Analysis of Oil Tanker Deck Under Hydrocarbon Fire

Diunggah oleh

Miguel Renato Manco RiveraHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Analysis of Oil Tanker Deck Under Hydrocarbon Fire

Diunggah oleh

Miguel Renato Manco RiveraHak Cipta:

Format Tersedia

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 8, NO.

2, DECEMBER 2014

17

Analysis of Oil Tanker Deck Under Hydrocarbon Fire

Manco, M. R.1, Vaz, M.A.1, Cyrino, J.C.R.1 and Landesmann, A.2

mmanco1@oceanica.ufrj.br, murilo@oceanica.ufrj.br, julio@peno.coppe.ufrj.br, alandes@coc.ufrj.br

1

Ocean Engineering Program, COPPE / UFRJ, Rio de Janeiro, Brazil

Civil Engineering Program, COPPE / UFRJ, Rio de Janeiro, Brazil

Abstract. The present paper presents a numerical study of the

behavior of a deck panel of an oil tanker under fire. The fire

condition assumed in the simulation is that of a hydrocarbon

burning process according to the time-temperature nominal

curve in the part 1.2 of EUROCODE 1 and 3 (EC1 and EC3,

2004), which also specify the variations of mechanical and

thermal properties of the steel with temperature. A finite

element model taking into account the initial imperfections

recommended by the ISSC, 2012 was developed through the

use of ABAQUS , 2011 commercial software. The thermal

and mechanical analyses were uncoupled, so the temperature

transient field caused by the fire condition was analyzed first

and then, this thermal load was applied to the structure to

evaluate its mechanical behavior. Once the fire scenario was

defined, it was possible to assess the development of the

temperature field as a function of time. The induced thermal

loads were considered in the analysis of the structural model

together with the pre-existent operating loads, allowing

assessing the behavior of the panel. Thus, the objective of the

present paper is to present a methodology for assessing the

structural behavior of a steel panel in the event of fire.

Index Terms stiffened panel; fire; finite element

1 INTRODUCTION

The design of steel structures for the offshore exploration and

production of oil and gas provides for the consideration of

different scenarios related to severe accidents, including: large

waves, extreme winds, earthquakes, collision between vessels

and fires. For all these conditions, the integrity of the facility

must be ensured and, in some cases, damages must be limited,

ensuring the maintenance of safe operating characteristics for

a given period of time. Due to the presence of large volumes

of flammable materials (liquid and gas), equipment operating

at high temperatures, active flames (e.g., flares) and human

lives, living and interacting in confined spaces, the manufacturers and operators of these facilities are required to follow

strict fire protection criteria (deemed the most severe among

all industrial facilities).

The occurrence of a fire in this type of structures is considered

one of the most unfavorable conditions, for the combustion of

hydrocarbons presents a very high rate of temperature increase

in the initial stage of the fire, causing a very rapid loss in mechanical properties of steel, thus generating the possibility of

deaths and economic and environmental damages.

Manuscript received Jan. 26, 2014. Corresponding Author: Miguel Renato

Manco Rivera (E-mail: mmanco1@oceanica.ufrj.br).

Tragic examples of this kind of accidents are those which took

place in the Piper Alpha platform in the UK, in July 1989,

killing 167 of the 229 occupants in less than 22 minutes and,

most recently, at the Deepwater Horizon platform, in the Gulf

of Mexico in April 2010, where 11 people disappeared and a

large environmental impact was generated.

Temperature changes generate degradation of the mechanical

properties causing effects that significantly change the failure

mode forecasted in the panel design (at room temperature).

Such effects are related to the introduction of axial and shear

forces, as well as bending moments due to the thermal gradient, causing the local buckling of the web (WB) and the flange

(FB) at the ends of the stiffener and its consequent collapse

because of the emergence of plastic hinges and subsequent

membrane behavior of the panel plate until the complete failure of the panel (Manco et al., 2013). In addition, the adopted

boundary conditions (described in item 3) facilitate the problem modeling due to the consideration that the properties in

the restraint do not change with temperature, but generate a

numerical problem in the mechanical analysis which is solved

by considering an additional region called Rigid End (Hassanein, 2011).

