Checklist ISO 22000

Diunggah oleh

Abdelhamid SadHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Checklist ISO 22000

Diunggah oleh

Abdelhamid SadHak Cipta:

Format Tersedia

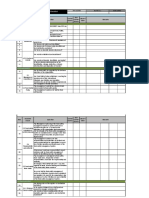

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

This Checklist is prepared according to the requirements of ISO 22000:2005. Applicable vertical/horizontal regulations shall be used as integrated

part of the assessment.

General

* Document Review Follow-up

* Use of Logo/ Certificate

* Organization Size (info including no. of employee etc)

Verification. Is audit time sufficient?

* Scope Wording Verification

1.

1.1

Management Responsibility

Is there evidence to show management commitment to Food

Safety system application?

Are these shown in the related objectives

Are objectives measurable?

1.2

Does the organisation have a food safety policy?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 1 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

1.3

Job No. Auditor Date

Has a HACCP plan been developed?

Does the plan cover all end products?

1.4

Has a multidisciplinary Food Safety team been formed?

1.5

Have the organisation appointed a Food Safety team leader and

defined the responsibilities and authorities

1.6

Does the organisation define the responsibility and authority of

the Food safety team.

1.7

Is the knowledge of the food safety team suitable and

appropriate(check training, qualifications, experience, etc)

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 2 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

1.8

Job No. Auditor Date

How is internal and external communication controlled and who

has responsibility? Is the communication effective?

1.9

Do the company have emergency preparedness and response

procedures in place? Have they been verified?

1.10

Is a Management Review activity carried out as required?

Is it effective?

2.

Resource Management.

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 3 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

11.1

Job No. Auditor Date

How are competencies defined for people who can have an effect

on product safety?

11.2

Does the organisation have training plans?

11.3

How many personnel have been trained in HACCP principles

and the relevant legislation and regulations?

11.4

How many personnel have been trained to perform internal

audits?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 4 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

11.5

How does the organization train personnel on sanitation control?

11.6

How does the organisation verify the effectiveness of training?

2.

PRODUCT SPECIFICATION

2.1*

Has the product or product range been fully described

2.2*

Does the specification include safety information (such as PH, aw,

etc.)?

2.3

Does the specification include details of raw material and

ingredients?

2.4

Does the specification include the type of packaging

2.5

Does the specification include the storage conditions

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 5 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

2.6

Does the specification include labelling instruction

2.7

Does the specification include the method of distribution (in

detail)?

2.8

Does the specification include shelf life and storage conditions?

2.9

Does the specification include the intended use?

2.10

Does the specification include the appropriate consumer? (e.g.

allergenic, elderly, infants or children, institutional feeding,

immune compromised, etc )

2.11

3

3.1

Does the specification include the specific methods of use?

PROCESS FLOW DIAGRAM

Is the process flow diagram comprehensive?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 6 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

3.2

Job No. Auditor Date

Are all raw materials, ingredients, packaging materials and

process/storage activities included in the process flow

diagram?

3.3

Have changes been made since the process flow diagram was

established

3.4

How does the HACCP team get notified of changes to the process

or product parameters?

3.5

How were the changes recorded and approved?

3.6

Were any changes discussed with HACCP team before

implementation

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 7 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

3.7

Job No. Auditor Date

Has the process flow diagram been verified on-site for the

compliance with the actual operation?

4.

HAZARDS ANALYSIS AND PREVENTIVE MEASURES

4.1

How was the hazard analysis conducted?

4.2

Have

all

hazards

been

evaluated

qualitatively

and/or

quantitatively?

4.3

Have all raw materials been included

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 8 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

4.4

Have all process steps been considered?

4.5

Have the hazards been specifically identified or just in general?

4.6

How did the team assess the likelihood of occurrence

4.7

What information sources were utilised?

4.8

Have appropriate preventive measures been set up for each

hazard?

4.9

Do the measures prevent or reduce to an acceptable level the

hazards and how were the measures were validated?

4.10

Are all preventive measures in place at the plant level?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 9 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

5.

