Jte103291 28988

Diunggah oleh

Thiago BatistaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Jte103291 28988

Diunggah oleh

Thiago BatistaHak Cipta:

Format Tersedia

Journal of Testing and Evaluation, Vol. 39, No.

4

Paper ID JTE103291

Available online at: www.astm.org

Nemkumar Banthia,1 Sidney Mindess,2 and Zhengwu Jiang3

Influence of Feedback Control on Flexural

Toughness of Fiber Reinforced Concrete in

ASTM C1399 Tests

ABSTRACT: The influence of feedback control on the measured flexural toughness of fiber reinforced concrete (FRC) remains elusive. Some

tests such as ASTM C1609/C1609M-07 require closed-loop control, while others such as ASTM C1399/C1399M-10 are considered control independent, and hence open-loop testing is allowed. Recent field experience has indicated that results from even ASTM C1399/C1399M-10 tests may be

test control dependent. Towards this end, a test program was initiated to understand the influence of feedback control in ASTM C1399/C1399M-10

tests. Tests were performed on specimens of two different concrete strengths and one dosage of a polymeric fiber under both open-loop and closedloop environments. In addition to performing the analysis using the ASTM C1399/C1399M-10 approach, Ri values as per the Canadian Highway

Bridge Design Code (CHBDC-S06-16) were calculated. Ri values are derived from the Average Residual Strength (ARS) values obtained from

ASTM C1399/C1399M-10 tests. The results indicate that while the influence of feedback control on the measured ARS values in the case of normal

strength FRC is only marginal, its influence on high strength FRC is significant. The same applies to the Ri values calculated in CHBDC-S06-16,

where the results indicate that based on the published minimum acceptance criteria, the choice of feedback control may in fact govern the acceptance

or rejection of a given FRC material. In the context of these findings, it is recommended that beyond a certain compressive strength, ASTM C1399/

C1399M-10 tests should only be performed in a closed-loop environment.

KEYWORDS: testing, fiber reinforced concrete, flexural toughness, feedback control, load instability

Introduction

It is well known that concrete is a quasi-brittle material with a low

strain capacity. Randomly distributed fiber used as reinforcement

can improve concrete brittleness, cracking resistance, toughness,

and ductility [1,2]. Fiber reinforced concrete (FRC) exhibits better

performance not only under static and quasi-statically applied

loads, but also under fatigue, impact, and impulsive loadings. This

energy-absorption attribute of FRC is often termed toughness.

Experimental characterization of FRC toughness remains an actively debated topic [36].

There are a number of available techniques for measuring the

toughness enhancement due to fiber reinforcement. Most of these

techniques adopt the simple flexural beam specimen as the basis for

quantifying toughness, although specimens loaded in other configurations such as compression, tension, and bi-axial bending

(plates) are also sometimes adopted [716]. The available test

methods for measuring the toughness of FRC include ASTM

C1018-98, ASTM C1399/C1399M-10, ASTM C1609/C1609M07, ASTM C1550 [14], JSCE SF-4 [8], JSCE SF-5 [9], and JSCE

SF-6 [15]. The suitability of these techniques, the concerns with

their applicability, and the subjectivity they introduce has been disManuscript received August 3, 2010; accepted for publication December 6,

2010; published online January 2011.

1

Professor of Civil Engineering, Univ. of British Columbia, 2024-6250 Applied Science Ln., Vancouver, BC V6T 1Z4, Canada (Corresponding author),

e-mail: banthia@civil.ubc.ca

2

Professor Emeritus of Civil Engineering, Univ. of British Columbia, 20246250 Applied Science Ln., Vancouver, BC V6T 1Z4, Canada, e-mail:

smindess@civil.ubc.ca

3

Associate Professor, Key Laboratory of Advanced Civil Engineering Materials of Ministry of Education, Tongji Univ., Shanghai 200092, China, e-mail:

jzhengwu@126.com

cussed [36]. A number of the concerns emanate from the fact that

post-crack loads and deflections have to be measured in the

specimensomething not done in most traditional concrete tests

and these requirements result in issues arising from spurious specimen deflections, the inability to correctly locate the instant of first

cracking, and the large instability that occurs when a brittle material cracks. ASTM C1018-98, the first of the beam tests developed

for FRC, suffered from a number of these drawbacks and has since

been replaced by the ASTM C1609/C1609M-07 beam tests that

successfully address these concerns [5]. ASTM C1550 is a round

determinate panel test and is generally used only for fiber reinforced shotcrete. Finally, there is a RILEM recommended test [16]

for steel FRC that employs a simply supported notched beam under

three-point loading. The material performance is characterized either in terms of areas under the load-deflection curve, or by the load

bearing capacity at a certain deflection or crack mouth opening displacement.

