Certification Engineers International LTD.: C 2501-Stripper Column Design Data

Diunggah oleh

sathish_iyengarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Certification Engineers International LTD.: C 2501-Stripper Column Design Data

Diunggah oleh

sathish_iyengarHak Cipta:

Format Tersedia

Certification Engineers International Ltd.

C 2501- STRIPPER COLUMN

DESIGN DATADesign Pressure: 31 kg/cm2

Design Temperature: 170 C max.

Operating Pressure: 26 kg/cm2 max.

Operating Temperature: 135 max.

Corrosion allowance: 6 mm. on CS, 0.0 on Clad or CS + Liner

Hydro test pressure: 46.5 kg/cm2 (Vertical condition)

Total length 42400 mm from TL to TL

ID- 2510 mm.

OBSERVATIONS

I)

VISUAL INSPECTION

a) INTERNAL VISUAL INSPECTIONShell is good in condition Moderate corrosion on shell wall and tray was observed

throughout the column. Weld joints checked visually and no significant abnormalities

were noticed. Erosion/ Pitting/ Cracks/ Bulging not observed.

b) EXTERNAL VISUAL INSPECTIONPainting of column was in progress. Moderate corrosion, pitting & deep depressions

was observed on the shell, weld joints and platform (Grating, Brackets, Hand rail,

Ladder). Thinning of ladder at edge was observed. Davit was observed non adequate

for further use i.e. broken & jammed. Foundation checked visually found in

satisfactory condition.

II)

III)

NON DESTRUCTIVE TESTING

NDT was not carried out from inside as all trays are not removed. Also due to

irregular surface from inside.

Thickness Measurement.

Thickness of column checked with D-meter as given below.

Item

Top dished

end

Shell 1 from

top

Shell 2 from

top

Material

(SA 516 GR

60 +SA 240

GR 316L)

(SA 516 GR

60 +SA 240

GR 316L)

SA 516 GR

60 +SA 240

GR 316L)

Nominal

thickness

Actual measured

thickness

Min.

Max.

%

Reduction

22+3.5

(Min.

19+3)

22.3

25.2

NA

17+3

21.3

22.4

NA

17+3

18.6

21.4

10

Remark

Certification Engineers International Ltd.

Shell 3 from

top

SA 516 GR

60 +SA 240

GR 316L)

Shell 4 from

(SA 516 GR

top (Cone)

60 +SA 240

GR 316L)

Shell 5 from

(SA 516 GR

top

60 +SA 240

GR 316L)

Shell 6 from

(SA 516 GR

top

60 +SA 240

GR 316L)

Shell 7 from

SA 516 GR

top

60)

Shell 8 from

SA 516 GR

top

60

Shell 9 from

SA 516 GR

top

60

Shell 10 from SA 516 GR

top

60

Shell 11 from SA 516 GR

top

60

Shell 12 from SA 516 GR

top

60

Shell 13 from SA 516 GR

top

60

Shell 14 from SA 516 GR

top

60

Bottom dished SA 516 GR

end

60

38+3

31.6

42.6

22.92

44+3.5

48.5

50.3

NA

38+3

36.0

43.8

12.19

38+3

37.0

43.9

9.75

45

45.9

46.4

NA

45

45.1

47.3

NA

45

44.3

46.3

1.5

45

44.0

45.6

2.2

45

44.0

46.3

2.2

45

43.7

46.3

2.8

45

44.7

46.3

0.6

45

45.9

46.8

NA

56 (Min.

48)

55.4

59.0

NA

NA- Not Applicable.

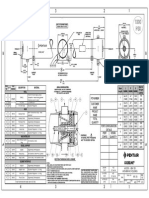

Refer attached sketch for more details

Nozzle Details

Nozzle

Details

TW 2 -1.5

TW 3-1.5

V- 2

D- 3

M1- 18

M2- 24

M3- 24

M4- 24

Material

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

-

Measured

Thickness.

SCH /

Thickness

(mm)

Min.

Max.

9.3

9.3

XXS /11.1

XXS/15.24

17+3

17+3

18

18

8.9

8.3

5.6

14.6

22.1

21.0

15.9

17.3

9.3

8.7

5.7

14.8

22.4

21.4

18.7

18.0

%

Reduction

4.3

10.7

48.6

42.0

NA

NA

11.6

3.8

Remark

Certification Engineers International Ltd.

