FLSmidth TST JawCrusher Brochure

Diunggah oleh

Franz AnggiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

FLSmidth TST JawCrusher Brochure

Diunggah oleh

Franz AnggiHak Cipta:

Format Tersedia

TST jaw crusher

Jaw crushers

FLSmidths history with the design and

manufacture of jaw crushers dates

back more than 100 years with the

Traylor and Fuller-Traylor double

toggle jaw crushers. These crushers

have continuously withstood the

harshest duties found in the world.

With constant and continual improvements to the designs, the TDT has

been solidified as a preferred crusher

throughout the industry. FLSmidth is

proud to add their new line of single

toggle jaw crushers, the TST, to the

heritage the double toggle crushers

established.

The TST jaw crushers are engineered

for trouble-free operation, characterized by safe and easy serviceability.

The most modern analysis techniques

and features available to date ensure

a strong and reliable crusher design.

In order to handle the increasingly

hard ores and remote locations

common in the industry today, the

TST is equipped with an efficient

crushing motion, modular frame and

a simple, low maintenance design.

Design

An often overlooked, but very

important, characteristic of the single

toggle jaw crusher is its kinematic

design. The chamber design enables

the TST to efficiently crush hard

material via a combination of shaft

eccentricity, toggle angle and

chamber layout. While the chamber is

designed with a very steep nip angle,

all other connected components are

designed to enable the units to easily

crush the hardest rock at high

production rates, while maintaining

the necessary product size.

Active feed opening can grip

material at the inlet

Swing jaw protection plate can

handle crushing the occasional

very oversized feed material

The active feed opening of the jaw crusher chamber ensures that any occasional oversize material will be gripped

and quickly pulled into the crusher. Once the jaw plates pull in the material, its steep nip angle ensures continual grip

and efficient crushing of even the hardest material.

Features

Add-ons

Drive motor

Automatic grease lube

Intergral motor mount

Hydraulic setting adjustment

Drive guard

PLC control system

Instrumentation

Vibrating grizzly feeder and

chutework

Mobile and stationary installations

Since a crusher is only as strong as the

components that support it, FLSmidth

concentrated on designing a very

strong base for all other components.

The design is based on a modular-type

frame that is bolted and pinned, and

capable of heavy duty operation.

FLSmidths exclusive design is stronger

and more robust than other traditional

and modular designs.

The frame and swing jaw crushers

feature double-roll spherical roller

bearings to allow for any misalignment

that may occur. All overloads are

absorbed by the generous bearing size

and safety factors that FLSmidth

utilizes in each crusher model. The

bearings are supported by a large

diameter forged alloy steel, generous

radii and no threads to ensure that all

stress risers are eliminated. Bearings

are lubricated by grease and protected

from dirt by a multi-pass labyrinth.

Instead of a breakable toggle plate,

FLSmidths design utilizes a tramp relief

shear pin (FLSmidths safety pin) which,

when un-crushable material is

encountered, shears and protects the

crusher. The safety pin works by

removing the flywheels kinetic energy

from the crusher shaft, thus preventing

overstressing the crusher.

4

3

2

1.

Abrasion resistant cheek plates are easier to

4.

replace

2.

FLSmidths bolted and pinned frame assembly

5.

comes together for a very strong and robust

design

3.

Rolling toggle design and replaceable abrasion

Spherical roller bearings use a multi-pass

labyrinth and grease to minimize dust and dirt

Hydraulic cylinder wedge adjustment takes up

ingress.

wear seen on the jaw plates

6.

7.

resitant toggle seats provide long life

Safety shear pin provides faster and safer

Swing jaw & front frame employ replaceable

maintenance than a typical breakable toggle

jaw plate holders in the event of wear.

plate

Dimensions

TST1100

TST1200

TST1400

TST1550

TST1900

Opening

850 x 1100

920 x 1200

1160 x 1400

1280 x 1550

1600 x 1900

mm / (in)

(33 x 43)

(36 x 47)

(46 x 55)

(50 x 61)

(63 x 75)

150kw

185kw

225kw

265kw

375kw

[200hp]

[250hp]

[300hp]

[350hp]

[500hp]

Height [h]

2928mm

3235mm

3755mm

4082mm

5400mm

mm / (in)

(115)

(127)

(148)

(161)

(213)

Length [l]

2815mm

3100mm

3400mm

4330mm

5170mm

mm / (in)

(111)

(122)

(134)

(170)

(204)

Width [w]

2425mm

2655mm

2965mm

3187mm

4170mm

mm / (in)

(95)

(105)

(117)

(125)

(164)

Crusher wt.

