Carbon Footprint As Environmental Performance Indicator For The Manufacturing Industry PDF

Diunggah oleh

Carolina De Moya MolinaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Carbon Footprint As Environmental Performance Indicator For The Manufacturing Industry PDF

Diunggah oleh

Carolina De Moya MolinaHak Cipta:

Format Tersedia

CIRP Annals - Manufacturing Technology 59 (2010) 3740

Contents lists available at ScienceDirect

CIRP Annals - Manufacturing Technology

jou rnal homep age : ht t p: // ees .e lse vi er. com/ci rp/ def a ult . asp

Carbon footprint as environmental performance indicator for the

manufacturing industry

A. Laurent, S.I. Olsen, M.Z. Hauschild (2)*

Department of Management Engineering, Technical University of Denmark (DTU), Lyngby, Denmark

A R T I C L E I N F O

A B S T R A C T

Keywords:

Manufacturing

Lifecycle

Carbon footprint

With the current focus on our climate change impacts, the embodied CO2 emission or Carbon footprint

is often used as an environmental performance indicator for our products or production activities. The

ability of carbon footprint to represent other types of impact like human toxicity, and hence the overall

environmental impact is investigated based on life cycle assessments of several materials of major

relevance to manufacturing industries. The dependence of the carbon footprint on the assumed scenarios

for generation of thermal and electrical energy in the life cycle of the materials is analyzed, and the

appropriateness of carbon footprint as an overall indicator of the environmental performance is

discussed.

2010 CIRP.

1. Background

2. Comparison procedure

In the global endeavour to meet the international commitments to reduction of greenhouse gas emissions, many

companies integrate environmental issues into their management systems, with potential effects in their entire production

chains. Several tools and metrics have been developed to

measure the environmental impact of a product in the life cycle

perspective of the whole product chain. A metric that has gained

prominence in recent times is the carbon footprint (CFP), which

quanties the climate change impact of greenhouse gas (GHG)

emissions in a life cycle perspective [1]. However, more

encompassing approaches exist, one of the most prominent

being a proper Life Cycle Assessment (LCA). Like the CFP, an LCA

focuses on a product system, comprising all the processes

related to a product or a servicefrom the cradle to the grave. In

contrast to the CFP, an LCA assesses all the environmental

impacts of the system, not just the contributions to climate

change [2]. Considering the multi-faceted nature of environmental impacts from production systems, one may contest the

ability of carbon footprint to represent the overall environmental performance of a product. To investigate the legitimacy

of CFP as indicator of environmental impacts more broadly, a

comparative analysis has been performed of CFP and life cycle

impacts on human health, from the production of a range of

metals, chemicals, plastics and textilesall materials that are

central for our manufacturing industry.

In LCA the inventory analysis quanties the elementary ows

of the product system in the form of inputs from the environment

without prior human transformations and outputs to the

environment without further human transformations. In the Life

Cycle Impact Assessment (LCIA), this information is translated via a

characterization step and aggregated to environmental impact

indicator results related to human health, natural environment

and resource depletion [3]. After the characterization, impact

category results are expressed in different metrics and can hence

not be compared across impact categories. Therefore, a normalization is performed, translating all impacts to a common unit by

calculating the magnitude of the impact indicator results

[characterization] relative to some reference information (socalled normalization references) [4]. The normalization reference

applied in this study is the annual contribution of an average

person to each impact, and the resulting common unit for all

impact categories is the Person Equivalent (PE).

The CFP typically considers the six GHGs identied in the Kyoto

Protocol, i.e. CO2, CH4, N2O, SF6, HFCs and PFCs. The normalization

reference for the CFP was calculated based on the global per capita

emission data for these GHGs in 2004 applying the latest set of

global warming potential (GWP) factors, released by the IPPC as

characterization factors [5].

Human toxic impacts (non-cancer effects) (HTI) from releases

of toxic substances to the environment were assessed using

characterization factors calculated with the USEtoxTM-model

(www.usetox.org). This model was developed as part of the

UNEP-SETACs Life Cycle Initiative and provides recommended

factors for a global assessment of human toxicity [6]. To ensure

consistency in the comparison to CFP, the normalization reference

for the HTI category was calculated for the same emission year as

for global warming, i.e. 2004.

