Acid Concentration

Diunggah oleh

Nguyễn Khánh HòaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Acid Concentration

Diunggah oleh

Nguyễn Khánh HòaHak Cipta:

Format Tersedia

ACID CONCENTRATION

AND MORE

P155e.0

DDPS has a unique combination of products and

competences. Specialised and experienced chemical

engineers work on all process-relevant questions from

the customer enquiry, through internal planning and

consultation up to commissioning of the plant on

customer's site.

From a wide experience with corrosion resistant

materials, DDPS is not only capable in designing

and manufacturing a wide range of key

process equipment, but provides also inhouse process know-how. We offer:

BASIC ENGINEERING

- Mass and energy balances

- Trial Experiments in the QVF pilot plant facility

- Process flow diagram (PFD)

- Preliminary layout of the plant

TEST FACILITY

- apparatus and pump specification

Individual process steps can be tested in the test facility if it is

not possible to fall back on DDPS know-how for new products

or processes. Therefor DDPS has a filter/drying test facility at

Rosenmund site and one for chemical engineering at QVF in

Mainz.

The customer test facility is used to develop company-own

components and processes as well as for testing and

optimising customer-specific tasks. Also the production of

small amounts of samples is possible.

DETAIL ENGINEERING

- P&ID

- General arrangement drawing

- Isometric drawing

- Manufacturing drawings

- Valve specification

- E&I Specification

PROCUREMENT

- Enquiry

NOx from nitration

NOx-gas

- Award

- Project control

NOx-gas

NASO

D5

P4

C2

H6

- Acceptance

CW

H7

CW

H5

purified

exhaust air

H3

CW

C3

C1

CONSTRUCTION

additional air

H10

D1

CW

H12

P31

demin.

water

D4

- Construction management

bleaching air

C30

C4

CW

- Scheduling

- Interface management

- Troubleshooting

Pr

HD

H11

diluted acid

H4

HD

H2SO4 make up

CW

H2SO4 approx. 89 wt.-%

P1

D2

H2SO4 approx. 74 wt.-%

COMMISSIONING

- Loop check

Pr

P3

D3

condensate

- Acceptance coordination (PED)

H9

K30

D30

H30

P2

P30

Nitric Acid approx. 50 wt.-%

- Test run with water

- Commissioning

- Performance test

Client QVF

nitric acid approx. 99 wt.-%

condensate

MAIN FOCUS ACID CONCENTRATION

Mineral acids are very important in chemical procedures. Not

only as a reaction participant and catalyst, but also as an aid,

as in the case of sulfuric acid for drying gasses or during

extractive distillation, but also as a cleaning agent as used in

the electronic industry.

Through our experience with corrosion-resistant materials, we

have process know-how in mineral acid handling and offer you

in part our own processes, such as for example the energysaving concentration of nitric acids (USA 10/296,297).

By the combination of borosilicate glass and glass-lined steel

you get most of the key process equipment from one source.

We offer our know-how in:

PRODUCT RECOVERY AND PRODUCT

PURIFICATION

WASTE WATER TREATMENT

- Solvent recovery by evaporation, distillation and

rectification like MDC, NMP, DMF, alcohols, Cleaning

Solvent, etc.

- Stripping of partly miscible components (toluene,

chloroform, MDC etc.)

- Rectification of binary and multi-component mixtures (e.g.

epichlorhydrin)

- Extraction of high boiling impurities without recovery

- Production of absolute alcohol by extractive or azeotropic

distillation

- Recovery of organics by solvent extraction: phenol,

pyridine, DMF, NMP

- Recovery of metal salts and acids by solvent extraction:

acetic acid, thioglycolic acid; Ferric chloride, ammonium

molybdate

- Stripping of ammonia

- Multiple-effect evaporation of waste water with or without

solvent recovery (e.g. NMP, DMF, phenol

EXHAUST GAS PURIFICATION

- Drying of SO2 or Cl2 using sulphuric acid

- Absorption of HCl, HBr, SO3, and Cl2, Br2, SO2

- Combined absorption of HCl and SO2

- Dehydration of organics (amines, THF) by caustic packed

bed adsorption

- NOx-Absorption

- Purification of natural extracts (e.g. essential oils)

- Absorption and recovery of volatile organic components

VOC

- Absorption of ethylene oxide or ammonia

- Solvent Condensation Unit

RECOVERY, CONCENTRATION AND

PURIFICATION OF MINERAL ACIDS

- Sulphuric Acid Dilution

- Sulphuric Acid Concentration

- Nitric Acid Concentration

- Denitration and recovery of mixed acids from nitration

plants

- Hydrochloric acid recovery

- Concentration of HCl by extractive distillation or two

pressure process

- Purification of spent acids from etching processes

- High purified (electronic grade) acids: HCl, HNO3, H2SO4

REACTION WITH HALOGENS / HCL

- Bromine recovery from sea water

- Iodine Recovery

- NaOCl Production

- H2S Gas Production

QVF ENGINEERING GMBH

Post box 33 69

D-55023 Mainz

Hattenbergstrae 36

D-55122 Mainz

Phone.: (+49) 0 61 31/ 97 04-0

Fax: (+49) 0 61 31/ 97 04-500

mail@qvf.de

www.qvf.com

04.06. P155e.0. subject to change

- Debromination/ bromine recovery from salt solutions

Anda mungkin juga menyukai

- ZEOCHEM Ethanol BrochureDokumen8 halamanZEOCHEM Ethanol BrochureNguyễn Khánh HòaBelum ada peringkat