One of the least understood parameters in FRC toughness measurement is the influence of feedback control. Tests can be run in an

open-loop arrangement or a closed-loop arrangement. In a closedloop system, there is feedback loop (via a sensor installed on the

specimen) to the machine controls, which can then manipulate/

adjust its inputs based on a predetermined criterion. In an openloop system, on the other hand, a feedback loop does not exist and

the test cannot be run with a desired specimen response. The most

common feedback control signal is in the form of specimen deformation. A closed-loop system can provide a stable deformation rate

and produce a stable specimen response, thereby improving precision. Improved stability and precision are of particular interest in

testing cementitious materials, as they are brittle and often display

instability at the instant of cracking.

ASTM C1399/C1399M-10 is a test that addresses the issue of

load instability (and hence bypasses the need to perform the test in

Copyright

by ASTM

Int'l (all

rights reserved);

Mon Harbor

Jul 13 16:20:13

EDT

2015

Copyright

2011

by ASTM

International,

100 Barr

Drive, PO

Box

C700, West Conshohocken, PA 19428-2959.

Downloaded/printed by

(UFPA) Universidade Federal do Para ((UFPA) Universidade Federal do Para) pursuant to License Agreement. No further reproductions authorized.

2 JOURNAL OF TESTING AND EVALUATION

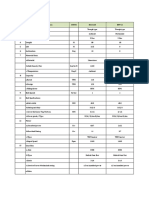

TABLE 1Mixture proportions of normal and high strength concretes

investigated.

Quantity

Ingredient

Cement type GU

Silica fume

Flyash type C

Sand

Aggregate 14 mm

Water

Air

Darex II

Fiber

(STRUX 90/40)

ADVA 190

w/cm

NS-FRC

fc = 35 MPa

303

74

710

1051

146

6.5 %

10

HS-FRC

fc = 80 MPa

400

32

150

560

890

190

6.5 %

36

mL/100 kg

3.0

359.0

0.387

3.0

400.0

0.326

kg/ m3

mL/100 kg

Unit

kg/ m3

kg/ m3

kg/ m3

kg/ m3

kg/ m3

kg/ m3

Note: ADVA 190 is a polycarboxylate-based high-range water-reducing admixture; Darex II is an air-entraining admixture; and Flyash Type is described in

ASTM C618 Type C [19].

Ri =

FIG. 1ASTM C1399/C1399M-10 test: (a) Test setup showing the 12 mm plate

under the specimen for initial loading; (b) reloading without the plate; (c) initial and reloading curves.

a closed-loop environment) by testing the beam in two stages. Fiber

reinforced beams are first pre-cracked under four-point flexural

loading, as in the ASTM C78 method [17], but in series with a 12

mm thick steel plate (Fig. 1). The steel plate provides the support

and absorbs the energy that is released from the machine at the occurrence of the peak load when the compliance of the specimen

changes suddenly. At a prescribed net deflection, the cracked beam

is unloaded and the steel plate is removed. The beam is then reloaded in four-point bending to obtain the residual load-deflection

curve. The loads supported by this beam at 0.5, 0.75, 1.0, and 1.25

mm are averaged and normalized to obtain residual strength (RS)

values by using an elastic analysis. In other words

RS =

P0.5 + P0.75 + P1.0 + P1.25

L

2

bd

4

ARS

R

where:

ARS = mean value of the ARS determined by carrying out the

ASTM C1399/C1399M-10 test on at least five FRC beam specimens and

R = mean value of the MOR determined by performing the

ASTM C78 test on at least five FRC specimens.

The approach is based on the rationale that the post-cracking

(1)

where:

P0.5, P0.75, P1.0, and P1.25 = load values at 0.5, 0.75, 1.0, and 1.25

mm beam deflection, respectively,

L = test span,

b = width of the beam, and

d = depth of the beam.