26,250kg

34,750kg

52,900kg

75,600kg

115,000kg

Kg / (lb)

(58,000)

(76,500)

(116,500)

(166,750)

(253,500)

Motor power

Capacities

Capacity

css

mtph / (stph)

TST1100

TST1200

TST1400

TST1550

TST1900

75mm

180

(3.0in)

(198)

-

100mm

224

270

(4.0in)

(246)

(297)

125mm

269

322

388

(5.0in)

(296)

(354)

(427)

150mm

314

375

450

513

656

(6.0in)

(345)

(413)

(495)

(564)

(622)

175mm

358

427

512

584

744

(7.0in)

(394)

(470)

(563)

(642)

(818)

200mm

403

479

574

654

833

(8.0in)

(443)

(527)

(631)

(719)

(916)

225mm

(9.0in)

250mm

530

636

725

921

(583)

(700)

(798)

(1013)

(10.0in)

275mm

698

795

1010

(768)

(875)

(1111)

(11.0in)

300mm

(12.0in)

865

1098

(950)

(1208)

935

1185

(1029)

(1303)

warranties (express or implied), and information and data contained in this brochure are for general reference only and may change at any time.

Mineral Processing

Technology Center

FLSmidth Salt Lake City, Inc.

7158 S. FLSmidth Dr.

Midvale, UT 84047-5559

USA

Tel: +1 801 871 7000

Fax: +1 801 871 7001

E-mail: info.slc@flsmidth.com

www.flsmidth.com

Rev. 5/3/13 al-us

Copyright 2013 FLSmidth A/S. ALL RIGHTS RESERVED. FLSmidth is a (registered) trademark of FLSmidth A/S. This brochure makes no offers, representations or

Anda mungkin juga menyukai

- JC Series Jaw Crusher PDFDokumen8 halamanJC Series Jaw Crusher PDFgarrybieber100% (1)

- TST JawCrusherDokumen8 halamanTST JawCrusherHãy Tin Anh100% (1)

- JW Series Jaw Crushers: Terex Minerals Processing SystemsDokumen16 halamanJW Series Jaw Crushers: Terex Minerals Processing SystemsKarin Anderson100% (1)

- Jaw BrochureDokumen12 halamanJaw Brochuremarcosandia1974Belum ada peringkat

- Excel Gears and Pinions For Cone CrushersDokumen2 halamanExcel Gears and Pinions For Cone CrushersJohnDim100% (2)

- TRIO Feeders BrochureDokumen8 halamanTRIO Feeders BrochureZiggy GregoryBelum ada peringkat

- Jaw CrusherDokumen4 halamanJaw CrusherRebekah HaleBelum ada peringkat

- Washing and Classifying Brochure EnglishDokumen24 halamanWashing and Classifying Brochure EnglishMohammed Alshami GeologistBelum ada peringkat

- Jaw Crusher For Primary Crushing - Fote Heavy MachineryDokumen18 halamanJaw Crusher For Primary Crushing - Fote Heavy MachineryIvy100% (1)

- SH Series Cone CrusherDokumen48 halamanSH Series Cone CrusherShanhu Group100% (1)

- Rocksledger: Primary Jaw CrushersDokumen2 halamanRocksledger: Primary Jaw CrushersMechanical department100% (2)

- TRIO TC Cones DiamondDokumen12 halamanTRIO TC Cones Diamondcarrialdi100% (1)

- Vibrating Pan FeedersDokumen3 halamanVibrating Pan Feedersrnt1212100% (1)

- En Hammer CrushersDokumen3 halamanEn Hammer CrusherspeymanBelum ada peringkat

- XL2000 Technical SpecificationDokumen3 halamanXL2000 Technical SpecificationLeonardo SilvaBelum ada peringkat

- Gyratory Mill: EccentricDokumen10 halamanGyratory Mill: EccentricAbhishek Kumar100% (1)

- Wet Iron Ore Crushing with Barmac VSIDokumen2 halamanWet Iron Ore Crushing with Barmac VSIrajeevup2004Belum ada peringkat

