New HV and LV Bonding Methods For Cross Arms

Diunggah oleh

halel111Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

New HV and LV Bonding Methods For Cross Arms

Diunggah oleh

halel111Hak Cipta:

Format Tersedia

Issue 9 30 Jun 2009

PLANT UPDATE

1. New HV and LV bonding methods

Pole top fires on Distribution structures are primarily caused by leakage current across the surface of insulators and into the wood. The continual leakage currents

concentrated at a specific point on the wood surface which leads to ignition of the wood resulting in a pole top fire/ burning. Photo 1.1 shows an example of charring and

Photo 1.2 shows the result of sustained burning and subsequent pole head failure, ie the pole head has burnt-off.

Photo 1.1

Photo 1.2

Photo 1.3

In an initial endeavour to prevent pole top fires, a method of dispersing the concentration of the leakage currents over a larger area was introduced. The dispersion was

achieved using of bonding kits, which had gang nails to dissipate the heat and copper conductor to short out insulator studs and cross-arm bolts. The existing bonding

kits are shown in Photos 1.4, 1.9, 1.10 & 1.15. The existing bonding kits are electrically connected, via the copper wires, with automotive type slide on connectors. The

problem with the existing bonding kits is the slide on connectors are disconnecting from their attachment points or corroding and thus not shorting out the insulator studs

and cross-arms as required. Photo 1.3 shows an example of where the bonding wire has become disconnected on the right hand insulator.

To eliminate the problems with the existing bonding kits the following changes are being made to the bonding kits.

DMS#6168870

Page 1 of 11

Issue 9 30 Jun 2009

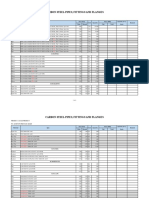

Existing HV intermediate structure bonding for new construction

New HV intermediate structure bonding for new construction

Existing bonding kit CE7553 (see photo 1.4) that was used for application on

intermediate steel cross arms.

The new bonding method is to fit bolts through the dispersion plate with the bolts

being fastened to the steel cross-arm. The bolt is held under constant pressure via

the coil spring washer. This arrangement will provide a solid electrical connection

between the insulator studs and wooden pole head.

Previously the gang nail plate did not have the pole bolts passing through the

circular hole (approx 25mm diameter). The gang nail plate was simply nailed to the

pole and the electrical connection was made via the copper conductor to the pole

bolts.

An example of the above bonding method is given in Photos 1.5 and 1.6. The

drawing showing the bonding is given in the Distribution Construction Standards

Handbook (DCSH) in R2/1.

Photo 1.4 CE7553

Photos 1.5

Photos 1.6

Initially we will continue to use the existing dispersion plates as shown in Photo

1.7, as we have a large number already in stock. When the existing dispersion

plates have been consumed they will be replaced with dispersion plates that have a

central circular hole, as shown on Photo 1.8.

Photo 1.7 CE7541 (Old style)

DMS#6168870

Photo 1.8 CE7541 (New style)

Page 2 of 11

Issue 9 30 Jun 2009

Existing Running disk angle bonding for new construction

New Running disk angle bonding for new and existing construction

The bonding kit as shown in photo 1.10a (CE7551) and Photo 1.10b was used for

application at a running disc angle structure.

The existing bonding kit has been replaced with the bonding kit shown in Photo

1.11 (CE7542). The bonding kit assembled as shown in Photo 1.12 and

Distribution Construction Standards Handbook drawing (DCSH) R2/3.

Steel wire

Dispersion plate

Bonding clip

Photo 1.10a

DMS#6168870

CE7551

Photo 1.10b

Photo 1.11 CE7542

Photo 1.12

Page 3 of 11

Issue 9 30 Jun 2009

Continued - New Running disk angle bonding for new and existing

construction

Left blank intentionally.

Photo 1.13

Photo 1.14

Photos 1.13 and 1.14 show the arrangement of the galvanised wire U bonding

clip to the phase insulator eye bolts. The 7/1.6 galvanised wire is passed through

the U end of the bonding clip with its 17mm diam hole. On the bonding clip of

the top and bottom phases a short section of wire must protrude at one end of

each clip. This assembly is then placed directly onto the protruding thread of each

eye bolt onto the existing nut and secured in a vertical position with the 16mm

lock nut provided.