Notice that the RS is the resulting stress and has units of MPa.

The average of RS values over multiple replicates is often called

Average Residual Strength (ARS).

In the Canadian Highway Bridge Design Code [18], the ARS is

further normalized with respect to the modulus of rupture (MOR)

obtained from ASTM C78. The Residual Strength Index, Ri, is defined as

(2)

FIG. 2STRUX 90/40 fiber and properties.

Copyright by ASTM Int'l (all rights reserved); Mon Jul 13 16:20:13 EDT 2015

Downloaded/printed by

(UFPA) Universidade Federal do Para ((UFPA) Universidade Federal do Para) pursuant to License Agreement. No further reproductions authorized.

BANTHIA ET AL. ON FIBER REINFORCED CONCRETE IN ASTM C1399 TESTS

TABLE 2Test program (number of specimens).

ASTM C78

ASTM C1399/C1399M-10

using open-loop control

ASTM C1399/C1399M-10

using closed-loop control

TABLE 3ASTM C78 results.

Normal Strength Matrix

fc = 35 MPa

5

High Strength Matrix

fc = 80 MPa

5

load carrying capacity of concrete with fibers (ARS) needs to be

normalized with respect to its MOR R in order to generate a nondimensional parameter Ri, which can then be specified based on a

specific bridge application. The parameter therefore is intended to

characterize the toughness of FRC over and beyond the stress carried by the concrete matrix at the instant of first crack. It also

implicitly recognizes that very high strength concretes (higher R

values) are intrinsically brittle, and hence a greater fiber dosage

(higher ARS) may be required to provide a needed crack control.

Doubts are often raised in the case of ASTM C1399/

C1399M-10 as to the ability of the pre-cracking procedure (with

steel plate) to effectively replace proper closed-loop testing. Part of

the problem is that in an uncontrolled open-loop test, during initial

loading, the deflection is very hard to control and the net deflection

requirements are seldom met. This is of particular concern in the

case of very high strength matrices. The primary objective of this

study was to investigate the effect of feedback control on the measured ARS and Ri values of FRC.

Experimental Program

Materials and Mixes

ASTM Type GU (Type 1) Portland cement was used in all concrete

mixes. Local natural river sand and gravel coarse aggregate with a

MOR (MPa)

Sample

1

2

3

4

5

Average R

a

Normal Strength Concrete

4.60

4.91

4.90

5.48

4.67

4.9 (7.1 %)a

High Strength Concrete

6.78

7.47

7.72

7.66

6.85

7.3 (6.15 %)a

Numbers in parentheses are COV.

maximum size of 14 mm was used. The mixture proportions of the

two concretes usednormal strength and high strengthare given

in Table 1.

Concrete mixtures (Table 1) were reinforced with 3.0 kg/ m3

(0.33 % by volume) of the STRUX 90/40 fiber (Fig. 2). Beams with

dimensions of 100 100 350 mm were cast in acrylic moulds,

demolded 24 h later, and cured in lime-saturated water for an additional 27 days. All tests were performed at an age of 28 days. The

test program is described in Table 2.

Test Details

The tests were performed and analyzed as per ASTM C1399/

C1399M-10 (Fig. 1). For both closed-loop and open-loop tests, a

fatigue-rated Instron 8800 test machine was used. In all tests, a

yoke was installed around the specimen to eliminate spurious deformation arising from crushing and support settlement and record

only the net deformation of the neutral axis. Simple supports, as

prescribed by ASTM, were used. These have rollers that are able to

rotate but not move horizontally. The lack of horizontal translation

may have added additional restraint in a specimen during a test,

especially at large deflections. This was ignored out of necessity.

FIG. 3Reloading curves in ASTM C1399/C1399M-10 tests for NS-FRC under open-loop control and RS analysis (numbers appearing in parenthesis represent

COV).

Copyright by ASTM Int'l (all rights reserved); Mon Jul 13 16:20:13 EDT 2015

Downloaded/printed by

(UFPA) Universidade Federal do Para ((UFPA) Universidade Federal do Para) pursuant to License Agreement. No further reproductions authorized.