- Mobile Jaw Crusher PDFDokumen7 halamanMobile Jaw Crusher PDFNguyễn LinhBelum ada peringkat

- Semi-Mobile Gyratory Crushing PlantsDokumen23 halamanSemi-Mobile Gyratory Crushing PlantsJosé Andrés Toro BelmarBelum ada peringkat

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetDokumen2 halamanWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- K 400 + Liner ConfigurationDokumen1 halamanK 400 + Liner ConfigurationBlake Cooley AndersonBelum ada peringkat

- Large Bevel GearsDokumen4 halamanLarge Bevel GearsJitu InduBelum ada peringkat

- Flowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBDokumen1 halamanFlowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBMukesh BharatBelum ada peringkat

- The MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDokumen1 halamanThe MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDiegoAlvarezHuguezBelum ada peringkat

- Excel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersDokumen2 halamanExcel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersCarlos Andres Maldonado ArdilesBelum ada peringkat

- TV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsDokumen8 halamanTV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsShawn ChenBelum ada peringkat

- Poliuretano - Mallas WS85Dokumen32 halamanPoliuretano - Mallas WS85Oscar C SotomayorBelum ada peringkat

- TV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsDokumen4 halamanTV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsJose grievis Giron pericheBelum ada peringkat

- Rubber Mill LinersDokumen8 halamanRubber Mill LinersDiegoAlvarezHuguezBelum ada peringkat

- EFM Sentinel Manual-SO#106134 (Symons 7 SH XHD, MI721)Dokumen29 halamanEFM Sentinel Manual-SO#106134 (Symons 7 SH XHD, MI721)Alejandro HernandezBelum ada peringkat

- Cone Crusher Metso Nordberg gp220 en 2816Dokumen3 halamanCone Crusher Metso Nordberg gp220 en 2816Binu VarkeyBelum ada peringkat

- Double Roll CrusherDokumen3 halamanDouble Roll CrusherjtpmlBelum ada peringkat

- PRESENTACIONDokumen20 halamanPRESENTACIONJorge VillalobosBelum ada peringkat

- Oil Temperatures Pressures Inspections Crusher PerformanceDokumen1 halamanOil Temperatures Pressures Inspections Crusher Performancesinter-musicBelum ada peringkat

- Guangxi Crukings Machinery Equipment Co., Ltd. ProfileDokumen26 halamanGuangxi Crukings Machinery Equipment Co., Ltd. ProfileJake HuangBelum ada peringkat

- Pans PDFDokumen8 halamanPans PDFJorge Prado DiazBelum ada peringkat

- QMS - General BrochureDokumen6 halamanQMS - General BrochureArpit VermaBelum ada peringkat

- Brochure Nordberg HP Series 4236-10-22 en AggDokumen20 halamanBrochure Nordberg HP Series 4236-10-22 en Aggkev YBelum ada peringkat

- HEPICS Whitepaper Improved MP1000 Liner PerformanceDokumen3 halamanHEPICS Whitepaper Improved MP1000 Liner PerformanceYousef AlipourBelum ada peringkat

- Bearings For Cone Crushers: Serving Industries WorldwideDokumen4 halamanBearings For Cone Crushers: Serving Industries WorldwideJgonzalez GonzalezBelum ada peringkat

- TBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualDokumen44 halamanTBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualIruna HupaloBelum ada peringkat

- ECT Symons 7s For SaleDokumen2 halamanECT Symons 7s For SaleOrlando MelipillanBelum ada peringkat

- Arw314124523secunda RioDokumen1 halamanArw314124523secunda Rioalonsooo_Belum ada peringkat

- LMM PXH Gyratory Crushers for High Capacity Primary CrushingDokumen7 halamanLMM PXH Gyratory Crushers for High Capacity Primary CrushinglandagoBelum ada peringkat

- Sravya Infracon Supplies Crusher Spare Parts For MetsoDokumen2 halamanSravya Infracon Supplies Crusher Spare Parts For MetsoajithBelum ada peringkat

- Project Case - CT4254 JAW PLATESDokumen4 halamanProject Case - CT4254 JAW PLATESNicole WuBelum ada peringkat

- Hard Rock Crushing PlantDokumen4 halamanHard Rock Crushing PlantErikBelum ada peringkat

- HP300 GA and Dimensional Drawings MM1472950 - 0Dokumen10 halamanHP300 GA and Dimensional Drawings MM1472950 - 0Thiago PaivaBelum ada peringkat