During the securing process the lower nut of the eye bolt must be held while

tightening the outer lock nut. This is an essential action for ensuring the contact

is well established. Electrically this does not have to attain a given ohm value.

The stay wire eye bolt is not attached by bonding apparatus. The bonding wire

must be kept 100mm away from the stay wire eye bolt.

DMS#6168870

Page 4 of 11

Issue 9 30 Jun 2009

Existing Retrofit bonding for existing Intermediate wood cross-arm New Retrofit bonding for existing wood cross-arm Intermediate

structures

structures

Photo 1.15 shows the bonding kit (CE7550) that was used for application on

existing HV intermediate wood cross arm structures. Photo 1.3 shows an existing

intermediate wood cross arm structure with bonding kit CE7550 applied.

Photo 1.16 shows the bonding kit that is applied to the metal hardware on

existing intermediate wood cross arm structures in the fashion seen in Photo1.17

and the Distribution Construction Standards Handbook drawing R2/5.

Photo 1.16 CE7543.

Photo 1.17

The insulator studs of the two outer phases are bonded to the king bolts by

means of a 7/1.6 steel wire and bonding clips.

Photo 1.15 CE7550

Onto the existing nut of the protruding thread of the upper 16mm king bolt of the

cross-arm place two bonding clips with the 17mm diam. holes. Into the U end

of each of the bonding clip the 7/1.6mm galv. wire is placed and secured with one

of the M16 nuts provided. Install the other 17mm diam. hole bonding clip onto

the lower king bolt after the galv. steel wire has been assembled as in Photo 1.18

and secure it with the M16 galv. nut.

Assemble the 7/1.6 galv. wire into the two 25mm diam. hole bonding clips for the

outer phases so that the wire is passed through the U end of each bonding clip.

Ensure that there is protrusion of the galv. wire at each end on the outer clips

while at the centre clip the wire passes through. The length of the assembled

wire and clips is the distance of the cross-arm from outer phase to outer phase

plus 10mm protrusion. The outer phase clips with the galv. wire inserted is then

locked onto the existing studs protruding thread with the M24 nuts provided.

DMS#6168870

Page 5 of 11

Issue 9 30 Jun 2009

Photo 1.18 CE7539

Photo 1.18 shows the final connection mode to ensure that a thorough electrical

contact is established between the outer phases and the king bolts.

Left blank intentionally.

Note that on the existing network there are insulators studs with various diameters

and field staff must carry a range of nuts that will fit the old insulator studs.

Photo 1.19 CE7539

Photo 1.20 CE7540

Photo 1.9 and 1.20 show the 17mm and 25mm diameter bonding clips with their

stock codes.

New Retrofit bonding for existing Wood Strain structures

For retro fit bonding of the hardware on existing wood strain structures the stock

code CE7542 (see photo 1.11) is applied.

The application assembly is in

principle the same as for the running disc angle with the exception that it is

applied onto the cross-arm eye bolts and not the pole.

DMS#6168870

Page 6 of 11

Issue 9 30 Jun 2009

2. Eye Bolt Galvanising

The current welded eye bolts used on strain structures, running disc angles and stays, as shown in Photo 2.1, are being replaced by a forged eye bolts as shown in

Photo 2.2. The current supplier is experiencing problems with the turn-around/ processing time taken by the only galvanising spinning plant. To get past these issues

the supplier is supplying an alternative designed eye bolt as shown in Photo 2.2. The new forged eyebolt has passed the loading tests and is suitable for strain and stay

applications.

Forged

Welded

Photo 2.1

DMS#6168870

Photo 2.2

Page 7 of 11

Issue 9 30 Jun 2009

3. Spreader Rod and Clip

In an endeavour to prevent LV conductor clashing a PVC spreader rod, as shown

in Photo 3.1, was introduced many years ago.

This rod was attached to the

conductor by means of a galvanised stainless steel clip see Photo 3.2. and

assembled is as shown in Photo 3.3. Although the spreader has been highly

successful in eliminating LV conductor clashing it has unfortunately, in time, been

damaging the conductors as shown in Photo 3.4.