M5- 24

M6- 24

RL- 14

RT- 4

T- 8

R- 3

F- 6

VR- 12

LG1- 2

LG2- 2

LA1- 2

LA2- 2

TC- 1.5

TI2- 1.5

TI3- 1.5

DP2- 1.5

DP3- 1.5

PA1- 1.5

PA2-1.5

UC- 2

TW1-1.5

TI1- 1.5

DP1- 1.5

IV)

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

SA 106 GR B

18

18

18

SCH160 / 13.5

SCH 160 / 23

XXS / 15.24

SCH 160 / 18.3

18

XXS / 11.1

XXS / 11.1

XXS / 11.1

XXS / 11.1

9.3

9.3

9.3

9.3

9.3

9.3

9.3

XXS / 11.1

9.3

9.3

9.3

17.0

16.1

18.4

12.4

7.9

7.8

6.3

18.1

7.7

11.2

6.9

11.2

7.9

9.3

9.1

7.7

7.5

7.7

7.0

8.9

3.7

2.3

2.7

18.1

17.6

18.7

12.9

8.0

8.0

6.9

18.3

9.6

11.4

10.0

11.4

9.3

9.6

9.4

9.0

8.0

9.8

9.8

9.0

4.0

4.5

5.7

5.5

10.5

NA

8.1

65.6

48.8

65.5

NA

30.6

NA

37.9

NA

15.0

NA

2.1

17.2

19.3

17.2

24.7

19.8

60.2

75.2

70.9

Heavy corrosion

& hole

HYDROSTATIC TEST

Hydrostatic test was not carried out by ONGC.

V)

RECOMENDATION-

Evaluating the thickness measurement for shell, column shell is

___________found to be adequate for further service. All Nozzles adequacy for

further service to be checked.

DFT of paint should be checked and should be within the acceptable range.

Platform, ladder, grating, handrail, require strengthening or wherever.

strengthening is not possible to be replaced, also to be painted to protect from

further corrosion.

Note- This is provisional inspection report, final report will be submitted later.

Anda mungkin juga menyukai

- Newnes Workshop Engineer's Pocket BookDari EverandNewnes Workshop Engineer's Pocket BookPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- 11c - Pile Cap Details - StructuralDokumen2 halaman11c - Pile Cap Details - StructuralAnthony FedericoBelum ada peringkat

- Gas-Liquid And Liquid-Liquid SeparatorsDari EverandGas-Liquid And Liquid-Liquid SeparatorsPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Materials Data for Cyclic Loading: Low-Alloy SteelsDari EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsPenilaian: 5 dari 5 bintang5/5 (2)

- Corrosion Above Ground Brochure EnglishDokumen6 halamanCorrosion Above Ground Brochure EnglishsyammohansBelum ada peringkat

- Design Guidelines for Surface Mount TechnologyDari EverandDesign Guidelines for Surface Mount TechnologyPenilaian: 5 dari 5 bintang5/5 (1)

- BbsDokumen24 halamanBbsGanesh EshwarBelum ada peringkat

- Sand Blasting Standards - Swedish SA 1, SA 2, SA 2.5, SA 3 VsDokumen12 halamanSand Blasting Standards - Swedish SA 1, SA 2, SA 2.5, SA 3 VsManivannanMudhaliarBelum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDari EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- 510 Practice Exam 5 OB QuestionsDokumen0 halaman510 Practice Exam 5 OB QuestionsGireesh Hegde100% (1)

- 03 Wire Rope Strand TerminationsDokumen20 halaman03 Wire Rope Strand Terminationsoluomo1Belum ada peringkat

- Pigging MFL or Ut TechniqueDokumen13 halamanPigging MFL or Ut Techniquesathish_iyengarBelum ada peringkat

- Avk Butterfly Valve - Installation Instruction 820Dokumen5 halamanAvk Butterfly Valve - Installation Instruction 820DjapaBelum ada peringkat

- Amine ContactorDokumen7 halamanAmine ContactorchetanmaleBelum ada peringkat

- Working Guide to Drilling Equipment and OperationsDari EverandWorking Guide to Drilling Equipment and OperationsPenilaian: 5 dari 5 bintang5/5 (9)

- Sample8 DrawingDokumen1 halamanSample8 DrawingRam Kumar NBelum ada peringkat

- Offshore QRA ChecklistDokumen2 halamanOffshore QRA ChecklistPillai Sreejith100% (5)

- Jis G3444Dokumen12 halamanJis G3444yapsguanBelum ada peringkat

- Carte Automatic TransmissionsDokumen20 halamanCarte Automatic TransmissionsGigelBelum ada peringkat