The numerical analyses are performed using the commercial

code ABAQUS, 2011, according to the finite element method (FEM), taking into account the structural and thermal effects resulting from the proposed fire. Variation in thermal and

mechanical properties of materials in case of high temperature

conditions are taken into account in the analysis, in accordance with the applicable standard recommendations, such as is

the case of part 1.2 of EC3, 2004. The fundamentals of the

applied analysis model are described in item 2 below. A case

study is proposed and briefly described in item 3 hereto. A

tanker ship deck panel, with the geometry employed by the

ISSC, 2012 in their benchmarking studies, is submitted to a

fire scenario, caused by the burning of hydrocarbons (Part 1.2

of EC1, 2004), allowing to evaluate the thermo-structural

behavior for different instances of the fire. The main results

obtained with the numerical model are presented and critically

assessed in item 4 of this work, taking into account the fulfillment of security requirements. The main conclusions extracted from the analyses performed are mentioned in item 5,

indicating that this methodology allows assessing qualitatively

and quantitatively the behavior of the panel, and can be used

in the improvement of current regulations related to the safety

of structures in the event of fire.

18

MANCO et al.: ANALYSIS OF OIL TANKER DECK UNDER HYDROCARBON FIRE

2 ANALYSIS METHODOLOGY

The analysis is carried out using FEM, the model includes a

direct and rigorous consideration of nonlinear physical and

geometric effects on the numerical formulation, allowing the

estimate of the possible structural collapse modes.

The proposed analysis procedure begins with the review of the

panel layout with the selection of the fire scenario. Then, the

thermal analysis is performed, which purpose is to determine

the variation of the temperature in the elements exposed to

fire. The main numerical formulation aspects of this stage are

addressed in item 2.1. The final stage of the procedure aims at

determining the structural behavior as a function of the

elapsed time of fire, in other words, depending on the thermal

conditions of fire exposure and applied external loads (mechanical). Computational characteristics adopted in this final

stage of the numerical simulations are briefly described in

item 2.2 hereto.

C.

2.1 Thermal Analysis

The numerical model used FEM to solve the two-dimensional

transient heat conduction problem, as shown in Cook, 2002,

Skallerud and Amdahl, 2002, Lewis et al., 2004 and Landesmann et al., 2010. The DS4 element made with 4 nodes was

used to represent the panels.

The partial differential equation which expresses the temperatures (in degrees Celsius) (x,y,z,t) is shown in Equation (1),

subject to a temperature field defined in its contour s, which

is represented in this analysis by fire-temperature curves (Part

1.2 of EC1, 2004).

k . k. k . .c.

x x y y z z

t

(1)

Where is the specific mass of steel (assumed temperature

independent), =7850 kg/m, c is the specific heat and k is the

thermal conductivity. In this paper, the thermal properties of

steel, as a function of temperature, are provided by part 1.2 of

EC3, 2004 and shown in Figure 1.

When prescribed temperatures are different from temperatures

on the surface, a heat flux qn with two portions is generated:

(i) one due to convection and another (ii) resulting from radiation, which can be written in a single equation through the

linearization of the radiation portion, as below:

qn qc qr c r . s g

Figure 1. Specific heat and thermal conductivity of carbon steel as a function

of the temperature

(2)

where: r r . r . s 2 g 2 . s g , r is the resulting emissivity, defined as 0.8 (for steel); r is the Stefan-Boltzmann constant (5.67 .10-8 W/mK4); and c is the convective heat coefficient adopted as 50 W/mK (part 1.2 EC1, 2004). This linearization of the portion of radiation is necessary given that the

FEM only solves a system of linear equations. Denoting C as

capacitance matrix, Kl and Kc are conductivity matrices (Kt=

Kl+Kc), fb as vector of nodal flux due to convection, Equation

(1) can be rewritten:

(t )

K t . (t ) f b (t )

t

(3)

Solution of Equation (3) is based on FEM, being possible to

determine the temperature at time n+1 based on data at time n:

C Kt t n1 C 1 tKt n t fbn fbn1 fbn (4)

where t is the time interval, is the temporal integration

factor (taken as 0.9) and the initial temperature throughout the

solid is assumed to be equal to 20C (o).