The contributing factors leading to damage/ failure of the conductors were found to

be the high leakage currents due to poor insulating properties of the PVC rod, a

corrosive chemical reaction between dissimilar materials (aluminium and stainless

steel) and the presence of saline moisture or industrial pollution.

There is an ongoing need to prevent LV conductor clashing, thus an alternative nor

reactive spreader has been developed.

The new spreader consists of a Ethylene Vinyl Acetate (EVA) rod and stainless

steel clip with plastic inserts. The new spreader is shown assembled in Photo 3.7

The EVA rod, shown in Photo 3.5, was tested in accelerated polluted conditions

and performed excellently.

The stainless steel clip (see photo 3.6) was also re-developed and a plastic insert

was added to provide a bigger contact area and insulation between the stainless

steel clip and the aluminium conductor. The plastic insert will help prevent galvanic

action.

Photo 3.1

Photo 3.2

The new spreader was also subjected to a five million cycle vibration test and no

mechanical wear was evident.

Photo 3.5

Photo 3.3

DMS#6168870

Photo 3.6

Photo 3.7

Photo 3.4

Page 8 of 11

Issue 9 30 Jun 2009

4. Brass Clip

Stock code: CE0300

Photo 4.1 shows an earth rod for uni & mini pillar with both the 210 clamp and

brass clip installed.

Left blank intentionally.

Photo 4.1

Due to the large number of the brass clips being returned to store and not used, the

supplier has been requested to supply future earth rods with the 210 clamps only.

The brass clips will be discontinued.

DMS#6168870

Page 9 of 11

Issue 9 30 Jun 2009

5. Krone LV Fuses

Krone supply the existing LV 400A fuse box as a single 3 phase unit, as shown in

Photo 5.1 (GS0111). This unit is susceptible to contamination in heavily polluted

areas resulting in shorting out the phases. The unit has shorted out as the base is

common and tracks over.

The new unit will be rated for 400A, replaces both the existing 400A unit (GS0111)

and the 160A (GS0110). The 160A unit has been replaced as it is rarely used.

The new model fuse box is shown in Photo 5.3 & 5.4.

.

Photo 5.1 GS0111

To eliminate problem single three phase unit being compromised by pollution three

separate unit will be used. That is, one unit per phase ganged for simultaneous

operation.

DMS#6168870

Photo 5.3

Photo 5.4

The new fuse box model GS0111 uses the following fuses:

GF2130 (100A)

GF1100 (160A).and

GF1101 (315A)

Page 10 of 11

Issue 9 30 Jun 2009

6. Surge Diverter in Nulec Control Box.

The Nu-lec reclosers and Load break switches are currently protected against

voltage surges and spikes by means of a 275V (Uc) 80kA (see Photo 6.1)

surge diverter installed in the control box.

Over the last few years Western Power experienced failures of these units and

subsequent damaged to the control boxes. Evidence showed that these

failures generally occurred in areas where the control box was supplied via

bare overhead LV conductors. In some cases dead birds were found on the

ground close to the installations which indicate some short circuit activity which

could have let to higher voltages across the surge diverter and subsequent

failure.

Photo 6.1

The surge diverter has been upgraded to a 460V (Uc) and 100kA energy level,

as shown in Photo 6.2. The frame size has remained the same and thus this

unit fits onto the existing mounting plate.

Network Performance has advised they will be developing a program to

replace the surge diverters in all Recloser and Load break switch control

boxes.

Photo 6.2

DMS#6168870

Page 11 of 11

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Appl - PF Correction of A Motor Protection - 756152 - EnaDokumen10 halamanAppl - PF Correction of A Motor Protection - 756152 - Enalagm54Belum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Relay Coordination GuideDokumen96 halamanRelay Coordination GuideShrimant Shanbhag80% (5)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Real-Time Implementation 1333420538Dokumen16 halamanReal-Time Implementation 1333420538Aslan SezerBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Three A's of Arc Flash PDFDokumen7 halamanThe Three A's of Arc Flash PDFhalel111Belum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Interconnect Protection of Dispersed GeneratorsDokumen13 halamanInterconnect Protection of Dispersed Generatorshalel111Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Victorian Electricity Safety Report 2012Dokumen84 halamanVictorian Electricity Safety Report 2012halel111Belum ada peringkat

