CONDENSATOR - Dimensionat

Diunggah oleh

SuDokuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CONDENSATOR - Dimensionat

Diunggah oleh

SuDokuHak Cipta:

Format Tersedia

GEA Heat Exchangers, Inc.

PHE Division

100 GEA Drive

York, PA 17406 USA

Ph: +717-268-6200

Fax: +717-268-6162

info.phe-systems.usa@gea.com

Website: www.gea-phe.com/usa

Condenser

Customer / Project Project Created 7/11/2015 12:41 PM

User name

Alex Croitoru

Selection ID

Print date

NUK9E7Q8G

7/11/2015

Model: C15BW

Heat of rejection rate (kW)

Log mean temp. diff. (C)

Overall HTC (W/mK)

Oversurface percent

Model size

Design Conditions

Refrigerant

23.0

5.3

1,385

19.2

5x20

Number of refrigerant circuits

Nominal surface (m)

Dimensions

Net weight (kg)

Side A - Condensing

1

3.7

124W x 532H x 144D

16.4

Side B - Liquid

R-134a

Ref. mass flow (kg/min)

7.1

Condensing temp. (C)

40.0

Condensing pressure (bar ga)

9.2

Gas entering temp. (C)

60.0

Subcooling (C)

6.0

Fluid type

Water

Fluid mass flow rate (kg/min)

66

Entering fluid temp. (C)

32.0

Leaving fluid temp. (C)

37.0

Fluid flow rate (L/min)

66.4

Fluid fouling factor (mK/W)

0.000018

Model Parameters

Number of channels

29

30

Velocity (m/s)

0.4

0.2

Pressure drop (kPa)

1.7

11.0

Heat transfer coef. (W/mK)

1,778

9,167

Internal volume (L)

4.311

4.460

GEA Heat Exchangers, Inc. PHE Division

100 GEA Drive

York, PA 17406 USA

Ph: +717-268-6200

Fax: +717-268-6162

info.phe-systems.usa@gea.com

Website: www.gea-phe.com/usa

Ratings at Varying Conditions

Percent difference

-15% -7%

0% 7% 15%

Pressure drop (kPa) (Side A)

1.2

1.4

Pressure drop (kPa) (Side B)

8.1

9.5 11.0

12.6 14.4

Heat of rejection rate (kW)

19.5

21.3 23.0

24.7 26.5

Fluid flow rate (L/min) (Side B)

56.4

61.4 66.4

71.4 76.3

Fluid mass flow rate (kg/min) (Side B)

56

61

1.7

66

1.9

71

2.1

76

Entering fluid temp. (C) (Side B)

32.0

32.0 32.0

32.0 32.0

Leaving fluid temp. (C) (Side B)

37.0

37.0 37.0

37.0 37.0

Oversurface percent

30.4

24.4 19.2

14.4 10.2

Disclaimer

This software and the generated calculations provided herein are estimates only and should be treated as such. GEA PHE Systems North America, Inc. always strives to give

complete and accurate information, but cannot provide any guarantees. This software and its output are provided "as is" and any express or implied warranties, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no event shall GEA PHE Systems North America, Inc. be liable

for any direct, indirect, incidental, special, exemplary, or consequential damages (including, but not limited to, procurement of substitute goods or services; loss of use, data,

or profits; or business interruption) however caused and on any theory of liability, whether in contract, strict liability, or tort (including negligence or otherwise) arising in any

way out of the use of this software, even if advised of the possibility of such damage.

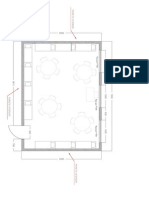

Dimension Sheet Brazed Plate Heat Exchanger

Customer:

Selection ID: NUK9E7Q8G

Project: Project Created 7/11/2015 12:41 PM

Model Nomenclature: C15BW

Dimensions data

A

C

Dimensions are in inches [mm]

reference only.

