4

844.0

20.8

1215.5

6.3. Losses in steam condensers

In the condensers,

a large quantity of energy enters (775 MW for each

NGS unit, and 1125 MW for each PNGS unit), of which

close to 100% is rejected; and

a small quantity of exergy enters (54 MW for each

NGS unit, and 44 MW for each PNGS unit), of which

25% to 50% is rejected and 50% to 75% is internally

consumed.

Thus, energy-analysis results lead to the erroneous conclusion that almost all losses in electricity-generation potential for NGS and PNGS are associated with the heat rejected by the condensers, while exergy analyses demonstrate quantitatively and directly that the condensers are

responsible for little of these losses (figure 3). This discrepancy arises because heat is rejected by the condensers

at a temperature very near that of the environment. The

189

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

Figure 5. Breakdown of the energy and exergy losses in the nuclear reactor of one PNGS unit. Material streams are represented by

solid lines, and heat ows by broken lines. The heavy solid line encloses the part of the nuclear reactor considered in the present

analysis. Exergy (in parentheses) and energy ow rates are indicated for streams, and exergy consumption rates (negative values in

parentheses) for devices. Flows of heat Q at points in the reactor at dierent values of temperature T are shown. All values are in

MW. P.H.T. denotes primary heat transport.

characteristics of condensers can be seen more clearly

by considering the net station condenser heat (energy)

rejection rate Renergy , and the net station condenser exergy rejection rate Rexergy . Following the expressions for

these quantities in equations (3) and (4), respectively, it

can be shown for each coal-fired unit that

Renergy =

746 MW

= 1.46

(524 13) MW

6.4. Miscellaneous losses

In the Power Production and Preheating sections of

the NGS and PNGS units, energy losses were found to be

very small (less than 10 MW total), and exergy losses

were found to be moderately small (100 to 150 MW

in the Power Production section and 20 to 25 MW in

the Preheating section). The exergy losses are almost

completely associated with internal consumptions.

and

Rexergy =

11 MW

= 0.0215

(524 13) MW

6.5. Comparison and further discussion

and for each nuclear unit that

1107 MW

= 2.10

Renergy =

(545 19) MW

and

Rexergy =

21 MW

= 0.0399

(545 19) MW

The R values indicate that the exergy rejected by the

condensers is less than 4% of the net exergy produced,

while the energy rejected is approximately 150% to 200%

of the net energy produced.

190

The thermodynamic behaviour of the coal-fired and

nuclear generating stations considered are similar in all

areas, except the Steam Generation sections. The significant differences in the Steam Generation sections affect their thermodynamic efficiencies, losses and performances, and cause these parameters to differ for the coalfired and nuclear stations. Some of the differences are as

follows:

The temperatures associated with heat generation are

constrained to lower values for PNGS than NGS, leading

to lower efficiencies for the nuclear station.

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

The heat generation and heat transfer mechanisms vary

greatly between the stations. For PNGS, heat is generated

in the calandria and transported to the steam generator,

while heat is generated in the steam generator without

the need for a transport step in NGS. Also, most heat

transfer in the steam generator of the coal-fired station

occurs from a gas to a solid, whereas the more efficient

liquid-to-solid heat transfer predominates in the nuclear

station.

Thermal neutrons are absorbed and moderated for

necessary operating and control processes in PNGS. This

process, which is somewhat analogous to wasting fuel, is

not present in the coal-fired station.

The potential of the used form of the fuel (spent

uranium for PNGS and combustion gases for NGS) is

much greater for the nuclear station, where the spent fuel

is highly radioactive and releases significant quantities of

thermal energy for many years.

These factors impact on the exergy- and energyrelated performances of the stations, and should be taken

into account in efforts to improve efficiencies.

7. CONCLUSIONS

In comparing the thermodynamic characteristics of

coal-fired and nuclear electrical generating stations, several illuminating insights into the performance of such

stations have been acquired. First, although energy and

exergy efficiencies are the same for PNGS and similar

for NGS, energy analyses do not systematically identify the location and cause of process inefficiencies, and

exergy analyses do. That is, energy losses are associated with emissions (mainly heat rejected by condensers),

and exergy losses primarily with consumptions (mainly

in the reactors) and little with cooling water and stack

gases. Second, since devices with the largest thermodynamic losses have the largest margins for efficiency improvement, efforts to increase the efficiencies of coalfired and nuclear electrical generating stations should focus on the combustion and nuclear reactors, respectively.