CRITICAL CONTROL POINTS CCPS

5.1

How were the CCPs identified?

5.1.1

By the use of CCP decision tree?

5.1.2

Have all necessary CCPs been identified?

6.

Job No. Auditor Date

CRITICAL LIMITS

6.1*

Have critical limits been established for each CCP?

6.1.1

How were the critical limits established?

Is there evidence? (national/ international standard, requirements

of relevant legislation, experimental data, literature references etc)

?

6.1.2*

What validation exists to confirm that the critical limits can

prevent possible occurrence of hazards?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 10 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

6.2

Job No. Auditor Date

How does the organisation differentiate the critical limits from

operational limits?

6.3

7.

7.1

Are the critical limits implemented at plant level

MONITORING PROCEDURES

Have monitoring procedures been established for all CCP's

established?

7.2

Is there any evidence that procedures are being followed

consistently?

7.3

What is the status of monitoring equipment?

7.4

Are the sampling plans statistically valid?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 11 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

7.5

Job No. Auditor Date

Have the organisation a clear system for product identification

of product to ensure traceability if deviation occurs?

7.6

Have the organisation taken any actions when deviation

occurred?

7.7

Are monitoring personnel trained and qualified?

7.8

Have monitoring results been recorded?

8.

8.1

CORRECTIVE ACTIONS

Are the corrective action procedures in place?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 12 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

8.2

Job No. Auditor Date

What evidence is there to demonstrate that effective corrective

actions are taken in the event of a CCP deviation?

8.3

Has the responsibility and authority for corrective action been

defined?

8.4

How non-conforming product controlled and recorded?

8.5

How does the organisation dispose of any affected products?

8.6

Has corrective action been recorded and how is the effectiveness

verified?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 13 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

8.7

Job No. Auditor Date

Do these corrective actions consider modifying the process or

HACCP plan, if the critical limit is violated consistently

9.

VERIFICATION PROCEDURES

9.1

Have verification procedures been established?

9.2

Have the responsibilities, authorities, methods, frequency and

type of verification been defined in the procedures?

9.3

Are the methods and frequency sufficient to ensure that the

system is working correctly, effectively and complies with

relevant regulations

9.4

How did the organisation conduct the initial validation of HACCP

plan

9.5

Do the procedures include review of records?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 14 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

9.6

Job No. Auditor Date

Is there a regular review of CCP failure and product

dispositions?

9.7

Do the procedures include calibration of monitoring and

measuring equipment?

9.8

Have personnel responsible for verification been trained?

9.9

Do the procedures include evaluation of customer and consumer

complaints?

9.10

Is there a regular review of results of sanitation control

procedures?

9.11

How is the data from verification being used to improve the

HACCP system?

10.

10.1

DOCUMENTATION AND RECORD KEEPING

What procedure does the organisation follow to manage system

documents ?

10.2

Does the documentation cover all of the HACCP system

operation?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 15 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

10.3

Job No. Auditor Date

Have documents been properly approved by authorised

personnel before issue,?

10.4

How is the documentation controlled

10.5

Has the organization obtained related codes, standards,

legislation and regulation to the food product?

10.6

How does the organisation control document changes? Are all

documents current?

10.7

Are the records accessible?

10.8

Are the HACCP records clearly identified?

10.9

Has the documentation and record control system been set up in

consideration of the size and nature of the organization?

10.10

Are the HACCP records retained in the proper conditions to

prevent damage, deterioration or loss?

10.11

How long does the organization retain the records?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 16 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

11.

11.1

Job No. Auditor Date

TRAINING

Have they developed a training procedure for identifying training

needs and training personnel?

11.2

Does the organisation have training plans?

11.3

How many personnel have been trained in HACCP principles

and the relevant legislation and regulations?

11.4

How many personnel have been trained to perform internal

audits?

11.5

How does the organization train personnel on sanitation control?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 17 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

11.6

12.

12.1

Job No. Auditor Date

How does the organisation verify the effectiveness of training?

RECALL

Does the organisation have a procedure to manage product

recall?

12.2

In what circumstance do the products need to be recalled?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 18 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

12.3

Have the responsibility and authority been defined?