4 JOURNAL OF TESTING AND EVALUATION

FIG. 4Reloading curves in ASTM C1399/C1399M-10 tests for NS-FRC under closed-loop control and RS analysis (numbers appearing in parenthesis represent

COV).

FIG. 5Reloading curves in ASTM C1399/C1399M-10 tests for HS-FRC under open-loop control and RS analysis (numbers appearing in parenthesis represent

COV).

Copyright by ASTM Int'l (all rights reserved); Mon Jul 13 16:20:13 EDT 2015

Downloaded/printed by

(UFPA) Universidade Federal do Para ((UFPA) Universidade Federal do Para) pursuant to License Agreement. No further reproductions authorized.

BANTHIA ET AL. ON FIBER REINFORCED CONCRETE IN ASTM C1399 TESTS

FIG. 6Reloading curves in ASTM C1399/C1399M-10 tests for HS-FRC under closed-loop control and RS analysis (numbers appearing in parenthesis represent

COV).

Results

Discussion

Modulus of Rupture Tests as per ASTM C78

Table 3 indicated the results of the MOR tests as per ASTM C78.

Notice that the two concretes closely followed a MOR to compressive strength fic relationship of

MOR = 0.82fc

(3)

Residual Strength Tests as per ASTM C1399/

C1399M-10

The reloading curves for Normal Strength Fiber Reinforced Concrete (NS-FRC) tested using open-loop control and the related

analysis (Eq 1) are given in Fig. 3. Closed-loop curves for the same

concrete are given in Fig. 4. Similarly, for High Strength Fiber Reinforced Concrete (HS-FRC), the open-loop reloading curves are

given in Fig. 5 and the closed-loop curves are given in Fig. 6. ARS

values as per ASTM C1399/C1399M-10 and Ri values as per the

Canadian Highway Bridge Design Code [18] are compiled in

Table 4.

TABLE 4Results of ASTM C1399/C1399M-10 ARS and CHBDC Ri.

Open-Loop Control

Closed-Loop Control

ASTM C1399/

ASTM C1399/

C1399M-10 ARS,

C1399M-10 ARS,

MPa (COV, %)

CHBDC Ri

FRC Type

MPa (COV, %)

CHBDC Ri

NS-FRC

1.48 (10.1 %)

0.30

1.51 (11.5 %)

0.31

HS-FRC

1.52 (24.5 %)

0.21

2.18 (23.9 %)

0.30

At the outset, based on Figs. 36, fiber reinforcement can be seen as

an effective way of enhancing the post-crack strength of concrete.

For the fiber type and dosage investigated, fibers carry post peak

stresses in the range of about 2030 % of the stresses carried at the

first crack, i.e., the stress corresponding to the MOR of the material. For the well bonded fibers such as the ones used here, fibers

require some crack opening (strain) before stresses can build-up. In

the current study, in the reloading regime, the fibers required an

approximate vertical net displacement of 0.2 mm before a plateau

value of stress could be attained. In some instances, deflection

hardening was seen to occur. The lower values of ARS for a given

FRC imply that there is some slip at the fiber-matrix interface, and

so only lower stresses can be developed at a given displacement or

crack opening. There is some statistical variability expected due to

uneven fiber distribution through the depth of the beam, but with a

sufficiently large sample size of five specimens per batch, the confidence in the ARS values is high.

The ASTM C1399/C1399M-10 standard specifically notes that

a closed-loop test control is not required. This may be completely

valid for NS-FRCs (Table 4), which only had a marginal increase in

its ARS values when a closed-loop environment was adopted. In the

case of HS-FRC, on the other hand, the influence of load control on

the apparent values of ARS is significant (Table 4). Here, an increase of nearly 40 % in the ARS was noted simply by changing the

deflection control from open-loop to closed-loop.

A dramatic increase in the ARS of HS-FRC upon changing the

load control from open-loop to closed-loop is interesting and may

have its genesis in the increased brittleness in high strength matrices. To further understand the reasons for this, the initial loading

curves under open-loop control for NS-FRC and HS-FRC were

compared, and the results are given in Fig. 7. Notice that at the instant of cracking (i.e., at the occurrence of the peak load), the lack

Copyright by ASTM Int'l (all rights reserved); Mon Jul 13 16:20:13 EDT 2015

Downloaded/printed by

(UFPA) Universidade Federal do Para ((UFPA) Universidade Federal do Para) pursuant to License Agreement. No further reproductions authorized.