For instance, technologies capable of producing electricity without combustion (e.g., fuel cells) or utilizing heat

at high temperatures could increase efficiencies significantly. This conclusion is, of course, overly simplistic,

as such decisions require consideration of other technical and economic factors, in addition to thermodynamic

efficiency. Third, the use of heat rejected by condensers

only increases the exergy efficiencies by a few per cent.

Cogeneration systems, which produce heat at useful temperatures at the expense of reduced electrical output, can

have greater efficiencies than conventional electrical generating stations, but the merit of cogeneration systems

must be determined using exergy analyses because energy analyses tend to overstate performance.

Acknowledgements

Financial support for this project was provided by the

Natural Sciences and Engineering Research Council of

Canada.

REFERENCES

[1] Ontario Hydro, Nanticoke generating station technical data, document, August 1996.

[2] Ontario Hydro, Pickering generation station data:

units 14, Data Sheet No. 966 A119:0, 1985.

[3] Scarrow R.B., Wright W., Commissioning and early

operation of Nanticoke generating station, Paper presented

to Thermal and Nuclear Power Section at Canadian Electrical Association Fall Meeting, Halifax, N.S., 1975.

[4] Moran M.J., Sciubba E., Exergy analysis: principles

and practice, J. Engrg. Gas Turbines Power 116 (1994) 285

290.

[5] Gaggioli R.A., Petit P.J., Use the second law rst,

Chemtech 7 (1977) 496506.

[6] Rodriguez L.S.J., Calculation of available-energy

quantities, in: Gaggioli R.A. (Ed.), Thermodynamics: Second

Law Analysis, ACS Symposium Series, Vol. 122, Amer.

Chem. Soc., Washington, DC, 1980, pp. 3960.

[7] Gaggioli R.A., Available energy and exergy, Internat. J. Appl. Therm. 1 (1998) 18.

[8] Moran M.J., Shapiro H.N., Fundamentals of Engineering Thermodynamics, 4th edn., Wiley, New York, 2000.

[9] Wall G., Gong M., Exergy analysis versus pinch technology, in: Proc. Int. Conf. on Eciency, Costs, Optimization, Simulation and Environmental Aspects of Energy Systems (ECOS 96), Stockholm, Sweden, 1996, pp. 451455.

[10] Kotas T.J., The Exergy Method Of Thermal Plant

Analysis, reprint edn., Krieger, Malabar, FL, 1995.

[11] Rosen M.A., Second-law analysis: approaches and

implications, Internat. J. Energy Res. 23 (1999) 415429.

[12] McIlvried H.G., Ramezan M., Enick R.M., Venkatasubramanian S., Exergy and pinch analysis of an advanced ammonia-water coal-red power cycle, in: Proc.

ASME Advanced Energy Systems Division, AES, Vol. 38,

1998, pp. 197203.

[13] Yasni E., Carrington C.G., The role for exergy

auditing in a thermal power station, in: HTD, Vol. 80, Amer.

Soc. Mech. Engineers, New York, 1987, pp. 101109.

[14] Habib M.A., Zubair S.M., Second-law based thermodynamic analysis of regenerative-reheat Rankine-cycle

power plants, EnergyInternat. J. 17 (1992) 295301.

[15] Habib M.A., Said S.A.M., Al-Bagawi J.J., Thermodynamic performance analysis of the Ghazlan power plant,

EnergyInternat. J. 20 (1995) 11211130.

[16] Habib M.A., Said S.A.M., Al-Zaharna I., Optimization

of reheat pressures in thermal power plants, Energy

Internat. J. 20 (1995) 555565.

191

M.A. Rosen / Exergy Int. J. 1(3) (2001) 180192

[17] Horlock J.H., Young J.B., Manfrida G., The rational eciency of fossil-fuel power plants, in: Proc. ASME

Advanced Energy Systems Division, AES, Vol. 38, 1998,

pp. 235242.

[18] Gaggioli R.A., Yoon J.J., Patulski S.A., Latus A.J.,

Obert E.F., Pinpointing the real ineciencies in power

plants and energy systems, in: Proc. Amer. Power Conf.,

Vol. 37, 1975, pp. 656670.

[19] Nishio M., Itoh J., Shiroko K., Umeda T., A thermodynamic approach to steam-power system design, in: Proc.

14th Intersoc. Energy Conver. Engrg. Conf., Amer. Chem.

Soc., Washington, DC, 1979, pp. 17511757.

[20] Rosen M.A., Scott D.S., Energy and exergy analyses

of selected production processes for hydrogen and electricity from coal, in: Wepfer W.J., Tsatsaronis G., Bajura R.A.

(Eds.), Thermodynamic Analysis of Chemically Reactive Systems, AES, Vol. 4, Amer. Soc. Mech. Engineers, New York,

1988, pp. 1321.