* Corresponding author.

E-mail address: mic@ipl.dtu.dk (M.Z. Hauschild).

0007-8506/$ see front matter 2010 CIRP.

doi:10.1016/j.cirp.2010.03.008

38

A. Laurent et al. / CIRP Annals - Manufacturing Technology 59 (2010) 3740

3. Results and discussion

Both the CFP and the HTI were calculated with the LCA software

SimaProTM using the inventory data for production of materials

available in the Ecoinvent database [7], and compared after

normalization. In the comparison, the materials were divided into

four categories: metals, chemicals, plastics and textiles. Results are

shown for each category in Fig. 1.

3.1. CFP versus HTI

With some variations the HTI scores dominate the CFPs for most

of the materials shown in Fig. 1, typically with 1 order of

magnitude for plastics, textiles and paper materials and up to 2

orders of magnitude for metals and chemicals. For metals, the

relative differences vary around a factor of 10 for aluminium, steel

and nickel, 1030 for the production of solder, whereas factors of

ca. 3070 are found for the production of zinc. Copper shows more

disparate results depending on the type of production considered

(e.g. combined metal production, primary/secondary copper) with

differences varying from 5 to 70 while the inclusion of Cu in alloys

such as bronze or brass results in factors of up to 150. Overall, this

means that the CFP contributes only a minor part to the materials

full normalized environmental impact.

Nevertheless, there may well be a methodological bias in the

normalization of the CFP and HTI results as discussed in Section 4,

explaining at least part of the dominance of the HTI scores.

Whether CFP gives a small or large contribution to the total

environmental impact depends on this, and it is therefore also

of interest to decide whether the CFP results are able to predict the

human toxic impacts, i.e. whether the plotted data points show

proportionality between HTI and CFP results. This may be the case

when the two types of impacts are caused by the same activities in

the life cycle (for aluminium in Fig. 1a the production of aluminium

hydroxide), and then the CFP may serve as a good proxy of overall

environmental impact.

On the other hand, it is clear from Fig. 1, that for most of the

materials, no such proportionality is observed. For the same

material the ratio between the two impact scores may vary up to

two orders of magnitude between different data sets and then CFP

is not a good proxy of the human toxic impacts.

3.2. Inuence of energy production scenarios

A large share of the environmental impacts from the life cycle of

material production comes from the generation of thermal or

electrical energy used in the life cycle processes. Thermal energy is

generally produced by combustion of (fossil) fuels but electricity

production involves technologies of widely differing environmental impact proles ranging from renewable energy technologies and nuclear power with limited carbon footprint to coal red

power with a high CFP per produced kWh. The ratio between CFP

and HTI and hence the ability of CFP to predict overall

environmental impact may thus depend on the electricity scenario

that is used when producing the material, and this will typically

differ between countries and regions. Furthermore, a shift in

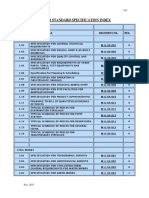

Table 1

Electricity supply source apportionment in the baseline scenario and the two

alternative scenarios.

Fig. 1. The normalized HTI scores plotted against normalized carbon footprint

scores (both in PE/kg) for a) metal production (the category Others includes,

among others, productions of lead, zinc, solder), b) chemical production (both

organics and inorganics), c) plastic production (the category Others includes

other thermoplastics, elastomers and biopolymers) and d) textile and paper

production. Each dot represents the impacts of one material viewed in a life cycle

perspective. The inserted line represents an equal magnitude for the two

normalized impact scores. Clusters located above this line represent materials

for which the normalized HTI is higher than the normalized CFP.

Hard coal

Lignite

Oil

Natural gas

Nuclear

Hydropower

Wind

Others (PV, cogen.)

a

Baseline

scenario

Scenario 1

Nat. gas

Scenario

2Wind

16%

14%

4%

16%

32%

12%

2%

1%

8%

7%

0%

28%

30%

10%

7%

3%

ca. 100%

Totals not exactly equal to 100% due to approximations and roundings.

A. Laurent et al. / CIRP Annals - Manufacturing Technology 59 (2010) 3740

energy technology is foreseeable as policy focus shifts towards

outfacing fossil fuels and GHG emissions.