6 JOURNAL OF TESTING AND EVALUATION

FIG. 7Open-loop initial loading curves (with steel plate) for high strength (left) and normal strength (right) FRC. Notice the greater variability in peak load and a

greater damage induced in HS-FRC signified by a larger average PID.

of feedback control leads to significant load instability and the

beam regains its load carrying capacity only at a much larger deflection. Here, a deflection at which the curve becomes stable once

again is defined as Post-Instability-Deflection (PID). When the PID

values are compared, it is clear that the average PID for HS-FRC is

much higher than that for NS-FRC. When combined with higher

peak loads, this means that in an open-loop test, during initial loading, a high strength matrix is subjected to a greater release of machine energy and consequently sustains greater damage, which

then manifests itself in a crack of greater length and opening. This

damage adversely affects its ability to carry loads during the reloading exercise, thereby reducing the ARS value. In a closed-loop

test, on the other hand, the release of energy at peak load is minimal

and so is the damage.

In Fig. 7, one can also note a greater variability in the recorded

peak loads for HS-FRC than for NS-FRC. This likely resulted in

different degrees of damage during initial loading in different

specimens and, consequently, inconsistent crack lengths and

widths. All these factors led to a higher Coefficient of Variation

(COV) in ARS for HS-FRC.

Table 5 presents the acceptance criteria for FRC as per CHBDC

[18]. Notice that for the specific application of surfacing of stressed

log bridges, while HS-FRC tested using the closed-loop arrangement would meet the minimum value of Ri, the same concrete

tested using an open-loop arrangement would not. This is of major

concern, and since a closed-loop arrangement better represents the

material performance, the ASTM C1399/C1399M-10 test should

only be performed in such an arrangement, especially for concretes

with higher strengths.

TABLE 5Current acceptance criteria for FRC as per CHBDC S06-16.

Application

Barrier wall with one mesh of bars

Barrier wall with two meshes of bars

Deck slab with one crack-control mesh

Deck slab with two crack-control meshes

Surfacing of stressed log bridges

a

Fibers not needed.

Minimum Value of Ri

0.25

0.0a

0.25

0.0a

0.30

Conclusions

The influence of feedback control was investigated in ASTM

C1399/C1399M-10 tests using two concrete strengths. The following conclusions were drawn.

(1) NS-FRC only had a marginal increase in its ARS values

when the test controls were changed from open-loop to

closed-loop. In the case of HS-FRC, however, the influence

of the load control on the apparent values of ARS was significant. An increase of nearly 40 % in the ARS was noted

simply by changing the deflection control from open-loop

to closed-loop.

(2) Higher ARS values noted for HS-FRC under closed-loop

control may have their genesis in the increased brittleness

in such concretes. When the PID values are compared, it is

clear that the average PID for HS-FRC is significantly

higher than that for NS-FRC.

(3) High strength concrete displays much greater variability in

ASTM C1399/C1399M-10 results regardless of the feedback control employed. The initial loading in HS-FRC tests

results in cracks of inconsistent lengths and openings, and

this leads to greater inconsistency in the reloading curves.

(4) The ASTM C1399/C1399M-10 test should only be performed in a closed-loop environment, especially for high

strength concrete matrices.

References

[1] Bentur, A. and Mindess, S., Fiber Reinforced Cementitious

Composites, Elsevier Applied Science, London, 1990.

[2] Banthia, N. and Sappakittipakorn, M., Toughness Enhancement in Steel Fiber Reinforced Concrete Through Fiber Hybridization, Cem. Concr. Res., Vol. 37(9), 2007, pp. 1366

1372.

[3] Banthia, N. and Dubey, A., Measurement of Flexural Toughness of Fiber Reinforced Concrete Using a Novel Technique,

Part 1: Assessment and Calibration, ACI Mater. J., Vol.

96(6), 1999, pp. 651656.

Copyright by ASTM Int'l (all rights reserved); Mon Jul 13 16:20:13 EDT 2015

Downloaded/printed by

(UFPA) Universidade Federal do Para ((UFPA) Universidade Federal do Para) pursuant to License Agreement. No further reproductions authorized.