12.4

Has there been a full or partial product recall?

12.5

How many products were concerned?

12.6

What was the reason?

12.7

How did the organisation handle these products?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 19 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

12.8

Job No. Auditor Date

How did the organisation ensure all affected product was

identified and recalled?

13.

13.1

COMPLAINT

Does the organisation have a procedure to deal with all

consumer and customer complaints?

13.2

Have the responsibility and authority been defined?

13.3

Did the complaints concern product safety

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 20 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

13.4

What actions have the organisation taken?

13.5

Have these complaints been documented?

13.6

Have these complaints been utilized for verification of the

system?

14.

SANITATION CONTROL PROCEDURES

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 21 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

14.1

Job No. Auditor Date

Does the organisation have documented hygiene control

procedures?

14.2

Do the procedures cover all aspects of sanitation and hygiene?

14.3

Have sanitation procedures been verified for effectiveness

14.4

What actions did the organisation take when the procedures were

violated?

14.1

Safety of Water

14.1.1

Has the organisation tested water quality, how often and by

whom?

14.1.2

Does the organisation use mains, well or bore hole water

What is the status of the environment?

14.1.3

Has the water been treated? (e.g. chlorination, softening)

14.1.4

Has the treatment been monitored?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 22 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

14.1.5

Job No. Auditor Date

Is there any contamination possibility? (e.g. crosscontamination between potable water and non-potable water

etc.)

14.1.6

Have records are kept of water treatment and quality

14.2

Condition and Cleanliness of Food Contact Surfaces

14.2.1

Does the condition of food contact surfaces meet the

requirement of hygiene? (Equipment, facilities, clothing and

gloves of employees etc.)

14.2.2

Does the organisation have cleaning plans?

14.2.3

Are the plans adequate

14.2.4

Are there adequate cleaning facilities in place and are the

facilities in good condition?

14.2.5

Have the results of cleaning been monitored and verified for

effectiveness?

(e.g. microbiological analysis)

14.2.6

Have the employees been trained for personal hygiene?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 23 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

14.3

Prevention of Cross-contamination

14.3.1

Is the layout, flow of material and personnel sufficient to

prevent cross contamination?

14.3.2

Have the equipment and facilities in different risk areas been

properly separated?

14.3.3

How does the organisation handle contaminated products

14.3.4

Is there any other cross-contamination that is likely to occur?

(e.g. truck, cart, etc.)

14.4

Maintenance of Hand Washing, Hand Sanitising and Toilet

Facilities

14.4.1

How does the organisation maintain these facilities?

14.4.2

Does the organisation have adequate hand washing and

sanitising facilities in production areas? (Entrances and main

production areas)

14.4.3

Does the organisation have adequate toilet facilities and is the

condition acceptable

14.5

Protection of Food, Food Packaging Material, and Food

Contact Surfaces from Adulteration

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 24 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

14.5.1

Are packaging materials stored in good condition?

14.5.2

Are the products and packaging materials being protected

from contamination?

14.5.3

Is condensate present

14.5.4

Are lubricants and cleaning chemicals properly controlled?

14.5.5

Are lights adequately protected? (Glass)

14.5.6

Is the condition of the environment around the production

area/s suitable

14.6

Proper Labelling, Storage and Use of Toxic Compounds

14.6.1

Has the organisation appointed personnel responsible for

toxic compounds? (e.g. cleaning and pest control chemicals)

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 25 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

14.6.2

Job No. Auditor Date

Are these toxic compounds stored separate to raw materials,

ingredients and packaging materials?

14.6.3

Are

these

toxic

compounds

clearly

labelled

for

identification

14.6.4

Are there handling/usage instructions available?

14.6.5

Does the organisation keep records of the use?

14.6.6

Have the personnel been trained in the safe handling and use

of such materials

14.7

Control of Employee Health Conditions

14.7.1

Are there any procedures to control employee health and

sanitation condition?

14.7.2

Are the procedures being implemented?

14.7.3

Have the employees undergone periodic health examination

or screening(Health certificates etc.)