Analyses presented here use the nominal fire curve corresponding to the burning of hydrocarbons (Part 1.2 of EC1,

2004), as given by Equation (5):

g (t ) o 1080. 1 0.325.e 0.167.t 0.675.e 2.5.t

(5)

where: t is the elapsed time of fire (in minutes), a is the temperature in the middle (in C) and o is the initial temperature

(equal to 20C).

2.2 Structural Analysis

Since the variation of the temperature field was established in

the previous analysis stage, the finite element mesh used, i.e.,

the nodal coordinates, the elements connectivity and the results for heat fluxes are used in the simulation of structural

behavior under the postulated fire conditions. The procedure is

initialized by the application of external loads, including the

own structural weight, fluid action and other operational loads.

At this stage, deformations and their respective stresses, corresponding to normal operating conditions of the panel, can be

seen. The variation of the temperature field determined in the

thermal analysis is imposed to the structural model along with

other external loads applied.

In building the mesh of finite elements for the structural analysis, the S9R5 element is used for the panel simulation. This

element is composed of 9 nodes and 6 degrees of freedom per

node (translations and rotations around global axes X, Y and

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 8, NO. 2, DECEMBER 2014

Z), with capacity for developing nonlinear physical and geometrical analyses. The complete Newton-Raphson solution

process is adopted to update the matrices and the linear solution of equations. The von Mises criterion is adopted for determining the element plastification criterion.

Apart from the thermal deformation imposed on the structural

model, variations in the mechanical properties of steel as a

result of temperature, as shown in Figure 2, are also taken into

account, including reduction: of yield strength (y,), modulus

of longitudinal elasticity (Ea,) and yield point (p,) obtained

based on recommendations of part 1.2 of EC3, 2004.

19

3 CASE STUDY

We studied a stiffened steel panel, which is part of the deck of

an oil tanker, subjected to fire caused by hydrocarbon burning.

The temperature of the hot gases inside the compartment under fire (on the side of the stiffeners) is described by Eq. (5),

while the external temperature was considered constant and

equal to 20 C. In the heat exchange process between the upper side of the plate and the environment we considered a heat

exchange coefficient (including radiation and convection) of 9

W/mK according to part 1.2 of EC1, 2004 recommendations

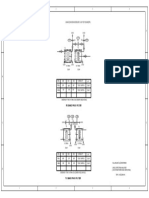

as shown in Figure 4. The geometry of the panel was chosen

similar to the ISSC, 2012 benchmark study and is shown in

Figure 4. The initial geometric imperfections of the panel were

based on the model recommended by ISSC, 2012 according to

Eqs. (7) and (8), where vopl is the imperfection in the plate,

wos is the imperfection in the stiffener and is a parameter

that defines the level of imperfection according to Smith et al.

(1992) (slight =0.00025, average =0.0015 and severe

= 0.0046). In the case study we employed the three levels of

initial imperfections of the stiffener to assess the influence on

the behavior of the panel under fire. Figure 5, presents the

initial imperfections magnified fivefold.

Figure 2. Stress-strain relationship for carbon steel at elevated temperatures.

Defining y,20 as the characteristic yield stress and Ea,20 as the

modulus of elasticity, at environment temperature, the degradation factors as well as the coefficient of linear thermal expansion of steel, as a function of temperature (), are shown

in Figure 3.

Figure 3. Reduction factor for the stress-strain relationship and thermal

expansion coefficient for carbon steel at elevated temperatures.

Figure 4. Case study and initial panel geometry

20

MANCO et al.: ANALYSIS OF OIL TANKER DECK UNDER HYDROCARBON FIRE

vopl 0.1 2 sin

mx

y

sin

Lu

bp

(6)

z

x

sin

(7)

hw

Lu

The computational mesh used is composed of three regions.