To explore the importance of the technology mix applied in the

modelling for thermal and electrical energy production, two

alternative scenarios, were built and applied to three of the

materials: aluminium, copper (coupled production with nickel),

and carbon monoxide. The rst energy scenario, named nat. gas,

represents foreseeable changes in the electricity technology mix

replacing coal by natural gassee Table 1. The second scenario,

named wind, represents the immediate consequence of an

extreme shift of the present energy supply sources of a factory to

wind turbines as exclusive electricity source in order to investigate

the sensitivity of the results to more extreme (but still possible)

electricity scenarios. In both alternative scenarios, natural gas

entirely substitutes oil and coal in the production of thermal energy.

39

For all three materials both the HTIs and the CFP decrease in

both alternative scenarios, but Fig. 2 clearly identies three

patterns. The rst pattern occurs when the toxic impacts do not

stem primarily from energy production but from other processes in

the life cycle of the material (typically disposal of materials during

production). This is observed for the production of aluminium,

where the changes in the energy generation scenario has little

inuence on the HTI, even when all electricity is produced by wind

power plants (see Fig. 2a). In contrast, the CFP is strongly reduced,

and in such a case, the ratio between human toxicity and carbon

footprint results depends strongly on the choice of the energy

generation scenario.

The second pattern is observed for the case of copper

production (coupled with nickel). Here, the main cause of HTI is

emissions from the energy generation. While the change of

Fig. 2. The sensitivity of carbon footprint and human toxicity to changes in energy generation from the baseline scenario (used in Fig. 1) to one of the two alternative energy

scenarios for productions of a) aluminium, b) copper and c) carbon monoxide.

40

A. Laurent et al. / CIRP Annals - Manufacturing Technology 59 (2010) 3740

energy scenario inuences the results for both indicators, the

HTI drops off more than CFP, even when electricity is supplied

entirely by wind power plants (see Fig. 2b). This is due to the

change to use of natural gas for thermal heat production. While,

the ratio between CFP and HTI for production of 1 MJ electricity

decreases by more than half from the baseline scenario to wind,

the trend is reversed when the Nat. gas scenario is used instead

of the baseline scenario, and the HTI is reduced more than

the CFP due to very limited emissions of toxic metals in the life

cycle of natural gas. For materials where thermal energy

requirements prevail over electricity requirements, the switch

of heat source to natural gas thus causes the impacts on human

health to decrease at a higher rate than the impacts on climate

change.

The third pattern is observed when the production requires

more electricity than thermal energy, and there are no

major sources of HTI in the life cycle, apart from the use of

energy. This pattern is illustrated by the carbon monoxide example

in Fig. 2c. The shift away from oil/coal/lignite as energy carriers in

the baseline scenario results in a higher decline of impacts on

human health than of impacts on climate change, which is similar

to the second pattern illustrated in Fig. 2b. The dominance of

electricity supply over thermal energy becomes obvious when the

baseline scenario is switched to the wind scenario and CFP drops at

a higher pace than HTI, thus enlarging the gap between the two

impact categories.

The three patterns observed in Fig. 2 show the strong inuence

of the energy scenario on the ability of CFP to represent HTI. When

energy production is the dominating source of both CFP and HTI,

the change in the ratio between CFP and HTI, for a replacement of

the baseline scenario by the alternative electricity scenarios,

depends on the required amount of thermal energy relative to the

electricity supply and will thus vary on a case-by-case basis. On the

other hand, when human toxicity stems from non-energy-related

processes (e.g. waste disposal during production), reductions in

GHG emissions are decoupled from toxic emissions and the ratio

between CFP and HTI will decrease when the electricity production

is changed to less fossil fuel-based technologies.

4. Uncertainties

The quantication of the global warming potentials of greenhouse gases is based on considerable scientic consensus work [5].

The resulting global warming potentials have not changed

considerably over the last 15 years and are presumably associated

with high reliability, ensuring high accuracy in the obtained

results. The same goes for the inventory of GHG emissions which

covers a very restricted number of gases and for the most

important gas among them, CO2, is based on stoichiometric

calculations form the used amount of fuel. The inventory, the CFP

results and the normalized values in Fig. 1 are thus deemed reliable

for this impact category.