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 26 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

14.7.4

Job No. Auditor Date

How does the organisation manage return to work following

illness

14.8

Exclusion of Pests

14.8.1

Does the organisation have a pest control plan/system?

14.8.2

Are rodent, bird and insect prevention facilities suitable and

appropriate?

14.8.3

Are doors, windows and other facilities in good condition

14.8.4

How does the organisation ensure all pests are being controlled

effectively?

14.8.5

Have these controls been documented?

14.9

Construction and layout

14.9.1

Are walls and floors in good condition?

14.9.2

Is drainage adequate?

14.9.3

Is ventilation adequate?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 27 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

Job No. Auditor Date

14.9.4

Are processes properly separated

14.9.5

Is the layout of equipment, facilities and processes suitable

and appropriate?

14.9.6

Is there any congestion in processing areas?

14.9.7

Are storage conditions adequate for keeping goods? (e.g.

dry/frozen goods etc.)

14.10

Waste Control

14.10.1

How does the organisation control waste?

14.10.2

Are there sufficient waste control facilities in production

area?

14.10.3

Is

waste

been

removed

periodically

from

the

production/storage areas adequate to prevent contamination?

14.10.4

How does the organisation treat the waste

Does the waste disposal method comply with any relevant

regulations?

15

INTERNAL HACCP AUDIT

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 28 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

15.1

Job No. Auditor Date

Does the organisation have an internal audit plan for

HACCP?

15.2

At what frequency does the organisation conduct internal audits?

15.3

Have the audit purpose, criteria, scope and methods been

defined?

15.4

How does the organisation ensure that the program covers all

aspects of HACCP system?

15.5

Have the auditors been trained?

15.6

Have the responsibilities and requirements for audit been

defined?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 29 of 30

ISO 22000:2005 Checklist and Audit Trace Record

Client

15.7

Job No. Auditor Date

How does the organisation ensure the independence and

impartiality of the activities?

15.8

Have the purposes of audit been achieved?

15.9

Is the audit data utilised for improvement of the HACCP system?

15.10

Have the audit results been documented?

Form 04-3-4g: Issue 1 / Rev 0 / 16.06.06

page 30 of 30

Anda mungkin juga menyukai

- P018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Dokumen9 halamanP018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Álvaro Martínez Fernández100% (1)

- Trainer Manual Internal Quality AuditDokumen28 halamanTrainer Manual Internal Quality AuditmonetteBelum ada peringkat

- Learn The Powerful Memory Techniques Used by TheDokumen2 halamanLearn The Powerful Memory Techniques Used by TheAchieverBelum ada peringkat

- ISCC EU RED II-GAP Audit Procedure Point-Of-Origin v1.0Dokumen4 halamanISCC EU RED II-GAP Audit Procedure Point-Of-Origin v1.0asantosoBelum ada peringkat

- A6. Control of Nonconforming ProductDokumen6 halamanA6. Control of Nonconforming ProductStanley MtamboBelum ada peringkat

- Descon FormatDokumen15 halamanDescon FormatKhuda BukshBelum ada peringkat

- Iso 22000 Checklist Fsms f6.4-22 (FSMS)Dokumen14 halamanIso 22000 Checklist Fsms f6.4-22 (FSMS)BRIGHT DZAHBelum ada peringkat

- SMETA Best Practice GuidanceDokumen47 halamanSMETA Best Practice GuidancePinaki Das100% (1)

- QMS Management Review ProcedureDokumen2 halamanQMS Management Review ProcedureSagar Daund100% (1)

- Iso 22000 2018 Sample8 PDFDokumen9 halamanIso 22000 2018 Sample8 PDFGabriel DoméBelum ada peringkat

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Dokumen11 halamanISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- Procedure For Preliminary Analysis of Production ProcessDokumen14 halamanProcedure For Preliminary Analysis of Production ProcessNurulsakinah SailinBelum ada peringkat

- How To Establish An FSSC 22000 ProgramDokumen16 halamanHow To Establish An FSSC 22000 ProgramfaisalBelum ada peringkat