G

F

4.88 (124.0)

B:

20.94 (531.9)

C:

2.88 (73.2)

D:

18.81 (477.8)

F:

5.51 (140.0)

G:

2.36 (59.9)

H:

5.67

(144.0)

BPHE weight:

Volume:

Circuit A: 0.152 ft (4.311 L)

A:

Circuit B: 0.157 ft (4.460 L)

36.2 lb (16.4 kg)

Connections

Circuit A

Circuit B

Height

Position 1

Position 2

Position 3

Position 4

Standard

0.79 (20.0)

1-3/8" IDS

7/8" IDS

1-3/8" IDS

1-3/8" IDS

Optional

1.58 (40.0)

Installation Notes:

Pipe in counter flow direction

Water Strainer (20-40 mesh) installation recommended

Technical data

Standard construction materials

Allowable Working Pressure and Temperature

Braze Alloy

Connector

Plate

Max pressure

Copper 99.9%

304 Stainless Steel

316L Stainless Steel

Code Approvals UL Listed, CRN pending

Optional: ASME (UM stamped), PED (CE)

Max temperature

Min temperature

Circuit A

Circuit B

450 psig (31.0 bar ga)

450 psig (31.0 bar ga)

350.0 F (176.7 C)

-320.0 F (-195.6 C)

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Coping With Narcissistic PatternDokumen209 halamanCoping With Narcissistic PatternJokerJack100% (1)

- Coping With Narcissistic PatternDokumen209 halamanCoping With Narcissistic PatternJokerJack100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Seed SavingDokumen21 halamanSeed SavingElectroPig Von FökkenGrüüven100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Sayre Materia Medica-3Dokumen87 halamanSayre Materia Medica-3ven_bams5840Belum ada peringkat

- Casio AP-80R Service ManualDokumen41 halamanCasio AP-80R Service ManualEngkiong Go100% (1)

- Panasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Dokumen39 halamanPanasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Gordon Elder100% (5)

- Effective Time ManagementDokumen61 halamanEffective Time ManagementTafadzwa94% (16)

- Space DynamicsDokumen37 halamanSpace Dynamicspurushottam KashyapBelum ada peringkat

- 1.2 - Sewing Machine and Special AttachmentsDokumen3 halaman1.2 - Sewing Machine and Special Attachmentsmaya_muth0% (1)

- GIS AccidentsDokumen5 halamanGIS Accidentsali110011Belum ada peringkat

- 13 Steps Manage FlashbacksDokumen1 halaman13 Steps Manage FlashbacksSuDoku100% (1)

- 13 Steps Manage FlashbacksDokumen1 halaman13 Steps Manage FlashbacksSuDoku100% (1)

- Artifact and Thingamy by David MitchellDokumen8 halamanArtifact and Thingamy by David MitchellPedro PriorBelum ada peringkat

- Europe's Onshore and Offshore Wind Energy PotentialDokumen91 halamanEurope's Onshore and Offshore Wind Energy PotentialSuDokuBelum ada peringkat

- 14 AmtaDokumen6 halaman14 AmtaSuDokuBelum ada peringkat

- BL-E 32/210-7,5/2-R1: Wilo Se Nortk Irche Nstr. 100 D 44263 Dortm Und 0231/4102-0 0231/4102-7363 Phone FaxDokumen3 halamanBL-E 32/210-7,5/2-R1: Wilo Se Nortk Irche Nstr. 100 D 44263 Dortm Und 0231/4102-0 0231/4102-7363 Phone FaxSuDokuBelum ada peringkat

- Wilo Condensator PompaDokumen2 halamanWilo Condensator PompaSuDokuBelum ada peringkat

- Green Building GlossaryDokumen17 halamanGreen Building GlossarySuDokuBelum ada peringkat

- Shrinking Outer CriticDokumen7 halamanShrinking Outer Criticxyhm100% (2)

- Instructiuni EcotectDokumen1 halamanInstructiuni EcotectSuDokuBelum ada peringkat

- Goal Setting and Motivation NotebookDokumen3 halamanGoal Setting and Motivation NotebookSuDoku100% (1)

- YangB Pag29Dokumen300 halamanYangB Pag29SuDokuBelum ada peringkat

- SEGRASTREYTDokumen20 halamanSEGRASTREYTSuDokuBelum ada peringkat

- Melikov Etal Energy and BuildingsDokumen8 halamanMelikov Etal Energy and BuildingsSuDokuBelum ada peringkat

- w1305 - Olesen - Pag 2-3 PDFDokumen9 halamanw1305 - Olesen - Pag 2-3 PDFSuDokuBelum ada peringkat

- Depliant Infra Plus en 01-02-2006Dokumen4 halamanDepliant Infra Plus en 01-02-2006SuDokuBelum ada peringkat

- Personalised Ventilation MelikovDokumen15 halamanPersonalised Ventilation MelikovSuDokuBelum ada peringkat

- Systema Cu DefaultsDokumen8 halamanSystema Cu DefaultsSuDokuBelum ada peringkat