- MulcoaDokumen2 halamanMulcoaRolando Cordova100% (1)

- GAS - by BASF - 1 PDFDokumen12 halamanGAS - by BASF - 1 PDFD K SBelum ada peringkat

- Creamery Juice HACCP PlanDokumen27 halamanCreamery Juice HACCP PlanDavid ChanBelum ada peringkat

- Sample2 DrawingDokumen1 halamanSample2 DrawingganeshBelum ada peringkat

- Sample13 DrawingDokumen2 halamanSample13 DrawingSourav HaitBelum ada peringkat

- Piping ComponentDokumen19 halamanPiping Componentreach_arindomBelum ada peringkat

- API-653 Tank Inspection Sample ReportDokumen19 halamanAPI-653 Tank Inspection Sample Reportツ ツ93% (15)

- PVEclc-6847-0.1 Generic Vessel PDFDokumen61 halamanPVEclc-6847-0.1 Generic Vessel PDFKarthik AnandanBelum ada peringkat

- Sko0061283 R2Dokumen52 halamanSko0061283 R2ciwidop390Belum ada peringkat

- 198 Faf2500 Flanged y Type StrainerDokumen4 halaman198 Faf2500 Flanged y Type Strainerinfo8176Belum ada peringkat

- Technical Information Series BVMM General Description: Ball ValvesDokumen6 halamanTechnical Information Series BVMM General Description: Ball ValvesAliArababadiBelum ada peringkat

- Flange Details & DrawingsDokumen338 halamanFlange Details & DrawingsshazanBelum ada peringkat

- 5-1 Gauge BlockDokumen21 halaman5-1 Gauge BlockJaisapmm SapBelum ada peringkat

- Example Vessel Re RatingDokumen9 halamanExample Vessel Re RatingRBKUMARBelum ada peringkat

- Gate Valve CataogueDokumen4 halamanGate Valve CataogueAditya B. RyantoBelum ada peringkat

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDokumen2 halamanButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsBelum ada peringkat

- Flat Wall and Cylindrical Tanks - Design SummaryDokumen8 halamanFlat Wall and Cylindrical Tanks - Design SummarychaitanyaBelum ada peringkat

- rc33026 D12-UscDokumen7 halamanrc33026 D12-Usceww08Belum ada peringkat

- Ceramic Membrane Technical DirectionsDokumen7 halamanCeramic Membrane Technical DirectionsSterlitech100% (1)

- Tico Pipe GripsDokumen4 halamanTico Pipe GripsBilel MarkosBelum ada peringkat

- Pipes & FittingsDokumen36 halamanPipes & Fittingsmajmor-1Belum ada peringkat

- Valves Bb-EDokumen4 halamanValves Bb-EMindrutauCosminBelum ada peringkat

- Spiral Wound Gasket CatalogDokumen30 halamanSpiral Wound Gasket Catalogmayur_lanjewarBelum ada peringkat

- Screen Sand ControlDokumen20 halamanScreen Sand ControlsaptagunungBelum ada peringkat

- Enhance Draw Gear and CuplingDokumen8 halamanEnhance Draw Gear and Cuplinganunay kumarBelum ada peringkat

- Mps & Itt - Spiral SteelDokumen23 halamanMps & Itt - Spiral SteelSiswo YuwonoBelum ada peringkat

- Sample2 Drawing PDFDokumen1 halamanSample2 Drawing PDFkinjalpatel12345Belum ada peringkat

- Specification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byDokumen13 halamanSpecification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreBelum ada peringkat

- Ari Checko V Pn63 - 160Dokumen8 halamanAri Checko V Pn63 - 160Josue MorenoBelum ada peringkat

- Table of ContentsDokumen131 halamanTable of ContentsNiraj PandyaBelum ada peringkat

- 2A-2AN Manual Servicio CilindroDokumen10 halaman2A-2AN Manual Servicio Cilindrohuguer1Belum ada peringkat

- 200 Series Check Valves: Features & BenefitsDokumen2 halaman200 Series Check Valves: Features & BenefitskicsnerBelum ada peringkat

- Design Calculation F 43120 A B CDokumen106 halamanDesign Calculation F 43120 A B CShrinidhilk 1999Belum ada peringkat

- CTRLDokumen57 halamanCTRLpbontyBelum ada peringkat

- Ammonia Vapoeizer (E-3101b) - BkuDokumen166 halamanAmmonia Vapoeizer (E-3101b) - BkuRAJESHWARBelum ada peringkat