- Catalogo Giratorio MetsoDokumen5 halamanCatalogo Giratorio MetsoPaulaBelum ada peringkat

- Tough Crushing: Smooth OperatingDokumen16 halamanTough Crushing: Smooth OperatingManuel GagnoBelum ada peringkat

- Nawapactor VsiDokumen4 halamanNawapactor Vsichand_yel100% (2)

- Gundlach Roll Crushers BrochureDokumen2 halamanGundlach Roll Crushers Brochurerajeevup2004Belum ada peringkat

- Lokotrack Mobile Crushing PlantDokumen6 halamanLokotrack Mobile Crushing PlantAleksandar GogovBelum ada peringkat

- Mobile granite crushing plant 150t/hDokumen4 halamanMobile granite crushing plant 150t/hSolomon MiBelum ada peringkat

- Bulletin 1047Dokumen2 halamanBulletin 1047Cesar Casachagua DavilaBelum ada peringkat

- Screen Media FL Smith CatalogDokumen24 halamanScreen Media FL Smith CatalogDAVID VENEGASBelum ada peringkat

- 8r77r-Cybas I ConeDokumen6 halaman8r77r-Cybas I Coneturkishdjem100% (1)

- Telsmith Product OverviewDokumen12 halamanTelsmith Product OverviewRicardoBelum ada peringkat

- CrushingSystems - Brochure2014 FL SMITHDokumen20 halamanCrushingSystems - Brochure2014 FL SMITHMauro Daniel100% (1)

- Single Roll CrushersDokumen8 halamanSingle Roll CrushersRinaldi SaputraBelum ada peringkat

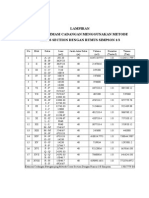

- Lampiran Hasil Estimasi Cadangan Menggunakan Metode Cross Section Dengan Rumus Simpson 1/3Dokumen1 halamanLampiran Hasil Estimasi Cadangan Menggunakan Metode Cross Section Dengan Rumus Simpson 1/3Franz AnggiBelum ada peringkat

- ELCOM Szallitoszalagos Konvejor Katalogus ENGDokumen72 halamanELCOM Szallitoszalagos Konvejor Katalogus ENGFranz AnggiBelum ada peringkat

- MergedjkljkljkDokumen2 halamanMergedjkljkljkFranz AnggiBelum ada peringkat

- Sejarah 223Dokumen33 halamanSejarah 223Franz AnggiBelum ada peringkat

- Data Lebar JalanDokumen2 halamanData Lebar JalanFranz AnggiBelum ada peringkat

- Go 2311321135Dokumen4 halamanGo 2311321135Nelly Ad-apBelum ada peringkat

- Deepak Project On Jaw CrusherDokumen95 halamanDeepak Project On Jaw Crusher9777907190100% (7)

- Jaw Crusher Review Kinematic Dynamic AnalysisDokumen4 halamanJaw Crusher Review Kinematic Dynamic AnalysisRagab AbulmagdBelum ada peringkat

- Parameter: Main Technical ParametersDokumen3 halamanParameter: Main Technical ParametersFranz AnggiBelum ada peringkat

- Pencemaran Air Dan Tanah Di Kawasan Pertambangan Batubara Di PT Berau Coal Kalimantan TimurDokumen10 halamanPencemaran Air Dan Tanah Di Kawasan Pertambangan Batubara Di PT Berau Coal Kalimantan TimurTessaSuciningtyasBelum ada peringkat

- Spesifikasi AlatDokumen5 halamanSpesifikasi AlatFranz AnggiBelum ada peringkat

- Nama Perusahaan Alamat Perusahaan No Contac Keterangan: Control Sheet SponsorshipDokumen3 halamanNama Perusahaan Alamat Perusahaan No Contac Keterangan: Control Sheet SponsorshipFranz AnggiBelum ada peringkat

- Pencemaran Air Dan Tanah Di Kawasan Pertambangan Batubara Di PT Berau Coal Kalimantan TimurDokumen10 halamanPencemaran Air Dan Tanah Di Kawasan Pertambangan Batubara Di PT Berau Coal Kalimantan TimurTessaSuciningtyasBelum ada peringkat