- DGS Friction StayDokumen36 halamanDGS Friction StayNguyễn Khánh HòaBelum ada peringkat

- Widegap Heat ExchangersDokumen6 halamanWidegap Heat ExchangersNguyễn Khánh HòaBelum ada peringkat

- Australia Active Dec 200lDokumen152 halamanAustralia Active Dec 200lNguyễn Khánh HòaBelum ada peringkat

- A Solution Ahead: de Dietrich® Optimix® ReactorDokumen3 halamanA Solution Ahead: de Dietrich® Optimix® ReactorNguyễn Khánh HòaBelum ada peringkat

- Gea Phe Sugar enDokumen12 halamanGea Phe Sugar enNguyễn Khánh HòaBelum ada peringkat

- Concitherm Plate Evaporators: ApplicationDokumen2 halamanConcitherm Plate Evaporators: ApplicationNguyễn Khánh HòaBelum ada peringkat

- Sales T&CDokumen5 halamanSales T&CNguyễn Khánh HòaBelum ada peringkat

- Sipart PS2 Siemens PositionerDokumen28 halamanSipart PS2 Siemens PositionerNguyễn Khánh HòaBelum ada peringkat

- Noi Dung Chuong TrinhDokumen2 halamanNoi Dung Chuong TrinhNguyễn Khánh HòaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- WSP Sor Volume - IDokumen53 halamanWSP Sor Volume - IAbhijeet VardheBelum ada peringkat

- WEF Technology and Innovation The Next Economic Growth Engine PDFDokumen33 halamanWEF Technology and Innovation The Next Economic Growth Engine PDFPiroch RudolfBelum ada peringkat

- Rahul ResumeDokumen7 halamanRahul ResumeMohit GautamBelum ada peringkat

- Presentation On Back OfficeDokumen56 halamanPresentation On Back OfficeARIF PATEL100% (1)

- CHAITANYA KAMBOJ - ProductDokumen2 halamanCHAITANYA KAMBOJ - Productchaitanya kambojBelum ada peringkat

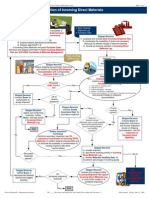

- Receiving and Inspection of Incoming Direct MaterialsDokumen1 halamanReceiving and Inspection of Incoming Direct MaterialssigmasundarBelum ada peringkat

- Public Procuement Rule of NepalDokumen147 halamanPublic Procuement Rule of NepalShreeBelum ada peringkat

- Catálogo Safety (Junho 2010)Dokumen852 halamanCatálogo Safety (Junho 2010)Robison Raniere MartinsBelum ada peringkat

- ConyDokumen5 halamanConykripeshdubeyBelum ada peringkat

- American Aviation Historical SocietyDokumen16 halamanAmerican Aviation Historical SocietyCAP History LibraryBelum ada peringkat

- Cast StudyDokumen5 halamanCast StudyFrancisco Rodriguez0% (3)

- 5s - Master PlanDokumen1 halaman5s - Master PlanDayal Weerasooriya100% (4)

- Pyrotech Electronics Private Limited - Manufacturer From Udaipur, Rajas Than, IndiaDokumen2 halamanPyrotech Electronics Private Limited - Manufacturer From Udaipur, Rajas Than, IndiaAdil AhmedBelum ada peringkat

- PSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressDokumen6 halamanPSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressChung LeBelum ada peringkat

- Vatluru Auction EstimateDokumen15 halamanVatluru Auction EstimateD.V.Srinivasa RaoBelum ada peringkat

- Fabco Plastic Factory Saudi ArabiaDokumen1 halamanFabco Plastic Factory Saudi Arabiaosto72Belum ada peringkat

- Opm IV ModuleDokumen18 halamanOpm IV ModuleSharma VishnuBelum ada peringkat

- Resume of PL SQL Developing PDFDokumen4 halamanResume of PL SQL Developing PDFVipin SinghBelum ada peringkat

- Germanisher LloydsDokumen390 halamanGermanisher LloydsSting TejadaBelum ada peringkat

- FRM Selatan SeliaDokumen203 halamanFRM Selatan SeliasssBelum ada peringkat

- C 099EB I Gard ManualDokumen18 halamanC 099EB I Gard ManualSejahtra AbadiBelum ada peringkat

- Jane Clark Evolution ITIL Service Management Presentation Sept07Dokumen11 halamanJane Clark Evolution ITIL Service Management Presentation Sept07Rohan SatputeBelum ada peringkat

- Case Study ABCDokumen17 halamanCase Study ABCIza Adnan100% (1)

- Ijmhrm: International Journal of Marketing and Human Resource Management (Ijmhrm)Dokumen9 halamanIjmhrm: International Journal of Marketing and Human Resource Management (Ijmhrm)IAEME PublicationBelum ada peringkat

- 6284 5 00 PDFDokumen9 halaman6284 5 00 PDFnpsBelum ada peringkat

- Turbocharger CatalogDokumen16 halamanTurbocharger CatalogAdi PoianaBelum ada peringkat

- Atmatec - Fibreglass Products For Drainage Systems PDFDokumen44 halamanAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalBelum ada peringkat

- Mining Sector Compliance RegistryDokumen2 halamanMining Sector Compliance RegistryhonchoabhiBelum ada peringkat

- How To Create Parallel Coordinates in ExcelDokumen12 halamanHow To Create Parallel Coordinates in ExcelPutra PutraBelum ada peringkat