- Att 2 - EdsDokumen30 halamanAtt 2 - Eds정동현Belum ada peringkat

- Needle Cages and Roller Cages: ConstructionDokumen12 halamanNeedle Cages and Roller Cages: ConstructionMohan Kumar MathrubaiBelum ada peringkat

- Wellhead Dual Cyclone DesanderDokumen2 halamanWellhead Dual Cyclone DesanderAhmed MusallamBelum ada peringkat

- Valvula Check 6000 Lbsv3xDokumen6 halamanValvula Check 6000 Lbsv3xMaik AmayaBelum ada peringkat

- T-413-B, Class 125 Bronze Check ValvesDokumen1 halamanT-413-B, Class 125 Bronze Check ValvesBalderas Rosas WilibaldoBelum ada peringkat

- With World Class Quality: GasketsDokumen12 halamanWith World Class Quality: GasketsblahblahBelum ada peringkat

- (2012) Complete IELTS Bands 5-6.5 Student's BookDokumen3 halaman(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- 40SS Series: High Pressure Stainless Steel FilterDokumen8 halaman40SS Series: High Pressure Stainless Steel FilterYair Alexis Muñoz RojasBelum ada peringkat

- Case 1Dokumen123 halamanCase 1gauravBelum ada peringkat

- GSR541 Indian RegulationDokumen20 halamanGSR541 Indian Regulationsathish_iyengar100% (1)

- (D (Pension Policy) DESW MoD PDFDokumen3 halaman(D (Pension Policy) DESW MoD PDFsathish_iyengarBelum ada peringkat

- Film Shooting PolicyDokumen13 halamanFilm Shooting Policysathish_iyengarBelum ada peringkat

- Training CalendarDokumen2 halamanTraining Calendarsathish_iyengarBelum ada peringkat

- Analysis of Incidents Reported To PNGRB From July 2013 To Dec 2014Dokumen14 halamanAnalysis of Incidents Reported To PNGRB From July 2013 To Dec 2014sathish_iyengarBelum ada peringkat

- Apply As Paint... BUT Zinga Is Not PaintDokumen4 halamanApply As Paint... BUT Zinga Is Not Paintsathish_iyengarBelum ada peringkat

- SMPV Draft Notification 2015 EnglishDokumen66 halamanSMPV Draft Notification 2015 Englishsathish_iyengarBelum ada peringkat

- Apply As Paint... BUT Zinga Is Not PaintDokumen4 halamanApply As Paint... BUT Zinga Is Not Paintsathish_iyengarBelum ada peringkat

- CERC Draft Grid CodeDokumen72 halamanCERC Draft Grid Codesathish_iyengarBelum ada peringkat

- AIA ChecklistDokumen10 halamanAIA Checklistsathish_iyengarBelum ada peringkat

- (D (Pension Policy) DESW MoD PDFDokumen3 halaman(D (Pension Policy) DESW MoD PDFsathish_iyengarBelum ada peringkat

- 1 Cover (Jasidih-9538)Dokumen1 halaman1 Cover (Jasidih-9538)sathish_iyengarBelum ada peringkat

- 01Dokumen2 halaman01sathish_iyengarBelum ada peringkat

- Hazardous Chemicals RulesDokumen58 halamanHazardous Chemicals RulessyamiocBelum ada peringkat

- Pyrolysis of Rice Husk in A Fixed Bed ReactorDokumen5 halamanPyrolysis of Rice Husk in A Fixed Bed Reactorsathish_iyengarBelum ada peringkat

- Analysis of Incidents Reported To PNGRB From July 2013 To Dec 2014Dokumen14 halamanAnalysis of Incidents Reported To PNGRB From July 2013 To Dec 2014sathish_iyengarBelum ada peringkat

- 2002 Aberdeen 7 BellerDokumen13 halaman2002 Aberdeen 7 Bellerplatipus_85Belum ada peringkat

- Corrosion Mitigation Oilfield Water Lines 2009Dokumen28 halamanCorrosion Mitigation Oilfield Water Lines 2009sulphideBelum ada peringkat

- Design Consideration of Pyrolysis Reactor For Production of Bio-OilDokumen3 halamanDesign Consideration of Pyrolysis Reactor For Production of Bio-OilseventhsensegroupBelum ada peringkat

- Fire Protection MANUALDokumen81 halamanFire Protection MANUALNizar MohamedBelum ada peringkat