BANTHIA ET AL. ON FIBER REINFORCED CONCRETE IN ASTM C1399 TESTS

[4] Banthia, N. and Dubey, A., Measurement of Flexural Toughness of Fiber Reinforced Concrete Using a Novel Technique,

Part 2: Performance of Various Composites, ACI Mater. J.,

Vol. 97(1), 2000, pp. 311.

[5] Banthia, N. and Trottier, J.-F., Test Methods of Flexural

Toughness Characterization of FRCs: Some Concerns and a

Proposition, ACI Mater. J., Vol. 92(1), 1995, pp. 4857.

[6] Banthia, N. and Trottier, J.-F., Concrete Reinforced with Deformed Steel Fibers, Part II: Toughness Characterization,

ACI Mater. J., Vol. 92(2), 1995, pp. 146154.

[7] ASTM C1018-97, 1997, Test Method for Flexural Toughness and First Crack Strength of Fiber Reinforced Concrete,

Using Beam with Third-Point Loading, Annual Book of

ASTM Standards, Vol. 4.02, ASTM International, West Conshohocken, PA, pp. 543550.

[8] JSCE SF-4, 1984, Method of Testing for Flexural Strength

and Flexural Toughness of Fiber Reinforced Concrete, Japan

Society of Civil Engineers, Tokyo, pp. 5866.

[9] JSCE SF-5, 1984, Method of Testing for Compressive

Strength and Compressive Toughness of Steel Fiber Reinforced Concrete, Japan Society of Civil Engineers (JSCE),

Tokyo, pp. 6773.

[10] Casanova, P. and Rossi, P., Analysis of Fiber Reinforced

Concrete Beams Subjected to Bending, Mater. Struct., Vol.

29(6), 1996, pp. 354361.

[11] EFNARC, 1997, European Specification for Sprayed Concrete, European Federation of Producers and Applicators of

Specialized Products for Structures, Hampshire, United Kingdom.

[12] ASTM C1609/C1609M-07, 2007, Standard Test Method for

Flexural Performance of Fiber-Reinforced Concrete (Using

Beam with Third-Point Loading), Annual Book of ASTM

[13]

[14]

[15]

[16]

[17]

[18]

[19]

Standards, Vol. 04.02, ASTM International, West Conshohocken, PA.

ASTM C1399/C1399M-10, 2010, Standard Test Method for

Obtaining Average Residual-Strength of Fiber-Reinforced

Concrete, Annual Book of ASTM Standards, Vol. 04.02,

ASTM International, West Conshohocken, PA.

ASTM C1550-05, Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded

Round Panel), Annual Book of ASTM Standards, Vol. 04.02,

ASTM International, West Conshohocken, PA.

JSCE SF-6, 1990, Method of Test for Shear Strength of Steel

Fiber Reinforced Concrete (SFRC), Japan Society of Civil

Engineers, Tokyo, pp. 4955.

RILEM TC 162-TDF, Recommendations of RILEM TC 162TDF: Test and Design Methods for Steel Fibre Reinforced

Concrete: Bending Test, Mater. Struct., Vol. 35(253), 2002,

pp. 579582.

ASTM C78-08, Standard Test Method for Flexural Strength

of Concrete (Using Simple Beam with Third-Point Loading),

Annual Book of ASTM Standards, Vol. 04.02, ASTM International, West Conshohocken, PA.

CHBDC-S06-10, 2010, Canadian Highway Bridge Design

Code, Chapter 16. Fiber Reinforced Structures, Section 16.6

on Fiber Reinforced Concrete, Canadian Standards Association, Mississauga, Canada.

ASTM C618-08 Type C, Standard Specification for Coal Fly

Ash and Raw or Calcined Natural Pozzolan for Use in Concrete, Standard Specification for Coal Fly Ash and Raw or

Calcined Natural Pozzolan for Use in Concrete, Annual Book

of ASTM Standards, Vol. 04.02, ASTM International, West

Conshohocken, PA.

Copyright by ASTM Int'l (all rights reserved); Mon Jul 13 16:20:13 EDT 2015

Downloaded/printed by

(UFPA) Universidade Federal do Para ((UFPA) Universidade Federal do Para) pursuant to License Agreement. No further reproductions authorized.