The situation is different with respect to the assessment of HTI

scores. Here, the emissions, inventory for both materials and

normalization reference is associated with considerable uncertainties due to the number of potentially contributing substances

and the need to measure emissions for each of these. Also the

factors that are used to characterise the human health impacts of a

substance can be rather uncertain [6]. The HTI scores are in general

dominated by metal emissions for most of the materials which

indicates that metals are likely to be inventorized with much more

precision than organic substances. This bias in the inventory data

for the materials may be somewhat counteracted by a similar bias

in the inventory data underlying the normalization reference for

HTI [8]. Considering the relatively higher certainty of the CFP

results, this may help explain the observed domination of HTI

results over CFP results.

5. Conclusions and recommendations

For most categories of materials analyzed here, CFP scores turned

out to be dominated by HTI scores representing the impacts on

human health. Biases in the normalization applied to bring the two

impacts on a common scale for the comparison may explain some of

this dominance, but except for a few materials there was no strong

proportionality between the two impacts. CFP has thus been found to

be a poor representative of this other category of environmental

impact. Only in cases where the main sources were the same for

both types of impact there was a proportionality that meant that CFP

could be used to represent toxic impacts as well. Investigating the

dependence on the technologies and fuels used to provide the

thermal and electrical energy in the life cycle of the produced

materials different patterns were observed. Overall there was a

strong dependence on the applied energy technologies for both types

of impact, and this is unfortunate for the general use of CFP to

represent human health impacts, but potentially also other types of

environmental impact. Electricity production scenarios show large

variations between geographical regions, and although a frequent

use of coal as fuel is observed, there are notable examples of countries

that base their energy supply on large shares of nuclear power (e.g.

France and Sweden) or hydro power (e.g. Norway). The inventory of

the toxic emissions is reasonable for electricity production for which

regulations and control of uegas emission exist, but for other types

of processes in the life cycle of the materials, it must be expected to be

much more decient than the inventory of GHGs. It is likely that a

satisfactory inventory of all chemical emissions with contributions

to HTI would make the deviations between the CFP and the HTI even

larger than what was observed here.

In summary, the large variations observed among materials

both the type of material itself and the type of productionand the

poor correlation between CFP and HTI show that carbon footprint

cannot be taken to represent the overall environmental impact, let

alone the human health impacts in the choice of materials for more

sustainable production. The applicability of carbon footprint as

indicator of environmental sustainability in the design and

manufacture of products thus needs to be documented on a

case-by-case basis.

References

[1] Finkbeiner M (2009) Carbon FootprintingOpportunities and Threats. International Journal of Life Cycle Assessment 14:9194.

[2] Hauschild MZ (2005) Assessing Environmental Impacts in a Life-cycle Perspective. Environmental Science & Technology 39(4):81A88A.

[3] Finnveden G, Hauschild MZ, Ekvall T, Guinee J, Heijungs R, Hellweg S, Koehler A,

Pennington D, Suh S (2009) Recent developments in Life Cycle Assessment.

Journal of Environmental Management 91:121.

[4] ISO. (2006) ISO 14044 International Standard. Environmental ManagementLife

Cycle AssessmentRequirements and Guidelines, International Organisation for

Standardization, Geneva, Switzerland.

[5] IPCC, 2007, Climate Change 2007: The Physical Science Basis, in Solomon S.,

Qin D., Manning M., Chen Z., Marquis M., Averyt K.B., Tignor M., Miller H.L.

(Eds.), Contribution of Working Group I to the Fourth Assessment Report of the

Intergovernmental Panel on Climate Change, Cambridge University Press,

Cambridge, United Kingdom and New York, NY, USA, 996 pp.

[6] Rosenbaum RK, Bachmann TM, Gold LS, Huijbregts AJ, Jolliet O, Juraske R,

Koehler A, Larsen HF, MacLeod M, Margni M, McKone TE, Payet J, Schuhmacher

M, Van de Meent D, Hauschild MZ (2008) USEtoxthe UNEP-SETAC toxicity

model: recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. International Journal of Life

Cycle Assessment 13(7):532546.