- Fundamentals of Overcurrent ProtectionDokumen34 halamanFundamentals of Overcurrent Protectionhalel111100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- High Voltage Transmission Line Protection With Single Pole Tripping and Reclosing GET 6555Dokumen24 halamanHigh Voltage Transmission Line Protection With Single Pole Tripping and Reclosing GET 6555halel111Belum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Dunsborough Fire ReportDokumen10 halamanDunsborough Fire Reporthalel111Belum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- GE Protection SelectiveDokumen11 halamanGE Protection SelectiveIsrael MarinBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Cross ArmsDokumen46 halamanCross Armshalel111Belum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Coordinating Ground Fault Protection With Phase Overcurrent ProtectionDokumen7 halamanCoordinating Ground Fault Protection With Phase Overcurrent Protectionhalel111Belum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- New HV and LV Bonding Methods For Cross ArmsDokumen11 halamanNew HV and LV Bonding Methods For Cross Armshalel111Belum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- RCM I1: Wood Cross Arm Failures and EffectsDokumen3 halamanRCM I1: Wood Cross Arm Failures and Effectshalel111100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Pole-Top Fires Risk Assessment A South African PerspectiveDokumen4 halamanPole-Top Fires Risk Assessment A South African Perspectivehalel111Belum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Reviewing Pole StrengthDokumen33 halamanReviewing Pole Strengthhalel111Belum ada peringkat

- Some Electrical Properties of Wood PulpDokumen6 halamanSome Electrical Properties of Wood Pulphalel111Belum ada peringkat

- Flammability of CCA Treated Timber PolesDokumen3 halamanFlammability of CCA Treated Timber Poleshalel111Belum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Electrical Proporties of Treated Wood With A Focus On Utility Pole ConductivityDokumen15 halamanThe Electrical Proporties of Treated Wood With A Focus On Utility Pole Conductivityhalel111Belum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Specific Gravity ExperimentDokumen16 halamanSpecific Gravity ExperimentSourav DuttaBelum ada peringkat

- Estimated Service Life of Wood PolesDokumen6 halamanEstimated Service Life of Wood Poleshalel111Belum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Wood Laminated Composite PolesDokumen108 halamanWood Laminated Composite Poleshalel111Belum ada peringkat

- Magnetic FieldDokumen8 halamanMagnetic Fieldhalel111Belum ada peringkat

- Specific Heat of Wood - BeallDokumen10 halamanSpecific Heat of Wood - Beallhalel111Belum ada peringkat

- Thermodynamics of wood swellingDokumen12 halamanThermodynamics of wood swellinghalel111Belum ada peringkat

- Currents in Power Line Wood PolesDokumen4 halamanCurrents in Power Line Wood Poleshalel111Belum ada peringkat

- Specific Gravity ExperimentDokumen16 halamanSpecific Gravity ExperimentSourav DuttaBelum ada peringkat

- Accuracy of Wood Resistance Sensors For Measurement of HumidityDokumen8 halamanAccuracy of Wood Resistance Sensors For Measurement of HumidityDamian Moctezuma EnriquezBelum ada peringkat

- ΝΟ-Study of Timber Crossarms Coated With Castor Oil-based Polyurethane Resins Electrical and Mechanical TestsDokumen4 halamanΝΟ-Study of Timber Crossarms Coated With Castor Oil-based Polyurethane Resins Electrical and Mechanical Testshalel111Belum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Bamboo As A Building MaterialDokumen58 halamanBamboo As A Building MaterialAsociación DamaBelum ada peringkat

- Prefab Construction Using Fiber Cement BoardsDokumen25 halamanPrefab Construction Using Fiber Cement BoardsKmw18 ce013Belum ada peringkat

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDokumen2 halamanAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987Belum ada peringkat

- Week 5 - Elastic AnalysisDokumen26 halamanWeek 5 - Elastic AnalysisTris CollectionBelum ada peringkat