- Home LiftDokumen2 halamanHome LiftSuDokuBelum ada peringkat

- Home LiftDokumen2 halamanHome LiftSuDokuBelum ada peringkat

- Pandurilor 51-1Dokumen14 halamanPandurilor 51-1SuDokuBelum ada peringkat

- Wood Fuels Handbook BTC enDokumen83 halamanWood Fuels Handbook BTC enfelramBelum ada peringkat

- Airflow Dampers enDokumen44 halamanAirflow Dampers enSuDokuBelum ada peringkat

- Plan Proiect ModelDokumen1 halamanPlan Proiect ModelSuDokuBelum ada peringkat

- DX Free CoolingDokumen4 halamanDX Free CoolingSuDokuBelum ada peringkat

- Depliant Infra Plus en 01-02-2006Dokumen4 halamanDepliant Infra Plus en 01-02-2006SuDokuBelum ada peringkat

- Trnsys 16: Weather DataDokumen55 halamanTrnsys 16: Weather DataMilovan MedojevicBelum ada peringkat

- 3 LabVIEWBasicprogrammingStructures (Partb)Dokumen12 halaman3 LabVIEWBasicprogrammingStructures (Partb)SuDokuBelum ada peringkat

- Elements of ClimateDokumen18 halamanElements of Climateእኔ እስጥፍBelum ada peringkat

- Who will buy electric vehicles Segmenting the young Indian buyers using cluster analysisDokumen12 halamanWho will buy electric vehicles Segmenting the young Indian buyers using cluster analysisbhasker sharmaBelum ada peringkat

- European GMP Annex 1 - 2008 Edition - 'Pmeasuring'Dokumen3 halamanEuropean GMP Annex 1 - 2008 Edition - 'Pmeasuring'Khairul AnwarBelum ada peringkat

- Naukri LalitaSharma (3y 4m)Dokumen2 halamanNaukri LalitaSharma (3y 4m)rashika asraniBelum ada peringkat

- Monodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFDokumen11 halamanMonodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFfishvalBelum ada peringkat

- DR-M260 User Manual ENDokumen87 halamanDR-M260 User Manual ENMasa NourBelum ada peringkat

- Lightwave Maya 3D TutorialsDokumen8 halamanLightwave Maya 3D TutorialsrandfranBelum ada peringkat

- F-16c.1 Ginkgo Ginkgolic AcidDokumen2 halamanF-16c.1 Ginkgo Ginkgolic AcidNarongchai PongpanBelum ada peringkat

- 07.03.09 Chest Physiotherapy PDFDokumen9 halaman07.03.09 Chest Physiotherapy PDFRakesh KumarBelum ada peringkat

- Qualitative Research EssayDokumen9 halamanQualitative Research EssayMichael FoleyBelum ada peringkat

- Handout Tematik MukhidDokumen72 halamanHandout Tematik MukhidJaya ExpressBelum ada peringkat

- DENSO COMMON RAIL INJECTOR REPAIR GUIDEDokumen22 halamanDENSO COMMON RAIL INJECTOR REPAIR GUIDEMarcoBelum ada peringkat

- 2 - Soil-Only Landfill CoversDokumen13 halaman2 - Soil-Only Landfill Covers齐左Belum ada peringkat

- IS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableDokumen1 halamanIS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableRenieBelum ada peringkat

- Troubleshooting Hydraulic Circuits: Fluid PowerDokumen32 halamanTroubleshooting Hydraulic Circuits: Fluid PowerMi LuanaBelum ada peringkat

- Caterpillar Ep15krtDokumen37 halamanCaterpillar Ep15krtIvan MajikBelum ada peringkat

- CANAL (T) Canal Soth FloridaDokumen115 halamanCANAL (T) Canal Soth FloridaMIKHA2014Belum ada peringkat

- Henry Stevens - Hitler's Flying Saucers - A Guide To German Flying Discs of The Second World War New Edition (2013, Adventures Unlimited Press) - Libgen - lc-116-120Dokumen5 halamanHenry Stevens - Hitler's Flying Saucers - A Guide To German Flying Discs of The Second World War New Edition (2013, Adventures Unlimited Press) - Libgen - lc-116-120sejoh34456Belum ada peringkat

- 07 Raction KineticsDokumen43 halaman07 Raction KineticsestefanoveiraBelum ada peringkat

- Air Wellness QRSDokumen2 halamanAir Wellness QRSapi-3743459Belum ada peringkat

- Aacra Draft Preliminary Report PDFDokumen385 halamanAacra Draft Preliminary Report PDFBeselam SeyedBelum ada peringkat