The first region, in blue in Figure 5, is called Rigid End and

simulates the panel support element (bulkhead or deck transverse) the mechanical properties of which are independent

from temperature. This end is used to avoid numerical errors

caused by the application of boundary conditions in the mechanical analysis. The second region, in gray in Figure 5,

covers length Lu /12 from the rigid end and has a higher mesh

density to allow assessing the WB and FB of the stiffener that

will occur in that area. Finally, the third region in green in

Figure 5 is considered with a less dense mesh to avoid working with very large matrices. As boundary conditions we considered the left cross-section of the Rigid End (see Figure 5) as

restrained, while for the right end of the region with less mesh

density the symmetry condition was considered to work only

with half the panel and reduce the computational cost. Finally,

in the side edges we considered the boundary conditions that

represent the continuity of the panel, as shown in Figure 5.

Other boundary conditions employed in similar problems can

be seen in the studies of Heninisuo & Aalto, 2008 and

Vimonsatit et al., 2005, among others. As loads, we considered only the structure own-weight and three values for side

pressure of 0.01, 0.02 and 0.03 MPa for each of the initial

imperfection levels considered in the stiffener.

wos Lu

the temperature difference between points A and B, indicates

the presence of a heat flow towards the stiffener. Note that the

temperature on the plate is always lower than on the stiffener

due to the heat exchange with the environment.

Figure 6. Temperature in points A, B, C, D and E, in view of time

4.2 Stress-strain Field

Figure 5. Initial geometric imperfections and boundary conditions

4 RESULTS

In all the cases analyzed the failure on the deck presents the

same behavior, only varying the severity of the stiffener distortion and the time it takes to occur as described below.

4.1 Temperature Field

As expected, the stiffener web is the element that heats more

quickly, because it has a greater massivity factor, i.e., presents

a larger area exposed to fire with a relatively low volume,

when compared to the plate or the stiffener flange. The flange

has an almost uniform heating as evidenced by the little temperature difference between the points D and E. In the plate,

Since we choose a fire scenario caused by hydrocarbon burning, considered the most severe possible fire, among the simplified models proposed by the part 1.2 of EC1, 2004, the

temperatures of the different panel components increased very

quickly, originating a pronounced drop of the mechanical

properties of the structural elements. According to Yang and

Gao (2004), those temperature increases, besides changing the

thermal and mechanical properties, generate temperature gradients in the panel constitutive elements, resulting in nonlinear forces and moments which, combined with the increasing of imperfec-tions due to thermal deformation, change the

behavior of the panel. Thus, in all the analyses developed from

the data on panel temperature field variation, we determined

the status of stress and strain at different times of the postulated fire.

Figure 7, presents the stress fields at the beginning of the heating, i.e., after considering the effect of gravity and the correspondent lateral pressure L.P. It was observed that the initial

imperfection does not significantly affect the results, changing

the stress magnitude by less than 2%. In this figure, the cases

with an average stiffener imperfection for each of the side

pressures considered (0.01, 0.02 or 0.03 MPa) are presented.

During the heating, the panel suffers non-uniform thermal

deformations that change the initial stress field, giving rise to

regions where the plastic regime is reached, generating plastic

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 8, NO. 2, DECEMBER 2014

hinges in the area close to the restraint and in the middle section of the panel. Those plastic hinges begin with the stiffener

WB and subsequently with the FB.

21

dashed and dotted lines represent the stress distribution for

times of 0 (beginning of heating), 5 and 10 min., respectively

and the colors black, red and blue define the cross-sections

located at x Lu / 2 , x Lu / 36 and x Lu / 72 , respectively. For not having trouble viewing (since the stiffener deforms) we used a local coordinate on the vertical axis at the

initial time ( Yo, L , the origin of which is the junction of the

plate and the web). In this figure we observe that the von Mises stress has a similar configuration as the axial stress 11, ,

indicating that it prevails over the others ( 22, and

12, )

and that after the appearance of the plastic hinge (graph

11,

black dashed or dotted line) the panel supports only tensile

loads and basically shows the panel yield (membrane behavior) until it breaks.