- 2018.08.03-ICS - Environmental Auditor GuidelineDokumen114 halaman2018.08.03-ICS - Environmental Auditor GuidelineXavier BaudequinBelum ada peringkat

- Audit Plan (07-09 Nov 2022)Dokumen2 halamanAudit Plan (07-09 Nov 2022)hrd cave sumber berkat 3Belum ada peringkat

- ISO 22005.2007 TraceabilityDokumen15 halamanISO 22005.2007 TraceabilitySunil Girdhar100% (2)

- Mosque BOQDokumen17 halamanMosque BOQHossam Al-Dein Mostafa HelmyBelum ada peringkat

- ISO 22000 - 2018 Compliance Audit - SafetyCultureDokumen66 halamanISO 22000 - 2018 Compliance Audit - SafetyCultureSalma ZaghbaBelum ada peringkat

- D - 14k - 3 - Delta Checklist ISO 14001-2015 - 20150917 - Short - EnglDokumen9 halamanD - 14k - 3 - Delta Checklist ISO 14001-2015 - 20150917 - Short - EnglPRASAD SHETTYBelum ada peringkat

- Taccp Presentation PDFDokumen36 halamanTaccp Presentation PDFAnous Alami100% (1)

- ISO 22000 Audit ChecklistDokumen32 halamanISO 22000 Audit Checklistlouiza100% (2)

- Food Safety CultureDokumen30 halamanFood Safety CultureAhmed rabie100% (1)

- FSSC Version 6 Requirements (Foodkida)Dokumen6 halamanFSSC Version 6 Requirements (Foodkida)jacky786Belum ada peringkat

- Methodology For Determination of Hazard Controls CCP S and OPRP SDokumen4 halamanMethodology For Determination of Hazard Controls CCP S and OPRP SRosinanteBelum ada peringkat

- Checklist ISO 22000 - 2018 and FSSC V 5.0 ENGDokumen18 halamanChecklist ISO 22000 - 2018 and FSSC V 5.0 ENGAicha's Pen0% (1)

- Guide For Internal Audit & Management Review For LaboratoriesDokumen24 halamanGuide For Internal Audit & Management Review For LaboratoriesRaman GolaBelum ada peringkat

- FSMS Stage 2 Audit of Cashew ProcessorDokumen15 halamanFSMS Stage 2 Audit of Cashew ProcessorArpita TripathiBelum ada peringkat

- Food Safety Management System: Asc Consultants (Pty) LTDDokumen6 halamanFood Safety Management System: Asc Consultants (Pty) LTDMohammed Imran100% (2)

- FSSC V5 2019Dokumen30 halamanFSSC V5 2019danuBelum ada peringkat

- ISO 22000 Internal Audit Checklist: Essential Questions to Ensure Food Safety ComplianceDokumen5 halamanISO 22000 Internal Audit Checklist: Essential Questions to Ensure Food Safety ComplianceMagesha kumarBelum ada peringkat

- 1A. Vendor Pre Qualification & Registration Form (HKG)Dokumen3 halaman1A. Vendor Pre Qualification & Registration Form (HKG)Arun Raj Arun RajBelum ada peringkat

- FSSC 22000 Scheme Requirements: Detailed Changes Between V4 and V4.1Dokumen30 halamanFSSC 22000 Scheme Requirements: Detailed Changes Between V4 and V4.1danuBelum ada peringkat

- 13 Standpipes Sprinklers FdnyDokumen20 halaman13 Standpipes Sprinklers FdnyHualy DelgadoBelum ada peringkat

- FSSC 22000 FSMS Implementation Package V5.1 BrochureDokumen44 halamanFSSC 22000 FSMS Implementation Package V5.1 BrochureSutha Tamil Nambe100% (1)

- Iso 22000 AuditDokumen19 halamanIso 22000 AuditBRIGHT DZAH100% (1)

- ASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.Dokumen11 halamanASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.JHUPEL ABARIALBelum ada peringkat

- Master Auditing Document Draft With Secondary Responses - SQF Level IIDokumen95 halamanMaster Auditing Document Draft With Secondary Responses - SQF Level IIFloreid100% (1)