- Cushman Wakefield - PDS India Capability Profile.Dokumen37 halamanCushman Wakefield - PDS India Capability Profile.nafis haiderBelum ada peringkat

- Break Even AnalysisDokumen4 halamanBreak Even Analysiscyper zoonBelum ada peringkat

- Prenatal and Post Natal Growth of MandibleDokumen5 halamanPrenatal and Post Natal Growth of MandiblehabeebBelum ada peringkat

- всё необходимое для изучения английского языкаDokumen9 halamanвсё необходимое для изучения английского языкаNikita Chernyak100% (1)

- Inorganica Chimica Acta: Research PaperDokumen14 halamanInorganica Chimica Acta: Research PaperRuan ReisBelum ada peringkat

- Federal Complaint of Molotov Cocktail Construction at Austin ProtestDokumen8 halamanFederal Complaint of Molotov Cocktail Construction at Austin ProtestAnonymous Pb39klJBelum ada peringkat

- Reg FeeDokumen1 halamanReg FeeSikder MizanBelum ada peringkat

- FS2004 - The Aircraft - CFG FileDokumen5 halamanFS2004 - The Aircraft - CFG FiletumbBelum ada peringkat

- Insider Threat ManagementDokumen48 halamanInsider Threat ManagementPatricia LehmanBelum ada peringkat

- 2-Port Antenna Frequency Range Dual Polarization HPBW Adjust. Electr. DTDokumen5 halaman2-Port Antenna Frequency Range Dual Polarization HPBW Adjust. Electr. DTIbrahim JaberBelum ada peringkat

- 15 - 5 - IoT Based Smart HomeDokumen6 halaman15 - 5 - IoT Based Smart HomeBhaskar Rao PBelum ada peringkat

- CR Vs MarubeniDokumen15 halamanCR Vs MarubeniSudan TambiacBelum ada peringkat

- Coffee Table Book Design With Community ParticipationDokumen12 halamanCoffee Table Book Design With Community ParticipationAJHSSR JournalBelum ada peringkat

- Exp 8 - GPG - D12B - 74 PDFDokumen4 halamanExp 8 - GPG - D12B - 74 PDFPRATIKSHA WADIBHASMEBelum ada peringkat

- Case StudyDokumen2 halamanCase StudyBunga Larangan73% (11)

- IoT BASED HEALTH MONITORING SYSTEMDokumen18 halamanIoT BASED HEALTH MONITORING SYSTEMArunkumar Kuti100% (2)

- (23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion SpringsDokumen6 halaman(23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion Springsstefan.vince536Belum ada peringkat

- Preventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Dokumen21 halamanPreventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Desy Fitriani SarahBelum ada peringkat

- Good Ethics Is Good BusinessDokumen9 halamanGood Ethics Is Good BusinesssumeetpatnaikBelum ada peringkat

- Riddles For KidsDokumen15 halamanRiddles For KidsAmin Reza100% (8)

- 50 Years of Teaching PianoDokumen122 halaman50 Years of Teaching PianoMyklan100% (35)

- Top Malls in Chennai CityDokumen8 halamanTop Malls in Chennai CityNavin ChandarBelum ada peringkat

- GlastonburyDokumen4 halamanGlastonburyfatimazahrarahmani02Belum ada peringkat

- Oxford Digital Marketing Programme ProspectusDokumen12 halamanOxford Digital Marketing Programme ProspectusLeonard AbellaBelum ada peringkat

- New Education Policy 2019Dokumen55 halamanNew Education Policy 2019Aakarshanam VenturesBelum ada peringkat

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDokumen22 halamanStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasBelum ada peringkat

- ITU SURVEY ON RADIO SPECTRUM MANAGEMENT 17 01 07 Final PDFDokumen280 halamanITU SURVEY ON RADIO SPECTRUM MANAGEMENT 17 01 07 Final PDFMohamed AliBelum ada peringkat

- Evaluating Sources IB Style: Social 20ib Opvl NotesDokumen7 halamanEvaluating Sources IB Style: Social 20ib Opvl NotesRobert ZhangBelum ada peringkat

- AgentScope: A Flexible Yet Robust Multi-Agent PlatformDokumen24 halamanAgentScope: A Flexible Yet Robust Multi-Agent PlatformRijalBelum ada peringkat

- Us Virgin Island WWWWDokumen166 halamanUs Virgin Island WWWWErickvannBelum ada peringkat