[21] Rosen M.A., Horazak D.A., Energy and exergy

analyses of PFBC power plants, in: Alvarez Cuenca M.,

Anthony E.J. (Eds.), Pressurized Fluidized Bed Combustion,

Chapman and Hall, London, 1995, pp. 419448, Chapter

11.

[22] Grimaldi C.N., Bidini G., Using exergy analyses

on circulating uidized bed combustors, in: A Future

For Energy: Proc. Florence World Energy Research Symp.,

Firenze, Italy, 1990, pp. 181192.

[23] Tawk T., Tsatsaronis G., Price D., Exergetic comparison of various IGCC power plant designs, in: Proc. Internat. Conf. Energy Systems and Ecology, Cracow, Poland,

1993, pp. 585593.

[24] Kim D.J., Jeon J.S., Kwak H.Y., Exergetic and thermoeconomic analyses of a combined cycle power plant,

in: Proc. ASME Advanced Energy Systems Division, AES,

Vol. 39, 1999, pp. 397405.

[25] Jin H., Ishida M., Kobayashi M., Nunokawa M.,

Exergy evaluation of two current advanced power plants:

supercritical steam turbine and combined cycle, J. Energy

Resources Technology 119 (1997) 250256.

[26] Silvestri G.J., Bannister R.L., Fujikawa T., Hizume A.,

Optimization of advanced steam condition power plants,

J. Engrg. Gas Turbines Power 114 (1992) 612620.

[27] Rosen M.A., Assessment of an integrated coalgasication combined-cycle (IGCC) power plant using energy and exergy analyses, in: Boehm R.F. (Ed.), Thermodynamics and the Design, Analysis and Improvement of

192

Energy Systems, AES, Vol. 27, HTD, Vol. 228, Amer. Soc.

Mech. Engineers, New York, 1992, pp. 101109.

[28] Habib M.A., First- and second-law analysis of

steam-turbine cogeneration systems, J. Engrg. Gas Turbines Power 116 (1994) 1519.

[29] Rosen M.A., Comparison based on energy and

exergy analyses of the potential cogeneration eciencies

for fuel cells and other electricity generation devices,

Internat. J. Hydrogen Energy 15 (1990) 267274.

[30] Rosen M.A., Energy utilization eciency in a

macrosystem (Ontario): evaluation and improvement

through cogeneration, in: Proc. Internat. Symp. CO2 Fixation and Ecient Utilization of Energy, Tokyo, 1993,

pp. 1726.

[31] Baumal A.E., Rosen M.A., First- and second-law

analyses of the Bruce B nuclear generating station, in: Proc.

19th Canad. Nuclear Assoc./Canad. Nuclear Soc. Student

Conf. on Nuclear Science and Engineering, Toronto, 1994,

pp. 4048.

[32] Rosen M.A., Scott D.S., Energy and exergy analyses

of a nuclear steam power plant, in: Proc. 7th Canadian

Nuclear Soc. Annual Conf., Toronto, 1986, pp. 187196.

[33] Rogers J.T., Optimization of thermal energy supply

from combined-purpose CANDU nuclear reactors, in: Proc.

2nd World Congr. of Chemical Engrg., Montreal, Quebec,

1981, p. 339.

[34] Currie T.A., Analysis of a pickering reactor unit

on an availability basis, Energy Research Group report

ERG 77-1, Carleton University, Ottawa, April 1977.

[35] Rosen M.A., Thermodynamic comparison of coalred and nuclear electrical generating stations, Trans.

CSME 24 (1B) (2000) 273283.

[36] Aspen Plus Reference Manual, Aspen Technology,

Inc., Cambridge, MA, 1994.

[37] Rosen M.A., Scott D.S., The enhancement of a

process simulator for complete energy-exergy analysis, in:

Gaggioli R.A. (Ed.), Analysis of Energy SystemsDesign and

Operation, AES, Vol. 1, Amer. Soc. Mech. Engineers, New

York, 1985, pp. 7180.

[38] Rosen M.A., Scott D.S., On the sensitivities of

energy and exergy analyses to variations in dead-state

properties, in: Moran M.J., Gaggioli R.A. (Eds.), Analysis

and Design of Advanced Energy SystemsFundamentals,

AES, Vol. 3-1, Amer. Soc. Mech. Engineers, New York, 1987,

pp. 2332.