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- PPC Master MarchDokumen148 halamanPPC Master MarchSandip JadhavBelum ada peringkat

- TMB 60Dokumen2 halamanTMB 60oac08Belum ada peringkat

- Owner's Manual: Downloaded From Manuals Search EngineDokumen12 halamanOwner's Manual: Downloaded From Manuals Search EnginegragrBelum ada peringkat

- Corrosion Prevention and Removal SystemsDokumen8 halamanCorrosion Prevention and Removal SystemsDiarista Thoma SaputraBelum ada peringkat

- Brochure HEFDokumen12 halamanBrochure HEFsreedhar srinivasanBelum ada peringkat

- Paint AnalysisDokumen51 halamanPaint AnalysisKai ZaiBelum ada peringkat

- Gu01 2009 Standard ReferenceDokumen7 halamanGu01 2009 Standard ReferenceFrancis BoeyBelum ada peringkat

- Emissivity TableDokumen13 halamanEmissivity TableUtubesBelum ada peringkat

- Terminal Blocks: J - AccessoriesDokumen24 halamanTerminal Blocks: J - Accessoriespaula09Belum ada peringkat

- Astm21 1510Dokumen18 halamanAstm21 1510Robert ChenBelum ada peringkat

- Test Certificate 12mmDokumen1 halamanTest Certificate 12mmSabyasachi Bangal67% (9)

- Gas Pipeline Hydraulic CourseDokumen49 halamanGas Pipeline Hydraulic Coursekarisnda100% (1)

- AISC ASTM A325 OR A490 BoltsDokumen7 halamanAISC ASTM A325 OR A490 BoltsJonatan López Carriel100% (1)

- Nova Suite BrochureDokumen15 halamanNova Suite BrochureSampathBelum ada peringkat

- Future Readymix - Original: K150 K200 Q Cost Q Cost 0.190 3.990 0.190 4.275 0.734 5.072 0.598 0.150 0.678 1.356 2 0.360Dokumen10 halamanFuture Readymix - Original: K150 K200 Q Cost Q Cost 0.190 3.990 0.190 4.275 0.734 5.072 0.598 0.150 0.678 1.356 2 0.360Mohammed Abd ElazizBelum ada peringkat

- Study of Prefabrication in IndiaDokumen6 halamanStudy of Prefabrication in IndiaSayed WafiBelum ada peringkat

- Install ManualDokumen190 halamanInstall ManualMarios KaridisBelum ada peringkat

- PI Metal Detector Hammerhead PDFDokumen15 halamanPI Metal Detector Hammerhead PDFAlvaro Garcia100% (1)

- Rev C - MS.50015 - ENDokumen4 halamanRev C - MS.50015 - ENBonifácio Pacheco AmaralBelum ada peringkat

- Data SheetDokumen24 halamanData Sheetbashok20Belum ada peringkat

- Aerated LagoonDokumen8 halamanAerated LagoonAmmu JoeBelum ada peringkat

- CHM510 Exp 5Dokumen12 halamanCHM510 Exp 5NURANISAH NADIAH MOHD NIZAMBelum ada peringkat

- Advanced Gear Manufacturing and FinishingDokumen1 halamanAdvanced Gear Manufacturing and FinishingImad LamBelum ada peringkat

- Littelfuse Fuse 216 Datasheet pdf-310019Dokumen5 halamanLittelfuse Fuse 216 Datasheet pdf-310019A. A.G.Belum ada peringkat

- Cooling Tower ReportDokumen11 halamanCooling Tower Reportbae zazBelum ada peringkat

- Flare SystemDokumen29 halamanFlare SystemLuis EnriqueBelum ada peringkat

- E 9018 Sika Permac 2330Dokumen4 halamanE 9018 Sika Permac 2330Mark InnesBelum ada peringkat

- PlumDokumen15 halamanPlumChristian ConsignaBelum ada peringkat

- Waves Group - Marketing Catalouge - 400MEDokumen26 halamanWaves Group - Marketing Catalouge - 400MEfrostysidBelum ada peringkat

- Design Guidelines For PE & ROTO Lined Carbon Steel PipingDokumen8 halamanDesign Guidelines For PE & ROTO Lined Carbon Steel PipingKamatchi Nathan100% (1)