- 07 - Linepipe FabricationDokumen21 halaman07 - Linepipe FabricationMetwally NaserBelum ada peringkat

- OREDA2002Dokumen835 halamanOREDA2002Carlos Sánchez Armas100% (1)

- 4509 Tata Santorini e BrochureDokumen19 halaman4509 Tata Santorini e Brochuresathish_iyengarBelum ada peringkat

- 01 - Course IntroductionDokumen25 halaman01 - Course Introductionsathish_iyengarBelum ada peringkat

- AIA ChecklistDokumen10 halamanAIA Checklistsathish_iyengarBelum ada peringkat

- Fire Protection MANUALDokumen81 halamanFire Protection MANUALNizar MohamedBelum ada peringkat

- Hazardous Chemicals RulesDokumen58 halamanHazardous Chemicals RulessyamiocBelum ada peringkat

- 262 Isrse05 Pipeline FinalDokumen6 halaman262 Isrse05 Pipeline Finalsathish_iyengarBelum ada peringkat

- 2011 08 Sprayer MevaTrenn GBDokumen2 halaman2011 08 Sprayer MevaTrenn GBmma87Belum ada peringkat

- Electrical HeatingDokumen66 halamanElectrical HeatingRamakrishna RagamBelum ada peringkat

- Saw SoldaduraDokumen17 halamanSaw SoldaduraAnselmo C. RamirezBelum ada peringkat

- DEVISE - Industrial HIGH-RATE - Brochure - r1Dokumen2 halamanDEVISE - Industrial HIGH-RATE - Brochure - r1mesratiBelum ada peringkat

- Type of Earthing SystemDokumen6 halamanType of Earthing SystemMokr AchourBelum ada peringkat

- Motor+Running Lighting+CapacitorsDokumen28 halamanMotor+Running Lighting+Capacitorssokol_poleceBelum ada peringkat

- First Monthly Test in TVLDokumen2 halamanFirst Monthly Test in TVLEpoyIrish BongaisBelum ada peringkat

- Difference Between Static Relays and Electromagnetic RelaysDokumen2 halamanDifference Between Static Relays and Electromagnetic Relayskriitka86% (7)

- Ko Large Bore PistonsDokumen0 halamanKo Large Bore PistonsvshalimovBelum ada peringkat

- Sulphur and Its CompoundsDokumen3 halamanSulphur and Its CompoundsvinayncskphbBelum ada peringkat

- Michael Faraday - On The Liquefaction of GasesDokumen111 halamanMichael Faraday - On The Liquefaction of GasesSubhojit AdhikaryBelum ada peringkat

- Productivity Improvement Through Lean ManufacturingDokumen30 halamanProductivity Improvement Through Lean ManufacturingmanikandaprabuBelum ada peringkat

- Crane & Grab PMSDokumen8 halamanCrane & Grab PMSSukhvinder SinghBelum ada peringkat

- Module SEPAM GeneralitiesDokumen34 halamanModule SEPAM Generalitiesmagrinraphael100% (1)

- Aliplast Katalog enDokumen140 halamanAliplast Katalog enJelena GraovčevićBelum ada peringkat

- EBH341U ManualDokumen96 halamanEBH341U ManualRoberto Samper RamirezBelum ada peringkat

- IS 3513 (Part-3) 1989Dokumen15 halamanIS 3513 (Part-3) 1989Asian Test EquipmentsBelum ada peringkat

- MasterSeal Traffic 1330Dokumen3 halamanMasterSeal Traffic 1330Jonathan Wardrop100% (1)

- Catalogue FX03 enDokumen2 halamanCatalogue FX03 enonur_guzel6403100% (1)

- Iglidur X - The High-Tech Problem SolverDokumen12 halamanIglidur X - The High-Tech Problem Solvergoooga299Belum ada peringkat

- IPR Meeting Commingling Project - Gate 1: Business Case PresentationDokumen18 halamanIPR Meeting Commingling Project - Gate 1: Business Case PresentationAnthony Hbk JerichoBelum ada peringkat

- CALOR EMAG Bag.1 PDFDokumen10 halamanCALOR EMAG Bag.1 PDFAditya AgasiBelum ada peringkat

- Bearing Design CalculationsDokumen42 halamanBearing Design Calculationsarunurs1100% (1)

- TDS005-Grade 2 and ASTM A307 BoltingDokumen2 halamanTDS005-Grade 2 and ASTM A307 BoltingKrish DoodnauthBelum ada peringkat