Figure 9 shows the geometric configuration of the panel in the

region close to the restraint ( x Lu / 36 and x Lu / 72 ) and

11

22

12

Figure 7. Stress fields after the application of gravity and L.P. considered

(panel with average imperfection)

Figure 8 shows the distribution of von Mises stresses ( vM , ),

axial stresses in the S11 and S22 directions ( 11, and

22, ,

respectively) and the shear stress ( 12, ), normalized in relation to the yield stress (at temperature determined at the

point at that instant) in the stiffener web. The continuous,

in the middle of the panel ( x Lu / 2 ) at different times, for

the case of a severe imperfection in the stiffener and a L.P. of

0.03 MPa. This figure evidences WB and FB of the stiffener in

the region close to the restraint (plastic hinge) and maximum

vertical displacement (MVD) as well as maximum transversal

displacement (MTD) in the middle of the panel.

Table 1, presents the analysis times, until panel failure for

each of the cases evaluated. We found that neither the imperfection level nor the magnitude of the side pressure (the value

of which was triplicated) significantly changes the analysis

time, varying 5% at the most. This happens because the problem is governed by temperature and not by the geometric

configuration or the load. MVD and MTD magnitudes are also

presented showing that their values are directly affected by the

S.P., on the other hand it also shows that the level of imperfection has a very large influence on the value of MTD and on the

stiffener final configuration.

Figure 10 shows the final geometric configurations of the

stiffener web for all the cases assessed, measured in a local

reference system, i.e. in a system with origin in the junction of

the plate with the web in the respective x coordinate. It is

worth emphasizing the important vertical displacements suffered by the panel that surpass 60 cm in the middle section,

anyway, the lateral displacements of the stiffener indicate loss

of its stiffness and the behavior of the plate as a membrane. It

should be mentioned that the MTD occurs in some cases in the

middle of the panel and in other cases in the region near the

restraint.

The same Figure 10 also shows that the magnitude of the

imperfection slightly alters the final geometric configuration.

In this manner a slight imperfection in the stiffener originates

a distortion in the opposite direction to the initial imperfection,

however for average and severe imperfections the slope of the

final configuration accompanies the direction of the stiffener

initial imperfection.

MANCO et al.: ANALYSIS OF OIL TANKER DECK UNDER HYDROCARBON FIRE

Figure 8. Stress fields after the application of gravity and L.P.= 0.03 MPa (panel with average imperfection)

Plastic

hinge

Figure 9. WB and FB Figure 9 in the region close to the restraint (L.P.= 0.03 MPa and average imperfections).

22

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 8, NO. 2, DECEMBER 2014

23

Figura 10. Final configuration of the stiffener web in all cases analyzed

TABLE 1: ANALYSIS TIMES UNTIL PANEL FAILURE, MAXIMUM VERTICAL DISPLACEMENT (MVD) AND TRANSVERSAL DISPLACEMENT (MTD) VALUES FOR ALL THE

CASES EVALUATED.

Level of imperfection in the stiffener

Lateral

Slight

Average

Severe

Pressure

Time Failure

MVD

MTD

Time Failure

MVD

MTD

Time Failure

MVD

MTD

(MPa)

(min.)

(mm)

(mm)

(min.)

(mm)

(mm)

(min.)

(mm)

(mm)

0.01

39.1

215.4

5.4

39.1

215.2

7.6

39.0

214.9

15.1

0.02

42.5

396.2

6.5

42.2

396.0

11.5

41.2

395.9

25.2

0.03

42.5

574.7

36.3

43.2

574.7

36.3

44.6

621.8

235.0

5 CONCLUSIONS

The numerical-computer methodology for analyzing the behavior of steel structures under fire conditions presented in

this paper was applied to evaluate the behavior of a stiffened

panel of the deck of an oil tanker submitted to a fire scenario.

Despite the idealized load conditions the thermo mechanical

behavior could be observed at different times of the postulated

fire, but it should be mentioned that the results obtained are

valid only for the load and boundary conditions taken into

consideration. In a real situation, when the structure suffers the

action of the waves and other loading conditions, a different

behavior can occur. Anyway, as shown by Manco et al., 2013

the influence of the outline on the longitudinal edge affects the

behavior of the stiffener facilitating its distortion.

Due to the non-linearity of the distribution of the stresses present in the panel during the fire, it is evident that such an analysis is very complex and cannot be addressed by simple analytical formulations and thus the use of a numerical method is

necessary. Anyway, we proved that the problem of the analyzed cases is governed by the temperature and not by the geometrical configuration or the load.