- BS en 15037-5-2013 - (2020-11-09 - 12-17-26 PM) PDFDokumen62 halamanBS en 15037-5-2013 - (2020-11-09 - 12-17-26 PM) PDFdenizinakBelum ada peringkat

- Rule 1220: Elevators & Related EquipmentDokumen10 halamanRule 1220: Elevators & Related EquipmentMonjo CasiñoBelum ada peringkat

- Experimental study of lateral-torsional buckling behavior of castellated beamsDokumen4 halamanExperimental study of lateral-torsional buckling behavior of castellated beamsAdnan NajemBelum ada peringkat

- Cengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 3Dokumen1 halamanCengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 3Benjamin EngelBelum ada peringkat

- C101 Electrolytic Tough Pitch CopperDokumen2 halamanC101 Electrolytic Tough Pitch CopperMADDI MADHAV.Belum ada peringkat

- Water and Waste Systems OverviewDokumen18 halamanWater and Waste Systems OverviewJOSUÉ CABRERABelum ada peringkat

- Swagelok Dielectric FittingsDokumen1 halamanSwagelok Dielectric FittingstotcsabBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- G.F.R.C. Guide for Polymer Modified ConcreteDokumen5 halamanG.F.R.C. Guide for Polymer Modified ConcreteVladoiu SorinBelum ada peringkat

- Kobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesDokumen6 halamanKobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesPhilBelum ada peringkat

- ContinueDokumen2 halamanContinueArdianBelum ada peringkat

- 4 Plan PDFDokumen1 halaman4 Plan PDFShruti JhaBelum ada peringkat

- Electric Convection Built-In Oven: Installation ManualDokumen28 halamanElectric Convection Built-In Oven: Installation Manualjulio ariasBelum ada peringkat

- General Requirements For ValvesDokumen16 halamanGeneral Requirements For ValvesKrishna Prasad R100% (1)

- Spectacle Blind FlangeDokumen3 halamanSpectacle Blind Flangemaniastur365Belum ada peringkat

- Taco Pump - VT Series - Vertical Turbine PumpsDokumen8 halamanTaco Pump - VT Series - Vertical Turbine Pumpsadalcayde2514Belum ada peringkat

- Bamboo Mat Corrugated Roofing Sheets PDFDokumen2 halamanBamboo Mat Corrugated Roofing Sheets PDFDante Lepe GallardoBelum ada peringkat

- Final KP - Line - Diagram 28.12Dokumen1 halamanFinal KP - Line - Diagram 28.12Chief Engineer40% (5)

- CARBON STEEL PIPES AND FITTINGS PRICE LISTDokumen4 halamanCARBON STEEL PIPES AND FITTINGS PRICE LISTIlham KelanaBelum ada peringkat

- List RDSO DrawingsDokumen52 halamanList RDSO Drawingsprasagnihotri75% (4)

- EML e BrochureDokumen21 halamanEML e BrochureECCSBelum ada peringkat

- Item 603 - GuardrailDokumen18 halamanItem 603 - GuardrailGlorybelle T. ValerioBelum ada peringkat

- Bridge Beam Details - 2nd Edition PDFDokumen9 halamanBridge Beam Details - 2nd Edition PDFKrzy HoBelum ada peringkat

- A Watertight Second-Story PorchDokumen5 halamanA Watertight Second-Story PorchJaelani AbdulBelum ada peringkat

- Hydraulic SystmDokumen4 halamanHydraulic SystmArchana Choudhary100% (1)

- AdmixturesDokumen27 halamanAdmixturesShubham ParmarBelum ada peringkat

- Understanding Automotive Electronics: An Engineering PerspectiveDari EverandUnderstanding Automotive Electronics: An Engineering PerspectivePenilaian: 3.5 dari 5 bintang3.5/5 (16)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDari EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsBelum ada peringkat

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryDari EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryPenilaian: 4 dari 5 bintang4/5 (5)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessDari EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessBelum ada peringkat

- Design for How People Think: Using Brain Science to Build Better ProductsDari EverandDesign for How People Think: Using Brain Science to Build Better ProductsPenilaian: 4 dari 5 bintang4/5 (8)