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Typical Exam Questions With Answers 2Dokumen17 halamanTypical Exam Questions With Answers 2Khadem Nuristani100% (1)

- Suction Pile SpecDokumen33 halamanSuction Pile Specriaz16shaik100% (1)

- Asl Ga55+90-02 9095 0504 76 PDFDokumen72 halamanAsl Ga55+90-02 9095 0504 76 PDFMushfiqur RahmanBelum ada peringkat

- D348 INDUSTRIAL & MARINE ENGINES CaterpillarDokumen32 halamanD348 INDUSTRIAL & MARINE ENGINES Caterpillarjosef67% (3)

- Fluid Flow Through Randomly Packed Columns and Fluidized BedsDokumen6 halamanFluid Flow Through Randomly Packed Columns and Fluidized BedsalexramquiBelum ada peringkat

- Sandvik DD321Dokumen4 halamanSandvik DD321Anonymous Dm7iMmt0% (2)

- Intergraph Caesar Course ContentDokumen2 halamanIntergraph Caesar Course ContentValesh MonisBelum ada peringkat

- ControlFlow GateValveDokumen37 halamanControlFlow GateValveclaudio godinezBelum ada peringkat

- Nissan 370Z: 3.7 PETROL Periodic MaintenanceDokumen3 halamanNissan 370Z: 3.7 PETROL Periodic MaintenanceMichael KaneBelum ada peringkat

- SHM Pendulum Required PracticalDokumen3 halamanSHM Pendulum Required PracticalSagar AgrawalBelum ada peringkat

- Training ReportDokumen60 halamanTraining Reportarjun100% (1)

- √ nρs) fc': Uncracked sectionDokumen5 halaman√ nρs) fc': Uncracked sectionSPDQC EngineeringBelum ada peringkat

- 5f9accc0f3f8f455bebc45f3 - 94 Shkolnik, Alexander - Final PaperDokumen13 halaman5f9accc0f3f8f455bebc45f3 - 94 Shkolnik, Alexander - Final PaperpeterBelum ada peringkat

- Armature Controlled DCMotors Fedfrom HWRectifierDokumen20 halamanArmature Controlled DCMotors Fedfrom HWRectifierTejas Sharma 2K20EE281Belum ada peringkat

- WTP Process DiagramDokumen1 halamanWTP Process DiagramKumar AbhishekBelum ada peringkat

- Farooqi Mohammed Yousuf Saudi Arabia 17.00 YrsDokumen5 halamanFarooqi Mohammed Yousuf Saudi Arabia 17.00 YrsKirkD'costaBelum ada peringkat

- Filtro Carbon ActivoDokumen1 halamanFiltro Carbon ActivoZzmangostazZBelum ada peringkat

- P PH Hy Ys Siic Ca All P Prro Op Pe Errttiie Es S: W WW WW W..s SP Pe Ec Ciia Allm Me Etta Alls S..C Co Om MDokumen4 halamanP PH Hy Ys Siic Ca All P Prro Op Pe Errttiie Es S: W WW WW W..s SP Pe Ec Ciia Allm Me Etta Alls S..C Co Om MIon PopescuBelum ada peringkat

- Control EngineeringDokumen14 halamanControl EngineeringCheong JkBelum ada peringkat

- Lab Report No 6 Bs PhysicsDokumen6 halamanLab Report No 6 Bs PhysicsITZ SUFYANBelum ada peringkat

- AFRC - Improving Performance of Coker HeatersDokumen29 halamanAFRC - Improving Performance of Coker Heatersashutosh_garg_10Belum ada peringkat

- RT Report Format Rev.1 17-3-19Dokumen6 halamanRT Report Format Rev.1 17-3-19mohd as shahiddin jafriBelum ada peringkat

- Centre of Mass - TheoryDokumen46 halamanCentre of Mass - TheoryNiteshBelum ada peringkat

- XTRACT Calculul Unui Perete de B.ADokumen1 halamanXTRACT Calculul Unui Perete de B.AHDu13Belum ada peringkat

- Quasiturbine EngineDokumen16 halamanQuasiturbine Engineapi-238832008100% (1)

- Laporan Barang Habis 23022023Dokumen265 halamanLaporan Barang Habis 23022023FauzanBelum ada peringkat

- Materials System SpecificationDokumen19 halamanMaterials System SpecificationGOSP3 QC MechanicalBelum ada peringkat

- AFL PED CertificateDokumen4 halamanAFL PED CertificateretrogradesBelum ada peringkat

- Lecture 2 UpdateDokumen80 halamanLecture 2 Updateماجد مدحت سعيدBelum ada peringkat

- ZL-7901A en V2.6b PDFDokumen8 halamanZL-7901A en V2.6b PDFElio Jose Burgos Brieva100% (1)