MANCO et al.: ANALYSIS OF OIL TANKER DECK UNDER HYDROCARBON FIRE

From the results we concluded that is necessary to apply elements of passive protection. It should be highlighted that considerably severe fire conditions were forecasted by assigning

the standardized curve for hydrocarbon burning. More refined

studies can be applied in order to make the simulations of fire

scenarios more realistic, as for instance employing CFD

(Computational Fluid Dynamics) models and, consequently,

the mechanical behavior of the structure can be estimated in a

more reliable way.

The conclusions obtained through the numerical simulations

indicate that the methodology presented in this paper can be

applied to assess the structural behavior of offshore structures,

with different load conditions and different materials for thermal protection and has a potential use in the reduction of

structural passive protection without impairing the levels forecasted for global safety. The layer of thermal protection, usually employed in this type of structure, delays the heating of

the protected element, helping to maintain the mechanical

properties for a longer time, improving the panel structural

behavior.

ACKNOWLEDGMENT

The authors wish to express their gratitude to the National

Petroleum Agency of Brazil (ANP), PETROBRAS and

COPPE-UFRJ for their support for the development of this

work.

REFERENCES

ABAQUS, Hibbitt, Karlsson e Sorensen, Version 6.11-3, 2011.

Cook, R.D., Malkus, D.S., Plesha, M.E. and Witt, R.J., Concepts

and Applications of Finite Element Analysis, 4th Ed., John

Wiley and Sons, New York, 2002.

Cullen, L., The Public Inquiry into the Piper Alpha Disaster, HM

Stationery Office, 1990.

European Committee for Standardization. EUROCODE No. 1: Actions on Structures, Part 1-2: Actions on Structures exposed to

24

Fire, ENV 1991-1-2, British Standards Institution, London, UK,

2004.

European Committee for Standardization. Eurocode No. 3: Design of

steel structures, Part 1.2: Structural fire design, ENV 1993-1-2,

British Standards Institution, London, UK, 2004.

Hassanein, M.F. Finite element investigation of shear failure of lean

duplex stainless steel plates girders, Thin-Walled Structures

Journal, Vol. 49, pp. 964 - 973, 2011.

Heinisuo, A. & Aalto, A., 2008. Shear Buckling of Steel Plates at

elevated Temperatures, Tersrakenteiden tutkimus- ja kehityspivt, Finland

ISSC. Report of Specialist Committee III.1 Ultimate Strength, Proceedings of the 18th International Ship and Offshore Structures

Congress (ISSC 2012), Edited by Wolfgang Fricke and Robert

Bronsart, Rostock, Germany, Vol.1, pp.285-363, 2012.

Landesmann, A., Mendes, J.R., Ellwanger, G. Numerical Model for

the Analysis of Offshore Structural Elements under Fire Conditions, Proceedings of XXXIV Jornadas Sudamericanas de Ingeniera Estructural, San Juan, Argentina, 2010.

Lewis R.W., Nithiarasu, P. and Seetharamu, K.N. Fundamentals of

the Finite Element Method for Heat and Fluid Flow, John Wiley

and Sons, England, 2004.

Manco, M.R., Vaz, M.A., Cyrino, J.C., Landesmann, A. Behavior of

stiffened panels exposed to fire, Proceedings of IV

MARSTRUCT, Espoo, Finland, pp. 101 - 108, 2013.

Skallerud, B. and Amdahl J. Nonlinear Analysis of Offshore Structures, Research Studies Press Ltd., Baldock, Herforshire, England, 2002.

Smith, C.S., Anderson, N., Chapman, J.C., Davidson, P.C. and

Dowling, P.J. Strength of Stiffened Plating under Combined

Compression and Lateral Pressure, the Royal Institute of Naval

Architecture, Vol. 133, pp. 131 147, 1991.

Vimonsatit, V., Tan, K. H., Ting, S.K., Shear Strength of Plate

Girder Web Panel at Elevated Temperatures, Journal of Constructional Steel Research, 2005.