- FSSC 22000 Scheme Version 6 WORDDokumen84 halamanFSSC 22000 Scheme Version 6 WORDKawtar FAOUZYBelum ada peringkat

- SQF Preventive Control Audit Checklist Edition 8Dokumen8 halamanSQF Preventive Control Audit Checklist Edition 8Jesús CastilloBelum ada peringkat

- What Is HACCP, TACCP, VACCP PDFDokumen34 halamanWhat Is HACCP, TACCP, VACCP PDFannaBelum ada peringkat

- FSSC 22000 Packaging FSMS Implementation Workbook 2018 Sample NewDokumen28 halamanFSSC 22000 Packaging FSMS Implementation Workbook 2018 Sample Newvikkas vermaBelum ada peringkat

- Food Safety Management System OverviewDokumen53 halamanFood Safety Management System Overviewdhir.ankurBelum ada peringkat

- Iso 22000 2018 LacDokumen4 halamanIso 22000 2018 LacHaitham Negm0% (1)

- Audit Checklist SampleDokumen2 halamanAudit Checklist SampleEnakhifo Victor100% (1)

- Lecture 9 ISO 22000Dokumen44 halamanLecture 9 ISO 22000ch videosBelum ada peringkat

- FsmsDokumen9 halamanFsmsEngr Muhammad Asim IqbalBelum ada peringkat

- BRC Food Safety Management System Implementation WorkbookDokumen36 halamanBRC Food Safety Management System Implementation WorkbookAbdellah Ftouhi100% (1)

- Findings Comments/Remarks Food Safety Management System General RequirementsDokumen15 halamanFindings Comments/Remarks Food Safety Management System General RequirementsEssam El-DesokeyBelum ada peringkat

- Korsreferens mellan ISO 9000; BRC; EFSIS; ISO 22000Dokumen3 halamanKorsreferens mellan ISO 9000; BRC; EFSIS; ISO 22000cassilda_carvalho@hotmail.com50% (2)

- ISO 22000 food safety fundamentalsDokumen14 halamanISO 22000 food safety fundamentalsVineeth Kumar MishraBelum ada peringkat

- ISO 22000 Audit ChecklistDokumen19 halamanISO 22000 Audit ChecklistjessiquimiBelum ada peringkat

- Guide To Auditing TechniquesDokumen11 halamanGuide To Auditing TechniquesSofia NogueiroBelum ada peringkat

- Hazard Analysis Critical Control PointDokumen9 halamanHazard Analysis Critical Control Pointjudeza100% (1)

- Dr. Ramakrishnan Nara V.P. Product Safety & Research Perry Johnson Registrar Food Safety Inc., (PJR, USA)Dokumen30 halamanDr. Ramakrishnan Nara V.P. Product Safety & Research Perry Johnson Registrar Food Safety Inc., (PJR, USA)Yoga PradanaBelum ada peringkat

- CIP Validating FormDokumen4 halamanCIP Validating FormCruz LheoBelum ada peringkat

- FSMS ISO 22000 ManualDokumen33 halamanFSMS ISO 22000 ManualTanzila SiddiquiBelum ada peringkat

- Fast Method To Define and Test Recall and Withdrawal ProceduresDokumen22 halamanFast Method To Define and Test Recall and Withdrawal ProceduresMukesh RaikwarBelum ada peringkat

- Global QCC Report-2015 PDFDokumen84 halamanGlobal QCC Report-2015 PDFDave MustanieBelum ada peringkat

- Change Management ProcedureDokumen4 halamanChange Management ProcedureCarlos Cueva GallegosBelum ada peringkat

- GSK Annual Report 2006 PDFDokumen71 halamanGSK Annual Report 2006 PDFslantyyBelum ada peringkat

- Corrective And Preventative Action A Complete Guide - 2020 EditionDari EverandCorrective And Preventative Action A Complete Guide - 2020 EditionBelum ada peringkat