[7] Ecoinvent Centre, 2007, Ecoinvent Data, Swiss Centre for Life Cycle Inventories,

Dubendorf. www.ecoinvent.ch.

[8] Heijungs R, Guinee JB, Kleijn R, Rovers V (2007) Bias in Normalization: Causes,

Consequences, Detection and Remedies. International Journal of LCA 12(4):211

216.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- HKBEAMDokumen0 halamanHKBEAMTse Lam ChanBelum ada peringkat

- Wind Turbine Installation-ManualDokumen23 halamanWind Turbine Installation-Manualויליאם סן מרמיגיוסBelum ada peringkat

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFDokumen321 halaman(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManBelum ada peringkat

- IPM 200 Series: Internal Permanent Magnet MotorsDokumen7 halamanIPM 200 Series: Internal Permanent Magnet MotorsLuu JosBelum ada peringkat

- Numatics Series 342Dokumen6 halamanNumatics Series 342Jebran FarazBelum ada peringkat

- Budget of Lesson Science 9Dokumen14 halamanBudget of Lesson Science 9Hezl Valerie ArzadonBelum ada peringkat

- DPDC MaintenanceDokumen5 halamanDPDC MaintenanceArfana Akter BanogirBelum ada peringkat

- Fire Pump Installation GuideDokumen3 halamanFire Pump Installation GuideJeff D. AgustinBelum ada peringkat

- CH 3 Gas Refrigeration CycleDokumen20 halamanCH 3 Gas Refrigeration CycleMeleseBelum ada peringkat

- Energy Manipulation and MeditationDokumen6 halamanEnergy Manipulation and Meditationapi-246292178100% (1)

- DensicatDokumen8 halamanDensicatAdel SukerBelum ada peringkat

- Amcor 2016Dokumen69 halamanAmcor 2016Romulo AlvesBelum ada peringkat

- MCQ 140Dokumen14 halamanMCQ 140Aawez AkhterBelum ada peringkat

- CXF 300 BrochureDokumen9 halamanCXF 300 BrochureSulaiman AbdulwasiuBelum ada peringkat

- 947 SampleDokumen6 halaman947 SamplesarveshkdahiyaBelum ada peringkat

- Two-Phase Flow (Gas-Flow) Line SizingDokumen24 halamanTwo-Phase Flow (Gas-Flow) Line SizingvictorvikramBelum ada peringkat

- Annual Syllabus 9 & 10Dokumen6 halamanAnnual Syllabus 9 & 10Kumar SiddhantBelum ada peringkat

- Water Standard Specification Index As On Dec 2015Dokumen10 halamanWater Standard Specification Index As On Dec 2015afp15060% (1)

- GCP: Google Cloud PlatformDokumen25 halamanGCP: Google Cloud Platformalya khan100% (1)

- Solar Air HeaterDokumen2 halamanSolar Air HeaterriyaBelum ada peringkat

- Arcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingDokumen12 halamanArcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingRaajBelum ada peringkat

- Caliber Modulo PCM PinoutDokumen7 halamanCaliber Modulo PCM PinoutManuel Suarez100% (3)

- Current Transformer - Electrical Notes & ArticlesDokumen47 halamanCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- Medium Power Substation Instruction ManualDokumen24 halamanMedium Power Substation Instruction ManualOmar GraterolBelum ada peringkat

- Installation Manual E-Brick en LoresDokumen80 halamanInstallation Manual E-Brick en LoresvideoramirezBelum ada peringkat

- 240-56063867 Transformer and Reactor Rapid Pressure Rise RelayDokumen6 halaman240-56063867 Transformer and Reactor Rapid Pressure Rise RelayMichael NgubaneBelum ada peringkat

- PPTs ON BONTON CABLESDokumen10 halamanPPTs ON BONTON CABLESShaishav Anand100% (1)

- Rpdir-L12 Shielding WebDokumen73 halamanRpdir-L12 Shielding WebWiie ArdiBelum ada peringkat

- Lightning Protection System Design PDFDokumen46 halamanLightning Protection System Design PDFhportezBelum ada peringkat

- AMX AC Power Source ManualDokumen114 halamanAMX AC Power Source ManualjassadBelum ada peringkat