Yang, X.J., Gao R., 2004. Factors Affecting the behavior of Steel

Structures in Fire, Proceedings of NASCC 2004, California,

EE.UU, 2004.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- JR CVDokumen5 halamanJR CVMostafa MohmmedBelum ada peringkat

- DRC800 Remote Control UserGuideDokumen2 halamanDRC800 Remote Control UserGuideLuis MurilloBelum ada peringkat

- 04 - Motion in Two DimensionDokumen3 halaman04 - Motion in Two DimensionMathan KalyanasundaramBelum ada peringkat

- Resume Hemant ChaurasiaDokumen3 halamanResume Hemant Chaurasiachaurasia_hBelum ada peringkat

- LATERAL EARTH PRESSURE CALCULATIONSDokumen55 halamanLATERAL EARTH PRESSURE CALCULATIONSRakesh SheteBelum ada peringkat

- En 818-6 PDFDokumen5 halamanEn 818-6 PDFlub007Belum ada peringkat

- Air SuspensionDokumen27 halamanAir SuspensionStanly JohnsonBelum ada peringkat

- Central Changing of Triggers in WinCC V6.2 Images (PDL)Dokumen10 halamanCentral Changing of Triggers in WinCC V6.2 Images (PDL)www.otomasyonegitimi.comBelum ada peringkat

- Linear System Theory and Desing PDFDokumen688 halamanLinear System Theory and Desing PDFJose David MartinezBelum ada peringkat

- Ca2 ZDokumen105 halamanCa2 ZAde RachmanBelum ada peringkat

- DBMS Lab ExperimentsDokumen45 halamanDBMS Lab ExperimentsMad Man100% (1)

- Gas SpringsDokumen122 halamanGas SpringsslavcecaciBelum ada peringkat

- Iec61000 4 7 (Ed2.0) en - DDokumen8 halamanIec61000 4 7 (Ed2.0) en - Dtwinvbooks100% (1)

- ASSAM - Uniform Zoning Regulation 2000Dokumen35 halamanASSAM - Uniform Zoning Regulation 2000rajatesh1Belum ada peringkat

- Mobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Dokumen5 halamanMobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Nicolás Ilich SamusBelum ada peringkat

- Arc Flash and Electrical Safety HazardsDokumen24 halamanArc Flash and Electrical Safety HazardsJulios Charl Panuncialman TagupaBelum ada peringkat

- D Screenplay DialoguesDokumen75 halamanD Screenplay DialoguesReza GhalibBelum ada peringkat

- COILDATADokumen1 halamanCOILDATABarış TaşkınBelum ada peringkat

- Space Programming 1Dokumen10 halamanSpace Programming 1Mache SebialBelum ada peringkat

- SHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016Dokumen27 halamanSHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016jscansinoBelum ada peringkat

- Notification ACF One Range Officer RajasthanDokumen2 halamanNotification ACF One Range Officer RajasthanAshok SainiBelum ada peringkat

- Astm D365Dokumen3 halamanAstm D365Frank LeeBelum ada peringkat

- Quiz 12Dokumen3 halamanQuiz 12mwende faiyuuBelum ada peringkat

- Centerline Alfa Catalog13Dokumen53 halamanCenterline Alfa Catalog13sisonco100% (1)

- RK-2001 Operation ManualDokumen11 halamanRK-2001 Operation Manuale-ComfortUSABelum ada peringkat

- PDF 256372311 Pec QC With Answerpdf DDDokumen6 halamanPDF 256372311 Pec QC With Answerpdf DDLee Robert OlivarBelum ada peringkat

- Tufail MaboodDokumen3 halamanTufail MaboodMickey DalbeheraBelum ada peringkat

- Manufacturing Process of Piston Rings and Cylinder LinersDokumen26 halamanManufacturing Process of Piston Rings and Cylinder Linersanish jain100% (6)

- Ms Acess 2Dokumen80 halamanMs Acess 2Mebrie1Belum ada peringkat

- 6 Shifter Interlock System in 90's Transmissions-ServiceDokumen10 halaman6 Shifter Interlock System in 90's Transmissions-ServiceJack Carl100% (1)