- Manufacturing Facilities A Complete Guide - 2019 EditionDari EverandManufacturing Facilities A Complete Guide - 2019 EditionBelum ada peringkat

- Good Distribution Practices A Complete Guide - 2021 EditionDari EverandGood Distribution Practices A Complete Guide - 2021 EditionBelum ada peringkat

- G-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionDokumen12 halamanG-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionRoo Fa100% (1)

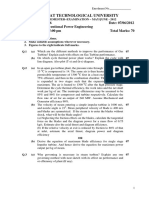

- R07 Set No. 2Dokumen8 halamanR07 Set No. 2dileepBelum ada peringkat

- MobisudDokumen2 halamanMobisudNguyen Duy KhangBelum ada peringkat

- Elon Musk - WikipediaDokumen64 halamanElon Musk - WikipediaPranay jalluBelum ada peringkat

- 1.1.3.4 Lab - Visualizing The Black HatsDokumen3 halaman1.1.3.4 Lab - Visualizing The Black HatsCordis CordisBelum ada peringkat

- How to Write Effective Business and Technical ReportsDokumen10 halamanHow to Write Effective Business and Technical ReportsDemverBelum ada peringkat

- Humidifier Servo and Non Servo Mode of DeliveryDokumen2 halamanHumidifier Servo and Non Servo Mode of DeliveryAlberth VillotaBelum ada peringkat

- Mobile Virtual Reality ServicesDokumen11 halamanMobile Virtual Reality ServicesRahul MaraviBelum ada peringkat

- M.tech Lab Manual JNTUHDokumen80 halamanM.tech Lab Manual JNTUHSivarama Prasad PamarthyBelum ada peringkat

- Jarme 3 1 2010Dokumen8 halamanJarme 3 1 2010kannanmech87Belum ada peringkat

- Malaysia Grid CodeDokumen2 halamanMalaysia Grid Codebee398Belum ada peringkat

- Object Oriented - AnalysisDokumen43 halamanObject Oriented - AnalysisAbdela Aman MtechBelum ada peringkat

- Note-145 Biostat Prof. Abdullah Al-Shiha PDFDokumen157 halamanNote-145 Biostat Prof. Abdullah Al-Shiha PDFAdel Dib Al-jubeh100% (2)

- MOHID Water Training Courses: Project InformationDokumen1 halamanMOHID Water Training Courses: Project InformationSaaz ZeeBelum ada peringkat

- Benling Falcon electric scooter specs and featuresDokumen2 halamanBenling Falcon electric scooter specs and featuresanu swamiBelum ada peringkat

- Data FNC BatteriesDokumen20 halamanData FNC BatteriessalmanahmedmemonBelum ada peringkat

- PSR 640Dokumen188 halamanPSR 640fer_12_328307Belum ada peringkat

- Sony MP3 NWZ B143F ManualDokumen82 halamanSony MP3 NWZ B143F ManualdummihaiBelum ada peringkat

- BEIT16 AbhishekgokheDokumen3 halamanBEIT16 AbhishekgokheSEIT02 Abhishek GokheBelum ada peringkat

- Avista - Vegetation Management Frequently Asked QuestionsDokumen5 halamanAvista - Vegetation Management Frequently Asked QuestionslgaungBelum ada peringkat

- GTU BE- Vth SEMESTER Power Engineering ExamDokumen2 halamanGTU BE- Vth SEMESTER Power Engineering ExamBHARAT parmarBelum ada peringkat

- First Law of ThermodynamicsDokumen21 halamanFirst Law of ThermodynamicsMariam50% (2)

- The Changing Face of The NewsDokumen2 halamanThe Changing Face of The NewsYanaBelum ada peringkat

- Anshul BhelDokumen96 halamanAnshul BhelMessieurs Avinash PurohitBelum ada peringkat

- IEC 61850 and ION Technology: Protocol DocumentDokumen52 halamanIEC 61850 and ION Technology: Protocol DocumentCristhian DíazBelum ada peringkat

- Mechanics of Flight by A.C KermodeDokumen2 halamanMechanics of Flight by A.C KermodeJhony BhatBelum ada peringkat